Looking at Packaging in a New Way to Reduce Food Losses

Understanding the distinction between protective and marketing functions of packaging and their respective costs can help reduce postharvest losses in developing countries.

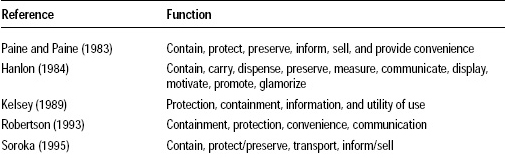

Packaging performs a number of functions in the containment, protection, shipment, and selling of goods. The textbook definitions vary (Table 1), but whichever definition is used, the package is expected to provide a combination of protection and marketing roles. The complex set of requirements is poorly understood outside of the packaging community (and sometimes within that community), resulting in lost opportunities. Furthermore, these functions are sufficiently integrated, especially in the developed world, that they are not considered individually (Anonymous, 1998).

A clearer separation of these roles may make it easier to identify areas in which packaging may significantly reduce postharvest losses and thereby improve the world food supply, as mandated in the 1996 World Food Security Declaration of Rome (FAO, 1996). The premise of this article is that an increased understanding of the distinction between protective and marketing functions of packaging, and a realization of the economics associated with these functions, could promote a significant improvement in the use of food packaging protection to reduce postharvest losses and thereby improve world food security.

The World Food Security summit sponsored by the Food and Agriculture Organization in Rome, Italy, in November 1996 drafted a declaration to reduce world hunger by 50% by the year 2015. The food security concept refers to securing food for those in need, which includes quantity and distribution of foodstuffs. The traditional approach to an improved food supply is agricultural in nature and concentrates on food production—i.e., farm production. This approach has been so successful over the past few decades that food production has outpaced population growth (FAO, 1997). Many doomsday forecasts were proven false. However, the trends are unlikely to continue in a linear fashion. Initial use of fertilizers, pesticides, and bioengineering had dramatic effects, but subsequent efforts offer diminishing returns.

I believe that some of the emphasis must switch to reducing postharvest food losses. Usable life of products can be extended with packaging—a statement that would find little disagreement. However, many potential users from the farm, co-op, and distribution systems might consider packaging too expensive. A more-informed evaluation could be made by separating the marketing and protection functions and associated costs.

Food companies in the developed world rarely consider individual aspects of packaging systems. A package is chosen to protect, ship, inform, and market a product, and the functions are considered as a composite. At a meeting addressing packaging costs at a major U.S. food company, one packaging professional surprised the attendees by offering a brown paper bag for a milled grain product that was not sensitive to moisture gain or oxygen influx. He suggested that this package would be adequate to protect the product, and that costs for additional packaging requirements were “marketing expense.” The amazement suggested that such a separation had not been considered. I suggest that there are many aspects of packaging that influence the cost, and that some of those aspects need to be considered by anyone who hopes to promote packaging solutions in developing nations in situations in which packaging is not currently employed. Postharvest food losses obviously fits into this category.

Considerations in Choice of Package

The cost of packaging is usually directly proportional to the amount of materials used. Costs are therefore minimized if the least materials are employed for any application. There are two components of the decision: which configuration to use for the pack (shape), and how much to package in a given pack (size). Other considerations in the choice of package include printing/decoration, appearance, choice of materials, availability of materials, type of economy, and legal concerns.

--- PAGE BREAK ---

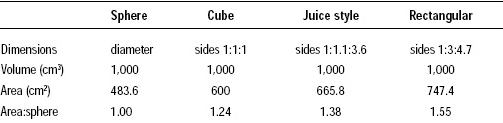

• Shape. The shape of a container relates to the amount of materials required. A sphere encloses the maximum volume with the least surface area of any possible geometry. The closer a package is to a spherical shape, the less material is used to enclose a given volume of the product. For box configurations, an octagonal or hexagonal shape will use less materials than a cube; a cube will use less materials than a rectangular format. Other considerations will obviously apply, such as ability and cost to prepare a format, utility of the shape in transit, etc., but shape will affect material requirements.

To identify the amount of difference, compare a sphere to a cube. A sphere containing 1,000 cm3 would have a radius of 6.20 cm and an area of 483.6 cm2 (volume of a sphere = 4/3πr3, and area = 4πr2). A cube 10 cm on a side would yield the same volume, which would require six 10-cm x 10-cm panels, or 600 cm2 of material (excluding overlap required to seal the package). The cube therefore requires 1.24 times the material, or 24% more than the sphere. Greater differences would be evident with a rectangular or gable-top container. For example, a 1-L orange juice container from Tetra Pak measures 6.4 cm x 7.0 cm x 21.5 cm high. The surface area of this package, not including overlap of materials required to make the seals, is two panels 6.4 x 7.0 + two panels 6.4 x 21.5 + two panels 7 x 21.5 = 665.8 cm2, or 1.38 times as much material as a comparable volume in a spherical shape.

A rectangular box, with a width 3 times the depth and a height 4.7 times the depth (such as a commercial ready-to-eat cereal package) to yield a 1,000-cm3 package would have a depth of 4.14 cm, a width of 12.42 cm, and a height of 19.46 cm. The area is 747.35 cm2 or 1.55 times the material required for a 1,000-cm3 sphere.

These comparisons are summarized in Table 2.

Costs also relate to the ease, speed, and machinery required to prepare the package. These factors must be considered in the ultimate package choice.

A large primary display panel, such as on a typical cereal carton, presents a forum to present the product. If the goal is to preserve food items without a need for a marketing presentation, package shapes approaching spherical will utilize less materials to enclose a given volume. In addition, less barrier is required to protect the product. If the area is reduced relative to the volume of the package, as in a sphere, the area available for permeation of gases and vapors is reduced, therefore affording additional protection to the enclosed food.

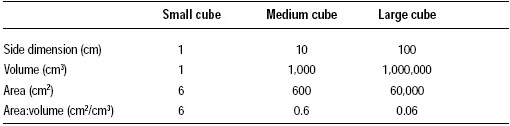

• Size. It is easy to explain that for a given package shape, the larger the quantity to be packed, the less packaging materials per unit volume required to enclose it. This comes from the mathematical relationship that the volume increases as a cubic (3-dimensional) function, while area increases as a square (2-dimensional) function. A cube 10 cm on a side, for example, has a volume of 103 or 1,000 cm3. The area of the package is 600 cm2 (six panels of 100 cm2 each). A cubic package with 100 cm per side would enclose 1003 or 1,000,000 cm3. The area of the package is 60,000 cm2 (six panels of 10,000 cm2 each). The smaller package requires 0.6 cm2/cm3 of product, while the larger package requires only 0.06 cm2/cm3. The increase in the length of each side of the cube by a factor of 10 increases the area by 100 (102), while the volume increases by 1,000 (103). The larger package would therefore be more economical for product protection (Table 3). It deserves mention that the above calculation is based on area and volume alone.

The actual situation for a sensitive product is more advantageous. The influx of any detrimental permeant, such as oxygen or moisture, is proportional to area. In the above example, the influx increases by 100 times. However, if the diffusion through the product is not limiting, then the permeant is diluted into 1,000 times the product. Therefore, the barrier can be relaxed with the larger package to maintain the equivalent barrier protection. The larger package uses less material and allows use of diminished barrier webs. Since barrier properties usually are available in more-expensive packaging materials, or the barrier can be adjusted by material thickness, additional savings may result from the materials chosen for the larger package; conversely, smaller packages may require additional barrier and therefore increase the price.

--- PAGE BREAK ---

If we apply this example to reduction of food losses, a retail pack may be cost prohibitive to specific circumstances in developing countries. Pallet-sized packaging, however, might be a cost-effective protection mode.

The change in area-to-volume ratio affects both the required amount of materials to enclose a given amount of product and the barrier requirements. As described with shape, a smaller area-to-volume ratio suggests that lower barrier will suffice. Since the area of a package increases at a slower rate than the volume as the package size increases, gases and vapors permeating the package are absorbed into a larger volume of product. The effective barrier protection therefore increases inversely with the area-to-volume ratio. A simpler explanation is that the permeation per gram of product for products packaged in comparable materials is proportional to the area-to-volume ratio. This means that a lower permeation—higher protection—is experienced with larger packages.

• Printing/Decoration. Printing and decoration are automatic components of virtually any consumer package. Labels must satisfy legal requirements (e.g., net weight, contents, nutrition labeling, safety messages), consumer use information, product and company identification, marketing copy, etc. Packaging development personnel would rarely consider printing or decorating as an option. However, use of packaging to extend the usable life of food products in regions with shortages, transient natural disasters, or chronic problems due to short distribution life of produce can be addressed with undecorated materials. Farmers and cooperatives may be willing to install or consider packaging options if the costs are justifiable. Removing the printing expenses will make such options more cost attractive.

Examples of printing/decorating expenses will vary widely with material, size, number of colors, and methodology. Two examples can illustrate the general concept:

Printing of food cans adds approximately 5% to the cost. Leonard (1980) presented the cost of decorating a 202 x 204 can by lithography as $3/1,000. The can cost was presented as $66/1,000. A 1-qt can with dimensions 401 x 504 would cost $175/1,000, with a printing/decorating cost of $9/1,000. Wrap-around labels would add higher costs to the package.

Printing board for carton making adds a higher percentage to the packaging costs. For example, a rice package with a board cost of $15.80/1,000 and a forming cost of $7.90/1,000 would incur additional costs of $8/1,000 for printing. The upcharge to print would add $8 to a package cost of $23.70, or 33.76% (Leonard, 1980). Different-size packages would give different numbers—between 20 and 30% for other mentioned examples.

Printing costs vary with type of printing system, speed, number of colors, and quantity printed. The costs will also vary from country to country. In general, printing/decorating does not add to barrier or protection functions of packages. For situations in which food preservation is the primary concern, printing and decorating become less important.

• Appearance. Marketing of food products in a competitive market requires concerns for appearance above and beyond the printing and decorating costs. Paperboard containers are often clay coated to provide a smoother surface. Carton board may be bleached to replace a gray substrate with a white product.

Pouch papers can be supercalendared, which smashes the paper fibers and forms a smoother, shinier surface. This operation will shorten the fibers, resulting in a loss of strength but increasing the appeal.

Special coatings, such as FC-807, may be employed to improve the grease resistance of food packages, such as a paper package for a milled grain. Moisture resistance can be achieved with waxes or coatings. Although such coatings are adding protection, the driving force is appearance related. In other words, the coating protects the package, not really the product, and incurs an expense that would not be necessary for product preservation.

All of these examples increase package costs for a perceived benefit which improves the marketability of a packaged product. For instances of shortages, these additional costs can be avoided without affecting product integrity.

--- PAGE BREAK ---

• Choice of Materials. The choice of packaging materials is influenced by many factors, including protection, environmental concerns, and marketability. An example of a change in packaging that utilizes more-expensive materials is the squeezable, high-barrier ketchup bottle that replaced glass containers. The coinjection stretch blow-molded structure offers convenience (squeezability), more flexibility in package shape, nonbreakability, and lowered distribution costs (the laminated structure is considerably lighter than glass) but costs more than glass. It actually reduces shelf life compared to glass but increases consumer acceptance.

An extension of this concept is the use of a polycarbonate-based barrier bottle in Japan. Polycarbonate is much more expensive than polyester or polypropylene used in the United States but offers a clarity that makes the Japanese package stand out from competition.

Such options add cost and must not be used as standards for situations of shortages which require cost-sensitive solutions.

An example of a relaxed standard in packaging materials may be seen in Africa. The packaging materials for an aseptic line of juices and dairy products is typically a high-barrier, aluminum foil–based structure. A low-barrier, less-expensive paperboard-based structure is produced in South Africa that enables dairy products to be dispensed with a short but usable shelf life at low cost. The system provides for a lower level of package protection in an area that could not support the higher-quality but more-expensive packaging.

• Availability of Materials. Supply and demand play a role in pricing structures of materials. Materials that are produced locally or utilize raw materials that are readily available will usually be less costly than materials that are not readily available. Therefore, material selection varies with geography. For example, U.S. usage may favor polyethylene terephthalate (PET) over nylon for cost reasons, whereas Europe and Japan may find the reverse.

The translation of this principle to reducing postharvest losses is to consider optimizing packaging materials used elsewhere in terms of effectiveness, but modify choices on the basis of price and availability. Subramanian (1993), at an International Symposium on Packaging, Economic Development and the Environment, cited lack of material availability as a contributing factor in food losses, with a concern about food rather than packaging waste as a problem.

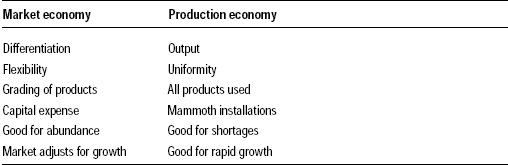

• Type of Economy. A brief discussion of production vs marketing economies can serve to illustrate philosophies that relate to packaging and distribution of products. The former Soviet Union was built with a centrally controlled production economy. This system allowed the Soviet Union to transform a feudal society into a world power in a relatively short time, compared to Western societies that accomplished the development since the Industrial Revolution. The fundamental principle was a planned economy with no competition. Central facilities were built to produce output, and were evaluated on that output.

Some of the principles employed in the rapid growth contributed to decline of the system. For example, If the goal is rapid and high output, without competitive factors, the choice is to build factories that tend to be large, not differentiate products, utilize all product (no grading), and use basic packaging and product presentation. Upgrading of capital equipment in large factories with high output may be considerably more costly than upgrading numerous, smaller facilities.

In a market economy, especially with an abundance of competitive products, differentiating one’s product from competition becomes necessary. A manufacturer of canned peas, for example could grade the peas and offer a premium line. The labeling for a premium product could contain additional colors, have sharper graphics, etc. Expanding this example further, a production orientation which did not grade the peas would be hard pressed to compete with the quality of the graded system. Price and total quantity produced, however, would be better with the production orientation.

The major point in this discussion is not the relative merits or deficiencies of the two systems (Table 4), but rather a realization that they each offer advantages in different areas. The production economy works well with shortages and promotes more product, at a faster growth than a market economy with the same resources. The imposition of the principles and practices of a market economy for regions with chronic food shortages may interfere with simpler solutions.

--- PAGE BREAK ---

If the above comparison is envisioned as a guideline for packaging of food products available in tight vs abundant supply, the principles could be used to improve the overall supply. Abundant resources will continue to be packaged to differentiate and promote products, while scarce resources will benefit from options that optimize output.

• Legal Issues. Legal requirements and issues influence package choices. Obviously, packaging materials must be in compliance with the laws of the country involved. Packaging employed for regions with high food losses, transient disasters, or chronic shortages may be prudently evaluated on a risk-benefit basis. The U.S., with high availability of food and packaging, can set very tight standards for residual monomers, processing agents, or low-level contamination from recycled materials. Tight standards for residual monomer, processing residues, or contamination from recycled content may limit the supply of packaging materials that could be possible with older production facilities. A risk-benefit analysis might be prudent to compare risk of packaging with slightly higher levels vs benefits from additional packaging.

Although much recycling of packaging materials is done in the U.S. and Europe, there are few applications that allow recycled packaging materials to be in direct food contact. In societies with starvation and lack of materials, modified criteria could be employed. Once again, the decision relates to availability. An abundant supply of packaging materials can tolerate more regulation and constraints than a tight supply. At the International Symposium on Packaging, Economic Development and the Environment mentioned above, the developing nations described problems with packaging and solid waste. They reported problems with excessive food waste and suggested that they could use those materials that posed a problem for the developed world. Regulations for packaging materials that allow slightly higher levels of contamination could be allowed to increase the availability of materials. Risk-benefit analysis needs to incorporate both the safety level of the materials and the detrimental effects of a restricted supply.

There are applications in which recycled materials may be safely used with direct food contact. Dried food, for example, can be safely packaged in recycled paperboard containers because there is no medium for transfer of potential contamination into the product. For example, dry macaroni can be in contact with recycled board. Such materials could be used to increase the supply of packaging materials and reduce food losses.

The Cost-Effective Choice

Many decisions are incorporated into the choice of packaging systems and materials for food products. In highly competitive systems with abundant supply, differentiation of products is essential; but in countries or commodities experiencing significant postharvest losses, differentiation becomes less necessary. The above discussion illustrates that the perception of packaging as a costly solution can be abated by separating the protection from the marketing functions of packaging and designing more cost-effective systems for food protection. Packaging solutions may prove cost effective for farm cooperatives, regional facilities, etc.

I hope that this article may transform a discussion concerning food packaging from “Can we afford to package food items?” to “Can we afford not to?” or “How can it be packaged efficiently for our economy?” The cost-effective choice of packaging may often be more than compensated for by a decrease in postharvest food losses.

by Kenneth S. Marsh

Author Marsh, a Professional Member of IFT, is the Cryovac Chair of Packaging Science, Clemson University, Packaging Science Dept., 227 Poole Agricultural Center, Box 340370, Clemson, SC 29634-0370 and Executive Director of the Woodstock Institute for Science in Service to Humanity, 130 Can Creek Harbor Rd., Seneda, SC 29672.

Edited by Neil H. Mermelstein,

Senior Editor

References

Anonymous. 1998. I don’t think you can separate marketing from packaging development. “Brand Packaging, Feb./March, p. 30.

FAO. 1996. Rome Declaration on World Food Security and World Food Summit Plan of Action. World Food Summit, Nov. 13-17. Food and Agriculture Org., Rome.

FAO. 1997. The state of food and agriculture. Food and Agriculture Org., Rome.

Hanlon, J.F. 1984. “Handbook of Package Engineering,” 2nd ed. McGraw-Hill, New York.

Kelsey, R.J. 1989. “Packaging in Today’s Society.” Technomic Publishing Co., Lancaster, Pa.

Leonard, E.A. 1980. “Packaging Economics.” Books for Industry, New York.

Paine, F.A. and Paine, H.Y. 1983. “A Handbook of Food Packaging.” Blackie & Son, Ltd., London.

Robertson, G. 1993. “Food Packaging.” Marcel Dekker, Inc., New York.

Soroka, W. 1995. “Fundamentals of Packaging Technology.” Inst. of Packaging Professionals, Herndon, Va.

Subramanian, M.R. 1993. Development or disaster? Packaging holds the key: A view from the Orient. In “International Symposium on Packaging, Economic Development, and the Environment.” Inst. of Packaging Professionals, Herndon, Va.