Viewing Salt with a Grain of Salt

FOOD SAFETY & QUALITY

The phrase “take it with a grain of salt” means to look at something skeptically. Accordingly, suppliers of salt and food companies using salt as an ingredient take a close look at the salt they produce or use, essentially looking skeptically at the salt until it is proven to have the quality intended or desired.

The phrase “take it with a grain of salt” means to look at something skeptically. Accordingly, suppliers of salt and food companies using salt as an ingredient take a close look at the salt they produce or use, essentially looking skeptically at the salt until it is proven to have the quality intended or desired.

Salt is an important ingredient in many foods, serving as not only a flavor enhancer but also a preservative and functional ingredient. It is generally cubic in structure but can be modified into additional shapes with different characteristics useful for specific food applications.

The two primary sources of salt are seawater and underground salt deposits. Salt from seawater is obtained through the effects of sun and wind (solar heating), and salt from salt deposits is obtained through rock salt mining, in which large chunks of salt are crushed and brought to the surface for subsequent processing into different crystal sizes by screening, or through solution mining, in which water is pumped into a salt deposit to dissolve the salt and the resulting brine is pumped to the surface for subsequent mechanical heating in open or closed (vacuum-pan) evaporators. Additives used in salt include anti-caking agents and nutritional compounds such as potassium iodide used to make iodized salt.

Morton Salt

Morton Salt Inc. (www.mortonsalt.com) began in 1848 when Alonzo Richmond created Richmond & Co., Agents for Onondaga Salt. Joy Morton acquired a major interest in the company in 1889 and renamed the company Joy Morton & Co. After several more acquisitions, the company was renamed the Morton Salt Co. in 1910. The company started adding an anti-caking agent to salt in 1911, creating a table salt that flowed freely, even in humid weather, and started using the iconic Umbrella Girl logo and slogan When It Rains It Pours® on the company’s table salt package and advertisements in 1914.

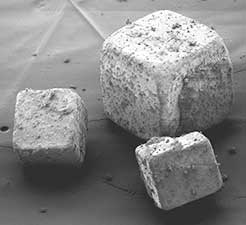

Today, the company produces more than 50 grades and mixtures of salt. Eric Shirk, Director of Quality, described three types of salt the company markets, based on production method. Rock salt is mechanically removed from an underground salt deposit by rock salt mining and ground and screened to various particle sizes. The resulting crystals are fractured cubes that have smooth surfaces and tend to be orthorhombic in shape (having 90º angles); these are the hardest of the salt particles. The only food-grade salt that Morton Salt produces by this process is Rock Pretzel Salt.

Solar salt uses brine from various sources, including seawater, saline lake water, and brine produced by dissolution of a salt deposit. The brine is evaporated in ponds using solar energy until the salt crystallizes. The crystals are then washed and screened to various particle sizes or compacted into larger particles, pellets, or blocks. Food-grade sea salt in fine, medium, and coarse versions is produced using this process. The crystals are hopper-shaped aggregates of cubes with the center filled in, resulting in relatively hard particles. Solar salt that has been ground consists of multi-shaped particles. Morton Salt’s sea salt is harvested directly from seawater off the coast of California and is marketed under the following product names: Refined Sea Salt, TFC Refined Sea Salt, and California Pure Sea Salt.

Vacuum-crystallized salt uses a saturated brine solution, acquired by either solution mining of a salt deposit or dissolution of salt from either a solar process or rock mine. The brine is treated before using it in the vacuum pan process to remove calcium and magnesium impurities that are usually present in small amounts from salt deposits, Shirk said. It is then concentrated in a series of steam-heated, multiple-effect vacuum pans until the salt crystallizes. The crystals are either used as they are, sorted by screening into various particle sizes, ground to fine particle sizes, or compacted into larger particles, pellets, bricks, and blocks. The resulting high-purity salt is used in both the food industry and the pharmaceutical industry. Food-grade consumer products made from vacuum-crystallized salt include table and cooking salts (iodized and plain) and kosher salt.

The most common salt for industrial use is generally called granulated salt and is made from saturated brine and produced without further treatment, Shirk said. This salt is relatively pure (at least 99.7%) and can be screened to produce two categories of salt in addition to the unscreened grade: table grade, marketed under the Morton® brand, and a very fine screened grade. All products in this category are cubic crystals that have a uniform particle size. Table grades include the salt used in most salt shakers and salt for the food processing market. The finest screen grade can be used for topical applications such as oil-roasted nuts and small crackers.

Granulated salt may also be compacted into larger particle sizes. Kosher salt is produced from the coarse grade of this product by compacting evaporated salt into thin flakes that adhere well to a food product. In addition, granulated salt can be ground and milled to produce very fine pulverized grades for use in microwave popcorn and butter where they can be carried by an oil or brine slurry into the food process. Coarse grades are also produced to meet other food processing requirements.

--- PAGE BREAK ---

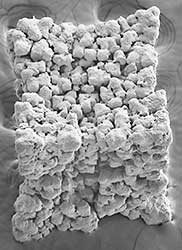

Morton Salt also produces a unique dendritic (star-shaped) crystal for the food industry called Star Flake®. The porous modified cubes have a lower bulk density and greater surface area than regular vacuum-pan salt and a slightly smaller average particle size. This salt is used in food applications such as snacks for which the extended surface area of the cubes increases adherence to surfaces. The product is also used in seasonings and baking mixes.

Morton Salt also produces a unique dendritic (star-shaped) crystal for the food industry called Star Flake®. The porous modified cubes have a lower bulk density and greater surface area than regular vacuum-pan salt and a slightly smaller average particle size. This salt is used in food applications such as snacks for which the extended surface area of the cubes increases adherence to surfaces. The product is also used in seasonings and baking mixes.

Shirk said that quality control tests are conducted to ensure that the company’s products meet the standards published by the U.S. Pharmacopeial Convention (USP) in its Food Chemicals Codex (FCC), a compendium of internationally recognized standards for purity and identity of food ingredients. Salt meeting USP standards exceeds the U.S. Food and Drug Administration’s good manufacturing practices. All salt products are tested for purity, and while purity levels vary by salt type, the purity of each process location tends to be fairly consistent. FCC specifications for sodium chloride include tests for sodium and chloride identity, sodium chloride assay, arsenic, and heavy metals. Like others in the salt industry, Morton Salt uses the American Society for Testing and Materials (ASTM) E534 method to analyze for the principal salt impurities and subtracts these values from 100 to determine the percent sodium chloride, Shirk added.

To analyze for other impurities that are either not normally present or present in minute amounts, the company uses methods from the FCC, the USP, Standard Methods for the Examination of Water and Wastewater, and adaptations validated by Morton Salt specifically for use on salt and brines. For example, salts for pharmaceutical products are tested using monograph methods specified by the USP, including colorimetry, titration, gravimetric analysis, atomic absorption spectroscopy, fluorometry,flame tests, turbidity, and others.

Particle size analysis is measured primarily using mechanical sieve shakers and is based on the ASTM C136 method. Bulk density testing is based on filling a container with a known volume and weighing the contents on a balance. Anti-caking agents are analyzed by titration, colorimetry, turbidimetry, or gravimetric methods. Iodine is analyzed by titration with sodium thiosulfate.

Shirk said that the technology for evaporating brine in vacuumpan crystallizers has been used for approximately 100 years. Computerization using pressure, temperature, and flow sensors is an advancement that enables virtual processing control systems. Analytical advances include use of inductively coupled plasma (ICP) spectroscopy to replace some of the manual procedures, but analyzing for sodium by both ICP spectroscopy and flame atomic absorption (FAA) spectroscopy can be challenging since it is crucial to prevent interferences due to the matrix. Difficult matrices such as a high concentration of dissolved salts can either suppress or enhance the analyte signal.

Cargill

In 1886 John and Louis Alberger, Charles Moore, and Horace Williams patented a new process for making salt and founded the Diamond Crystal Salt Co. This Alberger ® salt process made it possible to create unique-shaped crystals with numerous facets that exhibited extraordinary adherence, blendability, and flavor. The Diamond Crystal® brand was acquired by General Foods in 1929, Akzo Nobel in 1987, and Cargill (www.cargill.com), the largest marketer of salt in the United States, in 1997.

Jackie Van Norden, Product Line Manager at Cargill, said that the company offers kosher salt, sea salt, flake salt, and table salt for consumer use under the Diamond Crystal brand and salts for food industry use under various brands,including Alberger ®, Premier™, FlakeSelect™, and Microsized ® as well as granulated and sea salts. It also offers table salt for consumer use under the Sterling® brand.

Jackie Van Norden, Product Line Manager at Cargill, said that the company offers kosher salt, sea salt, flake salt, and table salt for consumer use under the Diamond Crystal brand and salts for food industry use under various brands,including Alberger ®, Premier™, FlakeSelect™, and Microsized ® as well as granulated and sea salts. It also offers table salt for consumer use under the Sterling® brand.

Cargill uses several processes to produce its salts. Sea salt is made by channeling Pacific Ocean seawater that only Cargill is allowed to bring in from San Francisco Bay to ponds where wind and sun evaporate it naturally. The resulting crystals are further processed to ensure food-grade quality, using standard industry processing techniques including screening, sorting, crushing, washing, or dissolution followed by mechanical evaporation. Sea salts tend to be less uniform in shape than salts produced by other processes.

Granulated salts sold under the Diamond Crystal and Cargill® brands are made through a closed evaporation process. Water is injected into underground salt deposits to create a brine. The brine is pumped up to a closed vacuum-pan evaporator on the surface where the water is evaporated by heat processing. The resulting crystals are sized by screening and may have various additives added to improve their ease of handling or provide nutritional supplement.

The Alberger brand salt is produced in an open-pan evaporation process, which produces salt more slowly than the closed process, allowing different shapes of salt crystals such as hollow pyramids and cubic agglomerates to form. The shape of the crystals provides unique characteristics. The crystals are sized by screening and may have various additives added.

--- PAGE BREAK ---

Van Norden said that granulated salts are generally cubic in shape and that the manufacturing processes affect the size and shape of the salt crystals. Salts made by the Alberger process are flakes that have high surface area and low bulk density with the largest crystals shaped like hollow pyramids and the smaller flakes shaped like cubed agglomerates. Premier salts and FlakeSelect salts are granulated salts that have been compacted into flat flakes that have higher surface area and lower bulk density than granulated salt and provide better adherence for topical applications. Alberger, Premier, and FlakeSelect salts range in size from a very fine flour salt to a very coarse topping salt. Microsized salts are granulated salts that are mechanically pulverized and screened to a very fine particle size. Providing a variety of salt sizes and shapes allows food manufacturers and foodservice operators to optimize their salt and sodium contents in specific food applications.

Sarah Hubert, Quality Assurance Leader, and Roger Sonnier, Regional Quality Assurance Manager, said that Cargill tests its salts for purity, moisture, insolubles, screen size, additives (if applicable), and bulk density, using wet chemistry equipment, spectrophotometers, pH meters, sieves, and atomic absorption spectrophotometry. To test for purity, the company uses acid/base titration with EDTA to determine the calcium and magnesium concentrations. Sulfate determination is a gravimetric procedure (dissolution of salt in water addition of barium chloride, subsequent filtering, drying, and weighing of the precipitate).

To determine bulk density, the company places a salt sample in a container of known volume. To test the anti-caking agent, a spectrophotometer is employed to measure the color created via a chemical reaction between an anti-caking agent and a laboratory reagent. For free-flow agents, an acid-base titration with a known concentration of aqueous sodium hydroxide is used. For particle size analysis, a sample of known weight is poured into the top sieve of a series of sized wire-mesh sieves, the sieves are mechanically shaken, and the individual sieves are weighed.

Compass Minerals

The former North American Salt Co. is in the process of changing its name to Compass Minerals (www.compassminerals.com). The company traces its history as far back as 1844. Jerry Poe, Director of Quality, said that the company’s salt production methods include mechanical evaporation, solar evaporation, and rock salt mining. The company offers its salts, both plain and iodized, for consumer use under the Carey Salt brand in the United States, the Sifto Salt brand in Canada, and a number of private labels. Its industrial food-grade salts (available in granulated, blending, iodized, and flour salt forms) are sold under the Special Purity brand in the United States and the HyGrade brand in Canada. For food use, the company offers only cubic crystals and sea salt crystals.

Compass Minerals offers granulated salt, kosher salt, sea salt, and canning and pickling salt. Sodium ferrocyanide, also known as yellow prussiate of soda (YPS), is added as a free-flowing/anti-caking agent that generally doubles the shelf life of salt, depending on storage conditions, Poe said. Salt is chemically stable infinitely but cakes into lumps over time, and YPS delays the lumping. Poe said that the company monitors the YPS content of the salt colorimetrically. YPS is converted into blue ferric ferrocyanide in the presence of iron in an acidic medium, and the color intensity can be measured against a known standard. The darker the blue color, the higher the YPS content in the salt. In addition, the company uses sodium silico aluminate as a desiccant in its consumer salt to attract moisture away from the salt and keep it flowing.

Poe said that Compass Minerals typically analyzes salt for purity by x-ray diffraction and ICP spectrophotometry. Insoluble matter is determined gravimetrically by ASTM Procedure E534, and particle size analysis is done with screens. Samples are sent to outside laboratories to determine content of heavy metals.

Tate & Lyle

Tate & Lyle

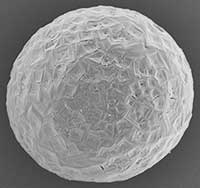

Through its Open Innovation program that creates outside partnerships to bring new innovations to market, Tate and Lyle (www.tateandlyle.com) signed an exclusive agreement with Eminate Ltd., a subsidiary of the University of Nottingham, in October 2011 to license and distribute Eminate’s Soda-Lo® Salt Microspheres worldwide. The salt was introduced in Europe and North America in November 2012 and subsequently in Latin America and Asia Pacific and received the Institute of Food Technologists’ 2013 Food Expo Innovation Award.

Sue Butler, Senior Research Scientist at Tate & Lyle, said that the product is made by a proprietary spray-drying technology that turns standard salt crystals into free-flowing, hollow crystalline microspheres. The lower-density microspheres optimize the perception of saltiness in foods by maximizing surface area relative to volume, making it possible to provide a clean salt taste with lower levels of sodium.

Every lot of the microspheres is quality tested to ensure that it is free of microorganisms and meets specifications for moisture and ash, Butler said. Particle shape and size are also measured. Some of the methods used include the forced-air oven method for moisture measurement and the laser light-scattering method for particle size analysis. In the forced-air oven method, a sample is heated under controlled conditions to drive off all free moisture and the reduction in weight is used to calculate the percentage of moisture lost. The laser light-scattering method measures the amount of light scattered by a solution at an angle relative to a laser beam, which enables particle measurement in the sub-micrometer range.

Neil H. Mermelstein,

Neil H. Mermelstein,

a Fellow of IFT, is Editor Emeritus of Food Technology

[email protected]