RF helps to quickly pasteurize eggs; Mobile algae bio-refinery

CUTTING EDGE TECHNOLOGY

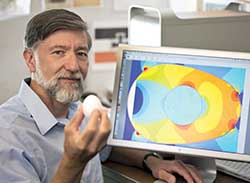

Researchers at the Princeton Plasma Physics Laboratory (PPPL) and the U.S. Dept. of Agriculture (USDA) have developed a pasteurization method using radio frequency (RF) ohmic heating and a combination of cool and hot water to rapidly treat eggs in the shell without degrading the delicate egg white. The process is designed to destroy salmonella bacteria.

According to the Food Safety and Inspection Service of the USDA, less than 0.5% of all shell eggs sold at retail in the United States is pasteurized. The USDA estimates that pasteurizing all shell eggs in the U.S. could reduce the number of egg-borne salmonella illnesses by up to 85%, or more than 110,000 cases annually.

According to the Food Safety and Inspection Service of the USDA, less than 0.5% of all shell eggs sold at retail in the United States is pasteurized. The USDA estimates that pasteurizing all shell eggs in the U.S. could reduce the number of egg-borne salmonella illnesses by up to 85%, or more than 110,000 cases annually.

RF energy transmits heat via electric current through the shell and into the yolk while the egg rotates. At the same time, cool water flows over the egg to protect the white. Next, the egg is bathed in hot water to pasteurize the white and finish pasteurizing the yolk. The goal is to produce a pasteurized egg that is “hardly discernible from a fresh, nonpasteurized egg,” said David Geveke, Lead Scientist at the USDA Agricultural Research Service, Wyndmoor, Pa.

His laboratory partnered with PPPL Engineer Christopher Brunkhorst, an expert in RF heating, to develop the pasteurization device. “You have to raise the temperature high enough to kill bacteria, but not high enough to cook the egg,” Brunkhorst said. “You’re really threading the needle on this.”

The prototype device—about the size of a shoebox—can pasteurize shell eggs in about one-third of the time that current methods require, according to Geveke. Such methods use about a 60-min hot water bath that can alter the appearance of the egg white. The RF process maintains the egg white’s transparency.

The USDA has applied for a patent on the technology and is seeking a licensee to commercialize its use.

Mobile algae bio-refinery

Two Dutch organizations—researcher TNO and algae cultivator Algae Food and Fuel—have announced that they are building a mobile algae bio-refinery to produce purified raw materials that can be used as food ingredients. The start-up phase is expected to be completed after the first quarter of 2014, which will be followed by installation at various locations for algae cultivation.

Algae may be the crop of the future due to their high productivity level per hectare and a potentially sustainable source for the production of a multitude of products. Unfortunately, algae are costly to produce. However, the costs of cultivation can be offset by refining the algae onsite and purifying the ingredients, thereby boosting the net value. This is currently the focus of the program “GAIA: Getting Algae Ingredients Applied” of TNO, Sabic, van Wijhe Verf, and de Wit Oils.

Algae’s value can be enhanced by opening the algae cell walls through refining and then separating and purifying the large fractions (i.e., proteins, fats, and carbohydrates) and minor components (e.g., sterols). The main challenge during the biorefining process is to retain the functionalities of the different algae ingredients. This requires a mild process technology that will be installed in the mobile refinery. In addition to the cell-opening technology, the mobile installation will include membrane modules, extraction equipment, and a number of reactor vessels. There will also be an opportunity to test on a larger scale new breakthrough technologies generated in the lab.

Purifying the algae on a relatively large scale (1 kg of dry matter/hr) will yield significant quantities of algae ingredients for GAIA participants to test in their production lines. The ingredients that will be produced include high-nutritional proteins, oil, omega-3 fatty acids, emulsifiers, pigments, antioxidants, and fibers.

If you are working on or know of some cutting edge technology that you would like to be featured in this column, please send an email to [email protected].