Annual Meeting & FOOD EXPO® Preview—Processing

PROCESSING

Papers Address Thermal, Nonthermal, and Other Processes

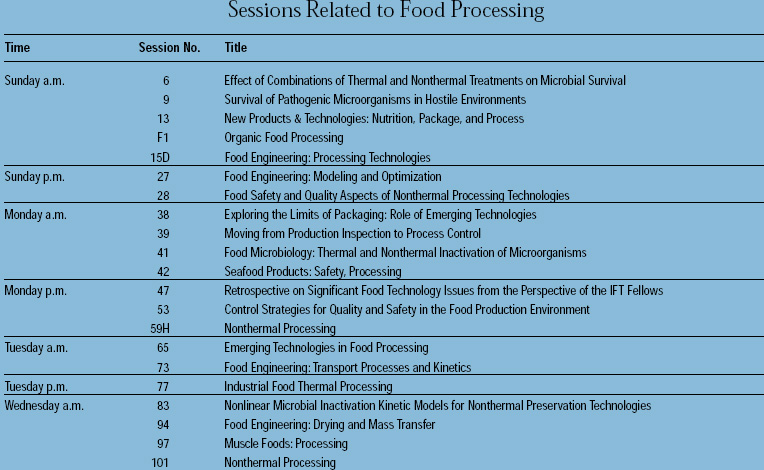

This year’s IFT Annual Meeting & IFT FOOD EXPO® will feature many symposia, papers, and exhibits on food processing. This section will briefly describe some of the papers in this area, grouped into various processing categories.

Thermal Processes

Although minimal and nonthermal processes are receiving increased attention today, traditional thermal processes are still being used and improved.

K. Collins of TechniCal, Inc., will review the history of thermal processing of perishable shelf stable low-acid and acidified food products. Advances in computers over the past 20 years have enabled researchers to take the heat resistance and heat transfer knowledge gained over the past 150 years to improve and accelerate collection of time/temperature data in food processing systems. He will discuss data collection and evaluation software and hardware that simplify these tasks for low-acid and acidified food processors. Paper 77-6

L. Huang of USDA-ARS-Eastern Regional Research Center will present an overview of the principles, design, operation, and process control of different thermal processing systems, including water-immersion and water-spray processes, industrial and laboratory-scale aseptic processing and packaging, as well as industrial thermal process development. With new developments in computer-aided design (CAD) and computer-aided manufacturing (CAM), microprocessor-based process control, and process automation, many new thermal processing systems of different sizes (R&D, pilot units, and commercial processing lines) have been made available. Paper 77-1

M.F. Blattner of AllPax Products, Inc. will describe water-immersion thermal processing systems, the most prevalent style of overpressure process in use today. Water-immersion rotary retorts provide a fast rate of heating and cooling. The mixing which occurs in “end-over-end” rotation also allows for high-temperature/short-time processing, which produces high-quality product. Containers such as retort pouches, plastic trays, plastic bottles, and plastic cups all require an overpressure process and can be processed in water immersion retorts, in which the packages are fully immersed in the process water. Paper 77-2

K.R. Swartzel of North Carolina State University will discuss the unique kinetic advantages of high-temperature/short-time processes, with emphasis on process design, delivery, evaluation, validation, and monitoring. Alternative and emerging preservation technologies have made impressive scientific and engineering advances during the past quarter century, but thermally processed food products maintain a clear dominance in the marketplace. Thermal processing has continued to evolve. Some of the most significant development efforts have concentrated on concurrently enhancing the safety, quality, and economics of thermal food preservation by pursuing continuous, more uniform, and rapid processes for shelf-stable and refrigerated foods. Paper 52-2

T.L. Heyliger of FMC FoodTech will describe water spray thermal processing systems. Over the past decade, many processors of thermally processed foods in hermetically sealed containers have moved from the traditional steam or water immersion retort to automated batch retort systems utilizing steam water spray technology. The ideal system will accommodate multiple types and sizes of packages and packaging materials, deliver uniform, energy-efficient thermal processes with overpressure capability, and be fully automated. Paper 77-3

C.R. Brownmiller of the University of Arkansas will discuss the effect of rotary and still retort processes on carotene content in carrots, sweet potatoes, and spinach. In conventional still retort processing of carotene-rich vegetables, the harsh thermal process required to achieve commercial sterility causes much provitamin A activity to be lost by conversion of all-trans-carotenes to steroisomers. Agitating retorts may reduce process time by faster and more uniform heat penetration throughout the product and thereby allow for greater retention of provitamin A carotenes in canned vegetables. Paper 44C-13

R.Y. Murphy of the University of Arkansas will report on results of a study to evaluate the effect of cooking conditions on pathogen process lethality and product yield for chicken patties processed in a pilot-scale air impingement oven. Paper 59F-25

B.A. Rasco of Washington State University will discuss use of radiofrequency for pasteurization of salmon caviar by thermal inactivation of Listeria innocua. International markets for caviar require products to be pasteurized, but there are no suitable pasteurization processes for salmon caviar that yield a product with an acceptable texture and high product quality. Paper 42-6

D.E.N. Amako of the University of Kentucky will report on a study to examine the effect of temperature-time and residual air volume on process parameters, quality factors, and nutrient retention of chili con carne thermally processed in semi-rigid plastic trays suitable for military-type rations. Paper 56-4

S. Bruin of Unilever Research Vlaardingen, in his Food Engineering Division Lecture, will review some of the main developments in food process engineering in the past 25 years, including progress in understanding control of food microstructure formation and rheology during processing, progress in separation processes, progress in flavor technology and understanding of flavor retention during processing and release and progress in preservation technology. He will then discuss exciting future developments, including the major impact of computation power on food process engineering, integrated process design approaches, application of novel “fields” in food processes, “precision” processing, and supply-chain approaches to food manufacturing. Paper 52-1

J.J. Miles of MicroThermics, Inc., will describe miniature processing systems and plant trial services for developing aseptic, pasteurized (high-temperature/short-time), hot-filled, and continuous-cooked products. The miniature systems accelerate product development by linking the laboratory to the manufacturing process and tailoring equipment and operating conditions to meet needs. Miniature systems are available to simulate direct and indirect heating, in-line homogenization, and deaeration for products ranging from juices to aseptic cheese sauces and puddings. Miniature plant trial services are used for qualifying formulas and ingredients, optimizing processes, and preparing samples for taste panels and trade shows. Paper 77-5

H. Fisker of Alfa Laval Inc. will discuss recovery and transformation processes for by-products of meat, poultry, and seafood processing, as well as use of food industry wastewater. Paper 82-4

T.S. Gentry of Cornell University will discuss use of 5-hydroxymethyl furfural as a time-temperature indicator of lethality in continuous microwave pasteurization of apple cider. The difficulty in calculating microbial destruction in microwave processing is obtaining an accurate temperature profile. Traditional methods for monitoring temperature, which are metal based, have physical limitations in microwave systems. Although fiberoptic probes can be used to monitor temperatures in microwave systems, they are expensive and delicate. Chemical markers may provide an additional method to verify the lethality of thermal processes. Paper 73C-1

K.V. Burns of Hosokawa Bepex Corp. will describe a new thermal process to make novel functional changes in corn, wheat, rice, oat, potato, and tapioca flours. The process consists of hydration, thermal treatment, and drying. The process avoids starch damage and retrogradation, so the structural properties of the raw material are maintained while swelling properties are improved. Paper 13-9

C.H. White of Mississippi State University will discuss recent developments in chilled dairy products, including extended-shelf-life refrigerated products, addition of carbon dioxide, high-pressure processing, pulsed electric fields, addition of antimicrobial ingredients, addition of prebiotics and probiotics, and development and distribution of organic milk products. He will also discuss the influence of packages for dairy products. Paper 32-4

S.K. Sastry of Ohio State University, and others will discuss electrothermal processes, including microwave, ohmic, dielectric, radiofrequency, and induction heating, as well as the emerging area of moderate electric field (MEF) processing. MEF processing is not intended for use for sterilization, but shows a vast array of interesting effects that may help improve conventional food processes, such as drying, fermenting, and blanching. Paper 65-2

P.J. Slade of National Center for Food Safety & Technology will discuss the potential for enhancement of food safety and shelf life through use of modified-atmosphere packaging in conjunction with irradiation, UV and visible light, microwaves, ultrasound, and high-pressure processing. He will also discuss use of MAP with active packaging, such as use of oxygen and carbon dioxide scavengers and emitters and ethylene absorbers, and use of time-temperature indicators. Paper 38-2

D.M. Barrett of the University of California will discuss effect of thermal processing on carotenoids, phenolics, and antioxidant activity of clingstone peaches. The peaches were cut in half, lye peeled, canned, and processed, then analyzed. Paper 46-4

High-Pressure Processing

More than 20 papers will be presented on high-pressure processing (HPP), one of the two most popular new minimal or nonthermal processes.

R.S. Meyer of Washington Farms will discuss the benefits of high-pressure processing of shelf-stable, low-acid foods. HPP has proven to be effective in eliminating all spores and enzymes while retaining a quality level equal to or better than frozen, and advances in equipment design and construction have brought down the processing costs to be competitive with retorting and freezing. It can be used to produce shelf-stable gourmet meals, such as macaroni and cheese, chicken ala king, salmon fettuccine, ravioli, and beef stroganoff, with freshly prepared flavor, texture, and color. Foods retain about 95% of their original nutrient content. Paper 6-6

B. Ray of the University of Wyoming will discuss effect of combinations of HPP (345 MPa), heat, and bioactive peptides, such as bacteriocins of food-grade lactic acid bacteria, on death of pathogenic bacterial cells in bacteriological media and low-acid meat products such as roast beef, Cotto salami, and summer sausage. Paper 6-7

D. Knorr of Technische University of Berlin will report on studies of combinations of high pressure (150 MPa) and low temperatures on foodborne pathogens, compared to pressure treatment at ambient temperature. More complex combination processes such as heat plus pressure plus ultrasound will also be reported. Paper 6-4

S. Basak of McGill University will report on studies designed to investigate the high-pressure destruction kinetics of Saccharomyces cerevisiae and Leuconostoc mesenteroides in single-strength and concentrated orange juice. Thermal pasteurization, the most common method for orange juice processing and preservation, extends shelf life with assured safety but may have a detrimental effect on wholesomeness, aroma, and flavor. HPP is gaining importance because of its ability to destroy microorganisms, inactivate enzymes, and denature protein without deteriorating sensory and nutritional attributes. The pressures used were 100–400 MPa. Paper 15B-5

P. Pandey of McGill University will compare the proteolytic characteristics of Cheddar cheese made from high-pressure-treated milk, microfiltered milk, raw milk, and pasteurized milk during ripening. Pasteurization of milk prior to cheese making influences both the extent and characteristics of proteolysis during cheese ripening. The ability of HPP to keep the flavor and natural characteristics of food samples intact provides added advantage over conventional heat processing, but it perturbs the balance of intramolecular and solvent–protein interaction of milk and can therefore affect the ripening characteristics of cheese. Paper 15C-32

Y.J. Kim of Korea Food Research Institute will discuss studies to extend the shelf life of bulgogi, a popular traditional Korean marinated meat, by applying high pressure (300–500 MPa) to the product packaged in an aluminum laminated pouch. Paper 15E-1

J.J. Rodríguez of Washington State University will report on a study to determine the contribution of the come-up time (time to reach the treatment pressure) to the high-pressure inactivation of L. innocua inoculated into whole milk. Paper 15E-4

V.M. Balasubramaniam of National Center for Food Safety & Technology will discuss the effect of pH and temperature on spore inactivation during HPP (up to 900 MPa) of foods. Some bacterial spores can be inactivated by a combination of high pressures and moderate temperatures, but limited information is available on influence of pH on spore inactivation by HPP. He studied inactivation of Bacillus subtilis spores in citrate-phosphate buffer, crabmeat blend, and tomato blend at 552, 690, and 827 MPa. Paper 15E-5

A. Schauwecker of National Center for Food Safety & Technology will report on the effect of HPP on migration of a pressure-transmission fluid through various of National Center for Food Safety & Technology will report on the effect of HPP on migration of a pressure-transmission fluid through various each package were studied. Paper 15E-6

C. Mok of Kyungwon University, South Korea, will report on a study to extend the shelf life of low-alcohol peach wine by high-pressure sterilization. The fermented peach wine containing 11% alcohol was packaged in a flexible pouch. Paper 15E-9

T. Truong of Ohio State University will discuss results of a study to optimize conditions for processing orange juice with a combination of HPP and carbon dioxide. High-pressure processing preserves fresh flavors and vitamin content in fruit juices while inactivating deleterious enzymes, such as pectin methylesterase (PME), which is responsible for undesirable cloud loss in citrus juices. Pressurized carbon dioxide has been shown to inactivate PME in orange juice. Paper 15E-10

J.I. Lee of Yonsei University, South Korea will report on the effects of combined HPP (400 MPa) and high-pressure carbon dioxide (2.94 MPa) on inactivation of enzymes and physical stability of carrot juice. Paper 15E-11

V.M. Balasubramaniam of National Center for Food Safety & Technology will discuss determination of the compression heating characteristics of various food materials under HPP conditions (up to 600 MPa). The foods studied were soybean oil, olive oil, glycol/water mixture, beef fat, chicken fat, mashed potato, orange juice, tomato salsa, fresh salmon flesh, and water. Paper 28-3

U. Nienaber of Ohio State University will discuss a study to determine the effectiveness of HPP in eliminating spoilage microorganisms in salad dressings and to investigate whether HPP causes any significant or detrimental rheological changes in the product. Salad dressings are cold-processed and mainly rely on acidity for preservation. Spoilage can occur by contamination with acid-tolerant yeasts, molds, and lactic acid bacteria. Ranch, French, and slaw dressings were inoculated with Zygosaccharomyces bailii and Lactobacillus fructivorans, and pressures of 500–800 MPa were applied. Paper 28-4

G. Sadler of National Center for Food Safety & Technology and others will discuss effects of HPP on high-barrier packaging structures for various liquid and solid foods. Film mechanical properties evaluated included modulus of toughness, ultimate seal strength, yield strength, elongation, tensile modulus, and ultimate tensile strength. Packages were also evaluated for microleaks. Paper 38-3

P.J. Slade of National Center for Food Safety & Technology will report on a study to develop models for inactivation of Escherichia coli K12 in apple juice by HPP (200–465 MPa) from which critical control points and critical limits can be derived. Paper 41-7

H. Calik of Oregon State University will discuss a study to establish optimum time and pressure conditions for inactivation of Vibrio parahaemolyticus in Pacific shell oysters by HPP. Paper 42-1

S. Oh of Ewha Womans University, South Korea, will discuss a study on the effect of pH on inactivation and germination of Bacillus cereus by HPP (up to 600 MPa). Paper 59F-32

E.Y. Ting of Flow International Corp. will discuss the importance of equipment design and practices on inactivation data and will recommend laboratory equipment practices for inactivation studies. Differences in high-pressure equipment design and laboratory procedures are frequently ignored in the scientific study of HPP on food products, and this can result in erroneous inactivation rates and either over- or underprocessing. Paper 65-5

J.M. Boff of Ohio State University will report on the effect of dissolved gases on the flavor profile and ascorbic acid content of orange juice processed by carbondioxide-assisted HPP (800 MPa), which can reduce the pressure and processing times and thereby improve cost efficiency, flavor quality, and ascorbic acid retention. Paper 88A-4

Pulsed Electric Fields

The other most popular new minimal or nonthermal process being investigated is use of pulsed electric fields (PEF).

D. Knorr Technische University of Berlin will report on studies of combinations of PEF and temperatures on foodborne pathogens. High-intensity electric field pulses have been shown to effectively inactivate vegetative microorganisms. Data regarding inactivation kinetics indicate nonlinear inactivation characteristics, and three state models have been developed explaining the mechanisms involved. He will discuss the effect of PEF treatment under high pressure (200 MPa) on permeabilization of microbial membranes. Paper 6-4

O.E. Pérez of Universidad de Buenos Aires, Argentina will discuss the effect of PEF treatment on protein structure and related functional properties, such as gelling behavior of beta-lactoglobulin and egg white. Paper 15D-33

S.K. Min of Ohio State University will discuss development of a measurement and data-logging system for PEF process variables, including chamber inlet and outlet temperatures, flow rate, pressure, voltage waveform, and current waveform, that will meet HACCP monitoring requirements. Paper 15D-34

Z.T. Jin of of Ohio State University will discuss use of PEF on foods containing particulates, such as tomato salsa and rice pudding. Particles 3–4 mm in size were processed by PEF with and without mild heating, then aseptically packaged into plastic cups for evaluation of microbiological quality and shelf life. Paper 15D-35

S.Q. Li of Ohio State University will describe development of a device that adds salt or other necessary components to a product after PEF processing but before aseptic packaging, since the presence of high concentration of salt or other ionizable components makes PEF processing challenging. The dosage device can deliver 5–20 mL of salt solution to 6-oz cups and is suitable for use in the processing of vegetable products such as salsa and ketchup. Paper 15D-36

J.J. Fernandez-Molina of Washington State University will report on effect of PEF processing, with and without conventional heating, on the microbial quality and shelf life of skim milk. Paper 15E-14

S. Bendicho of the University of Lleida, Spain, will discuss effect of a combination of PEF and mild heat on a lipase from Pseudomonas fluorescens. Most lipases present in raw milk are inactivated by heat treatments, but some, especially those from psychrotrophic bacteria, resist traditional treatments and remain active after the thermal death of the bacteria, causing flavor defects in dairy products. Paper 15E-18

P. Ratanatriwong of Ohio State University will discuss determination of PEF processing conditions for and evaluation of shelf life of rice pudding, using a combination of PEF and heating. Paper 15E-19

M.M.Gongora-Nieto of Washington State University will discuss a study to evaluate the energy applied by different PEF processing conditions and its effect on the microbial quality of liquid whole egg during refrigerated storage, and to determine if the energy expenditure could be reduced by the combination of preservation factors. Paper 15E-23

G.A. Evrendilek of Ohio State University will describe a study to process cranberry juice by PEF and evaluate the shelf life of the aseptically packaged product at various temperatures. Paper 15E-24

H.W. Yeom of Ohio State University will discuss the effect of electric field strength and temperature on the inactivation of pectin methylesterase in orange juice by PEF. Paper 28-5

S.Q. Li of Ohio State University will discuss PEF inactivation of natural flora in a functional food derived from fruit juice and milk. Paper 44E-24

H.W. Yeom of Ohio State University will discuss effects of a continuous PEF process on highly viscous foods such as a yogurt-based product and determine its microbial, sensory, and physical properties during storage. Commercial plain low-fat yogurt was mixed with strawberry jelly and strawberry syrup, processed by PEF, and aseptically packaged. Paper 28-7

S.Q. Li of Ohio State University will discuss inactivation of Sacchromy-cesuvarum and Rhodotorula rubra in a highly carbonated beverage under various PEF conditions. Paper 28-6

S. Bendicho of the University of Lleida, Spain, will discuss the effect of PEF processing on a protease from B. subtilis, a Gram-positive psychrotrophic bacteria that may be present in raw milk. This bacteria produces a protease that resists current thermal treatments and causes the development of a bitter flavor or even coagulation of milk and dairy products. Paper 15E-16

K.M.F.A. Reyns of Katholieke Universiteit Leuven, Belgium, will discuss a study to investigate whether reaction products generated by electrolysis or disintegration of electrode materials during PEF treatment contribute to inactivation of bacterial vegetative cells. Cells of E. coli, Salmonella typhimurium, and L. innocua were added to buffer and PEF treated under various conditions. Paper 41-4

M.M. Gongora-Nieto of Washington State University will discuss development of an automated monitoring system for PEF technology. Automated, efficient, and accurate measurement of electric parameters that define PEF treatment and lethality is of utmost importance in the commercialization of this technology. Paper 57-1

R. Unal of Ohio State University will discuss a study to determine whether various pretreatments for E. coli O157:H7 and Listeria monocytogenes alter the composition of cell envelope and thereby increase the efficacy of PEF treatment. E. coli O157:H7 was pretreated with disodium ethylene diamine tetraacetic acid, lysozyme, and their combination. The effect of different growth temperatures on the susceptibility of L. monocytogenes to PEF was also investigated. Paper 59F-20

Q.H. Zhang of Ohio State University will discuss scale-up of PEF processes. He studied PEF processing of fruit and vegetable juices at three scales: laboratory (flow rate 5–10 L/hr), pilot plant (100–200 L/hr), and commercial scale (1,000–2,000 L/hr). Paper 65-3

P. McClure of Unilever Research, UK, will review the critical process factors and main characteristics of food products that determine the microbial inactivation kinetics of both PEF and HPP processes. Paper 83-4

Ultrasound

M.T. Jimenez-Munguia of Universidad de las Americas-Puebla, Mexico will discuss mold Spore of inactivation during cavitation due to ultrasound treatments. Application of low-frequency ultrasound (20 kHz) promotes microbial inactivation during heat treatment. Lethality of ultrasound has been associated with cavitation, and variables that may enhance cavitation during ultrasonication include air bubbles, cavitation nuclei, and ultrasound wave amplitude. Spores studied were Aspergillus niger and Penicillium digitatum. Paper 15E-17

A. Lopez-Malo of Universidad de las Americas-Puebla, Mexico, will discuss a study to determine the inactivation kinetics of Aspergillus flavus spores by combination of heat and ultrasound treatments. Paper 73C-4

T.J. Kim of Mississippi State University will discuss the effect of continuous high-frequency ultrasound (CHFU) on physical and chemical properties of reconstituted orange juice, pectin methylesterase activity, and yeast counts of fresh orange juice. Paper 101-3

A. Lopez-Malo of Universidad de las Americas-Puebla, Mexico, will discuss effect of combinations of heat and ultrasound on inactivation of Penicillium digitatum spores. Paper 15E-3

D. Guzey of the University of Tennessee will discuss effect of sonication time and power level on the surface activity of protein solutions and thus their ability to produce emulsions. High-intensity ultrasonic processing is increasingly used in the food industry to homogenize emulsions, accelerate chemical reactions, and aid filtration and extraction processes, but its effect on the physicochemical characteristics of food components such as proteins needs to be further investigated. Paper 101-4

S.N. Guerrero of Universidad de Buenos Aires, Argentina, will discuss inactivation of S. cerevisiae by the combined action of ultrasound, mild heat treatment, and natural antimicrobials such as cinnamon oil or low-weight chitosan. Paper 88D-19

Ozonation

Much research is also being done on use of ozone as an antimicrobial and replacement for chlorine-containing disinfectants.

B.C. Hampson of California Polytechnic State University will discuss ozone and its uses. Ozone has the ability to kill viruses, bacteria, and amoebocytes, while simultaneously reducing off-flavors and odors, with nominal formation of disinfection by-products. Ozone recently attained GRAS affirmation, allowing for use as a direct-contact food-sanitizing agent. Paper 53-3

D.M. Graham of R&D Enterprises will present an overview of ozone chemistry and applications in the food industry, including use of aqueous ozone for cleaning sausage curing racks, washing chopped celery, fresh garlic cloves, and apples, and cleaning flume water, and use of gaseous ozone for dry onion storage, warehouse environments, and grain processing. Paper 65-4

L.A. Balesteri of California Polytechnic State University will discuss determination of the efficacy and by-products of ozonated water applied as a spray wash to sanitize surfaces in fruit and vegetable, meat, and dairy processing pilot plants. Ozone, a strong oxidizing agent, is able to clean soil and biofilm from surfaces and leaves behind no chemical residue. With a half-life measured in minutes, ozone must be generated as used, and application results in the formation of few disinfection by-products. Paper 85-5

A. Garcia of the University of Tennessee will discuss effectiveness of ozone and chlorine treatments, alone or in combination, on reducing natural microflora strains and extending shelf life of fresh-cut lettuce salads. Chlorine is an effective sanitizer against many foodborne microorganisms, but it may cause the formation of carcinogenic trihalomethane compounds. Ozone is an effective disinfectant, with greater oxidation potential than chlorine. Paper 30B-28

Y.S. Song of National Center for Food Safety & Technology will discuss effect of ozone treatment of drinking water on plastic packaging materials. The researchers measured the migration of residual compounds and degradation products into ozonated water from polyethylene terephthalate and high-density polyethylene bottles, polypropylene caps, and ethylene vinyl acetate liners. Paper 73D-18

B.F. Ozen of Purdue University will discuss effect of ozone on mechanical, thermal, and barrier properties of plastic films used in food packaging, including linear low-density polyethylene, oriented polypropylene, and biaxially oriented nylon films. Paper 73D-19

L.H. Choi of Purdue University will discuss effects of ozonation and pasteurization on the quality and nutritional value of apple cider. FDA has mandated a 5-log reduction of pathogenic organisms in fruit and vegetable juice products. The most common method is thermal pasteurization, but it may increase product cost and lower nutrition, quality, and consumer acceptability of apple cider. Paper 88E-16

A.D. Prudente of Louisiana State University will discuss use of ozone to decontaminate aflatoxin B1 in corn. Paper 44G-22

E.S. Hwang of the University of Illinois at Urbana-Champaign will discuss determination of the degradation of mancozeb and ethylene thiourea in solutions as a result of ozone and chlorine dioxide treatments. Paper 44G-23

M. Reed of Mississippi State University will discuss effect of ozonated fish chiller water on Acinetobacter baumannii and L. monocytogenes, two organisms with some prevalence in raw catfish. Paper 73F-1

C.E. Beyer of California Polytechnic State University will discuss use of ozone-enriched irrigation water as an antimicrobial agent on broccoli sprouts inoculated with E. coli. Paper 85-7

N. Singh of Purdue University will discuss effect of various inoculation methods—dip, drop, and sprinkle methods—for evaluating the efficacy of ozone and chlorine dioxide against E. coli O157:H7 on shredded lettuce. Paper 59E-19

M.N. Kelly of Air Liquide will discuss a study to determine if a combination of acidulants, particularly citric and lactic acids, with ozone would increase its antimicrobial efficacy against E. coli on the surface of fresh apples. Paper 15E-15

P. Kaothien of South Dakota State University will discuss ozone’s effectiveness in controlling L. mono-cytogenes in cured ham. Paper 101-7

Y. Han of Purdue University will discuss effect of ozone and chlorine dioxide on inactivation of E. coli O157: H7 on green peppers and development of predictive models using response surface methodology. Paper 88E-7

J.B. Robbins of the University of Illinois, Urbana-Champaign, will discuss effect of ozone and chlorine, alone and in combination, on non-attached cells and biofilms of L. monocytogenes. Paper 59F-24

H. Xi of Louisiana State University will discuss use of ozone to reduce catfish fillets off-flavor caused by 2-methylisoborneol and geosmin. Paper 88A-6

B.F. Ozen of Purdue University will discuss the effect of ozone and chlorine dioxide gases on the quality characteristics of cut green peppers. Two treatments were used: gas treatment followed by modified-atmosphere packaging, and injection or flushing the package containing the product. Paper 88E-6

Ohmic Heating

S. Salengke of Ohio State University will discuss effect of ohmic pretreatment on oil uptake of potato slices during frying and subsequent cooling. Paper 15D-37

P. Pongviratchai of Oregon State University will discuss a study to evaluate the functionality of starches and protein additives in surimi seafood gels cooked under ohmic and water bath heating. In surimi seafood (e.g., crab stick), the primary cooking is completed rapidly because of the thinness of the surimi sheet. However, test gels prepared using a conventional water bath are subjected to extremely slow heat penetration. This discrepancy in heating rate between gel testing and commercial production leads to the question of whether test gels provide accurate information for the commercial product. Paper 42-9

C.J. Doona of US Army-Natick SBCCOM will discuss a study to determine conditions that induce faster relative heating in solid whey gel than in solution. The study used chemical markers to map temperature distribution throughout the whey gel, since the uniformity of temperature distribution must be verified when basing the sterilization of food particulates on measurements of solution temperature. Paper 101-1

L. Chiu of McGill University, compared the quality of ham emulsion cooked under ohmic and conventional heating conditions. Traditional cooking of large-size comminuted meat products in smokehouses takes up to 12 hr, is energy intensive, and often results in low production rates. Ohmic heating could allow considerable energy savings, while raising the production rate. Paper 97-2

H.J. An of Louisiana State University will discuss effect of ohmic heating on leaching of amylose from rice starch and white and brown rice flours. Paper 15D-32

M.R. Zareifard of Agriculture & Agri-Food Canada will discuss a study to determine the temperature profiles and the fluid and particle electrical conductivities of two-phase food systems during ohmic heating. Paper 15D-31

I. Sensoy of Ohio State University will discuss effect of moderate electric field (MEF) processing on the permeability of cell membrane of fresh mint leaves, which affects the extraction of cellular materials.Paper 15D-38

Other Processes

Reports on various other processes, including use of magnetic fields, hydrodynamic processing, and various electrical processes, will also be presented during the technical program.

M.O. Balaban of the University of Florida will discuss the synergistic use of carbon dioxide and pressure in nonthermal processing of juices. Fresh, unpasteurized orange juice and apple cider were used for natural flora and cloud experiments, and thermally pasteurized juices spiked with Salmonella choleraesuis, L. monocytogenes, and E. coli O157:H7 for pathogen trials. Pressures from 20 to 103 MPa were used. Paper 6-3

E.Y. Wuytack of Katholieke Universiteit Leuven, Belgium, will discuss determination of the sensitivity of various microorganisms to high-pressure homogenization (HPH) at up to 200 MPa or higher) and comparison of HPH to high-pressure processing (HPP) for the preparation or stabilization of emulsions and suspensions.Paper 41-6

D.G. Hoover of the University of Delaware will discuss injury and recovery of bacteria exposed to food processing methods and other environmental stresses. He will discuss nonthermal methods such as use of low temperatures, chemical preservatives, hydrostatic pressure, irradiation, electricity, sonication, and other forms of energy; thermal processing; combinations of nonthermal procedures with mild elevated temperatures. Paper 6-2

F. Harte of Washington State University will discuss determination of whether pulsed magnetic fields will inactivate E. coli, S. cerevisiae, B. subtilis, and L. innocua. Frozen samples were used to control the temperature, because to reach the desired magnetic field the resistivity of the magnet was lowered by cooling the magnet with liquid nitrogen. Paper 15E-20

J.S. Eastridge of USDA’s Agricultural Research Service will discuss effect of hydrodynamic pressure processing (HDP) on tenderness of beef eye of round. The HDP process involves detonation of an explosive in a container filled with water in which vacuum packaged meat has been placed. The explosion exposes the meat to a supersonic shock wave. Paper 55-1

A.G. Senecal of the U.S. Army SBCCOM will discuss whether HDP could improve the tenderness/textural properties of beef muscle during both freeze dehydration and subsequent storage.Paper 30C-3

M.B. Solomon of USDA’s Agricultural Research Service will discuss the effect of HDP on ribeye muscles either chilled overnight or frozen after pressure treatment.Paper 30C-2

D.M. Graham of R&D Enterprises will discuss the development of electrotechnologies for food processing and preservation during the 20th century, including membranes for separation, concentration, and microbial count reduction; ohmic heating; irradiation; rapid freezing; microwave processing; ozonation; and use of industrial process heat pumps. He will also discuss the effect of energy availability on future use and development of these processes. Paper 47-3

L.A. Buckalew of Ineos Fluor Americas, LLC, in the New Products & Technologies Session will discuss use of 1,1,1,2- tetrafluoroethane (HFC-134a) as a selective extraction solvent for the generation of novel flavor and fragrance ingredients. She will also describe a pilot-scale facility for extractions using HFC-134a, which was initially developed as a replacement for R-12 refrigerant. Paper 9565

Processing & Packaging Exhibitors at 2001 IFT Food Expo

A.R. Arena Prods. Inc. 4759

ABB Bomem Inc. 870

Alcide Corp. 662

American Ingredients Co. 2241

Amerivap Systems 1863

Analytical Process, Inc. 977

ARBO Engineering Inc. 616

Arca Systems 5919

ARDE Barinco, Inc. 411

Atlas-Stord Denmark A/S 6024

BioSterile Technology, Inc. 1412

Boley & Associates, Inc. 2170

Bonar Plastics 1013

Bran & Luebbe, Inc. 559

Brookfield Engineering 754

Buhler Inc. 4122

CHEMetrics, Inc. 4422

Clextral Inc. 3256

Cole-Parmer Instrument Co. 618

Cox Recorders 1176

Custom Food Processors, Inc. 648

Cyrano Sciences, Inc. 6237

Deltatrak Inc. 1118

Dionex Corp 1076

Dixie Canner Co. 4748

Eastman Chemical Co. 2623

Ecolab Inc. 4615

EM Science 617

Flavourtech Americas, Inc. 861

Flow International Corp. 4415

Fluid Metering, Inc. 628

Foster Miller Inc. 5748

Glatt Air Techniques, Inc. 774

Videos Related to Food Processing

“Nonthermal Processing Techniques,” IFT’s videoconference, features panelists from IFT’s Science and Technical Panel on Alternative Processing Technologies. IFT President Mary K. Schmidl introduces the panelists. J.W. Larkin of the Food and Drug Administration discusses FDA regulations and how they would apply to new processing technologies. F.F. Busta of the University of Minnesota comments on control of pathogens and evaluation of the inactivation/effectiveness of the process. C.P. Dunne of U.S. Army Natick discusses the U.S. Army’s investment to determine the feasibility of nonthermal processing and development of a commercial production base. And D.R. Heldman discusses quality consideration of nonthermally processed food products. Session 16, 9:45 a.m. Sunday

“Good Manufacturing Practices,” a training video for food processing plant personnel, covers all important aspects of good manufacturing practices. Session 45, 9:20 a.m. Monday

“Smart Sanitation,” a practical training tool for new sanitation employees or a refresher for veterans, helps employees understand the food safety impact of their day-to-day cleaning and sanitation activities. Session 45, 9:40 a.m. Monday

“HACCP—Your Key to Seafood Safety” shows the importance of HAACP as a training tool for those involved in the seafood and allied industries. Session 45, 10:20 a.m. Monday

“The Heart of HACCP” provides a clear overview of the seven HACCP principles and practical guidance on how to monitor critical control points and implement corrective actions in the work environment. Session 45, 10:40 a.m. Monday

“HACCP Training for Managers” presents industry-specific examples and case studies explaining the seven HACCP steps, identification of critical control points, record keeping and documentation, auditing, and monitoring. Session 102, 10:55 a.m. Wednesday

Registered Yet? Get more information on pages 37 and 169 of this issue.

by NEIL H. MERMELSTEIN

Senior Editor