Easy Steps to Less Salt

INGREDIENTS

Salt just works. No other single food additive can be said to have a use in nearly all prepared dishes. Salt gives and enhances flavor, masks off flavors, stabilizes structure and texture, and preserves. Most important of all, salt nourishes—sodium and chloride, in the right amounts, are essential for sustaining life through roles that include helping to regulate fluid and electrolyte balance, pH, and metabolism. Summed up, you could say, we’re all “salt-seeking creatures,” as are all land-living vertebrates, because we’re drawn to salt continually to replace what we lose on a daily basis. Before the advent of modern geology and industry, salt “was one of the world’s most sought-after commodities,” states Mark Kurlansky’s Salt: A World History, adding that it has “provoked and financed wars, secured empires, and inspired revolutions.” More than most, food technologists will also appreciate a quote used in Kurlansky’s book from the ancient Roman statesman Cassiodorus (A.D. 523): “Upon your industry all other products depend, for although there may be someone who does not seek gold, there never yet lived the man who does not desire salt, which makes every food more savory.”

Salt just works. No other single food additive can be said to have a use in nearly all prepared dishes. Salt gives and enhances flavor, masks off flavors, stabilizes structure and texture, and preserves. Most important of all, salt nourishes—sodium and chloride, in the right amounts, are essential for sustaining life through roles that include helping to regulate fluid and electrolyte balance, pH, and metabolism. Summed up, you could say, we’re all “salt-seeking creatures,” as are all land-living vertebrates, because we’re drawn to salt continually to replace what we lose on a daily basis. Before the advent of modern geology and industry, salt “was one of the world’s most sought-after commodities,” states Mark Kurlansky’s Salt: A World History, adding that it has “provoked and financed wars, secured empires, and inspired revolutions.” More than most, food technologists will also appreciate a quote used in Kurlansky’s book from the ancient Roman statesman Cassiodorus (A.D. 523): “Upon your industry all other products depend, for although there may be someone who does not seek gold, there never yet lived the man who does not desire salt, which makes every food more savory.”

Why then make the effort to reduce salt in foods? The oftrepeated statistic is that average sodium consumption in the United States remains at about 3,400 mg per day, far above the U.S. Dept. of Health and Human Services recommendation for adults to consume no more than 2,300 mg of sodium (about a teaspoon of salt) per day and for subgroups, including African Americans and persons with hypertension or chronic kidney disease, to consume no more than 1,500 mg (a quarter of a teaspoon of salt) per day. These guidelines are largely based on the indication that as sodium intake decreases, so will blood pressure, and, thereby, so will the risk of cardiovascular disease and stroke. However, the recommendations have come under scrutiny in light of a 2013 Institute of Medicine (IOM) report acknowledging that there is little if any evidence of benefit for intakes below 2,300 mg of sodium per day for the general population. At the root of the debate are data showing that sodium intake below 2,300 mg might actually harm, rather than help, potentially because of compensatory mechanisms the body produces hormonally to maintain proper sodium-water balance. The IOM report has led some scientists to argue that any recommendation below average consumption levels—at 3,400 mg—is premature without additional evidence, and that efforts to lower blood pressure should include other components such as decreasing total caloric intake and increasing dietary potassium (found mainly in fruits and vegetables). Others argue that average sodium intake is still higher than it should be and that population-wide sodium reduction should continue as a health priority.

Notwithstanding ongoing discussions over ideal sodium guidelines and conflicting data, several government, public health, and professional organizations have made it their objective to implement strategies to reduce sodium intake. The World Health Organization (WHO) goal is to reduce sodium intake to less than 2,000 mg by 2025. The U.S. Centers for Disease Control and Prevention (CDC) has also made sodium reduction a “key component” of its initiatives to control blood pressure and improve cardiovascular health. Moreover, the American Heart Association, the New York City Dept. of Health, the American Heart Association, and the American Society of Hypertension each have their own dietary sodium reduction initiatives. Most recently, Hypertension Canada announced that it is raising sodium recommendations to 2,000 mg/day. Previously the organization recommended 1,500 mg per day for those ages 14 to 50, 1,300 mg/day for those ages 51 to 70, and 1,200 mg/day for those ages 70 and older. The new recommendations, in line with those of the WHO, became effective this month.

The IOM’s recommendation as a primary strategy by which to reduce population-wide dietary sodium is to mandate national standards for sodium content in foods and, as an interim strategy, to encourage food manufacturers and restaurant and foodservice operators to voluntarily reduce sodium in processed foods. According to the CDC, Americans consume 77% of dietary sodium from processed foods, prepackaged foods, and restaurant foods, while 6% is added during home cooking, 5% is added at the dinner table, and 12% is naturally occurring in the food itself. As reported previously in Food Technology magazine, food manufacturers have responded to calls for reduced sodium intake by launching a number of no-sodium (less than 5 mg), very low–sodium (less than 35 mg), low-sodium (less than 140 mg), and reduced-sodium (25% less than the regular version) products across several food categories. According to Mintel’s Global New Products Database, there was an almost 115% increase in the number of products with low-, no-, and reduced-sodium claims from 2005 to 2008. Although, from 2010 to 2011, the number of products launched with these claims decreased 5%, with only 2% of products making the claims in 2011, probably due to poor sales and sodium-reduction challenges or perhaps because food manufacturers are opting for a “stealth health approach” to sodium reduction.

Stealthy Sodium Reduction

Stealthy Sodium Reduction

Companies are finding a stealth health approach ideal because customers often perceive low-, no-, and reduced-sodium claims as a sacrifice to flavor. A survey conducted by the International Food Information Council (IFIC), for example, found that only 13% of consumers say they would choose a product with a “low-sodium” claim as compared to other front-of-pack claims or no claims. As David Freedman reports in the July/August issue of The Atlantic in an article titled “How Junk Food Can End Obesity,” companies including McDonald’s have had to learn hard lessons from past product launch failures (such as McLean Deluxe), finding that consumers can be turned off by “healthy” marketing claims. Now McDonald’s and other companies, reports Freedman, have opted to make their offerings healthier—with reductions to sodium, as well as fat and sugar—more quietly so as not to alarm consumers. Last October, speaking at the Academy of Nutrition & Dietetics’ Food & Nutrition Conference & Expo (FNCE) in Houston, Unilever Senior Nutrition Manager Barbara Ledermann said, “Explicitly claiming x% less salt is not motivating for consumers.” She advocated a stealthy reduction over time, allowing customers to adjust to lower sodium levels in foods.

--- PAGE BREAK ---

Consumer preferences for products that are high in salt are acquired over time, often since childhood, so a gradual approach to sodium reduction is critical for altering taste likings. Nestlé, Vevey, Switzerland (www.nestle.com), is an example of a company that has successfully put a gradual approach into action, slowly reducing sodium, and allowing consumers to adapt their tastes for salt since 2005. By 2012, Nestlé reports, their products contained 14,043 fewer tons of salt. Nestlé has now announced a pledge to accelerate reduction of sodium across its brands globally. Through investment in new sodium reduction technologies, the company has committed to reducing sodium in hundreds of its high-sodium products by 10% in the next three years. These include frozen meals and pizzas, soups, noodles, and recipe mixes, offered through brands such as Stouffer’s, Maggi, DiGiorno, and Buitoni.

Taking notice of these sodium reduction trends are the largest producers of salt, who are now offering clients a combination of technical expertise and product solutions for sodium reduction in foods. According to Jackie Van Norden, Product Line Manager for Cargill, Minneapolis, Minn. (www.cargill.com), “We continue to see food processors taking a stepped approach to sodium reduction in food products. The vast majority of such changes are done in stealth with no packaging claims or announcements to indicate that the food product has been reduced in sodium.” She adds that these gradual approaches to sodium reduction are often not met by one strategy alone, but with a variety depending on the product. Fortunately, over the last four decades, food technologists have found various ways to reduce sodium content in foods. “One thing that we have learned in our 40 years of experience in sodium reduction is that there is no ‘one-size-fits-all’ solution,” says Linda Kragt, Director of Technical Services, Morton Salt Inc., Chicago, Ill. (www.mortonsalt.com). She adds that the majority of step-wise approaches used by food technologists start with focusing first and foremost on making the most of salt’s flavor in products. “We know that consumers are interested in health and wellness offerings, but are not interested in sacrificing on taste,” she says.

Focus on Salt First

The first step to reducing salt in food products begins with maximizing how salt in the product interacts with the tongue. An example is in snack foods, such as pretzels or tortilla chips, where tongue interaction occurs mainly on the surface of the product. That leaves opportunity for using different crystal sizes and shapes as found in varieties of Kosher salts, sea salts, and specialty salts to increase the boldness of salt’s flavor. “This may seem counterintuitive since specialty salts are still pure sodium chloride,” Van Norden says. “However, using a different salt product may provide you with the desired flavor characteristics while allowing you to actually use less salt.” Cargill offers a line of specialty salts, such as Alberger Brand Flake Salts for help in sodium reduction. Alberger Brand Flake Salts crystal sizes have large surface areas to offer a burst of flavor when used topically on applications such as crackers, breadsticks, baked goods, in cheeses, and in seasoning blends. They also have a low bulk density for better solubility, blend-ability, and adherence when compared to cube-based salt for applications such as prepared soup or sauce mixes.

Morton Salt also offers a number of different salts with varying particle sizes and textures specific for certain processes or to maximize salt’s taste in food applications. At the 2013 IFT Annual Meeting and Food Expo in Chicago, the company presented prototypes including triple-salted caramel brownies; in that formulation, Refined Sea Salt was used in the caramel, Star Flake Dendritic Salt was used in the batter, and Top Flake Coarse Salt was sprinkled as a topping to offer different functionality and taste sensations. For example, Morton Star Flake Dendritic Salt dissolves more rapidly than common granulated salt while the Top Flake Coarse Salt provided a lingering sensation of saltiness on the tongue. In another caramel brownie application by Morton, Coarse Sea Salt was used as a salt topping for a slower, more lingering saltiness and visual appeal.

Morton Salt also offers a number of different salts with varying particle sizes and textures specific for certain processes or to maximize salt’s taste in food applications. At the 2013 IFT Annual Meeting and Food Expo in Chicago, the company presented prototypes including triple-salted caramel brownies; in that formulation, Refined Sea Salt was used in the caramel, Star Flake Dendritic Salt was used in the batter, and Top Flake Coarse Salt was sprinkled as a topping to offer different functionality and taste sensations. For example, Morton Star Flake Dendritic Salt dissolves more rapidly than common granulated salt while the Top Flake Coarse Salt provided a lingering sensation of saltiness on the tongue. In another caramel brownie application by Morton, Coarse Sea Salt was used as a salt topping for a slower, more lingering saltiness and visual appeal.

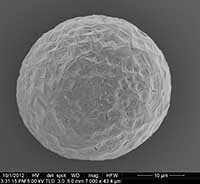

In other applications where salt is best distributed throughout a food matrix, another option is to go with smaller, lower-density crystals. According to Nancy Gaul, Senior Manager, Health and Wellness, Tate & Lyle, Hoffman Estates, Ill. (www.tateandlyle.com), has taken small to a new level by turning standard salt crystals into free-flowing, hollow salt microspheres. The microspheres are produced using patented spraydrying technology and facilitated by gum acacia hydrocolloid as a processing aid. While typical salt crystals range from 40 to 800 microns and are solid, SODA-LO Salt Microspheres are consistently smaller at 20 to 200 microns depending on their grade, Fine or Extra Fine. They are also hollow to maximize surface area relative to volume, Gaul says, allowing them to dissolve more rapidly, contributing to a salty taste more quickly upon impact on the tongue. Notably, one study by Spanish researchers using National Health and Nutrition Examination Survey (NHANES) 2007–2010 data demonstrated that potential use of SODA-LO Salt Microspheres in 953 commonly eaten foods could reduce sodium intake by approximately 9%. The modeled reductions were used to estimate that 5% to 9% more Americans would be expected to meet sodium guidelines.

In other applications where salt is best distributed throughout a food matrix, another option is to go with smaller, lower-density crystals. According to Nancy Gaul, Senior Manager, Health and Wellness, Tate & Lyle, Hoffman Estates, Ill. (www.tateandlyle.com), has taken small to a new level by turning standard salt crystals into free-flowing, hollow salt microspheres. The microspheres are produced using patented spraydrying technology and facilitated by gum acacia hydrocolloid as a processing aid. While typical salt crystals range from 40 to 800 microns and are solid, SODA-LO Salt Microspheres are consistently smaller at 20 to 200 microns depending on their grade, Fine or Extra Fine. They are also hollow to maximize surface area relative to volume, Gaul says, allowing them to dissolve more rapidly, contributing to a salty taste more quickly upon impact on the tongue. Notably, one study by Spanish researchers using National Health and Nutrition Examination Survey (NHANES) 2007–2010 data demonstrated that potential use of SODA-LO Salt Microspheres in 953 commonly eaten foods could reduce sodium intake by approximately 9%. The modeled reductions were used to estimate that 5% to 9% more Americans would be expected to meet sodium guidelines.

Substitute with Potassium

Once having made the most of salt’s impact on the tongue in an application, the practical approach is to replace extra salt with potassium chloride or combinatorial mineral salt substitutes. Because dietary potassium intake itself has been shown to improve blood pressure, it is an ideal substitute for counteracting the effects of sodium. According to Kragt, Morton has for decades offered products such as KaliSel Potassium Chloride and Morton Lite Mixture, containing a blend of 50% salt and 50% potassium chloride. These can be used across several categories of products including processed meats and poultry, bakery goods, snacks, sauces, and dressings. In 2012, the company also launched KaliSel Fine Potassium Chloride to give food processors a smaller particle size option for use in seasonings, snacks, and topical applications. To highlight the new ingredient, Morton presented prototypes of tortilla chips and chipotle kettle corn at the 2013 IFT Food Expo, each using a combination of its Star Flake Dendritic Salt and KaliSel Fine Potassium Chloride. Cargill Salt also offers a number of ingredients that include potassium chloride such as Premier potassium chloride or a combination of potassium chloride with salt or sea salt. For example, the company offers 12 FlakeSelect varieties that come in different screen cuts including flour, fine, coarse, and extra course. These can also be used within one of the company’s SaltWise sodium reduction systems that combine salt, potassium chloride, and other components to mitigate off notes that are associated with using potassium chloride. Van Norden says, “What really differentiates Cargill from other companies is our technical expertise.” She adds that the company has a food applications team that focuses solely on salt, but also other research teams focus on the role of salt in the food. The goal is to replace salt for targets up to a 50% reduction without sacrificing flavor, texture, or shelf life of a finished product.

--- PAGE BREAK ---

However, potassium chloride can bring potential problems of offnotes. The main issues associated with use of potassium chloride are a metallic aftertaste and a different mouthfeel, according to Mariano Gascon, Vice President Research and Development at Wixon, St. Francis, Wis. (www.wixon.com). The solution, he says, is a potassium chloride blended with added flavor compounds that enhance saltiness and mask the metallic perception. Wixon’s KClean Salt works well in oily emulsions such as salad dressings and mayonnaise and can reduce sodium by up to 50%. He says it can also be used in snacks and topical applications. “Usually you can perceive the potassium chloride right away in these applications, but not with KClean salt,” he says. The company also offers a line of several products to assist with sodium reduction in meat products: Wix-Fresh Max enhances meat’s natural flavor while extending shelf life; Wix-Fresh Mimic is a product that helps mask off notes associated with both potassium chloride and listeria growth inhibitors; and Wix-Fresh Max Mimic is a combination of the two products. In addition, Wix-Fresh Umami combines potassium chloride, savory notes, and spices to enhance overall savory flavor, increase salt perception, and mask off-flavors; and Wix-Fresh RSS (Reduced Sodium System) is an all-in-one solution that is shown to reduce sodium by up to 50% in a variety of meat and poultry applications without compromising flavor.

When lowering salt in meat products, the first noticeable change is weakened flavor followed by possible microbiological instability, according to Ivo van der Linden, Category Manager Food Preservation, Corbion Purac, Dusseldorf, Germany (www.purac.com). Corbion Purac offers two product lines to enable reduced-sodium products while maintaining stability, he says: PURASAL® HiPure P Plus potassium lactate is created with a patented process to provide a clean flavor and help control water activity in meat applications for extended shelf life; PuraQ ® Aroma NA4 is a natural flavor aimed to offset loss of overall savory flavor applications in meat and poultry. Together, these products can help reduce sodium by up to 40% without sacrificing quality.

When lowering salt in meat products, the first noticeable change is weakened flavor followed by possible microbiological instability, according to Ivo van der Linden, Category Manager Food Preservation, Corbion Purac, Dusseldorf, Germany (www.purac.com). Corbion Purac offers two product lines to enable reduced-sodium products while maintaining stability, he says: PURASAL® HiPure P Plus potassium lactate is created with a patented process to provide a clean flavor and help control water activity in meat applications for extended shelf life; PuraQ ® Aroma NA4 is a natural flavor aimed to offset loss of overall savory flavor applications in meat and poultry. Together, these products can help reduce sodium by up to 40% without sacrificing quality.

A patented, single-crystal processing technology from Nu-Tek Food Science, Minnetonka, Minn. (www.nu-tekfoodscience.com), is used for the development of Nu-Tek Salt Advanced Formula Potassium Chloride. According to Don Mower, Nu-Tek’s President and COO, the technology is “paradigm changing for sodium reduction because the final product delivers on taste and functionality of traditional salt at a cost of less than 1/8 cent per serving.” Mower also says the product can reduce sodium levels in a variety of foods by up to 50% while maintaining flavor. The product is suitable for applications including processed meat and poultry products, cheese and dairy products, baked goods and snacks, as well as prepared meals and entrees in restaurant chains.

Another company that has long offered a line of potassium-based salt replacement blends under the brand sub4salt ® is Jungbunzlauer Basel, Switzerland (www.jungbunzlauer.com). In February 2013, the company announced the launch of sub4salt ® cure that combines sub-4salt with sodium nitrite for use in low-sodium meat products. Trials comparing sub4salt against standard curing salt show no difference in performance.

The product is a stable one-to-one substitute for nitrite curing salt that can allow for up to 35% sodium reduction without affecting flavor, texture, or microbiological stability of a finished product.

Bring on Savory

After using a variety of approaches to reduce the quantity of salt in a product, principally potassium chloride, the next step is to work on savory notes to enhance salt’s flavor. When looking for savory note ingredients, an obvious choice is monosodium glutamate (MSG) and other glutamate-containing ingredients developed by Ajinomoto, Eddyville, Iowa (www.ajiusafood.com). Ajinomoto MSG works to provide the purest taste of umami in snacks, soups, and gravies; and the Ajitide ™ line of nucleotides such as disodium 5’ inosinate and disodium 5’ guanylate are used to work in greater synergy with taste characteristics of foods using glutamates and other flavor-enhancing nucleotides. The company also offers a line of savory systems for a variety of applications such as Aji-Aroma HS to help deliver finish flavors in savory soups or meat and poultry products like beef and sausage; Super UM is a glutamate-rich yeast extract for seasoned snacks, soups, meat and poultry, and seafood; and most recently, Savor-Rich Chicken Seasoning for replacing chicken stock for soups, entrees, and sauces.

When creating applications where a “clean label” is preferred, flavor expert Anne Perreault, Technical Director at Metarom NeoTech, St-Hubert, Quebec (www.metaromneotech.com), accomplishes the task with the addition of glutamate-rich yeast and mushroom extracts, followed by notes of onion and garlic, as well as spices to give the product some heat. Perreault says the objective is “to provide a more complex flavor profile and, therefore, to fool the mouth.”

Perreault recommends yeast extract products from DSM Food Specialties, Parsippany, N.J. (www.dsm.com), for the job of delivering sophisticated natural savory flavors. These include Multirome LS, which helps to reduce sodium without compromising flavor, and Maxavor YE All Natural Range, which is said to give a more authentic flavor in comparison to conventional process flavors while being cost-effective. The products can reduce sodium in a wide range of products by up to 50%. Another ingredient, Maxagusto ™ natural flavors offer taste and aroma in a concentration up to four times greater in comparison to alternatives offering cost-savings. Perreault also suggests Nikken Foods USA, St. Louis, Mo. (www.nikkenfoodsusa.com), for its broad portfolio of mushroom extracts that include Champignon Mushroom Extract Powder, Shiitake Mushroom Extract Powder, and Mushroom Bouillon Powder. The company also offers several natural flavor-enhancing powders, onion and garlic flavor powders, and reduced-sodium soy sauce powders.

Bio Springer, Maisons-Alfort, France (www.biospringer.com), specializes in creating clean-label yeast extracts including dried yeasts, autolyzed yeasts, and flavors for assisting sodium reduction in poultry, roasted meat, and cheese. Plus, Scelta Mushrooms, Venlo, The Netherlands (www.sceltamushrooms.com), has also recently introduced a mushroom concentrate containing vitamins and minerals designed to replace MSG and salt in foods for use in soups, sauces, and meats. By adding as little as 0.06% of the concentrate, the product is said to reduce up to 50% of sodium in some applications.

At the 2013 IFT Food Expo, Sensient Flavors, Milwaukee, Wis. (www.sensient.com), presented soup prototypes that featured Sensasalt, a line of custom-formulated flavor enhancers and salt replacers for specific savory applications. According to the company, a proprietary enzymatic technology helps replace salt while masking the off-notes of potassium chloride. The Sensasalt product line includes application-specific formulas that address sodium reduction in several processed foods without sacrificing flavor in an economically viable way. Sensasalt Vegetable, for example, can be used to reduce sodium in marinara sauce by up to 40% while maintaining salty flavor and fresh tomato taste. In addition, Sensasalt Beef helps with meat toppings, and Sensasalt Bakery can help in pizza dough and baked goods.

--- PAGE BREAK ---

For applications where non-GMO ingredients are preferred, look to Savory Systems International (SSI), Branchburg, N.J. (www.savourysystems.com). The company offers a line of corn, soy, and wheat non- GMO hydrolyzed vegetable protein (HVP) products to assist formulators with avoiding GMOs in product formulations such as soy sauce, as well as corn-, beef-, and chicken-flavored applications. At the 2013 IFT Food Expo, SSI also introduced a couple of new products including Tomato Salt Replacer and a Non-GMO Light Corn HVP to its current line of products that include umami-flavored yeast extracts. SSI’s Tomato Salt Replacer is based on yeast extract and has a demonstrated ability to reduce sodium by one-third in food applications such as tomato basil sauce or tomato soups. The product enhances savory flavor while potentiating qualities of tomato. SSI’s Non-GMO Light Corn HVP is a general savory flavoring derived from GMO-free corn that is suitable for meat and poultry applications.

Color It for Kids

Color It for Kids

Like other companies, Salt of the Earth, Atlit, Israel (www.salt.co.il), has long been involved in developing all-natural solutions to stay with current trends of sodium reduction while meeting client demands for clean labels. However, the company has recently gotten creative in helping lower sodium intake in children with new WonderSalt, a line of low-sodium sea salts enriched with vegetables and fruits (such as radish, carrot, apple, and lemon). The sea salts come in four vivid colors including yellow, red, orange, and green. According to Marketing Director Inbal Trop Kirsch, “Salt is invisible when added to foods. By coloring WonderSalt with fruit and vegetable essences, it is possible not only to help kids and adults eat low-sodium foods, as a bonus, they can see how much salt to put on their food.”

Give It Some Heat

Nothing enhances flavor like a little heat. It’s a fact that is well understood by Jud McLester, Corporate Executive Chef and Ingredient Sales Manager, Tabasco Brand Products, of McIlhenny, Avery Island, La. (www.tabasco.com). “At Tabasco, we consider ourselves a flavor company, to be used as an ingredient to make foods taste better,” McLester says. “When you remove sodium or fat, there is some flavor being removed. Since Tabasco has umami-like properties, you can remove any extra sodium because adding Tabasco will elevate the flavors of any dish as a whole without increasing the sodium content.” Indeed, Tabasco Original Red contains only 35 mg of sodium per each 1 teaspoon serving, which is currently the lowest on the market for hot sauces, according to McLester. The only time any salt is added to the product is simply for preservation purposes when peppers are ground. He says, “We rely on the aging process to really develop the flavor that we all know and love. The peppers are mashed the same day they are picked and placed in white oak barrels to age for up to three years. The fully aged mash is then cleaned, drained, and mixed with high quality, distilled, vinegar for up to 28 days. This time-honored method assures the unique flavor of Tabasco Sauce and eliminates the need to add sodium for flavor.”

Sauce It Up

Asked about the role of salt and how to reduce overall salt in prepared dishes, Chef Michael Hodgins, Director of Sustainable Food Systems at Rio Salado College, Tempe, Ariz., who operates the college’s onsite café, Café @ Rio, says, “Salt can take a dish from tasting ‘flat’ to exuding flavor, which is why it is so widely used and why chefs are trained to salt most, if not all, dishes. In our Sustainable Food Systems program, we teach students in our culinary classes to salt items such as soups, sauces, and salad dressings at the end of the cooking process. If a salad dressing has soy sauce in it, it may not need any extra salt.”

Soy sauce, in fact, is used in quite a number of applications including sauces, soups, dressings, beef sandwiches, frozen foods, nut mixes, and even tortilla chips or Asian-style tacos. With soy sauce, food producers often don’t need to add any more salt. For these reasons, Magda Dziembowski, Industrial Marketing Specialist at Kikkoman Sales USA Inc., San Francisco, Calif. (www.kikkomanusa.com), says soy sauce can be expected to play a major role in helping to reduce sodium in a variety of food products. “Kikkoman is already solving this issue for a multitude of food manufacturers,” Dziembowski said. “If you want a delicious soy sauce taste, we have products for that, but if you want the umami effect and a clean label but without the soy sauce taste, we have you covered there, too.” Kikkoman offers a variety of solutions for less sodium including Premium Total Nitrogen Less Sodium Soy Sauce (PTN-LS), which has 45% less sodium than our regular soy sauce, and Natural Flavor Enhancer (NFE), which boosts flavor (but adds no soy sauce flavor), to reduce sodium by up to 50% in several applications. The powdered NFE is already used in tortillas, pizza dough, and other baking applications. Kikkoman Preservative-Free Soy Sauce is used on tortilla chips to add flavor in place of salt. In addition, Dziembowski says, there are numerous other applications where Kikkoman products can help. Moreover, Dziembowski says, Kikkoman sauces have few, easily identifiable ingredients, allowing food manufacturers to keep labels clean.

Smoke It Up

A company with a mission to help food producers bring out the most of salt’s natural flavor is SaltWorks (www.seasalt.com), Woodinville, Wash. President and co-founder Naomi Novotny says that the company’s eight different grain sizes can help food producers round out flavor and texture allowing for reduction in total salt used in a variety of applications. The company also offers an entire line of Kosher-certified gourmet smoked sea salts. The smoked flavor offers an all-natural way to flavor salt, Novotny says. The gourmet smoked salts, which are produced one batch at a time using wood smoke from bark-free logs, go by brand names including Salish® Alderwood, Bonfire® Extra-bold Wood Blend, Yakima® Applewood, El Dorado® Mesquite, Wildfire® Pecan Wood, and Hellfire® Mesquite Wood Smoked Salt and Habanero Blend.

Got Milk Permeate?

Dairy product solids, or milk-derived permeates, are also showing promise as salt enhancers in foods. The sensory properties that give permeate its salty taste are not yet known, and it is currently under investigation at the Southeast Dairy Foods Research Center at North Carolina State University. However, milk permeate powder is already being offered for sodium reduction by companies including Idaho Milk Products, Jerome, Idaho (http://idahomilkproducts.com). IdaPro Milk Permeate Powder is made using by-products of the cheese-making process. In bakery products, it can be used as a one-to-one replacement for sweet whey powder and to assist in sodium reduction of cookies, caramels, and cakes.

One-Stop Shop

Recently unveiled by global distributor of food ingredients Univar, Redmond, Wash. (www.univar.com), is a new interactive online formulation tool for product enhancement, including sodium reduction. The searchable database features dozens of ingredients from well-known suppliers. Charles Purcell, Technical Development Specialist for Food at Univar, said the tool was developed to be a “one-stop shop” to help food manufacturers find new ingredients. An example, he says, is Salona developed by ICL Performance Products, Lawrence, Kan. (www.icl-pp.com), a low-sodium sea salt derived from waters of the Dead Sea. Univar recently used Salona to replace salt by nearly 50%, Purcell says, in Sweet Cinnsation Cookies, which were showcased with CP Kelco, Atlanta, Ga. (www.cpkelco.com), at the 2013 IFT Annual Meeting and Food Expo to demonstrate the latest in healthier indulgent treats.

--- PAGE BREAK ---

No Single Sodium Reduction Strategy

Strategies to reduce sodium in a given product clearly vary depending upon salt’s functionality in the product. Roger Clemens, IFT President 2011–2012, summarized the various roles that sodium has in food products in a letter to the USDA and FDA dated January 14, 2012. For example, he pointed out that salt is not only used to impart its own flavor and enhance or mask other flavors, but also for controlling water activity and growth and metabolic activity of microorganisms. So any reformulation often requires extensive pathogen testing. Salt is also necessary to control the growth of yeast or starter culture in products such as cheese and cabbage and to promote the development of gluten structure in bread. In meat products, salt supports several functions including water holding, protein-gelation, and fat-emulsification capacities. In ice cream, dough, and pastries, salt also minimizes ice crystal formation. In baked goods, sodium also is used in the form of sodium bicarbonate, or baking soda, for the creation of carbon dioxide bubbles that help with the expansion of dough and batter. Given salt’s multi-faceted functionality, it should be no surprise that more research and innovation is necessary to overcome challenges. Salt is truly worth its salt.

The age-old English fairy tale, “Cap o’ Rushes,” charmingly illustrates salt’s value in food and why it should be more appreciated: The story goes that a rich gentleman asked each of his three daughters how much they loved him. The first daughter replied, “as much as my life,” the second, “as much as the world,” and the third, “as much as fresh meat loves salt.” Enraged by the last answer, the rich gentleman drove his third daughter out. She was left homeless, forced to gather rushes with which to clothe herself, and became a servant who was called Cap o’ Rushes. Reminiscent of Cinderella, the story continues with Cap o’ Rushes attending a ball in disguise, wherein her master’s son falls in love with her; then, once discovered and her true identity revealed, she is to be married. But before her wedding, she tells the cook to “dress every dish without o’ mite of salt.” On her wedding day, the guests found each dish served revolting. Finally, one guest burst into tears; it was the bride’s father, who explained that he’d once had a daughter who said she loved him “as much as fresh meat loves salt,” and that he turned her away and feared she may be dead. “No, father, here she is,” said Cap o’ Rushes. Then she put her arms around him, and all the salt-seeking creatures lived happily ever after.

Next month’s Ingredients section will focus on the use of yogurt as an ingredient.

www.ift.org

Members Only: Read more about sodium reduction online at www.ift.org. Type the keywords into our search box at the upper right side of our home page.

David Despain,

a member of IFT, is a freelance writer and nutritionist based in Gilbert, Ariz. ([email protected]).