Extrusion Bolsters Food Security in Africa

If developing economies are to eradicate poverty and achieve food and nutrition security, more effort is needed in harnessing extrusion technology for producing safe food utilizing locally grown legumes and cereal grains.

Extrusion technology is central to value addition to agricultural commodities, especially cereals/legumes, to enhance food security and sustainable development. It is a powerful processing operation, which can produce products with unique textural properties having high and low density, as well as highly expanded and condensed products, depending on the processing condition. Extrusion is a process that combines several unit operations, including mixing, cooking, kneading, shearing, shaping, and forming (Riaz, 2013a).

The high-temperature short-time (HTST) process usually reduces microbial contamination, inactivates enzymes, and facilitates the elimination of anti-nutrient factors, resulting in products that are in a dry state with typically low water activity (aw), which do not require refrigeration storage. Such products are suitable for a tropical region like Africa where infrastructure for a cold supply chain is inadequate (Filli et al., 2010).

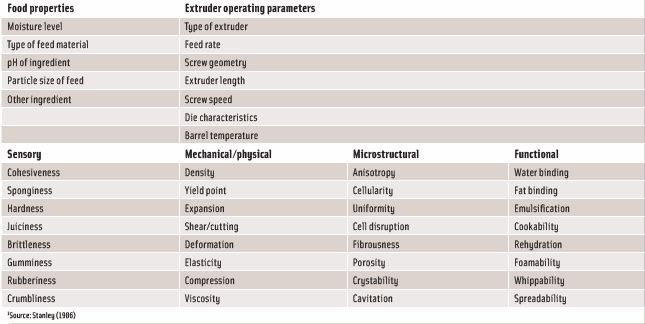

Extrusion of foods, however, demands close control of many variables such as feed moisture, feed composition, feed particle size, feed rate, barrel temperature, screw speed, screw configuration, and die geometry. The material properties and process variables determine the extent of macromolecular transformations during the extrusion process, which in turn influence the rheological properties of the food melt in the extruder and, consequently, the product characteristics of extrudates (Meng et al., 2010).

Extrusion Cooking

Extrusion cooking (EC) has become an increasingly popular procedure in the cereal, snack, and ready-to-eat food categories, which utilize starchy and proteinaceous raw materials (Lins et al., 2000). Boonyasirikool and Charaunuch (2000) reported a nutritious soy snack by EC, which gained a moderately high score in texture preference and acceptance. EC has some unique features compared to other heat processes. It is capable of breaking covalent bonds in biopolymers and facilitating reactions otherwise limited by diffusion of reactants and products (Iwe et al., 2001).

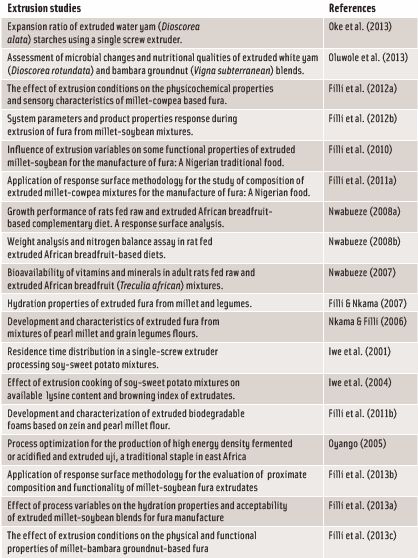

Several researchers in Africa have made considerable progress in product development using extrusion technology (ET) for the development and production of traditional-based products from indigenous materials (Table 1). For some time now, interest has been shown throughout the world, especially in Africa, for the production of nutritious blended foods for all population groups with high nutritional requirements in order to tackle the problem of food and nutritional insecurity.

One of the main purposes of extrusion is to increase the variety of foods in the diet by producing a wide range of products with different shapes, textures, colors and flavors from basic ingredients. Extrusion has great potential in developing economies. Chigumira (1992) outlined the advantages of EC as follows: (1) gelatinization of starch which enhances digestibility; (2) protein denaturation enhancing digestibility; (3) inactivation of some thermally labile growth inhibitors such as trypsin inhibitors; (4) inactivation of deteriorative enzymes (lipases and oxidases) results in a product with better storage stability; (5) destruction of natural toxicants—goitrogens, haemagglutinins cynogenetic, glycosides; (6) product instantization, which can be prepared quickly, saving time and equipment; (7) reduced cooking time, thus enhancing the retention of vitamins and nutritive value of the food; (8) shelf stability of extrusion-cooked foods, thus ensuring nutritious food year-round; and (9) fuel costs associated with normal lengthy cooking are almost negligible.

Extrusion technology can make traditional products more acceptable in the fast changing global society if properly adopted for upgrading production processes. ET is particularly useful and significant when cooking or gelation is required at some point of food processing which forms a greater portion of most traditional African foods. Its use in the production of meat analogs, sausage products, animal food, pet foods, snacks, cereals, paste foods, and a series of other products has long been reported (Harper, 1979).

Properly designed convenience foods can be made through extrusion, which can influence nutritional requirements in societies where social changes are altering traditional patterns of food preparation and acceptability. Often, the fabricating process of food involves imparting cohesive qualities to materials lacking cohesiveness and EC performs this function. The resulting structure of a desired product must have a texture similar to that of the target product (i.e., it must simulate such important sensory characteristics of chewability and mouthfeel).

--- PAGE BREAK ---

Nutritional Benefits

The cereal grains grown in Africa, including sorghum, millet, rice, maize, fonio (acha and iburu) and tef, are predominantly used for the main staple meals. The majority of these staples are, however, limited in both protein quantity and quality. In addition, the high viscosity of gruels prepared from these cereal grains make it difficult to consume enough amounts to meet both energy and protein requirements as a result of low nutrient density. However, research has revealed that these food crops respond well to extrusion processing. To improve the nutrient intake in regions of Africa that experience caloric and acute malnutrition, attention needs to be focused on processing technology, like extrusion, and the use of inexpensive sources of protein materials to fortify them. Processing methods such as malting and extrusion have proved acceptable for increasing the nutrient densities of the respective foods produced using these methods (Obatolu, 2002).

Extrusion processing offers the possibilty of better storage stability, added value, lower transportation cost, generation of employment, and creation of new markets in the food and feed industrial sectors. Over 800 million people of the world, and particularly in developing economies, do not have enough food to meet basic nutritional needs. Food supply is of general constraint in sub-Saharan Africa. The food supply chain demands an organized system that requires huge energy input because of the high energy demand for postharvest activities. In the global context, the potentials of ET as applied to food processing and how it can be adopted to improve food production and food security in developing economies need attention.

Energy Savings

Energy costs are rapidly increasing and becoming a larger portion of the production costs in food processing (Grobler, 2013). The energy crisis has led to deforestation by utilization of wood for fuel, which has necessitated a need for the production of ready-to-eat pre-cooked foods in Africa using alternative energy efficient methods like extrusion. HTST-EC could be used to produce cereal-based foods of high nutritional quality and in a ready-to-eat form, thereby requiring no additional energy. Various cereal-based blends, fortified or unfortified with legumes, have been developed through EC (Conway, 1973; Filli et al., 2012a,b; 2013a,b; Oluwole et al., 2013). Extrusion processing could be used to achieve the objective of energy efficiency by regulating a vital portion of energy costs in the processing cycle. Fellows (1988) and Riaz (2013a) outlined the following as to why extrusion is gaining popularity: (1) versatility: a wide variety of products are possible by changing the minor ingredients and the operating conditions of the extruder; (2) reduced costs: extrusion has lower processing costs and higher productivity than other cooking or forming processes. Savings in raw materials (19%), energy (100%), and labor (14%) are reported when extrusion of breakfast cereals is compared with traditional cooking methods; (3) high production rates and automated production: for example, production rates of up to 315 kg/hr-1 for low-density cereals and 9,000 kg/hr-1 for dry expanded pet foods are possible; and (4) little or no process effluents are produced.

Scaling Up Extrusion Processing

Considerable research efforts for the past 20 years have shown that there is great possibility of industrial scaling up of extrusion processing, if properly implemented, in Africa. Because of the complex nature of the process, scaling up is not without challenges. The end use characteristics of products leaving the die are determined by feed properties and process and system parameters, which make the input and output factors to be both multiple.

In general, single-screw extruders provide adequate operating ranges and are cheaper to purchase than twin-screw extruders, meaning that start-up costs are less. With the availability of low-cost extrusion equipment, processing of cereals and legume-based products are feasible. There is no doubt that the application of extrusion to traditional African foods can lead to the diversification of new and novel foods, which can result in increased usage of the technology for sustainability. The possibility of fortifying local and indigenous cereal grains, such as millet, rice, maize, sorghum, fonio (acha and iburu), and tef, with legumes, such as soybean, cowpea, bambara nut, and groundnut, using EC has great potential in providing ready-to-eat nutritious foods for all age groups.

Furthermore, EC will bring increased utilization of local raw materials, industrial development, and creation of income coupled with the possibility of producing various bio-polymers as raw materials for sustainable thermoplastic materials. Proper implementation of research efforts will boost food production, result in poverty reduction to enhance promotion of peace and political stability through provision of food security, and discourage conflict activities.

Case Studies in Africa

Case Studies in Africa

Table 1 summarizes some extrusion studies on some indigenous food crops. These and other similar studies show the potential to make a significant impact on the rural economy, if properly implemented, for sustainable food production in Africa. Pelembe et al. (2002) reported that the reduced viscosity of protein-rich sorghum-cowpea instant porridge produced by HTST-EC could be very beneficial for infant feeding and increased food production. The addition of cowpea not only improves the protein content and quality of the extruded porridge, but additionally the reduced viscosity would enable the porridge to be fed to infants at higher concentration, hence increasing nutrient density. Such instant pre-cooked porridge is comparable in composition and functional properties with a commercial instant maize-soya porridge product (Pelembe et al., 2002).

--- PAGE BREAK ---

Iwe et al. (2001) reported the processing of soybean-sweet potato mixtures as a viable means for achieving food production. Obatolu (2002) reported successful production of improved nutrient and sensory qualities of extruded malted or unmalted millet-soybean mixtures. Nontraditional methods of processing cowpea such as thermal extrusion are needed for broadened applications of dry edible beans. It is a well-known fact that addition of legumes to cereals increases both content and quality of the protein mix. Oyango (2005) reported the process optimization for the production of high energy dense fermented or acidified and extruded uji, a traditional staple in East Africa.

Development of an acceptable nutritious soy fortified snack by EC was reported by Boonyasirikool and Charaunuch (2000) and Riaz (2013a). The former reported that there was a greater quantity of lysine and methionine plus cystine; and all those essential amino acids accounted for at least 80% of the recommended value (FAO/WHO, 1973). Furthermore, the product had a good content of micronutrients, such as vitamin B-6, B-2, calcium, and sodium, and rich in B-12 and iodine.

With the prevalence of malnutrition due to the high cost of animal protein foods and lower earning power, there is a need to look into ways of enriching traditional products that are shelf stable and acceptable. In developing economies, poverty is manifested by a shortfall of many aspects, of which inadequate nutrition is of primary importance. Adequate nutrition is the first requirement for any development without which people are physically and socially displaced. To improve the nutrient intake of children in regions of chronic and acute malnutrition, attention is focussed on processing technology and the use of inexpensive sources of protein to fortify cereals.

However, challenges to extrusion processing in developing economies such as Africa include: (1) lack of consistent, uniform, quality grain supplies; (2) extension of existing processing technology is unavailable; (3) governmental policy; (4) subsidized maize, rice, or wheat-based food systems; (5) nutritional myths, tannins, and poor digestibility; (6) few shelf-stable convenience foods; (7) logistics and markets issues; (8) subsidy on imported cereal products; (9) poor image of sorghum and millet; and (10) grain mold.

Extruded product needs would, of course, vary from country to country. Nonetheless, in its implementation a number of questions repeatedly arise, including the effect policy makers will have on distribution of processing plants, raw materials availability, and requirements of a population. A strong political commitment is required to make extrusion technology part of food production in national development.

The way forward on extrusion processing in developing economies would require production of staples, thereby making them more profitable; improvement in producer access to new technologies; innovative technology commercialization strategy; joint sponsorship of workshops, seminars, and short-term training; improved grain quality to stimulate development of food processing enterprises; training and capacity building of both scientists and institutions; creation of links and working relationships with other agencies up and down the supply chain; and fortification programs. It is apparent from health benefit and economic growth standpoints that there is much scope for commercialization of traditional indigenous products.

Case Study of Instant Fura

Fura is a traditional thick dough ball snack produced principally from millet and sorghum, which is very common in West Africa and globally where migrants from this subregion live. It is a single cereal-based product that is not high in nutritional quality and it has a short storage life of about two days at ambient conditions. Studies have been conducted on the development and processing of high protein fura (Nkama and Filli, 2006; Filli et al., 2012a,b; 2013a,b). Inclusion of legumes as a basic ingredient in extrusion of fura has shown great improvement in its nutritional value and physical state. Instantization of fura through EC was observed to have made an important contribution to the nutritional quality and its acceptability. Extruded fura provides consumers with fast and easy preparation, which is similar to the traditionally made fura (Figure 1) in terms of acceptability by consumers. Extrusion enhanced water uptake of the product with reduction in viscosity, which is an indication of concomitant increase in nutrient density. The EC of fura from mixtures of millet-legume blend has the potential of great improvement of the aforementioned shortcoming. Incorporation of legumes into millet flour has been advantageous because their blends would provide complementary proteins and play an important role in nutrition.

--- PAGE BREAK ---

Commercial production of extruded fura has the potential of use in the aviation industry, refugee camps, food aids, or areas prone to protein and energy malnutrition and those living in war-torn, famine-ravaged areas (Filli and Nkama, 2007). EC of fura constituted a great improvement over the traditional product that usually has a high moisture content of 60–75% and readily deteriorates at room temperature. Extrudates obtained from EC have a moisture content less than 7 g/100 g and would not require refrigeration for storage (Filli et al., 2010). Aesthetic presentation through EC will enhance acceptability of this product, thereby making a great contribution to the global food supply.

The inclusion of soybean to pearl millet improved the protein quality and quantity by greatly increasing the lysine content of fura extrudate (Filli et al., 2010). An image of pearl millet-soybean fura extrudates (FE) is shown in Figure 2. Further improvement in protein content and quality, physical state, functionality, safety, and shelf life of the end product was achieved using response surface methodology (RSM) and a single screw extruder. RSM was effective in explaining the effects of process variables (e.g., feed composition, feed moisture, and screw speed) during the optimization of water absorption index, water solubility index, and the viscosity of fura from millet-soybean flour mixtures by EC. Response variables predicted with model equations under optimum conditions were in general agreement with experimental data.

The inclusion of soybean to pearl millet improved the protein quality and quantity by greatly increasing the lysine content of fura extrudate (Filli et al., 2010). An image of pearl millet-soybean fura extrudates (FE) is shown in Figure 2. Further improvement in protein content and quality, physical state, functionality, safety, and shelf life of the end product was achieved using response surface methodology (RSM) and a single screw extruder. RSM was effective in explaining the effects of process variables (e.g., feed composition, feed moisture, and screw speed) during the optimization of water absorption index, water solubility index, and the viscosity of fura from millet-soybean flour mixtures by EC. Response variables predicted with model equations under optimum conditions were in general agreement with experimental data.

The application of this study could be projected to explore the possibility, by interested food processors, for effective prediction of known process conditions for the purpose of achieving desired product quality. Increased utilization of millet and legumes will give great hope to the farmers for increased production, creating employment and wealth. With EC, fura can be made available throughout the year because of its shelf-stable nature (Nkama and Filli, 2006).

Designed experiments following RSM for the extrusion of pearl millet and cowpea-based fura using a single-screw extruder (Filli et al., 2011a) was effective in investigating the expansion ratio, bulk density, proximate composition, and amino acid profile of FE. The three extrusion variables were found to influence FE properties either independently or interactively. Analysis of variance indicates that the amino acid content was influenced significantly (p<0.05) by the linear and quadratic terms for lysine, leucine, valine, and threonine.

The linear effects of feed composition were positive for lysine, which suggests that increasing the amount of cowpea resulted in an increased amount of lysine content in the FE. The high correlation coefficient of multiple determinations at 95% confidence level and the model equation developed can be used for predicting expansion ratio, bulk density, proximate composition, and amino acid profile of millet-cowpea-based fura (Filli et al., 2012b). The combined effect of three variables on extrudate response can be predicted, which is difficult to achieve with conventional methods. The understanding of the effect of the process variables on quality parameters of FE such as expansion ratio, bulk density, proximate composition, and amino acid profile is important to facilitate industrial adoption of this technology (Filli et al., 2011a, 2012a,b). The high cost of commercial infant and weaning formulas, poor hygienic practices of mothers, and the high viscous character of some commercially available weaning foods are major constraints in providing children with adequate nutrients and calories.

Case Study for Material Applications

Case Study for Material Applications

An attempt was made to establish a preliminary processing window for extrusion foaming of blends of zein and pearl millet flour and to estimate the properties of the extrudates (Filli et al., 2011a) and to clarify if the blend of these two biomaterials could be used for producing a foamed structure with extrusion. Compounds with higher zein content tended to give a more foamed structure. This was performed in a single screw extruder to assess the feasibility of foaming such blends and note trends, not to optimize the process or the foam properties. Suitable processing conditions were identified and foams with densities in the range of 350–500 kg/m3 could be made. It is likely that improvements of the foamed structure and its properties can be attained by tuning the processing conditions and the composition of the blends. Figure 3 shows the foaming of the extrudate as it exits the die.

--- PAGE BREAK ---

Mechanism of Structural Changes

It is now widely accepted that food texture is a result of microstructure, which in turn depends upon the influence of physical forces on chemical components. During extrusion, molecules in foods are exposed to heat and shear force, causing chemical reactions and consequently changes in component structure. These changes include gelatinization of starch and denaturation, realignment and cross-linking of protein (Suknark et al., 1998). Thus, the structural characteristics of a food product dictate mechanical properties and, hence, sensory response. With fabricated foods, researchers must create a structure that will respond in the desired manner and can be manipulated in a predictable way, whether the process used is thermal extrusion, fiber spinning, freeze texturization, or restructuring of muscle foods. An examination of microstructure is equally needed, even though it is unlikely that it would be possible to accurately predict the exact degree to which changes in microstructure influence textural response (Kinsella, 1976; Harpner, 1981). Starch-based snack foods are a popular example of extruded materials. Studies on starch extrusion (Owusu-Ansah et al., 1983, 1984) have shown that during heating in the presence of water, shearing imparts structure to the final product through the transformation of starch granules by the mechanism of gelatinization. Gomez and Aguilera (1986) described a process in which shear causes mechanical damage to the starch while the application of heat and the moisture favors a loss in crystallinity. Lower moisture content causes increased viscosity and more mechanical damage and reduced molecular size (Davidson et al., 1984). These damaged starches are characteristically less cohesive than gelatinized undamaged starch.

Studies have led to the understanding of food component effects on structural changes, especially the effect of amylase/amylopectin (Faubion et al., 1982); alignment of protein molecules (Ramsem and Clerk, 1978; Holay and Harper, 1982); enzyme-hydrolyzed protein (Rhee et al., 1981); protein size (Simonsky and Stanley, 1982); and pericarp color (Vargas-Solórzano et al., 2014).

Extrusion Equipment

Extrusion equipment used today is classified according to the method of operation (cold extruders or extruder-cookers) and the method of construction (single- or twin-screw extruders). The principles of operation are similar in all types, with feed materials in granular form fed into the extruder barrel. The screw(s) then convey the material and compress and work (shear or knead) it to transform into a semi-solid plasticized mass (Fellows, 1988; Raiz, 2013a). In extrusion cookers, food is usually heated by steam-jacketed barrels and/or by a steam-heated screw. Compression is achieved in the extruder barrel by: (1) increasing the diameter of the screw and decreasing the screw pitch, (2) using a tapered barrel with a constant or decreasing screw pitch, or (3) placing restriction in the screw flights. In cold extruders, the product is extruded into strips without cooking or distortion of the food caused by expansion. The extruder usually has a deep-flighted screw, which operates at a low speed in a smooth barrel, to work and extrude the material with little friction. It is used to produce pasta, hot dogs, pastry dough, and certain types of confectionery.

From an engineering point of view, an extruder is simply a pump that provides the pressure necessary to force the process mash through a restrictive die. Conceptually, the barrel of a single screw extruder (SSE) can be divided into three separate zones, depending on what is happening to the process mash in each zone. These are the feed, transition, and metering (or cooking) zones.

Single screw operations depend on the pressure requirements of the die, the slip at the barrel-extrudate interface, and the degree to which the void volume in the barrel is filled. Feed rate, screw speed and design, and the characteristics of the extrudate dictate screw fill. The interaction of all these variables creates the limits in the operating range and flexibility of SSE. The twin-screw extruders (TSE) offer greater operating flexibility and with greater operational control. They can be co-rotating, counter-rotating, intermeshing, or non-intermeshing in terms of basic designs. Co-rotating, intermeshing screw designs are very common because of relative ease of design and manufacture compared to counter-rotating designs. The screw design of TSE can dramatically affect operating efficiency and machine capability. Screw components in the feed section of the barrel can be single, double, or even triple flight arrangements. With more flights intertwined on the shaft, the conveying capacity of the screw is reduced but the residence time distribution is lower, promoting a first-in, first-out movement of the extrudate. However, double- and triple-flighted screws produce more shear across the screw channel and therefore improved processing uniformity (Riaz, 2013b).

Food properties and extruder operating parameters affect the end use characteristics of extruded foods (Table 2). The type of ingredients like pericarp color in sorghum (Vargas-Solórzano et al., 2014), feed moisture content, and process variables (e.g., barrel temperature, screw speed, screw configuration, die size, and feed rate) influence the physical characteristics of extruded products (Arambula et al., 1998). Typically, SSE is the best choice for simple products, however, it provides limited flexibility for new and unique products. TSE is able to provide multiple processing steps (i.e., kneading, mixing) and also turn out higher production rates.

Food properties and extruder operating parameters affect the end use characteristics of extruded foods (Table 2). The type of ingredients like pericarp color in sorghum (Vargas-Solórzano et al., 2014), feed moisture content, and process variables (e.g., barrel temperature, screw speed, screw configuration, die size, and feed rate) influence the physical characteristics of extruded products (Arambula et al., 1998). Typically, SSE is the best choice for simple products, however, it provides limited flexibility for new and unique products. TSE is able to provide multiple processing steps (i.e., kneading, mixing) and also turn out higher production rates.

--- PAGE BREAK ---

Conclusion

With increasing globalization and rising food prices, postharvest technology in developing economies like Africa can benefit from the advances in extrusion technology. This contemporary processing technology can mitigate the problems associated with traditional cereal-based products in terms of improvement in functionality and end use characteristics. Research efforts in extrusion cooking using indigenous crops for upgrading existing products and product development are numerous, but very few of such products have been translated to large-scale industrial manufacturing.

Extruded products for industrial production such as fura, dambu, and kunu gyada extrudates from blends of indigenous pearl millet, grains, and legumes have received scientific investigations. In EC studies of fura, independent variables of importance are, in order, feed composition > feed moisture > screw speed. Other extrudates of great potential are products from sweet potato, soybeans, bambara groundnut, malted or unmalted millet-soybean mixture, noodles from cassava, and African breadfruit mixtures.

If developing economies are to meet their goals in eradication of poverty and achieve food and nutrition security, more effort is needed in harnessing ET for safe food and feed through the adoption of research outputs from indigenous cereal grains and legumes.

Kalep Bulus Filli is Senior Lecturer, Dept. of Food Science & Technology, Federal University of Technology, PMB 2076 Yola, Nigeria ([email protected]). Afam I.O. Jideani, a Professional Member of IFT, is Professor and Head of the Dept. of Food Science & Technology, University of Venda, Private Bag x5050, Thohoyandou 0950, South Africa ([email protected]). Victoria. A. Jideani, a Professional Member of IFT, is Associate Professor, Dept. of Food Technology, Cape Peninsula University of Technology, Bellville 7535, Cape Town, South Africa ([email protected]).

The authors acknowledge the Federal University of Technology Yola, Nigeria and the National Research Foundation South Africa that supported this work. The article is based on a paper “Extrusion cooking: a viable technology for achieving food production and security in Africa” presented during the ExtruAfrica Conference, Protea hotel Kruger Park, Skukuza Mpumalanga province, South Africa, August 1–2, 2013.

References

Arambula, V.G., Figueroa, J.D.C., Martinez-Bustos, F., Ordorica, F.C.A., and Gonzalez-Hernandez, J. 1998. Milling and processing parameters for corn tortillas from extruded instant dry masa flour. J. Food Sci. 63(2): 338-341.

Boonyasirikool, P. and Charunuch, C. 2000. Development of nutritious snack by extrusion cooking. Kasetsart J. Nat. Sci. 34: 355-365.

Chigumira, P. 1992. The potential for extruded sorghum food products in Zimbabwe and the regional market. Pages 89-94 in: Utilization of Sorghum and Millets. M.I. Gomez, L.R. House, l.W. Rooney, and D.A.V. Dendy, eds. International Crop Research Institute for the Semi-Arid Tropics. Patancheru, A.P. 5024, India.

Conway, H.F. 1973. Extrusion cooking of cereals and soybeans I. Food Product Development 5: 27-33.

FAO/WHO 1973. FAO Energy and Protein Requirements. Report of Joint FAO/WHO ad hoc Expert Committee. Rome.

Faubion, J.M., Hoseney, R.C. and Seib, P.A. 1982. Functionality of grain components in extrusion. Cereal Foods World 27(5): 212-218.

Fellows, P. 1988. Food Processing Technology: Theory and Practice. Pages 294-308. Ellis Horwood Ltd. New York.

Filli, K.B., and Nkama, I. 2007. Hydration properties of extruded fura from millet and legumes. British Food J. 109(1): 68-80.

Filli, K.B., Nkama, I., Abubakar, U.M., Jideani, V.A. 2010. Influence of extrusion variables on some functional properties of extruded millet-soybean for the Manufacture of fura: A Nigerian traditional food. African J. Food Sci. 4(6): 342-352.

Filli, K.B., Sjöqvist, M., Öhgren, C., Stading, M., and Rigdah, M. 2011b. Development and characterization of extruded biodegradable foams based on zein and pearl millet flour. Annual Transaction Nordic Rheology Society, 19: 200-203.

Filli, K.B., Nkama, I., Jideani, V.A. and Abubakar, U.M. 2012a. The effect of extrusion conditions on the physicochemical properties and sensory characteristics of millet-cowpea based fura. European J. Food Res. Review 2(1): 1-23.

Filli, K.B., Nkama, I., Jideani, V.A., and Abubakar, U.M. 2011a. Application of response surface methodology for the study of composition of extruded millet-cowpea mixtures for the manufacture of fura: A Nigerian food. African J. Food Sci. 5(17): 884-896.

Filli, K.B., Nkama, I., Jideani, V.A. 2013c. The effect of extrusion conditions on the physical and functional properties of millet-bambara groundnut based fura. American J. Food Sci. Technol. 1(4): 87-101.

Filli, K.B., Nkama, I., Jideani, V.A., and Abubakar, U.M. 2013b. Application of response surface methodology for the evaluation of proximate composition and functionality of millet-soybean fura extrudates. Wudpecker J. Food Technol. 1(5): 074-092.

Filli, K.B., Nkama, I., Jideani, V.A., and Ibok, I.U. 2012b. System parameters and product properties responses during extrusion of fura from Millet – Soybean Mixtures. Nigerian Food J. 30(1): 82-100.

Filli, K.B., Nkama, I., Jideani, V.A., and Ibok, I.U. 2013a. Effect of process variables on the hydration properties and acceptability of extruded millet - soybean blends for fura manufacture. British Food J. 115(6): 884-898.

Grobler, L.J. 2013. Energy and the Agro Processor: Quo Vadis? Presented at the ExtruAfrica Conference, “Needs, barriers and opportunities for extrusion in Africa”, at Protea hotel Kruger Park, Skukuza Mpumalanga province, South Africa August 1–2.

Gumez, M.H., and Aguilera, J.M. 1986. Sweetened extruded corn/soy product as intermediate moisture food. J. Food Sci. 51(4): 979-981.

Harper, J.M. 1979. Food extrusion. CRC Crit. Rev. Food Sci. Nutri. 11: 155-160.

Harper, J.M. 1981. Extrusion of Foods. Vol. I & II., pp 67-70. CRC, Press, Boca Raton, FL.

Holay, S.H., and Harper, J. M. 1982. Influence of extrusion shear environment on plant protein texturization. J. Food Sci. 7: 869-875.

Iwe, M.O., Van Zauilichem, D.J., Ngoody, P.O. and Ariahu, C.C. 2001. Residence time distribution in a single-screw extruder processing of soy-sweet potato mixtures. Lebensm – Wiss. U. – Technol. 34(7): 57-61.

Iwe, M.O., Van Zuilichem, D.J., Stolp, W., and Ngoddy, P.O. 2004. Effect of extrusion cooking of soy–sweet potato mixtures on available lysine content and browning index of extrudates. J. Food Eng. 62: 143-150.

Kinsella, J.E. 1976. Texturized proteins: Fabricating flavoring and nutrition. CRC Crit. Rev. Food Sci. Nutri. 10: 147-151.

Lins, S., Huff, H.E., and Hseih, F. 2000. Texture and chemical characteristics of soy protein meat analog extrudate at high moisture. J. Food Sci. 65(2): 264-269.

Meng, X., Threinen, D., Hansen, M., and Driedger, D. 2010. Effects of extrusion conditions on system parameters and physical properties of a chickpea flour–based snack. Food Res. Intl., 43: 650–658.

Nkama, I. and Filli, K.B. 2006. Development and characteristics of extruded fura from mixtures of pearl millet and grain legumes flours. Intl. J. Food Properties 9: 1-9.

Nwabueze, T.U. 2007. Bioavailability of vitamins and minerals in adult rats fed raw and extruded African breadfruit (Treculia african) mixtures. J. Food Agriculture Environ. 5(314): 465-470.

Nwabueze, T.U. 2008a. Growth performance of rats fed raw and extruded African breadfruit-based complementary diet. A response surface analysis. J. Sci. Food Agr. 88(3): 522-528.

Nwabueze, T.U. 2008b. Weight analysis and nitrogen balance assay in rat fed extruded African breadfruit-based diets. Nigerian Food J. 46(1): 27-41.

Obatolu, V.A. 2002. Nutrient and sensory qualities of extruded malted or unmalted millet/soybean mixture. Food Chem. 76: 129-133.

Oke, M.O., Awonorin, S.O., and. Workneh, T.S. 2013. Expansion ratio of extruded water yam (Dioscorea alata) starches using a single screw extruder. AJAR 8(9): 750-762.

Oluwole, O.B., Awonorin, S.O., Henshaw, F., Elemo, G.N., and Ebuehi, O.A.T. 2013. Assessment of microbial changes and nutritional qualities of extruded white yam (Dioscorea rotundata) and bambara groundnut (Vigna subterranean) blends. Food Nutri. Sci. 4: 100-107.

Owusu-Ansah, J., Van de Voort, F.R., and Stanley, D.W. 1984. Textural and micro structural changes in corn-starch as a function of extrusion variables. Canadian Institute Food Sci. Technol. J. 17: 65-70.

Owusu-Ansah, J., Van de Voort, F.R., and Stanley, D.W. 1983. Physicochemical changes in corn starch as a function of extrusion variables. Cereal Chem. 60: 319-324.

Oyango, C. 2005. Process optimization for the production of high energy density fermented or acidified and extruded uji. Dissertation submitted for the Award of Doctor Ingenieur (Dr.-Ing.). Fakultat Maschinenwesen Institut for Lebensmithtel und Bioverfahrenstechhnik Technische Universitat Dresden, Dresden, Germany.

Pelembe, L.A.M., Erasmus, C., and Taylor, J.R.N. 2002. Development of a protein-rich composite sorghum-cowpea instant porridge by extrusion cooking process. Lebensm – Wiss. U. – Technol. 35: 120 – 127.

Ramsem, C.H., and Clerk, J.P. 1978. A viscosity model for cooking dough. J. Food Process Eng. 2(1): 39-45.

Rhee, K.C., Kuo, C.K., and Lusas, E.W. 1981. Texturization. Pages 51-57 in: Protein Functionality in Food. J.P. Cherry ed., ACS Symp. Series No. 147. Am. Chem. Soc., Washington, D.C.

Riaz, M. 2013b. Introduction to Extrusion. Presented at the ExtruAfrica Conference, “Needs, barriers and opportunities for extrusion in Africa”, at Protea hotel Kruger Park, Skukuza Mpumalanga province, South Africa, August 1–2.

Riaz, M. 2013b. Soy based products. Presented at the ExtruAfrica Conference, “Needs, barriers and opportunities for extrusion in Africa”, at Protea hotel Kruger Park, Skukuza Mpumalanga province, South Africa, August 1–2.

Simonsky, R.W. and Stanley, D.W. 1982. Texture-structure relationship in textured soy protein. V. Influence of pH and protein acylation on extrusion texturization. Canadian Institute Food Sci. Technol. J. 15: 294-300.

Stanley, D.W. 1986. Chemical and structural determinants of texture of fabricated foods. Food Technol. 40(3):65-69.

Suknark, K., Phillips, R.D., and Chinnan, M.S. 1998. Physical properties of directly expanded extrudates formulated from partially defatted peanut flour and different types of starch. Food Res. Intl. 30(8): 575-583.

Vargas-Solórzano, J.W., Carvalho, C.W.P., Takeiti, C.Y., Ascheri, J.L.R., and Queiroz, V.A.V., 2014. Physicochemical properties of expanded extrudates from colored sorghum genotypes. Food Res. Intl. 55: 37-44.