Overcoming Challenges in Functional Beverages

When formulating functional drinks with added vitamins, minerals, herbs, or other nutraceutical ingredients, manufacturers often face significant flavor challenges.

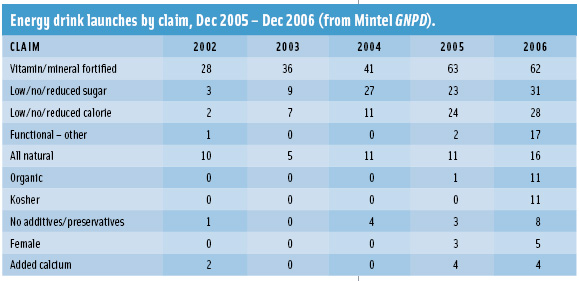

The demand for new functional beverages has seen tremendous growth over the past several years. The number of new energy drink introductions, for example, increased from 6 in 2000 to 239 in 2006, according to Mintel GNPD. And taste preference has become a more-significant issue. Initially, health and wellness consumers were willing to forgo taste in exchange for the health benefits offered by these products. Now that such products have reached the mainstream, functional beverage manufacturers have begun dealing with a new consumer for whom taste is the top priority.

A consumer will not pay for a functional beverage that offers, for example, the recommended daily intake of 14 essential vitamins and minerals if the drink tastes like burnt milk. While it is important to include the functional ingredients, if the beverage doesn’t taste good, the consumer won’t come back for a second try.

To overcome undesirable attributes such as lack of sweetness or increased acidity, a flavor scientist has to have a thorough understanding of basic taste perception, which flavor molecules bind to which receptor, and how to work the synergies between the receptors and flavor chemicals. An understanding of these attributes will help lead to improvement in the overall flavor and palatability of the product and will drive consumer acceptance and preference.

Flavor/taste perception is a complex process with sensory input from the tongue (gustation), the nose (olfaction), and the sense of touch (texture of the product) while a food or beverage is sipped, slurped, chewed, and swallowed. Most undesirable attributes are perceived on the tongue, which determines the basic taste impression. We can perceive five basic taste directions on the tongue: sour, bitter, salt, sweet, and umami (delicious). The different taste receptors on the tongue (ion channels and G-protein–coupled receptors) have all been identified, studied, and characterized by flavor scientists.

Designing a flavor system for functional beverages requires bringing basic taste attributes into balance with flavor chemicals to deliver the desired flavor and taste profile in the end product. Every flavor solution is a unique design for the specific end application.

The key is not only to work with flavor chemicals that provide a desired overall flavor profile but also to use flavor chemicals that interact with the taste receptor to either mask undesired bitterness or to modulate the perception of sweetness in low-calorie products or the perception of saltiness in low-sodium products.

The flavor scientist must design a flavor that will perform in systems containing high concentrations of proteins, minerals, vitamins, caffeine, amino acids, etc., which almost all carry undesirable flavor attributes such as bitterness, harshness, and metallic aftertaste, to name a few.

Fortification Challenges

The U.S. Food & Drug Administration recently proposed allowing new claims that calcium and vitamin D show potential to reduce the risk of osteoporosis. As expected, many beverage manufacturers are now looking to add calcium or boost calcium levels in their products. Particularly in beverages with a low pH (<4.4), it is a challenge to increase calcium levels above 30%, since the result will be tooth etching and a chalky mouthfeel.

--- PAGE BREAK ---

Magnesium and zinc, given their low flavor impact and recommended daily intake, can be formulated into beverages at meaningful levels, whereas iron and potassium tend to lead to a more bitter and metallic aftertaste, requiring the flavorist to work with modulators to mask and rebalance the characterizing flavor.

Herbals represent the newest flavor challenge. The herbal market has seen significant growth, especially with recently released products that boast calorie-burning capabilities. So-called weight-loss ingredients such as hoodia, hydroxyl citric acid (for alleged brain function satiety), and epigallocatechin gallate (EGCG, a thermogenic agent, helpful in burning fat) also cause bitter or astringent notes in the mouth.

To overcome the off-notes associated with herbal beverages, flavorists modulate the taste receptors by masking the bitter receptors and increasing the sweetness perception through receptor binding or through steric blocking of the receptor.

For example, to formulate an herbal tea with ginseng, guarana, and EGCG, a beverage technologist would start out by determining what the ideal caloric value should be and whether the product can include artificial sweeteners. When the base is formulated, the flavorist gets to work. To deal with the herbal notes, the flavorist may apply sweetness modulators for masking technology. Through manipulation of the flavor chemicals, the flavorist can make the product taste like whatever the beverage manufacturer desires, whether it be mango flavor or herbal notes.

Processors face a greater challenge when working with vitamins such as B-1 (thiamin), which has a naturally meaty note. A vitamin with a meaty note would make sense in a beverage with a base such as tomato juice, but no one wants to drink a light orange juice or lemonade with a meaty aftertaste.

While it is possible to include so little of a vitamin that the negative notes can be overcome, it is a better idea to design the flavor with the right end product in mind. Beta-carotene has an off-note that consumers have grown accustomed While it is possible to include so little of a vitamin that the negative notes can be overcome, it is a better idea to design the flavor with the right end product in mind. Beta-carotene has an off-note that consumers have grown accustomed to over time, since it is used in many orange drinks for color. Now it’s somewhat perceived as part of the orange flavor and can be used in applications that are citrus in nature.

Protein Challenges

Functional beverages enhanced with proteins have seen a huge jump in popularity. Since low-carbohydrate diets are a fading fad, consumers with a dietary focus have turned to protein beverages—with satiety components—that act as meal replacements. Other health- and fitness-conscious consumers purchase protein-enhanced beverages to consume during and after their workouts to help build muscle mass.

A few years ago, companies introducing protein-enhanced beverages had to choose between flavor and functionality. Flavor technology had not yet advanced to the degree it has today, so most often the manufacturer would sacrifice flavor for functionality. Now more than ever, flavor plays a significant role in helping these products sell to a growing population of consumers. Beverage processors face surmountable challenges when increasing their protein content to fill consumers’ needs for more protein-enhanced drinks.

--- PAGE BREAK ---

The vast majority of protein-enriched beverages launched for the general public use soy protein or whey protein, often with casein to round out the amino acid profile and to add viscosity. Pea, rice, and egg proteins (albumin and yolk) are used more often in drinks fortified specifically for bodybuilding or protein recovery.

A challenge manufacturers face when formulating a ready-to-drink, high-pH (>4.5) protein beverage is the harsher processing conditions such as retorting, high-temperature/short-time processing, or ultra-high-temperature (UHT) processing. These conditions often create off-notes such as burnt, caramelized, nutty, beany, cereal, sulfuric, or bitter. The addition of protein is done with both dry and liquid protein sources and will often require homogenization to emulsify the fats to increase the beverage stability.

Traditionally, flavorists were forced to counter these off-notes with high-sweetness flavors such as chocolate, vanilla, and strawberry. Vanilla is and will continue to be one of the best masking agents available. The increased demand, however, for an array of choices—high-carbohydrate, low-fat, diet, low-carbohydrate/low-fat, meal-replacement, and nutritional-supplement drinks, to name a few—has created the need for an equally vast array of masking agents, modulating flavors, and characterizing flavors to address the needs of the particular beverage segment.

Traditionally, flavorists were forced to counter these off-notes with high-sweetness flavors such as chocolate, vanilla, and strawberry. Vanilla is and will continue to be one of the best masking agents available. The increased demand, however, for an array of choices—high-carbohydrate, low-fat, diet, low-carbohydrate/low-fat, meal-replacement, and nutritional-supplement drinks, to name a few—has created the need for an equally vast array of masking agents, modulating flavors, and characterizing flavors to address the needs of the particular beverage segment.

Products made with soymilk, which have gained tremendous popularity worldwide, can include a heart-healthy claim when delivering greater than 6.25 g of protein/serving. To make the protein palatable, the raw soy concentrate must be processed to minimize the inherent green/beany/nutty notes present in the bean. Although some traditional consumers have learned to enjoy these particular soy notes, today’s mainstream consumers seek soymilk as a milk substitute. Therefore, the soy protein must be processed to eliminate strong base notes and be stabilized, sweetened, and modulated to reduce off-notes and flavored to taste like milk.

Ready-to-drink, low-pH (<4.4) protein beverages require special processing or ingredients to provide a stable formulation. Pectins, alginates, and other stabilizers are often used to protect and/or suspend the protein in the beverage. The protein will need to go through its isoelectric point when the acid is added, requiring a relatively large amount of acid and homogenization. The use of partially hydrolyzed whey protein isolates has enabled developers to make low-pH, clear, fruit-flavored beverages with very high levels of protein (≥30 g/8 fl oz), a product ideal for bodybuilders. These levels of protein create salty and bitter notes that must be modulated on the tongue to minimize these effects and overridden with a rebalanced characterizing flavor, often with base modifications.

High-molecular-weight proteins also characteristically absorb added flavor. While the remaining portion may not absorb the entire flavor, the flavor that is perceived is then thrown entirely out of balance. The approach is then to modulate and rebalance the beverage’s flavor to an acceptable characterizing flavor.

Processing and pH

Developing a base for a functional beverage requires many different parameters to be set prior to flavor application. One of the most important parameters is determining the kind of processing the product will undergo to ensure that the beverage meets its shelf-life requirements. Determining this will allow off-notes to be masked at the forefront rather than after the complete product is manufactured. To determine adequate processing parameters, producers of functional drinks need to establish the pH of the system they intend to produce.

--- PAGE BREAK ---

Most shelf-stable products are low pH (<4.4) to ensure microbial stability. Two preservation methods for low pH are hot filling and chemical preservation. In hot filling, the product is heated to a temperature generally above 180ºF, then filled at that temperature. The product is then cooled to ambient temperature, allowing the cap to create a seal to prevent product contamination.

Chemical preservation uses ingredients such as potassium sorbate, sodium benzoate, and sodium hexametaphosphate to control and inhibit microbial growth. These ingredients are not active as preservatives at high pH levels because they are in their salt form, not the active acid form (e.g., benzoic acid preserves, but sodium benzoate does not). Acids such as citric acid and phosphoric acid must be added to activate the preservative.

Products made using chemical preservation must start “clean” (low microbial counts for bacteria, yeast, and mold) and are generally cold filled. They pose a different challenge for the product developer in that they require flavor masking to rid the product of off-notes created by the chemical burn of the preservatives. Chemical preservatives are considered by consumers as a “negative.” This, coupled with the off-notes from the functional ingredients, makes product developers tend to steer away from this preservation method.

Products with pH >4.5 require more-stringent measures for preservation, since spoilage microorganisms such as Clostridium botulinum could contaminate the product.

Aseptic filling and UHT processing followed by refrigeration are two ways to produce products with a neutral pH. In aseptic filling, the product is heated to 285° F, thus killing any spoilage microorganisms, then filled into a container in a clean environment. This type of processing allows for a longer shelf life. In UHT/refrigeration, the product generally undergoes heat treatment at higher temperatures than a standard hot fill and finally is cooled and refrigerated. This process provides a shorter shelf life for the finished beverage. The finished beverage must be kept refrigerated if the product is processed into a nonsterile container.

Other factors should be taken into account when adjusting the pH in a functional beverage. For example, some functional ingredients change their taste perception as the pH is changed. For example, EGCG found in teas tends to become increasingly bitter as the pH is lowered. The use of stronger flavors such as heavier peach notes and vanillas may aid the masking of the bitter off-notes from this ingredient. Soy protein isolate will also produce bitter and beany off-notes at lower pH values. The product developer determining the process beforehand can adjust for this as the development process moves along.

Teamwork Helps Ensure Success

Creating a functional food or beverage that tastes great requires teamwork. An applications scientist will set the parameters for function and flavor, taking into account the cost and regulatory status of ingredients, as well as the economics of mass production. They use quantitative measurements such as number of calories/serving, comparison to competition, and qualitative measurements such as overall tastiness, recognizable ingredients, stability, etc.

--- PAGE BREAK ---

Applications scientists must acquire ingredients, test the product for stability, and adjust formulations to meet potential claims requested by the customer. Customer and applications scientists must work closely together with the flavor chemists to determine the best overall flavor profile.

The flavor chemists will work with the base provided by the applications specialist to design the required flavor profile, including masking the undesirable attributes coming from the added nutrients or modulating the desired flavor profile.

All of this development work will be accompanied by sensory testing with a tasting panel. Sensory evaluation is a powerful tool used to support the quality assurance, research and development, and marketing functions. It provides valuable and meaningful data to help better understand the flavor profile of the products being created. It can help determine not only whether there is a difference between formulations but also, more important, identify the differences and how great they are. Sensory analysts use techniques such as descriptive analysis whereby trained panelists describe the attributes of the product and measure their intensity. The collected data are analyzed and graphed, providing a visual representation of the information that developers use as a guide for further development.

Markus Eckert, Ph.D. ([email protected]) is Vice President of Technical and Paul Riker ([email protected]) is Manager of Beverage Applications, Flavors North America, Mastertaste Inc., 546 U.S. Hwy. 46, Teterboro, NJ 07608. Both are Professional Members of IFT. Send reprint requests to Paul Riker.