What’s Cooking in the Kitchen of the Future

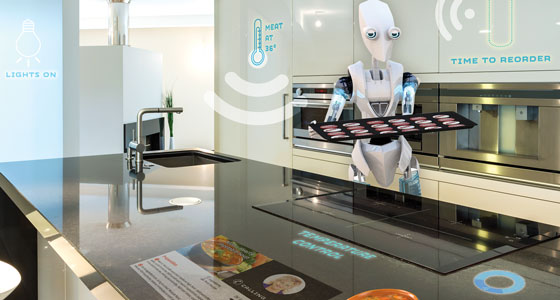

Interconnected smart appliances, 3-D printers, and touchscreen controls are just a few of the technological tools that the next generation of home cooks will use to simplify food preparation, create customized meal solutions, and produce far less waste.

When consumers head into the kitchen of the future, they’ll very likely be getting help from a new generation of smart appliances on things like reducing food waste, cooking to address their personal health profiles, and staying better connected to the origins of their food—issues that are important to consumers and the food industry. Even now, high-end refrigerators can extend the shelf life of produce, allowing consumers to waste less of it. And thanks to temperature probes and software programs, ovens can manage the entire cooking process without sacrificing quality, safety, or accuracy. Then there’s 3-D printing, which may soon allow busy parents to create fun foods covertly packed with the veggies their picky kids need.

In the kitchen of tomorrow, connectedness is key. These so-called smart appliances are connected via the Internet of Things (IoT), the network of objects embedded with electronics, software, sensors, and network connectivity that allows them to collect and exchange data. Basically, thanks to the IoT, all of the appliances within the home can “talk” to each other. “The trend of appliances being controlled by phones is now a reality as phones get smarter and become more integrated into personal lives by offering new ways to monitor and control things that are important to consumers, be it managing health and wellness, personal finance, home energy consumption—even preheating an oven,” says Brian Jones, director of marketing for appliance brands Sub-Zero and Wolf, Madison, Wis. “Homeowners want to manage and control their home features and appliances from anywhere they wish, be it on a command center in their home, on their phones or other devices in the home, or remotely.”

Plenty of today’s appliances already use this kind of technology, allowing consumers to turn their lights on when they wake up and tell their coffeemakers to begin brewing even before they’ve stepped out of bed. Sophisticated devices and systems such as Amazon’s Echo and Apple’s HomeKit can serve as the main hub of connected homes; using “if this, then that” (IFTTT) programs, consumers can set up “recipes” that make controlling these devices easier (Mintel 2015). For instance, using these rules, a consumer can instruct his lights to come on at sunset or use GPS to have his thermostat sense when he’s close to home and flip the heat on. In the future, companies plan to further these technologies and the capabilities of fridges, ovens, and other appliances to allow consumers to buy, store, cook, and clean up their meals as efficiently and conveniently as possible.

--- PAGE BREAK ---

Convenience and Control in the Kitchen

According to Consumer Trends 2015 data from market research firm Mintel, Chicago, “smart devices—from watches to ceiling fans—appeal to consumers because they save time and money, as well as promise convenience and control … what’s changing is that this ever-growing Internet of Things is no longer the domain of start-ups—major players are now embracing the trend and raising consumer confidence in it.” The report finds that 40% of consumers would like to buy technology products that easily connect to products they already have, with 59% of U.S. consumers showing interest in using apps or websites to control their home (Mintel 2015). And according to Euromonitor International, 10% of consumers are willing to pay more for appliances with connected functionality (Euromonitor 2015).

“As the ever-evolving Internet of Things continues to experience widespread adoption, one of the areas in the smart home that is expected to see the greatest change over the next decade is, indeed, the kitchen,” says Pavel Marceux, technology, communications, and media specialist with Euromonitor International. “According to a recent trade report, the result of this burgeoning technology will make way for a US$10.1 billion smart kitchen market by 2020. The study found that out of all connected kitchen appliances, many consumers favor fridges that will allow them to monitor food inventory with their smartphone.” Indeed, 14% of U.S. consumers say they would pay more for a refrigerator with a built-in computer to keep inventory, suggest recipes, and perform other tasks (Mintel 2015).

The Port Washington, N.Y.–based NPD Group writes in its Kitchen Audit that nearly a quarter of consumers already own coffee pod machines like Keurig (NPD 2014), and GE Appliances, Louisville, Ky., even released a fridge with a Keurig built right into the door. Beginning now and stretching into the future, consumers will grow to expect this level of convenience from all of their kitchen appliances. Technologies from several companies already allow consumers to control parts of their kitchen from anywhere via their mobile devices: GE’s Wi-Fi-enabled Brillion technology lets consumers preheat their ovens while they’re pulling into the garage and alerts them when the timer is going off.

The Port Washington, N.Y.–based NPD Group writes in its Kitchen Audit that nearly a quarter of consumers already own coffee pod machines like Keurig (NPD 2014), and GE Appliances, Louisville, Ky., even released a fridge with a Keurig built right into the door. Beginning now and stretching into the future, consumers will grow to expect this level of convenience from all of their kitchen appliances. Technologies from several companies already allow consumers to control parts of their kitchen from anywhere via their mobile devices: GE’s Wi-Fi-enabled Brillion technology lets consumers preheat their ovens while they’re pulling into the garage and alerts them when the timer is going off.

Programmable appliances like these, which are also available from appliance makers such as Wolf, enable consumers to begin their cooking and walk away, giving them the freedom to get dinner going while also letting them take advantage of this new free time to relax or accomplish other tasks. The company’s M series ovens offer 10 cooking modes via an LCD touchscreen control panel. In addition, “The new Gourmet mode includes a menu of preset options that help guide users through the cooking process of commonly prepared foods, including temperature and rack placement, eliminating any guesswork,” says Doug Swank, Wolf’s vice-president of design engineering. Consumers can also multitask as they cook: Whirlpool, Benton Harbor, Mich., designed a cook space that also includes a touchscreen display, letting users browse the Internet for recipes, instructional videos, or new emails while they prepare their meals.

Consumers can also take advantage of the technology in their kitchens to shop for groceries: Amazon’s Dash Buttons already allow consumers to easily and remotely reorder staples of such products as Kraft Macaroni & Cheese and Larabars, and Instacart promises grocery deliveries in just an hour; according to Mintel, 18% of U.S. adults who shop online weekly use an automatic reorder service from retailers for regular shipments of items that they replenish frequently, and 35% of U.S. adults are doing more of their shopping on the Internet than before (Mintel 2015).

This convenience will also be found in the kitchens of tomorrow, quite likely facilitated through the refrigerator, where technology may allow the appliances to actively monitor their contents and reorder when it senses supplies are running low, at least according to researchers from the University of Central Lancashire and Ocado; they also envision a fridge that uses nanoarticulated technology to move products that are near their expiration dates closer to the front (Daily Mail 2010). In GE’s Home of 2025 project, smart appliances will perform inventory management and automatically place orders for food, and refrigeration units outside the front door will enable these deliveries to stay cold until consumers come home.

As more and more consumers eventually adopt these technologies, the way they shop will likely change. Even now, shoppers are doing more small-basket shops every day rather than planning a whole week’s meals, says Melissa Abbott, vice-president, Hartman Retainer Services, for The Hartman Group, Bellevue, Wash. Manufacturers that make their products easily available online and in more convenient locations will enjoy brand loyalty from busy consumers, and manufacturers should consider alternative ways to promote their brands apart from in-store marketing, which some of these consumers might never even see.

“We are a nation that cooks with an index finger,” writes Kim Severson in The New York Times, and just like now, many consumers will still turn to the microwave over the next decade—even if the way that the technology inside the microwave changes. “To create this one-button food,” Severson adds, “appliance makers and food manufacturers have to work together” to drive designs, as well as the nature of the food itself (Severson 2010); according to Abbott, whose group studies how consumers interact with their kitchens, people are still using their microwaves. They’re just turning to foods from brands they consider “healthier,” like Evol, Lyfe Kitchen, and so on, that don’t use preservatives.

To ensure their foods’ place in the microwaves of tomorrow, manufacturers may wish to identify ways to create more frozen and packaged foods that consumers won’t feel bad about microwaving, either as the whole meal or as a side that can accompany something they’ve created from scratch. Companies might also want to focus on taking advantage of packaging opportunities to make cooking microwavable foods safer and easier.

TrueCookPlus technology, which is already available in some microwaves, includes codes that allow consumers to microwave foods more accurately; by inputting just a few numbers, consumers can take the guesswork out of cooking direction ranges and ensure that their food is cooked to a safe temperature and tastes the best that it can. In addition, packaging that uses thermochromatic ink, such as the “hot” indicator found on Hungry Jack microwavable syrup bottles, lets users know when the syrup is heated, says Claire Koelsch Sand, president of packaging consulting firm Packaging Technology and Research and an adjunct professor at Michigan State University. There is also a need for other indicators that could communicate foods’ doneness, she adds; possible applications include cook-in-the-bag meals and vegetables. Extending these kinds of technology into a range of food types could continue to make microwave cooking even more simple for consumers.

In the future, the microwave might not be a microwave exactly per se. There are a range of appliances in the works that will be capable of heating food quickly and conveniently—while offering other benefits. For example, Freescale’s Sage solid-state radio frequency oven would use radio frequency (RF) emitters instead of the magnetrons in microwaves; could control the cycles, locations, and levels of cooking energy; and may even be able to detect doneness. It would also include a convection heating element, eliminating the need for packaging tools such as the susceptor technology that is currently used in the crisping sleeves that brown Hot Pockets and microwave pizzas (Perlow 2015).

--- PAGE BREAK ---

Multidimensional Cooking

In the not-too-distant future, at-home 3-D printers will also provide a convenient way to create fresh food at the push of a button. “According to our Dinnertime MealScape study, we know that for 40% of dinners the decision of what to make was made within just 30 minutes of the meal,” writes Darren Seifer on The NPD Group Blog. “A device like [a 3-D printer] would fit very well during that narrow window of time. All consumers would need is the raw materials on hand and the ability to push a button” (Seifer 2015).

Foodini, which will come on the market the first quarter of 2016 and retail for $1,500, will serve as “a food manufacturing plant in people’s kitchens,” according to Lynette Kucsma, cofounder and chief marketing officer of Natural Machines, the company creating Foodini. The sleek countertop device lets consumers create whatever foods they desire via an extrusion system that employs stainless steel cartridges the consumers fill with their own sauces, doughs, and ingredients—whether they make those from scratch or buy them in stores. Kucsma says that Foodini will never force consumers to spend money buying prefilled cartridges for the machine (Foodini will always come with empty cartridges that users can fill themselves), but the company has been approached by manufacturers that want to develop meal kits for them.

Foodini, which will come on the market the first quarter of 2016 and retail for $1,500, will serve as “a food manufacturing plant in people’s kitchens,” according to Lynette Kucsma, cofounder and chief marketing officer of Natural Machines, the company creating Foodini. The sleek countertop device lets consumers create whatever foods they desire via an extrusion system that employs stainless steel cartridges the consumers fill with their own sauces, doughs, and ingredients—whether they make those from scratch or buy them in stores. Kucsma says that Foodini will never force consumers to spend money buying prefilled cartridges for the machine (Foodini will always come with empty cartridges that users can fill themselves), but the company has been approached by manufacturers that want to develop meal kits for them.

According to researchers at the Nestlé Research Center (NRC) in Lausanne, Switzerland, however, there is still a great deal of work that needs to be done in this area before manufacturers can realistically produce foods for most machines such as these. “Food printing is an emerging technology and is currently pitched to unlock a new design approach in personalized dietary choices,” says Martin Michel, expert scientist at the NRC. “Nestlé carefully monitors this technology, but it is too early to tell where it will go.” In addition, he says there are a number of challenges many food printers must overcome, such as speed of printing, texture and taste, and complexity. “The culinary world embraces a huge number of recipes as well as many ingredients and processes in order to provide a larger variety of foods,” he explains. “Whereas it is easy in color printers to create thousands of color shades from four different inks, this is not currently the case for food printing.”

Kucsma, though, is undeterred by these potential challenges. “We think in the next 10 to 15 years, every kitchen will have a 3-D food printer similar to how most kitchens have a microwave today,” she says. If this does turn out to be the case, it would be in food companies’ best interests to continue working with the developers of these machines to give consumers the option to make 3-D printing even easier; branded meal kits with all the components needed to print a ravioli and meat sauce or throw a pizza party could serve to make this technology even more convenient and give consumers even more say in what they’re eating. With Foodini, “You control everything that goes into your food,” says Kucsma. “This is real food, just 3-D-printed.”

Speaking of control, “I’m predicting right now that, for the next decade, all of the new advances in home cooking are going to be geared toward precision,” writes J. Kenji López-Alt, managing culinary director of the Serious Eats blog (López-Alt 2015). He was talking about Cinder, a new countertop appliance that aims to achieve the same results as sous-vide cooking—holding food at a low, steady temperature over time to retain moisture, maintain texture, and break down tough proteins. According to Philip Preston, founder of PolyScience, Niles, Ill., the company that first moved sous-vide cooking out of commercial kitchens and into consumers’ homes, precise temperature cooking gives consumers much more control over their cooking than baking, grilling, and simmering. (See a Food Technology Online Exclusive at ift.org/food-technology/current-issue for more on this technology.)

In addition, probe thermometers now come standard in freestanding and countertop ovens from companies including Miele, Wolf, GE, and KitchenAid. After these probes are inserted into meat, ovens are set to cook the proteins until they reach a desired temperature, then kept warm until the rest of the meal is ready. When probes are used correctly, medium-rare steaks become effortless and chicken breasts are cooked safely every time.

In addition, probe thermometers now come standard in freestanding and countertop ovens from companies including Miele, Wolf, GE, and KitchenAid. After these probes are inserted into meat, ovens are set to cook the proteins until they reach a desired temperature, then kept warm until the rest of the meal is ready. When probes are used correctly, medium-rare steaks become effortless and chicken breasts are cooked safely every time.

This kind of precision and accuracy is also possible in other countertop appliances. One such gadget, Nestlé’s Nespresso Vertuoline single-serve coffeemaker, scans a barcode on the cup’s lid to determine the optimal water contact time, temperature, rotational speed, and flow rate for the specific type of coffee or espresso the user is making. Food manufacturers might consider collaborating with appliance companies to create products for appliances such as these, following Campbell’s lead in developing soup cups for use with Keurig machines.

This kind of precision and accuracy is also possible in other countertop appliances. One such gadget, Nestlé’s Nespresso Vertuoline single-serve coffeemaker, scans a barcode on the cup’s lid to determine the optimal water contact time, temperature, rotational speed, and flow rate for the specific type of coffee or espresso the user is making. Food manufacturers might consider collaborating with appliance companies to create products for appliances such as these, following Campbell’s lead in developing soup cups for use with Keurig machines.

--- PAGE BREAK ---

A Kitchen That Works for You

“Versatility is key in the kitchen of the future,” attests Madeline Stone in a 2014 Business Insider article. Today’s consumers love customizing their lives, as the popularity of fast-casual eateries like Chipotle and Blaze reveal; according to research from Euromonitor International quoted by The Washington Post, the market for fast-casual food has grown by 550% since 1999 (Stone 2014; Ferdman 2015). It’s not surprising then that they would embrace kitchen appliances and products that can offer them the same level of personalization.

Unox, Newtown, Pa., an appliance company that produces CHEFTOP ovens for professional kitchens, allows users to control the temperature, humidity, air speed, and time of their cooking. The multifunctional appliances also allow users to cook different foods at different temperatures at the same time, schedule all foods to be ready at once, save chefs’ recipes and cooking processes for later use, and adapt the programmed conditions should something change—if a door is opened, for instance—to still achieve the desired results. Perhaps in the kitchen of the future, home chefs will be able to draw on this technology to customize their dinner parties and holiday meals.

What’s available now, though, are ranges such as those created by Wolf and German company Miele, the latter of which offers a MasterChef software program containing more than 100 cooking programs. Once the user selects the type of food they’re making—being as specific as whether their pizza dough is fresh or frozen—the oven then takes over, cooking the food to the consumer’s desires. MasterChef Plus, meanwhile, adds 15 baking settings and integrates steam when desired, as can a variety of ranges from other manufacturers.

In addition, many manufacturers are focusing on induction cooktops. These countertop cooking surfaces use magnetic energy and compatible pans to heat up only the pan placed on it; the rest of the surface can be safely used for anything. Some appliance makers are envisioning this surface as a place to browse the Internet, measure ingredients via a built-in food scale, and use as a cutting board. In IKEA’s Concept Kitchen 2025, the dining table is the heart of the kitchen and can be used for nearly anything the home owner desires. IKEA’s vision includes video projections and sensing technology that together can instruct the chef how to prepare the foods they’ve placed on the tabletop and cook directly on its surface—all while allowing the user to connect with friends via social media sites and children to do homework right next to where the pan cooks dinner.

It’s not just appliances or work surfaces that offer customization, though: in the modular kitchen called Tielsa from German manufacturer Alno, the counters themselves are changeable. At the touch of a built-in button or via a mobile device, the counters, sinks, and cooking surfaces can move up or down 15 to 16 centimeters in either direction. This personalized approach can appeal equally to tall and short people sharing a kitchen as well as those with handicaps. The stove can also be moved up so that children don’t burn themselves, while the sink can be lowered so they can easily wash their hands before dinner. In the future, Alno president Christian Hartsmanngruber envisions integrating facial recognition technology so that the kitchen can automatically set itself to a combination of desired settings—from counter height to ambient lighting to background music—as soon as it sees the user is home.

It’s not just appliances or work surfaces that offer customization, though: in the modular kitchen called Tielsa from German manufacturer Alno, the counters themselves are changeable. At the touch of a built-in button or via a mobile device, the counters, sinks, and cooking surfaces can move up or down 15 to 16 centimeters in either direction. This personalized approach can appeal equally to tall and short people sharing a kitchen as well as those with handicaps. The stove can also be moved up so that children don’t burn themselves, while the sink can be lowered so they can easily wash their hands before dinner. In the future, Alno president Christian Hartsmanngruber envisions integrating facial recognition technology so that the kitchen can automatically set itself to a combination of desired settings—from counter height to ambient lighting to background music—as soon as it sees the user is home.

Alno’s kitchen also includes a retractable television-screen back-splash that users can move to face any direction they like, letting them watch videos, access recipes, or communicate with friends while they cook. According to Hartman’s Abbott, mainstream home owners—the people who cook the most—are learning about technology developments from Facebook, YouTube, and message boards. These consumers are already tapped into social networks, so the idea of a kitchen that can continue that relationship may appeal equally to early adopters and those who jump in later. Whenever that does happen, food manufacturers have a real opportunity to tie their products more directly into the content that consumers are viewing. In some kitchen concepts, such as GE’s Home 2025, virtual chefs can be projected directly into consumers’ kitchens to guide their cooking; perhaps one day Betty Crocker might join them.

In addition, according to Michael Wolf, creator of the Smart Kitchen Summit, the first smart home event targeted to kitchen technologies, the kitchen of the future will allow consumers to embrace their passions and take them further. Users will have the opportunity to elevate their crafts because they will be able to automate the time-consuming parts that prevent them from being able to brew beer or can jams after a weekday dinner. “Maybe there’s an analogy with musicians,” says Wolf. “You can automate certain levels of the work, the base things you don’t want to do, and it allows you to take your art to a higher level.” Maybe food manufacturers will be able to assist consumers even further by creating kits that will work with in-home brewing machines the way Pepsi has collaborated with SodaStream carbonating systems.

Customizing Health and Wellness

Of course, 3-D printing may be the epitome of customization. Foodini will be able to print a range of foods, from pizza, rolls, and baked goods to burgers, chicken nuggets, and ravioli. Barring textural limitations, users can print nearly anything they want; gravity is a factor in this kind of 3-D printing and components therefore must not flow too freely, but cooks are not limited to sugar, gels, or pastes. And with 3-D printing, each family member could print the dinner they want when they want, taking into account likes and dislikes, food allergies, and nutritional needs.

With many people monitoring their sodium, carbs, sugars, and fats, consumers have a lot to keep track of. According to Mintel, 22% of all U.S. consumers have purchased a wearable device such as a Fitbit or Apple Watch (Mintel 2015). In the future, kitchens will take advantage of the Internet of Things to help consumers keep track of the data from these devices, as well as the kitchen appliances themselves, to monitor their health and cook meals that are appropriate for their needs.

According to an interview with Thomas Johansson, design director for Electrolux, that appeared on the FutureFood 2050 website, the kitchen of the future will be able to monitor users’ health and suggest appropriate menus based on current nutritional needs (Lubick 2014). Foodini, meanwhile, will be able to be programmed according to individuals’ desires; for example, a user could instruct the machine to cease printing a meal once the components total 600 calories.

Hartsmanngruber envisions an integrated system that can read data from fitness-monitoring devices and suggest meals appropriate to certain situations, such as muscle recovery after a strenuous workout. He would ultimately also want this data to be free for consumers to share as they see fit, including with their doctors and specialists who might be located half a world away. Alno is also working on programming that takes into account the needs of individual family members; for example, the program won’t suggest recipes with ingredients that a particular person can’t eat, whether because of allergies, religious preferences, or temporary conditions such as pregnancy.

PolyScience’s Preston thinks that a kitchen might one day be able to tell that someone has been eating out frequently, and the system might subsequently suggest recipes that are lower in sodium to help balance their diet. Electrolux’s Johansson believes information stored in the cloud—the virtual hub that houses all of the smart home’s data—linked to fitness devices could be used by families to ensure that their meals are addressing each member’s health needs. And in GE’s Home 2025, the sink would come equipped with a finger sensor that could read users’ hydration levels, dispensing water when it’s needed.

Manufacturers should look for ways to integrate their products into these algorithms so these programs suggest their brands and specific products as good ways to meet consumers’ health needs, even if some of them may stay firmly in the “treat” category.

--- PAGE BREAK ---

Preventing Waste Through Better Storage

In the future, resources—from water to food to energy—will be scarcer than ever. Space too will be at a premium, as more people move into cities or into smaller homes, according to GE. The population, though, will continue to grow, with the global population expected to reach nearly 9 billion in 2050. Today, roughly a third of all food produced is wasted (UNEP 2015), and to meet the demands of feeding an additional two billion people, preserving the resources we do have available will be even more important. Whether designed expressly to address food waste or not, some appliance manufacturers have already developed and implemented technology intended to extend the freshness and shelf life of foods.

Today’s Sub-Zero and KitchenAid fridges are equipped with filters that remove the ethylene gases that are responsible for produce decaying. GE, Sub-Zero, and KitchenAid have also designed appliances that separate the environments between the fridge and freezer sections, optimizing conditions for both fresh and frozen food, reducing odors and providing optimal shelf life for the foods found in each section. In addition, KitchenAid ExtendFresh sensors make sure produce stored in this compartment remains at its optimal temperature to maintain freshness. GE fridges and freezers, meanwhile, contain multiple shelves and doors to reduce the amount of air that escapes when the doors are opened. These also help keep everything inside organized and easy to find, preventing food from being forgotten and ultimately thrown away unused.

In the future, refrigerators will continue to focus on conserving resources and preventing food from being wasted through a variety of means. Video monitoring within fridges will help consumers see exactly what foods they have, and these systems may one day be linked to ovens and stoves that can create recipes that use the meal preparation ingredients that are expiring first, according to Shaun Kirby, chief technology officer for Cisco Consulting, San Jose, Calif. Preston imagines a fridge that uses ultraviolet light to sterilize the foods within it, keeping them safe from spoilage and food safety concerns; he would also incorporate a blast chiller to instantly take leftovers out of the danger zone where bacteria thrive.

The fridge itself might also change. GE is developing magnetic refrigeration technology, a water-based system that uses no refrigerants or compressors and will be 20% more efficient than today’s technology (GE 2014). As part of the 2010 Electrolux Design Lab competition, Russian designer Yuriy Dmitriev created a zero-energy freestanding fridge filled with a biopolymer gel that food is simply submerged in (Bergen 2011). Whirlpool envisions what it calls a FreshConnect system of small refrigeration units with temperature controls tailored to the foods they contain, and IKEA and Electrolux have also looked into similar concepts. In addition to pinpointing the accuracy of the temperatures for the foods stored in these cubes, they might also be movable, allowing consumers to truly customize their kitchens.

The fridge itself might also change. GE is developing magnetic refrigeration technology, a water-based system that uses no refrigerants or compressors and will be 20% more efficient than today’s technology (GE 2014). As part of the 2010 Electrolux Design Lab competition, Russian designer Yuriy Dmitriev created a zero-energy freestanding fridge filled with a biopolymer gel that food is simply submerged in (Bergen 2011). Whirlpool envisions what it calls a FreshConnect system of small refrigeration units with temperature controls tailored to the foods they contain, and IKEA and Electrolux have also looked into similar concepts. In addition to pinpointing the accuracy of the temperatures for the foods stored in these cubes, they might also be movable, allowing consumers to truly customize their kitchens.

Of course, to really monitor the freshness of the foods in their fridges, consumers must know when and from where they originated. Tracking technology in the world of tomorrow will be able to help consumers understand where their foods come from, and it can also help retailers and manufacturers affirm and promote the freshness of their ingredients and wares. Lisa Wirthman, writing for Forbes, says that temperature tags containing radiofrequency identification (RFID) technology can send constant data about food throughout the stages of the supply chain to help manufacturers and retailers prevent loss (Wirthman 2013). Kirby adds that sensors integrated into the trucks and trains transporting food will be able to help them find alternative routes should they encounter unexpected conditions like hot weather or delays that could negatively impact the produce, and according to Koelsch Sand, RFID tags are also being integrated alongside emerging technologies like biosensors and humidity and oxygen sensors to detect when foods inside packages have spoiled.

Sensors integrated into handheld devices can also analyze the chemical composition of fruits and vegetables; these could be used by consumers to monitor the ripeness of the foods they already bought or by retailers to track the freshness of the produce they are selling. Retailers could then employ dynamic pricing to quickly sell the food that is near expiration and even equip shoppers with sensors to measure and share the freshness of the produce on display. Kirby says that one retailer is looking into using shoppers to crowdsource this information and then share on its website just how fresh the produce is at any given location.

Opportunities and Challenges

Ultimately, the best way to prevent food waste is to give consumers tools they can use to easily and confidently cook with the foods that they buy. Down the road, better, more efficient storage; convenient cooking methods; and personalized resources for maintaining health and wellness will enable home cooks to become the masters of their domains, even if they have a lot of support running silently in the background.

“Consumers spend massive amounts of time and dollars trying to create better food, and for many of us technology will change how we do that in nearly every way in the coming decade,” says Wolf. While it’s clear that there are many opportunities for appliance and food makers alike in the kitchen of the future, there may be some challenges to overcome as well.

For starters, consumers may not immediately embrace these appliances. “Smart appliances and the interconnectivity they offer provide new opportunities for the user to engage. While these new possibilities offer many benefits, there can be some hesitancy toward technology in the kitchen as the commitment to cooking and preparing food in the home, for many people, is paired with warm memories and traditions of what was historically a very manual process,” observes Brian Rizzo, corporate chef for Sub-Zero and Wolf.

In addition, according to Abbott, Millennials and Boomers are more interested in spending their money on experiences, and the consumers who cook the most—those with young kids—aren’t willing or able to invest in the latest and greatest technology at the current prices. Of course, as time goes by and technology gets better and cheaper, these kinds of advances will be found even in mainstream ovens; Wolf says that today’s cutting-edge technologies will likely come standard in five years.

--- PAGE BREAK ---

Consumers are also worried about security. The data that allow the smart home to function so effortlessly must be secured in order to elicit consumer trust; no one will be willing to sync their lives into the cloud if they are afraid the cloud is permeable. The kitchen has to be just as safe from hacking as it is from catching fire. And those consumers who don’t trust the security might also not be willing to learn how to use all of the functions these machines offer. Abbott, though, thinks those fears might be misplaced. In her observations of how consumers use kitchens, she’s seen that eventually home cooks figure out what their appliances are capable of—even if they continue to just use them for one thing, like buying a $700 Vitamix blender that can make hot soups and nut milks but only making smoothies in it.

Ultimately, customers have the final say when it comes to creating a kitchen that suits their needs, says Hartsmanngruber. “They have to be able to control the home, not be controlled by it,” he attests. With smart kitchen technology in its nascent stage, there is a true opportunity for food manufacturers to get into this game and collaborate with appliance makers to make sure that their ingredients and products continue to have a place in the kitchen of tomorrow. There are an astounding number of ways in which today’s technology might evolve, and food companies should be following these developments closely to focus on creating packaging, prepared foods, and meal components that consumers will find easy to pop into whatever heating element ends up in tomorrow’s kitchen.

Online Exclusive: Countertop Cooking

Read more about the devices offering today’s cooks convenience and control at ift.org/food-technology/current-issue.

Melanie Zanoza Bartelme is associate editor of Food Technology magazine ([email protected])

References

Bergen, J. 2011. “Bio Robot Refrigerator will keep your food cool in the year 2050.” geek.com, May 2.

Daily Mail. 2010. “Revealed: The hi-tech fridge of the future that will tell you what to have for dinner.” Daily Mail, Dec. 25.

Euromonitor. 2015. “Home Goods and the Internet of Things: The Real Value of the Smart Home Industry” webinar. Euromonitor International, Nov. 4.

Ferdman, R. 2015. “The Chipotle effect: Why America is obsessed with fast casual food.” The Washington Post, Feb. 2.

GE. 2014. “From Ice Blocks to Compressors to Magnets: The Next Chapter in Home Refrigeration.” Press release, March 13. GE Appliances, Louisville, Ky. geappliances.com.

López-Alt. 2015. “Can Cinder, the World’s Most Precise Griddle, Replace Sous-Vide?” Serious Eats, Oct. 9.

Lubick, N. 2014. “Will there be kitchens in 2050?” FutureFood 2050, Dec. 15.

Mintel. 2015. Consumer Trends 2015. Mintel Group, Chicago. mintel.com.

NPD. 2014. “Coffee Pod Machines Make Room for the Newest Kids in the Kitchen Pantry—Soda Makers and Sriracha Sauce.” Press release, Dec. 2. NPD Group, Port Washington, N.Y. npd.com.

Perlow, J. 2015. “Freescale’s Radio Frequency Oven:The End of the Microwave?” ZDNet, June 22.

Seifer, D. 2014. “Update: Is Science Fiction Entering Our Kitchens?” The NPD Group Blog, April 16.

Severson, K. 2010. “Kitchen Gadgets Take the Fast-Food Mentality Into the Home.” The New York Times, March 17.

Stone, M. 2014. “This Is What the Kitchen of the Future Could Look Like.” Business Insider, May 1.

UNEP. 2015. “Food Waste: The Facts.” United Nations Environment Programme, Oct. 16.

Wirthman, L. 2013. “Food Industry Upgrades Include Freezers That Detect Expiration Dates.” Forbes, June 12.