Novel Strategies for Reducing Sodium

INGREDIENTS

For example, in processed meat products, salt controls the water content and influences the protein structure and therefore the texture of the product. In controlling the water activity, sodium chloride also plays a significant role in the microbial stability of the product. In baked goods, salt influences the growth of yeasts, the gluten properties of the dough, and consequently the final consistency of the product. In many thermally-processed products such as soups and sauces, salt supports the microbiological stability over a long period and improves the shelf life of the product as well as modifying the texture.

Anecdotal evidence suggests that the slow and gradual reduction of salt from a formulation can go unnoticed by consumers as their palates adjust to the revised sensory profile if the changes are small enough (Bertino et al., 1982, Wheelock and Hobbiss, 1999). This approach is sometimes referred to as reduction by stealth and when gradually continued over time, large reductions can be achieved. However, a threshold will almost inevitably be reached, beyond which a loss in appealing flavor will be noticed by consumers, with the potential for a significant risk of declining sales. In addition, this process will not achieve the significant reductions in salt content of processed foods sought by international governments in the short term.

Therefore, although reduction by stealth may be suitable for small reductions, for larger reductions, it not only holds the risk of a loss of flavor, but may compromise the shelf life, stability, safety, and acceptability of products.

Salt Replacers

Salt Replacers

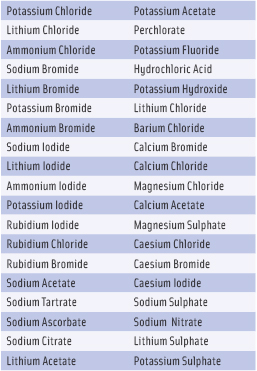

One approach to reducing sodium is the use of salt replacers. Combinations of ingredients for use as salt replacers have been based on the replacement of the sodium cation with potassium, ammonium, calcium, and lithium, and by anions such as phosphate and glutamates (Wheelock and Hobbiss, 1999). Salts such as lithium chloride and ammonium chloride, although providing a salty taste, are considered unsuitable due to their stability, smell, and high toxicity.

Of these, the following are the most commonly used in salt replacement blends:

• Potassium chloride

• Potassium lactate

• Magnesium sulphate

--- PAGE BREAK ---

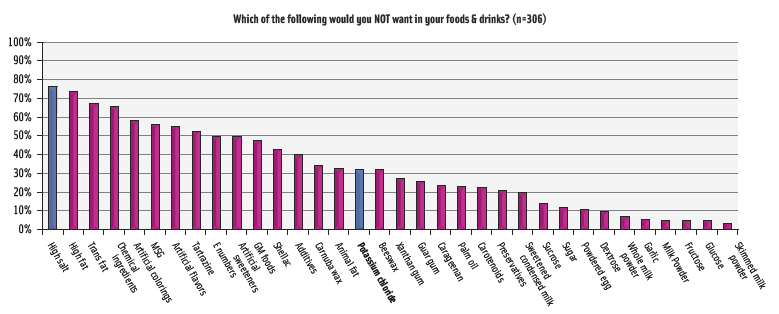

Potassium chloride (KCl) is the most popular choice as a feasible salt replacer (Renqvist, 1919; Burney and Lucas, 1966; Dzendolet and Meiselman, 1967; Frank and Michelsen, 1970; Murphy et al., 1981; Klaauw and Smith, 1995). It is considered by consumers to be less “undesirable” than a multitude of other ingredients as demonstrated in a survey by Leatherhead Food Research in 2010 and illustrated in Figure 1.

Potassium chloride (KCl) is the most popular choice as a feasible salt replacer (Renqvist, 1919; Burney and Lucas, 1966; Dzendolet and Meiselman, 1967; Frank and Michelsen, 1970; Murphy et al., 1981; Klaauw and Smith, 1995). It is considered by consumers to be less “undesirable” than a multitude of other ingredients as demonstrated in a survey by Leatherhead Food Research in 2010 and illustrated in Figure 1.

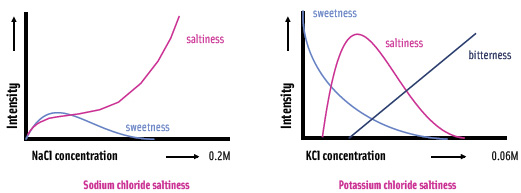

Potassium chloride has been shown to have an equivalent antimicrobial effect on typical pathogenic bacterial species (Bidlas and Lambert, 2008). Its acceptability is, however, limited due to its pronounced bitter, chemical, metallic taste and aftertaste. This is shown in Figure 2, which compares the time/intensity profile of potassium chloride with that of sodium chloride.

Potassium chloride has been shown to have an equivalent antimicrobial effect on typical pathogenic bacterial species (Bidlas and Lambert, 2008). Its acceptability is, however, limited due to its pronounced bitter, chemical, metallic taste and aftertaste. This is shown in Figure 2, which compares the time/intensity profile of potassium chloride with that of sodium chloride.

Sodium reduction obtained by simply substituting a proportion of the sodium chloride with potassium chloride is the easiest option for manufacturers. However, masking the undesirable sensory attributes associated with potassium chloride remains a problem.

Potassium lactate can be used to reduce the amount of salt present while maintaining a certain level of perceived saltiness. It is most commonly seen in the processed meat sector. As previously mentioned, salt in processed meat products helps control the water content and therefore plays a key role in the microbial stability of the products. Potassium lactate is derived from organic lactic acid, a component naturally present in meat and other food products, thus meaning it is not declared as a preservative but as an acidity regulator or an antioxidant.

Magnesium sulphate provides both a bitter and a salty taste, depending on its concentration (Delwiche et al., 1995; Lawless et al., 2003). At low levels, it is associated with a salty taste compared to at high levels, being bitter (Shallenberger, 1993). For this reason, it may have the potential to be used as a salt replacer. Research published by Breslin and Beauchamp (1995) states that magnesium sulphate has a suppressing effect on saltiness at intermediate concentrations of sodium chloride. At higher concentrations, magnesium sulphate had no influence on the saltiness of sodium chloride.

Salt Enhancers

A second approach to salt reduction is to use salt enhancers, which are substances that do not have a salty taste in themselves, but enhance a salty taste when used in combination with sodium chloride. A range of ingredients is reported to act as salt enhancers, including products such as amino acids, monosodium glutamate, lactates, yeast products, and other flavorings. Taste enhancers work by activating receptors in the mouth and throat and they help compensate for the salt reduction and enhance flavor.

--- PAGE BREAK ---

A study carried out at Leatherhead Food Research looked at the salt-enhancing effects of the amino acids glycine, glycine ester, lysine, taurine, and arginine in soups, snacks, and bakery applications (Angus et al., 2005). Glycine ester successfully compensated for salt taste in products with a 30% reduction in their salt content. It was most successful on chips but it also contributed a sour note. In the other products, it imparted levels of sourness, bitterness, and umami to the profile. Interestingly, the enhancement properties of this amino acid were not seen in products containing typical levels of salt; it wasn’t until some of the salt was removed that these effects were seen. Lysine, arginine, and taurine had no consistent enhancement effect on salt perception in solution or in food.

Using MSG in certain savory foods can help in reducing the sodium content. Although glutamate is not salty itself, using a small amount of glutamate in low-sodium products can be effective. MSG contains only one-third of the amount of sodium in table salt and is used at much lower levels, meaning that the sodium level in the finished recipe can be reduced by as much as 30%. MSG dissolves easily in water, absorbs no moisture, causes no agglomeration, and gives the food a characteristic umami or savory flavor.

Research has shown that people find food with low levels of salt much more acceptable when a small amount of MSG is added. For example, in a study by Prescott and Young, consumers’ responses to a clear soup with and without MSG and with differing levels of salt were evaluated. Without the addition of MSG, the soup did not become palatable until the salt concentration reached 0.75%. With additional MSG, however, the soup was palatable with a salt concentration of only 0.4% (Prescott and Young, 2002).

Physically Modifying Sodium Chloride

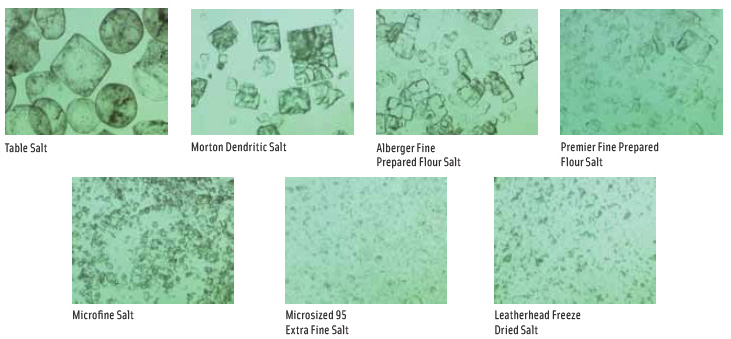

A third alternative for salt reduction is the optimization of the physical form or structure of the salt crystal, lowering the threshold at which saltiness is detected, and therefore reducing the amount of salt needed. Figure 3 gives some examples of salt crystals of varying dimensions.

Once in solution, salt will behave in the same manner, irrespective of its pre-dissolution crystalline nature. However, in dusting or topical applications where salt is added as a solid, it might be expected that the crystal characteristics of the salt could influence the perceived sensory saltiness. This is because in order to contribute to sensory saltiness, the salt must dissolve in the mouth. The rate of dissolution in the mouth is related to the characteristics of the salt crystal, including crystal form (shape and density) and the crystal size (surface area, bulk density), and it would therefore be expected that such differences in crystal characteristics might be manifested in the altered sensory perception of crystalline salt (e.g., altered intensities and/or altered salt release rates).

Once in solution, salt will behave in the same manner, irrespective of its pre-dissolution crystalline nature. However, in dusting or topical applications where salt is added as a solid, it might be expected that the crystal characteristics of the salt could influence the perceived sensory saltiness. This is because in order to contribute to sensory saltiness, the salt must dissolve in the mouth. The rate of dissolution in the mouth is related to the characteristics of the salt crystal, including crystal form (shape and density) and the crystal size (surface area, bulk density), and it would therefore be expected that such differences in crystal characteristics might be manifested in the altered sensory perception of crystalline salt (e.g., altered intensities and/or altered salt release rates).

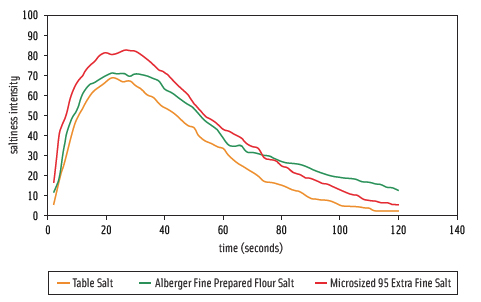

Conducted by Leatherhead Food Research, a study looking into the particle size of salt crystals compared the saltiness perception of different sodium chloride structures when applied to crisps over time. The sodium chloride types used in this research are shown in Figure 3. The time/intensity profiles of three of these types are given in Figure 4 and confirm that the smaller particle sizes resulted in a more rapid release and an overall higher salt intensity than the larger particle sizes.

Conducted by Leatherhead Food Research, a study looking into the particle size of salt crystals compared the saltiness perception of different sodium chloride structures when applied to crisps over time. The sodium chloride types used in this research are shown in Figure 3. The time/intensity profiles of three of these types are given in Figure 4 and confirm that the smaller particle sizes resulted in a more rapid release and an overall higher salt intensity than the larger particle sizes.

--- PAGE BREAK ---

It has also been reported that consumers perceive food as more salty if the salt is on the exterior of foods and if the grains are larger (ILSI, 2009).

Flavor & Aroma Technology

Flavor companies have been actively researching the effect of salt in various application areas. When the salt is reduced in a formulation, flavors can effectively build back the salty aspects that are missing. One of the key elements in achieving this has been developing an understanding of the “salt curve” associated with the taste of food. Salt delivers an initial mineral bite, followed by a body or mouthfeel phase, and leaves a lingering profile.

Fermentation-derived materials can boost richness and depth of flavor when sodium is lacking. “Kokumi” is a term which describes this added complexity. Customized blends of salts and acids can make the tongue think that there is more sodium present than there is in reality (Baggs, 2009).

A few studies have been conducted looking at the effect of enhancement of saltiness by odors and such an effect could be of interest to product developers. The concept of odor-induced taste enhancement has been shown previously for tastes such as sweetness, bitterness, and sourness but only a few have looked at saltiness. It has been suggested that saltiness could be enhanced by cheese odor (Pioneer et al., 2004). Soy sauce odor has also been demonstrated to enhance saltiness perception (Djordjevic et al., 2004).

A study looking at odor-induced taste enhancement found that in some cases the ratings of saltiness of food products were affected by the names of the food products, even prior to tasting. For example, anchovy and bacon items were considered to be the most saltiness-associated food names. Intensity ratings were found to be subjective measures of our perception and expectations that are influenced by our knowledge and experience. In model systems, some odors such as carrot and tomato were shown to have a low or even negative effect on salt perception and a positive effect on sweetness (Lawrence et al., 2009).

Product Parameters Affect Saltiness Perception

In liquid foods, it is widely believed that taste perception decreases with increased viscosity and that as a result, higher levels of salt would be required in viscous products to maximize taste compared to runny liquid products (Walker and Prescott, 2000). It has been reported that the suppression of flavor, including saltiness, by a wide range of thickeners is concentration dependent and could be generalized in terms of the ratio of the concentration of the hydrocolloids to the c* concentration (Baines and Morris, 1987). C* concentration is the concentration where the hydrodynamic domains occupied by the thickener start to overlap. At this concentration, a corresponding viscosity of 10–20 mPas (millipascal seconds) is seen and above this concentration the viscosity increases rapidly and flavor and taste perception decrease. For example, for products thickened with HPMC (hydroxypropyl methylcellulose), a considerable decrease in perception is detected for both flavor and saltiness with increasing viscosity.

Some effects are dependent on the type of thickener. For example, flavor and taste perception of xanthan gum solutions are unaffected by viscosity at concentrations well above c* (Morris, 1994).

--- PAGE BREAK ---

In food systems thickened with different starches, the viscosity-induced flavor and taste perception is much smaller than for HPMC. The perceived taste with starch solutions was found to be related to the efficiency with which the solution mixes with saliva in the mouth. Starch pastes, where the granular structure is largely retained, mix efficiently, and this is responsible for their different mouthfeel and increased flavor perception in comparison to random coil polysaccharides (Ferry et al., 2006).

In solid systems, salt is known to affect the texture and flavor characteristics that are essential for determining product quality and consumer acceptance. Cheese has been identified as one of the main foods contributing to salt intake. For example, if a person consumed an average of 40 g of cheese/day, this would account for 10% of the recommended salt intake. The perception of saltiness may also be impacted by the fat level in the cheese. It has been demonstrated that reducing salt levels has an impact on aroma release, particularly in low-fat products. Therefore, formulating flavored food products with both reduced salt and reduced fat presents an even greater challenge than reducing salt alone (Saint-Eve et al., 2009).

Technical Challenges in Achieving Salt Reduction Targets

In the UK, the Food Standards Authority (FSA) has proposed reducing the salt in bread from its 2010 target of 0.430 g of sodium/100 g to 0.400 g/100 g by 2012, which may pose practical difficulties for the bakery industry. The main challenge in making low-salt bread is that it becomes sticky and is less easy to process with lowering salt levels, meaning that there is a potential for the dough to stop processing lines, leading to downtime and wastage.

The rheological properties of dough are dependent on the concentration of salt. A very low usage rate effectively weakens the gluten which makes the dough sticky, although it has been reported that additives such as potassium chloride have a similar effect on strengthening gluten to sodium chloride (Tournay, 2009), so using salt replacers based on potassium chloride or other ions may overcome this issue. This has been demonstrated practically with a 32.3% reduced sodium brown bread that was acceptable in terms of baking qualities, appearance, texture, and taste. In this case, the potassium, magnesium, and calcium contents of the bread were increased by 55.2%, 69%, and 34.8%, respectively (Charlton et al., 2007).

Other challenges in bakery products are how to rebalance the product flavors and how to replace salt where it plays a specific functional role, for example, where it is used in the extrusion process of cereal-based products. It is possible that using other types of flour, such as rye and malted flour, in lower salt breads may help to compensate for the loss of flavor, and liquid and dried sourdoughs can also add flavor and extend shelf life.

Raw meat itself is a relatively poor source of sodium, containing only 50–90 mg of sodium/100 g (Verma and Sharma, 2009). However, the addition of sodium chloride during the processing of meat and meat products significantly enhances their sodium content.

--- PAGE BREAK ---

Salt is important to both the taste and aroma of meat products for several reasons. First, the sodium in salt binds to protein receptors and imparts the salty taste that is familiar to consumers. Secondly, sodium enhances some of the natural flavors present in meat such as savory and meaty notes. Salt is also effective at releasing volatile aroma compounds from the food matrix, therefore improving the aroma of the product. Salt effectively changes the osmotic pressure in a given product and makes the volatile aroma compounds less soluble in the food matrix. Hence, these volatile compounds are more easily released into the atmosphere as an aroma.

In terms of the flavor, it could be argued that the main challenge in reducing salt in meat products is not in fact the reduction in saltiness itself but the loss of impact on enhancing the meaty and savory flavors in the product. A further technical challenge is that salt also interacts with meat proteins, in particular the myofibrillar proteins which are then extracted and enabled to bind water that is retained within the meat product. Therefore, reducing salt in meat products may lead to products that are different texturally as well as in terms of their flavor profile.

Phosphates are commonly used in processed meat products to extract protein and help with water binding. Even though sodium phosphates contribute to the overall sodium content of the product, they can allow a reduction in the amount of sodium chloride needed for protein functionality and therefore reduce the overall sodium content in the product. In addition, potassium phosphates can be used instead of sodium phosphates.

In reality, sodium can only be reduced to a threshold level because a certain amount of salt and phosphate is essential for acceptable texture and flavor. However, it is claimed that sodium can be reduced to levels of 30–50% without negatively affecting the flavor by replacing it with potassium in both the salt and phosphate and using flavor enhancers and masking agents to overcome the bitter notes sometimes associated with potassium. The salt substitutes commonly used in meat products are potassium chloride, spices, and natural flavors. Blends containing masking agents are also used.

An alternative technology, described in Meat International, is the use of pre-rigor meat. This is commonly used in sausage products due to increased protein functionality when compared with post-rigor meat. This increase in functionality occurs because myosin and actin are not permanently bound as actomyosin. The use of pre-rigor meat allows for the use of less sodium because less salt is needed to extract the myofibrillar proteins. The myofibrillar proteins in the form of actin and myosin are more effective at binding water and encapsulating fat, leading to an improved flavor and aroma in the final products (Schilling et al., 2009).

Finally, salt plays a crucial role in the preservation and microbiological safety of meat products. As a preservative, salt reduces the water activity and prevents the growth of food poisoning and spoilage organisms. To ensure the quality and safety of reduced salt meat products, it might be necessary to add other antimicrobial compounds. For example, products such as potassium lactate and sodium diactetate have been shown to be effective in maintaining microbial shelf life in products where salt has been reduced by up to 40% (Devlieghere et al., 2009).

--- PAGE BREAK ---

In May 2009, the FSA published revised salt reduction targets for 2012 for 80 categories of foods including snacks. For standard potato crisps, the target is 1.38 g salt/100 g, reduced from the previous target of 1.5 g. Pelleted snacks are now tasked with achieving a reduction down to 2.25 g/100 g from 2.5 g per 100 g, and extruded snacks must achieve 1.88 g/100 g, down from 2.8 g/100 g. These targets are an average depending on different flavors but exclude salt and vinegar flavor which has separate specified levels.

Salt in snacks is important in the overall flavor profile since it not only adds flavor in itself but also enhances many of the other seasonings used. However, it also acts a carrier for the uniform distribution of other ingredients such as flavors, colors, and antioxidants on the surface of the snacks.

The main focus of the salt reduction of snacks has been to reduce the surface salt, but the further reductions outlined by the FSA may require the reduction of sodium in the snack matrix itself where it can have important processing and textural benefits. It is known that infusion of different salts can have an effect on vegetable texture. For example, research at Leatherhead Food Research showed that infusing produce with calcium chloride could improve the texture of canned fruit and vegetables, so similar changes may be observed in potato crisps (Pegg, 2010).

The Future of Salt Reduction

It is hard to predict the future sales of salt reducers and salt replacers. It can be assumed that due to the growth in global low-salt and no-salt product launches over the last few years that this trend will continue. Ever increasing pressure on the food industry from legislative bodies will keep caterers and manufacturers assessing the levels of salt in their food and where possible alternatives should be used.

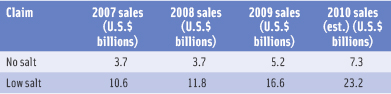

Based on U.S. and UK figures, the global low-salt market is estimated at $50 billion in 2010 and no-salt claims products, which use complete salt replacement products, are worth an estimated $16 billion globally. Table 2 shows sales trends of products with low-sodium and no-sodium claims in the U.S.

Based on U.S. and UK figures, the global low-salt market is estimated at $50 billion in 2010 and no-salt claims products, which use complete salt replacement products, are worth an estimated $16 billion globally. Table 2 shows sales trends of products with low-sodium and no-sodium claims in the U.S.

Lower sodium sea salt will continue to gain popularity as consumers are becoming more health-conscious and seek new “better for you” options.

Furthermore, the growth of the market for salt replacement ingredients will gain steam as new innovations are developed and become available to food manufacturers. As has already been discussed, many food ingredient companies for some time have been putting resources into producing quality salt replacers that not only offer technical similarities to salt but also the same sensorial properties. The potential future growth of this market is dependent on international governments’ push to tackle salt reduction in the food sector and the influence that salt reduction campaigns have on consumer purchasing.

This article is based on a report “Salt Reduction” from Leatherhead Food Research. For more information, please visit http://www.leatherheadfood.com/salt-reduction-report or contact Matt Incles at [email protected] .

www.ift.org

Members Only: Read more about Sodium online at www.ift.org. Type the keyword into our search box at the upper right side of our home page.

Wayne Morley, Ph.D., ([email protected]) is Head of Innovation, Leatherhead Food Research, Leatherhead, Surrey, KT22 7RY UK.

References

Angus, F., Phelps, T., Clegg, S., Narain, C., den Ridder, C., and Kilcast, D. 2005. Salt in Processed Foods Collaborative Research Group. Leatherhead Food International. March.

Baggs, C. 2009. Balancing Taste, Prepared Foods, Nov. 49-53.

Baines, Z.V. and Morris, E.R. 1987. Flavour/Taste Perception in Thickened Systems: The effect of guar gum above and below c*. Food Hydrocolloids 3: 197-205.

Bertino, M., Beauchamp, G.K., and Engleman, K. 1982. Long term reduction in dietary sodium alter the taste of salt. Amer J Clin Nutr. 36: 1134-1144.

Bidlas, E. and Lambert R.J.W. 2008. Comparing the antimicrobial effectiveness of NaCl and KCl with a view to sodium replacement. Intl J of Food Micro. 124: 98-102.

Blais, C.A., Pangborn, R.M., Borhani, N.O., Ferrell, M.F., Prineas, R.J., and Laing B. 1986. Effect of dietary sodium restriction on taste responses to sodium chloride: a longitudinal study. Amer J of Clin Nutr. 44: 232-43.

Breslin, P.A.S. and Beauchamp, G.K. 1995. Suppression of bitterness by sodium: variation among bitter taste stimuli. Chem Senses. 20(6): 609-623.

Burney, D.H. and Lucas J.A. 1966. Gustatory cross adaptation between salts, Psychonomic Sci. 4(8): 301-302.

Charlton, K., MacGregor, E., Vorster, N.H., Levitt, N.S., and Steyn, K. 2007. Partial replacement of NaCl can be achieved with potassium, magnesium and calcium salts in brown bread. Intl J of Food Sci and Nutr. 58(7): 508-21.

Delwiche, J.F., Halpern, B.P., and Desimone, J.A. 1995. Anion Size of Sodium Salts and Simple Taste Reaction Times. Physiology & Behavior. 66(1): 27-32.

Devlieghere, F., Vermeiren L., Bontenbal, E., Lamers, P-P., and Debevere, J. 2009. Reducing salt intake from meat products by combined used of lactate and diacetate salts without affecting microbial stability. Intl J of Food Sci and Tech. 44: 337-41.

Djordjevic, J., Zatorre, R.J., and Jones-Gottman, M. 2004. Effects of perceived and imagined odours on taste detection. Chem Senses. 29: 199-208.

Dzendolet, E., and Meiselman, H.L. 1967. Gustatory quality changes as a function of solution concentration. Perception & Psychophysics. 2: 29-33.

Ferry, A-L.S., Mitchell, J.R., Hort, J., Hill, S.E., Taylor, A.J., Laggarrigue, S., and Valles-Pamies, B. 2006. In-Mouth Amylase Activity Can Reduce Perception of Saltiness in Starch-Thickened Foods. J of Agric and Food Chem. 54: 8869-73.

Frank, R.L. and Michelsen, O. 1970. Sodium-Potassium chloride mixtures as table salt. Third Symposium on Salt. 2: 135-139.

ILSI 2009. Symposium Report: Industry innovation and best practice in reducing salt in foods. Food Australia. 61(12): 504-6.

Klaauw, N.J.V.D. and Smith, D.V. 1995. Taste quality profiles for fifteen organic and inorganic salts. Physiology & Behavior. 58(2): 295-306.

Lawless, H.T., Rapacki, F., Horne, J., and Hayes, A. 2003. The taste of calcium and magnesium salts and anionic modifications. Food Quality and Preference. 14(4): 319-325.

Lawrence, G., Salles, C., Septier, C., Busch, J., and Thomas-Danguin, T. 2009. Odour-taste interactions: A way to enhance saltiness in lowsalt content solutions, Food Quality and Preference. 20: 241-8.

Morris, E.R. 1994. Rheological and organoleptic properties of food hydrocolloids. In Doi E., (Ed) Food Hydrocolloids Structures, Properties and Functions. New York. Plenum Press. 201-10.

Murphy, C., Cardello, A.V., and Brand, J.G. 1981. Tastes of fifteen halide salts following water and NaCl: Anion and cation effects. Physiology & Behavior. 26: 1083-1095.

Pegg, A. 2010. Secret of salt reduction success. Food and Drink Technology. Jan. 12-13.

Pioneer, E., Nicklaus, S., Chabanet, C., Mioche, C., Taylor, L., and Le Quere, J.L. 2004. Flavour perception of a model cheese: relationships with oral and physico –chemical parameters. Food Quality and Preference. 15: 843-52.

Prescott, J. and Young, A. 2002. Does information about MSG content influence consumer ratings of soups with and without added MSG. Appetite. 29: 25-33.

Renqvist, Y. 1919. Uber den Geschmack, Skandinavisches Archiv fur Physiologie. 38: 97-201.

Saint-Eve, A., Lauverjat, C., Magnan, C., Deleris, I., and Souchon, I. 2009. Reducing salt and fat content: Impact of composition, texture, and cognitive interactions on the perception of flavoured model cheeses, Food Chem. 116: 167-75.

Schilling, M.W., Behrends, J.M., Williams, J.B., and Jackson, V. 2009. Flavour challenges of sodium. Meat Intl. 19: 8-10.

Shallenberger, R.S. 1993. Taste chemistry. Blackie Academic & Professional. New York.

Tournay, B. 2009. Salt and Satiety. European Baker. Sept-Oct. 16-18.

Verma, A.K. and Sharma, B.D. 2009. Functional meat products; development and challenges – a review. Indian Food Industry. Jan. 33-41.

Walker, S. and Prescott J. 2000. The influence of solution viscosity and different viscosifying agents on apple juice flavour. J of Sensory Studies. 15(3): 285-307.

Wheelock, V. and Hobbiss, A. 1999. All you ever wanted to know about salt but were afraid to ask. Skipton, Yorkshire. Verner Wheelock Associates.