Evaluating Nonthermal Processes

PROCESSING

The Institute of Food Technologists’ Nonthermal Processing Division may be unique among the Institute’s 28 Divisions in sponsoring and presenting an annual international workshop since 2000. The most recent workshop was held on September 14–16, 2005, at the Eastern Regional Research Center (ERRC) of the U.S. Dept. of Agriculture’s Agricultural Research Service in Wyndmoor, Pa. The next workshop will be held on September 2006 in Ireland, hosted by University College Cork and Queen’s University Belfast in an impressive act of cooperation across borders.

These workshops are especially notable in that they have helped produce consensus on critical issues regarding nonthermal processes and have influenced thinking at regulatory agencies such as the Food and Drug Administration and USDA’s Food Safety Inspection Service, which typically must approve and regulate new processing technologies.

As an example of the respect in which the workshops are held, the keynote speaker for this year’s event was Robert Buchanan, Senior Science Advisor and Director of the Office of Science in FDA’s Center for Food Safety and Applied Nutrition, College Park, Md. (phone 301-436-2369).

How FDA Evaluates New Technologies

Buchanan addressed the topic “How Much is Enough?” referring to how much of a given treatment is needed. He first alluded to older preservation processes such as acidification, dehydration, and antimicrobials. These familiar, relatively simple processes have a substantial impact on food composition and sensory attributes. They are bacteriostatic, not bactericidal; i.e., they inhibit the growth of microorganisms but do not necessarily kill them.

In contrast, he said, nontraditional processes are driven by the desire to have minimal impact on sensory properties, can be complex, and can induce physical changes, including heating, since many involve applying novel forms of energy. They may either inhibit or kill microbes, depending on the circumstances.

Buchanan explained FDA’s approach to risk management, which has changed in recent years. The traditional standard was to achieve a risk level “as low as reasonably achievable (ALARA).” He pointed out that “reasonable” was in the eye of the beholder, a matter of judgment. It was common to assume a worst case, e.g., high initial levels of contamination, overfilling of a container, higher viscosity than target, and so forth. Such assumptions led in the case of standard practice for canning to targets of 12 decimal (12D) reductions in Clostridium botulinum spores. Such thermal processes typically result in overcooking foods and reduced levels of vitamins and color.

The new approach, Buchanan said, relies on setting a public health goal and concentrating on achieving that goal rather than specifying how it is achieved. There are two significant elements on which the agency focuses: validation and verification. Validation demonstrates that a given goal can be achieved. Verification assures that the goal actually is achieved. Buchanan presented the concept in setting a Food Safety Objective (FSO), which, expressed as decimal reductions, must be greater than the sum of the initial level of contamination minus the reduction achieved, plus any increase or recontamination.

The critical question, of course, is what is the “appropriate level of protection (ALOP)?” Buchanan pointed out that even if there is 95% confidence of achieving some target, if there are three steps, each with that level of confidence, there could be a 14–15% chance of failure. Thus, validation implies not that a process cannot fail, but rather that the rate of failure is within acceptable limits. This is a highly significant point—approved preservation processes may have a finite, though small, probability of failure, even when operated correctly.

Validating a Process

The key to process validation, Buchanan said, is a process capability study in which the results are typically presented as a control chart, showing a process outcome as a function of time. The process outcome would typically be the decimal reduction actually achieved, for instance. One practical issue is how to detect extremely low levels of microorganisms in foods. Thus, process capability studies typically involve challenges, often using surrogate organisms added to a food in such levels that even after significant reductions they can still be detected. An important principle in such studies is that the process should be driven to failure, typically by using extremes of process conditions, to understand the ruggedness of the process. FDA wants to see the data from such a well-designed study for any new technology, he said.

He cited as a recent example the HACCP guidance for fresh fruit juices, which specifies a 5D reduction in pathogens. He explained that the goal was risk reduction, not elimination, and that the agency hoped to preserve at least some distinctive fresh flavor in the products. Exceptions to the rule requiring a mild thermal process are pasteurized shelf-stable juices, which undergo a more severe process anyway, and citrus juices made from surface-treated, hand-picked sound fruit, which are considered to be essentially sterile, provided that the skin is washed with hot water and sanitizer.

He cited as a recent example the HACCP guidance for fresh fruit juices, which specifies a 5D reduction in pathogens. He explained that the goal was risk reduction, not elimination, and that the agency hoped to preserve at least some distinctive fresh flavor in the products. Exceptions to the rule requiring a mild thermal process are pasteurized shelf-stable juices, which undergo a more severe process anyway, and citrus juices made from surface-treated, hand-picked sound fruit, which are considered to be essentially sterile, provided that the skin is washed with hot water and sanitizer.

A major challenge for new processes, Buchanan added, is knowledge of the kinetics of bacterial destruction, so that conditions can be simulated and results correlated. Kinetics are understood for irradiation and are beginning to be understood for high pressure, but other processes require continuing research in this area. The high pressure model applies to vegetative cells but not, so far, to spores. By law, some processes require premarket approval because they have been defined as additives and so are regulated as such. Examples are all radiation processes (not just ionizing radiation) and antimicrobials that are not generally recognized as safe (GRAS). High pressure is not defined as an additive, but how FDA will consider any filings for approval will depend on whether the treatment has a lasting effect, according to Buchanan.

An important element of any study submitted to FDA is evidence that diversity has been considered, meaning potential biological variation in target microbes, variations due to equipment, geographical variations (e.g., environmental conditions), and variations in the food itself. Buchanan pointed out that changes of just 0.1 in pH units can matter in food safety.

The significant data that must be measured and submitted include the initial load, the reduction achieved by the process, and the increase or recontamination that could occur, all measured over a variety of conditions and recognizing the potential for variation. The FSO must be specified and defended, using, for instance, the limit of detection that may be appropriate. FDA is still waiting for a filing for a high-pressure process.

Buchanan also alluded to the complex debate over the description of food as “fresh.” Many nonthermal processes claim to retain “freshness” in some sense. FDA is concerned about the legal and scientific bases for such claims. Finally, Buchanan observed that FDA wants surrogate organisms to be more resistant to a process than the target pathogens. FDA also wants at least one test with “real” pathogens, which itself causes anxiety in researchers, who are conscious of the dangers of such microbes. For that reason, most process capability studies are performed in pilot plants rather than production facilities.

This keynote talk, by a senior scientist at FDA, set out the goals and procedures for evaluating and obtaining approval for nonthermal processes and illustrates how significant this divisional workshop is.

Determining Kinetics

Also on the workshop program, IFT President-Elect Dennis R. Heldman (phone 203-770-0508), now a private consultant in San Marcos, Calif., after years in universities, industry, and a trade association, discussed some of the candidate kinetic models for new processes. In particular, he presented several modifications to the traditional first-order rate equation.

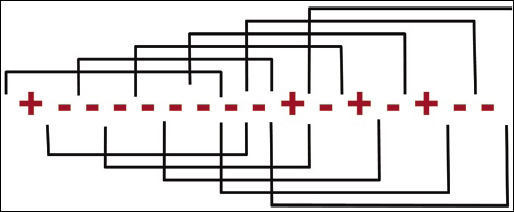

Thermal processes have traditionally been described with a first-order differential rate equation, he said. In integrated form, this equation shows a linear decline in relative numbers of microbes with time at constant temperature when plotted on semi-logarithmic graph paper. This gives rise to the convention of decimal reductions in describing processes.

For some new processes, it is possible that this reliable model does not apply, so the mathematics and experimentation can become more complex. For high pressure, Heldman pointed out that the rate constant may be a function of pressure and that most high-pressure processes also involve some adiabatic heating, so temperature almost certainly changes. Spores may be injured by decompression in addition to whatever damage heating under pressure may cause. It can be difficult to distinguish between injured and permanently inactivated cells, he said.

These complications for high pressure can then be compared with issues that arise in other processes, such as microwave and radiofrequency heating, ohmic and induction heating, pulsed electric fields, high-voltage arc discharge, pulsed light, oscillating magnetic fields, and others. The basic question in every case is what is the required time at given process conditions to achieve a given food safety objective.

Finding the Data

Another speaker, Mark Tamplin (phone 215-836-3794), Lead Scientist in Microbial Modeling and Bioinformatics at ERRC, described the database of microbial responses in food environments that he and his colleagues have assembled. Called ComBase and available at www.combase.cc, it has more than 32,000 records of growth and survival for microbes in foods. There are data for 28,000 pathogens and 4,000 spoilage microorganisms. Access is free. In 2006, a new feature will allow ComBase data to be integrated with ERRC’s Pathogen Modeling Program, found at www.arserrc.gov/mfs/pathogen.htm. The point is that this information, previously scattered in many forms throughout the literature, is now being collected and presented in a convenient form.

Not only was the workshop educational and well-organized, but it also demonstrates what a creative and energetic division within the Institute can accomplish.

by J. Peter Clark,

Contributing Editor,

Consultant to the Process Industries, Oak Park, Ill.

[email protected]