Signaling Food Spoilage

PACKAGING

Axiomatic in the education of every food scientist and food technologist is that food loses quality over time and that packaging’s role is to help delay that change. At a minimum, food spoilage can lead to waste; at its worst, it can cause illness or death. Thus, the food profession’s main objectives are food preservation and maintenance of food safety. As well as food professionals are achieving these goals, and for this they should be proud, the methods to achieve these goals are not perfect and will never be perfect. But the food industry keeps trying, and to this end, a new era has emerged: not just obviating spoilage but identifying it accurately.

Sensory observation, wet chemistry, and microbiology have been major selection processes to date, but each has its time and precision limitations. When the health of consumers is the crucial variable, timeliness and accuracy are indispensable. Of course, the concern with food waste is a corollary not only for economic reasons but also for nourishing an ever-expanding population. The ability to anticipate and signal food spoilage is significant to deliver safe food in regions suffering from food shortages.

Anticipatory Information

Many years of development have been invested in intelligent packages that are surrogates for direct measurement of microbiological and biochemical food safety. Time-temperature integrators (TTI) have been widely used since at least the 1960s but infrequently applied due to cost, accuracy, and inability to interpret. Do time and temperature on a package surface truly reflect the quality status of the contents? TTIs cannot provide microbiological status, but colorimetric changes on TTI labels will continue to be seen as indicators until the sophistication of deep probes of temperature history from food processing through distribution is commercialized.

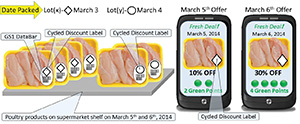

Allies to TTIs are the European computer chips embedded in food packaging that predicts the expiration moment of the contents. Offered in Europe as a substitute for printed expiration dates to combat food waste, these devices are claimed to be capable of transmitting messages to mobile phones to alert consumers that a food is approaching the end of safe consumption time. Because these chips are cost prohibitive, they could be supplanted by GS1 DataBar™ technology, which is an extension of the ubiquitous universal product code and is useful because of the greatly increased quantity of data that can be stored and transmitted. By anticipating the end of a product’s shelf life, these GS1 DataBar symbols can automatically spur action by prompting distribution channel members to move vulnerable products to the front for immediate sale or consumption. These codes are part of the End Grocery Waste (www.endgrocerywaste.com) program, and although its primary objective is economic, the information is also applicable to signaling impending spoilage.

Allies to TTIs are the European computer chips embedded in food packaging that predicts the expiration moment of the contents. Offered in Europe as a substitute for printed expiration dates to combat food waste, these devices are claimed to be capable of transmitting messages to mobile phones to alert consumers that a food is approaching the end of safe consumption time. Because these chips are cost prohibitive, they could be supplanted by GS1 DataBar™ technology, which is an extension of the ubiquitous universal product code and is useful because of the greatly increased quantity of data that can be stored and transmitted. By anticipating the end of a product’s shelf life, these GS1 DataBar symbols can automatically spur action by prompting distribution channel members to move vulnerable products to the front for immediate sale or consumption. These codes are part of the End Grocery Waste (www.endgrocerywaste.com) program, and although its primary objective is economic, the information is also applicable to signaling impending spoilage.

Volatile Organic Spoilage Compound Detectors

The applied physics lab at Johns Hopkins University has developed molecularly imprinted polymers engineered to selectively detect specific compounds. Polymers are constructed with ligands to contain cavities closely matching the shapes of the target molecules, which are incorporated into and bond with a pre-polymer mix. The mix is polymerized with the target molecules in place. After polymerization, the target molecules are removed, leaving cavities shaped like the target molecules. The lab has developed polymeric sensors with selective binding affinity for biogenic amines (protein spoilage end products) capable of changing color upon exposure to end products such as cadaverine or histamine.

The Center for Advanced Sensor Technology at the University of Maryland at Baltimore published research describing a prototype package sensor that detects spoilage in seafood via amine (i.e., scrombrotoxin histamine) detection. This fresh indicator is based on non-enzymatic amine modification/detection chemistry. The device is described as a thin circular wafer affixed to the seafood before packaging. In the presence of amines, a stable dye disperses to the surface. The color is correlated to sensory change due to spoilage. Although originally designed for seafood deterioration, the technology is reportedly applicable to other foods.

A team from Rice University and Massachusetts Institute of Technology reportedly produced in-mold labels made from photonic cells that change color in the presence of food spoilage compounds. Polymers are combined in a singular self-assembled meta-material that changes color according to its ability to detect hydrophilic molecules (i.e. amines). The material’s thickness is measured in microns, is capable of covering large areas of a package structure, and is fabricated from nanoscale layers of hydrophobic polystyrene and hydrophilic polyvinyl pyridine in pancake-stack format.

--- PAGE BREAK ---

Tufts University has developed an edible device with embedded gold antennae in a film fabricated from a purified silk substrate sensitive to food spoilage compounds. The sensors detect the changes in the substrate and generate an electromagnetic signal capable of being read by a smartphone. The structure of the sensors is silk and is edible, and the amount of gold is about the same as gold leaf in confectionery.

A relatively new technology called quorum sensing is said to be capable of reacting to biochemical activity of colonies of growing microorganisms. Quorum sensing involves mass quantities of microorganisms that communicate with each other biochemically in much the same manner as flocks of birds or schools of fish. Instead of responding to recent past actions by indigent microbial populations, as do most spoilage detectors, quorum sensing appears to be capable of anticipating further biochemical activity by microorganisms and thus enables operators to take action to obviate the spoilage reactions. This technology would deal with spoilages due to microbiological growth.

A collaboration of Belgium’s Ghent and Radboud Universities called IWT is developing CheckPack to detect and identify volatile compounds released by contained food during deterioration. The volatiles interact with sensitive package coatings to alter the refractive index and are sensed by infrared devices. The reflected radiation is said to be capable of qualifying and quantifying the identity and concentration of the volatiles. As with most of these spoilage detectors, the initial targets are meat and seafood.

Digitized Noses Know

Wageningen University is developing a built-in nose to detect spoilage compounds in seafood and transmit the information. The volatile compounds are dissolved in water in the sensor, which measures pH, acidity, conductivity, and amines. The objective now is to develop a chip that can be incorporated into the package structure to be read by an RFID device and transmitted to a smartphone. And John Lavigne of the University of South Carolina is investigating polymeric sensors that respond to biogenic amines. The technology was reported as capable of identifying 22 different spoilage amines with 97% accuracy.

From Stanford University comes a sensor that applies sequences of oligodeoxyfluoriside fluorophores attached to DNA backbone whose fluorescent responses upon ultraviolet excitation signals in the presence of volatiles (amines, sulfur compounds, etc.) emitted by spoilage microorganisms. Such compounds can be printed on package surfaces to function as visual signalers or be read by smartphones.

Another application of electronic nose technology from the United Kingdom has appeared in the form of a portable device by Peres (www.getperes.com) that analyzes airborne data to determine the freshness of animal protein and transmits a signal through a smartphone app. According to releases, Peres uses four detectors—temperature, humidity, ammonia, and volatile organic compounds—to measure the volatile organic compounds produced by protein degradation in decomposing poultry, pork, and seafood.

Another application of electronic nose technology from the United Kingdom has appeared in the form of a portable device by Peres (www.getperes.com) that analyzes airborne data to determine the freshness of animal protein and transmits a signal through a smartphone app. According to releases, Peres uses four detectors—temperature, humidity, ammonia, and volatile organic compounds—to measure the volatile organic compounds produced by protein degradation in decomposing poultry, pork, and seafood.

What Will the Future Hold?

One commonality among these devices is the sensing of volatile organic compounds, which are generally odorous and derived from protein breakdown. Humans use odor detection to avoid ingestion of toxins or microbiological infections. Is there anything that detects non-odorous spoilage coming from non-protein decomposition by microbiological growths? Some Clostridium botulinum types produce spoilage and toxins absent of odors. Small quantities of E. coli O157:H7 can be toxic but too few microbiological cells and volatiles would be present to be detected. Different sensing technologies must be applied to ensure that spoilages from such invisible sources can be detected.

It is relatively easy to enumerate the many technologies that are offered for spoilage sensing and even to evaluate for commercial applicability. Accuracy of these devices is highly important as society cannot afford many false positives or, more critically, false negatives. The fact that many entrepreneurs and small organizations are attempting to commercialize remote food safety intelligent packaging should be encouraging: the science is not ensconced in university laboratories to be used for publications. But the paucity of actual commercial successes should give pause. What are the obstacles that must be removed to produce a commercial breakthrough?

Aaron L. Brody, Ph.D., CFS, Contributing Editor

Aaron L. Brody, Ph.D., CFS, Contributing Editor

President and CEO, Packaging/Brody Inc., Duluth, Ga.,

and Adjunct Professor, University of Georgia

[email protected]