Food Packaging and Its Environmental Impact

The Institute of Food Technologists has issued a Scientific Status Summary on food packaging and its impact on the environment. Here is a synopsis.

Advances in food processing and packaging play a primary role in keeping the United States food supply one of the safest in the world. Packaging protects food between processing and usage by the consumer. Following usage, food packaging must be removed in an environmentally responsible manner. Packaging technology must therefore balance food protection with other issues, including energy and material costs, heightened social and environmental consciousness, and strict regulations on pollutants and disposal of municipal solid waste (MSW).

MSW consists of items commonly thrown away, including packages, food scraps, yard trimmings, and durable items such as refrigerators and computers. Legislative and regulatory efforts to control packaging are based on the mistaken perception that packaging is the largest component of MSW. Instead, the Environmental Protection Agency (EPA, 2006) found that only approximately 31% of the MSW generated in 2005 was from packaging-related materials; this percentage has remained relatively constant since the 1990s despite an increase in the total amount of MSW. Non-packaging sources such as newsprint, telephone books, and office communications generate more than twice as much MSW.

MSW consists of items commonly thrown away, including packages, food scraps, yard trimmings, and durable items such as refrigerators and computers. Legislative and regulatory efforts to control packaging are based on the mistaken perception that packaging is the largest component of MSW. Instead, the Environmental Protection Agency (EPA, 2006) found that only approximately 31% of the MSW generated in 2005 was from packaging-related materials; this percentage has remained relatively constant since the 1990s despite an increase in the total amount of MSW. Non-packaging sources such as newsprint, telephone books, and office communications generate more than twice as much MSW.

Nevertheless, food packaging is a noteworthy contributor to MSW because food is the only product class typically consumed three times per day by virtually every person. Accordingly, food packaging accounts for almost two-thirds of total packaging waste by volume (Hunt et al., 1990). Moreover, food packaging is approximately 50% (by weight) of total packaging sales.

Although the specific knowledge available has changed since publication of “Effective Management of Food Packaging: From Production to Disposal,” the Institute of Food Technologists’ first Scientific Status Summary on the relationship between food packaging and MSW (IFT, 1991), the issue remains poorly understood, complicating efforts to address the environmental impact of discarded packaging materials.

Consequently, IFT has issued a new Scientific Status Summary that describes the role of food packaging in the food supply chain, the types of materials used in food packaging, and the impact of food packaging on the environment. Appearing in the April 2007 issue of Journal of Food Science, the new Summary, “Food Packaging—Roles, Materials, and Environmental Issues,” provides an overview of EPA’s solid waste management guidelines and other waste management options, addresses disposal methods of and legislation on packaging disposal, and describes the current sustainable cradle-to-cradle concept, which replaces the cradle-to-grave emphasis. The sustainability goal of the cradle-to-cradle concept is to recover sufficient materials and energy in a way that imposes zero impact on future generations. This article is a synopsis of the Scientific Status Summary.

Food Packaging Roles and Materials

The principal roles of food packaging are to protect food products from outside influences and distribution damage, to contain the food, and to provide consumers with ingredient and nutrition information. Traceability, convenience, and tamper indication are secondary functions of increasing importance. The goal of food packaging is to contain food in a cost-effective way that satisfies industry requirements and consumer desires, maintains food safety, and minimizes environmental impact.

Package design and construction play significant roles in determining the shelf life of a food product. The right selection of packaging materials and technologies maintains product quality and freshness during distribution and storage. Materials that have traditionally been used in food packaging include glass, metals (aluminum, foils and laminates, tinplate, and tin-free steel), paper and paperboards, and plastics. Today’s food packages often combine several materials to exploit each material’s functional or aesthetic properties.

--- PAGE BREAK ---

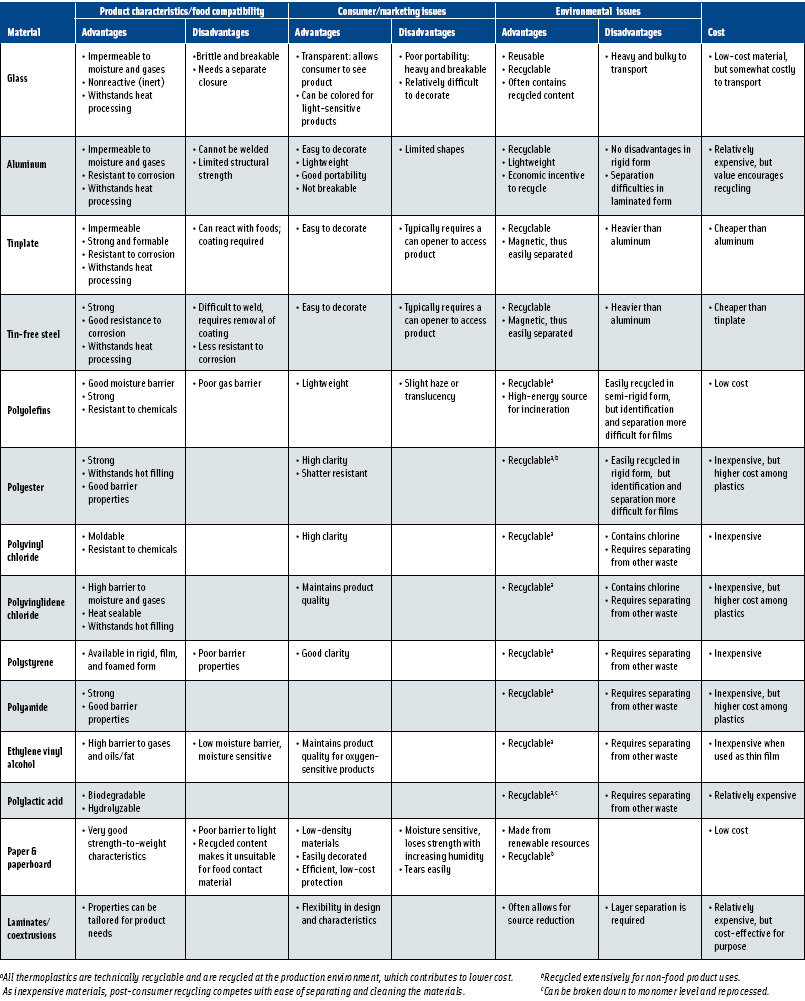

As research to improve food packaging continues, advances in the field may affect the environmental impact of packaging. The table on p. 49 summarizes the advantages and disadvantages of various packaging materials in terms of product protection, product distribution, and environmental impact.

As research to improve food packaging continues, advances in the field may affect the environmental impact of packaging. The table on p. 49 summarizes the advantages and disadvantages of various packaging materials in terms of product protection, product distribution, and environmental impact.

Waste Management Approach

Proper waste management is important to protect human health and the environment and to preserve natural resources. EPA’s guidelines for solid waste management (EPA, 1989) emphasize the use of a hierarchical, integrated management approach involving source reduction, recycling, composting, combustion, and landfilling.

• Source Reduction (i.e., waste prevention) is reducing the amount and/or toxicity of the waste ultimately generated by changing the design, manufacture, purchase, or use of the original materials and products. EPA considers source reduction the best way to reduce the impact of solid waste on the environment because it avoids waste generation altogether.

Source reduction encompasses using less packaging, designing products to last longer, and reusing products and materials (EPA, 2002). Specific ways to achieve source reduction include using thinner gauges of packaging materials (i.e., lightweighting), purchasing durable goods, purchasing larger sizes (which use less packaging per unit volume) or refillable containers, and selecting nontoxic products.

• Recycling diverts materials from the waste stream to material recovery. Unlike reuse, which involves using a returned product in its original form, recycling involves reprocessing material into new products.

A typical recycling program entails collection, sorting and processing, manufacturing, and sale of recycled materials and products. Almost all packaging materials (glass, metal, thermoplastic, paper, and paperboard) are technically recyclable, but economics favor easily identified materials such as glass, metal, high-density polyethylene, and polyethylene terephthalate.

• Composting, considered by EPA as a form of recycling, is the controlled aerobic or biological degradation of organic materials, such as food and yard wastes. Accordingly, it involves arranging organic materials into piles and providing sufficient moisture for aerobic decomposition by microorganisms. Because organic materials make up a large component of total MSW (about 25% for food scraps and yard trimmings), composting is a valuable alternative to waste disposal.

• Combustion, the controlled burning of waste in a designated facility, is an increasingly attractive alternative for waste that cannot be recycled or composted. Reducing MSW volume by 70–90%, combustion incinerators can be equipped to produce steam that can either provide heat or generate electricity (waste-to-energy combustors). In 2004, the U.S. had 94 combustion facilities, 89 of which were waste-to-energy facilities, with a process capacity of approximately 95,000 tons/day or about 13% of MSW (Kiser and Zannes, 2004).

• Landfilling provides environmentally sound disposal of any remaining MSW and the residues of recycling and combustion operations. As waste disposal methods, both landfilling and combustion are governed by regulations issued under subtitle D of the Resource Conservation and Recovery Act (40 CFR Parts 239–259). Thus, today’s landfills are carefully designed structures in which waste is isolated from the surrounding environment and groundwater.

--- PAGE BREAK ---

EPA also strives to motivate behavioral change in solid waste management through nonregulatory approaches such as pay-as- you-throw and WasteWise. In pay-as-you-throw systems, residents are charged for MSW services on the basis of the amount of trash they discard. This creates an incentive to generate less trash and increase material recovery through recycling and composting. WasteWise is a voluntary partnership between EPA and U.S. businesses, institutions, nonprofit organizations, and government agencies to prevent waste, promote recycling, and purchase products made from recycled contents.

Moreover, EPA’s Environmentally Preferable Purchasing program helps federal agencies and other organizations purchase products with less effect on human health and the environment than other products that serve the same purpose. Pollution prevention is the primary focus, with a broader environmental scope than just waste reduction.

Disposal Statistics

The most recently compiled waste-generation statistics indicate that 245.7 million tons of MSW were generated in 2005, a decrease of 1.6 million tons since 2004 (EPA, 2006). The decrease in waste generation is partly attributable to the decreased rate of individual waste generation.

EPA analyzes MSW in two ways:

1. By materials: paper and paperboards, glass, metals, plastics, rubber and leather, textiles, wood, food scraps, and yard trimmings.

2. By major product categories: containers and packaging (mainly waste from food packaging, such as soft drink cans, milk cartons, and cardboard boxes); nondurable goods (newspapers, magazines, books, office paper, tissues, and paper plates and cups); durable goods (household appliances, furniture and furnishings, carpets and rugs, rubber tires, batteries, and electronics); and other wastes.

The containers and packaging category remained relatively constant at about 31% of the total waste generated between 2003 and 2005. EPA analysis of individual MSW generation rate shows a relatively constant rate of 4.5 lb/person/day since the 1990s, excluding the years 2000 and 2004 when it reached an all time high of 4.6 lb/person/day.

Even though waste generation has steadily grown since 1960, recovery through recycling has also increased. In 2005, 79 million tons (32.1%) of MSW was recovered through recycling and composting— slightly more than 58.4 million tons by recycling and 20.6 million tons by composting. The net per capita recovery reached an all time high of 1.5 lb/person/day.

Recovery was the highest for the containers and packaging category (39.9% of amount generated), followed by nondurable goods (31%).

Despite the trend of increased recovery rates, the quantity of MSW requiring disposal has historically risen as a result of the increase in amounts generated. In 2005, approximately 168 million tons (68%) of MSW was discarded into the municipal waste stream—33.4 million tons (20%) combusted prior to disposal and 133.3 million tons directly discarded in landfills. The total amount of MSW generated has actually declined slightly since 2004; however, it is too early to determine if this is a change in the overall trend or merely a small variation that will not be maintained.

--- PAGE BREAK ---

Limitations of Solid Waste Management Practices

Proper waste management requires careful planning, financing, collection, and transportation. Solid waste generation increases with population expansion and economic development and poses several challenges. For example, source reduction and convenience are often opposing goals in food packaging. Convenience features such as unit packages, dispensability, and microwavability usually require additional packaging. Similarly, tamper-indication features also add to the amount of waste generated.

Moreover, recycling and reuse are influenced by the costs of transporting, sorting, and cleaning collected materials. Many recycled materials, primarily plastics and paperboard, are restricted from food-contact applications. And both combustion and landfilling can have negative impacts on the environment through release of greenhouse gases or contamination of air and groundwater.

These aspects of packaging design and disposal must be weighed against environmental concerns in packaging. Because consumers dictate what is produced by what they choose to buy, at some point they need to evaluate whether the convenience and added safety are worth the increase in materials.

Choosing Packaging Materials

The key to successful packaging is to select the package material and design that best satisfy competing needs with regard to product characteristics, marketing considerations (including distribution needs and consumer needs), environmental and waste management issues, and cost. Balancing so many factors is difficult and also requires a different analysis for each product.

Factors to be considered include the properties of the packaging material, the type of food to be packaged, possible food/package interactions, the intended market for the product, and the desired product shelf life. Other factors include environmental conditions during storage and distribution, product end-use, eventual package disposal, and costs related to the package throughout the production and distribution process.

Ideally, a food package would consist of materials that maintain the quality and safety of the food over time; are attractive, convenient, and easy to use while conveying all the desired information; are made from renewable resources, thereby generating no waste for disposal; and are inexpensive. Rarely, if ever, do today’s food packages meet these lofty goals. Creating a food package is as much art as science, trying to achieve the best overall result without falling below acceptable standards in any single category.

From a product characteristic perspective, the inertness and absolute barrier properties of glass make it the best material for most packaging applications. However, the economic and safety disadvantages of glass boost the use of alternatives such as plastics. While plastics offer a wide range of properties and are used in various food applications, their permeability is less than optimal—unlike metal, which is totally impervious to light, moisture, and air.

Attempts to balance competing needs can sometimes be addressed by mixing packaging materials— such as combining different plastics through coextrusion or lamination—or by laminating plastics with foil or paper. Plain paper is not used to protect foods for long periods of time because it has poor barrier properties and is not heat sealable. When used as primary packaging (i.e., in contact with food), paper is almost always treated, coated, laminated, or impregnated with materials such as waxes, resins, or lacquers to improve functional and protective properties. In contrast, paperboard is seldom used for direct food contact, even though it is thicker than paper.

Ultimately, the consumer plays a significant role in package design. Consumer desires drive product sales, and the package is a significant sales tool. Although a bulk glass bottle might be the best material for fruit juice or a sports beverage, sales will be affected if competitors continue to use plastic to meet the consumer desire for a shatterproof, portable, single-serving container.

--- PAGE BREAK ---

Minimizing Environmental Impact

The impact of packaging waste on the environment can be minimized by prudently selecting materials, following EPA guidelines, and reviewing expectations of packaging in terms of environmental impact. Still, the primary purpose of food packaging must continue to be maintaining the safety, wholesomeness, and quality of food. Knowledgeable efforts by industry, government, and consumers will promote continued improvement, and an understanding of the functional characteristics of packaging will prevent much of the well‑intentioned but ill‑advised solutions that do not adequately account for both pre- and post-consumer packaging factors. New materials, combinations, and technologies will allow the move from cradle-to-grave to cradle-to-cradle by eliminating negative environmental impact altogether (McDonough and Braungart, 2002).

To maintain a sustainable society, consumers must rethink their purchasing and convenience expectations as well as their material and energy usage to interact more intelligently with the world in which they live.

Scientific Status Summary Online

The IFT Scientific Status Summary, “Food Packaging—Roles, Materials, and Environmental Issues,” appears in the April 2007 issue of Journal of Food Science and is also available online at www.ift.org. It was written by Kenneth Marsh, Ph.D. ([email protected]), a Professional Member and Fellow of IFT, President of Kenneth S. Marsh & Associates, Ltd., and Executive Director of the Woodstock Institute for Science in Service to Humanity, 102B Ole Towne Sq., Central, SC 29630, and Betty Bugusu, Ph.D. ([email protected]), Research Scientist, Dept. of Science and Technology Projects, Institute of Food Technologists, 1025 Connecticut Ave. N.W., Washington, DC 20036.

Kenneth Marsh, Ph.D. ([email protected]), a Professional Member and Fellow of IFT, is President of Kenneth S. Marsh & Associates, Ltd., and Executive Director of the Woodstock Institute for Science in Service to Humanity, 102B Ole Towne Sq., Central, SC 29630. Betty Bugusu, Ph.D. ([email protected]), is Research Scientist, Dept. of Science and Technology Projects, Institute of Food Technologists, 1025 Connecticut Ave. N.W., Washington, DC 20036. This synopsis was prepared with the assistance of Toni Tarver ([email protected]), Scientific and Technical communications Manager, Dept. of Science and Communications, IFT, 525 W. Van Buren St., Chicago, IL 60607

References

EPA. 1989. The solid waste dilemma: An agenda for action. EPA530-SW- 89-019. Environmental Protection Agency, Washington, D.C.

EPA. 2002. Solid waste management: A local challenge with global impacts. EPA530-F-02-026.

EPA. 2006. Municipal solid waste in the United States: 2005 facts and figures. EPA530-R-06-011.

Hunt, R.G., Sellers, V.R., Franklin, W.E., Nelson, J.M., Rathje, W.L., Hughes, W.W., and Wilson, D.C. 1990. Estimates of the volume of MSW and selected components in trash cans and land fills. Report prepared by the Garbage Project and Franklins Associates Ltd. for the Council for Solid Waste Solutions, Tucson, Ariz.

IFT. 1991. Effective management of food packaging: From production to disposal. Inst. of Food Technologists scientific status summary by K.S. Marsh. Food Technol. 45(5): 225-234.

Kiser, J.V.L. and Zannes, M. 2004. The 2004 IWSA directory of wasteto- energy plants. Integrated Waste Services Assn., Washington, D.C.

McDonough, W. and Braungart, M. 2002. “Cradle to Cradle: Remaking the Way We Make Things.” North Point Press, New York.