Presenters, Exhibitors to Parcel Out Packaging Information

PACKAGING PREVIEW

The world of packaging continues to evolve, and some of those evolutions will be discussed in several sessions at IFT15.

For session 015, “Challenges and Opportunities for Commercial Biosensors,” on Sunday, July 12, from 8:30 a.m. to 10:00 a.m., speakers will discuss recent and significant advances in biosensors and their applications. Yanbin Li will focus on the rapid detection of foodborne pathogens with electrochemical immunosensors combined with magnetic immunoseparation. Jonathan C. Claussen will discuss using ink-jet printed graphene paper to create disposable electrochemical biosensors that monitor meat spoilage. Daniel M. Jenkins will talk about new technology designed to conduct LAMP-based assays for agriculture and food safety. And Ramaraja Ramasamy will discuss electrochemical biosensors for pathogen detection in food and agriculture.

During session 024, “Packaging Materials to Enhance Food Quality and Safety: Methods, Approaches, and Case Studies,” on Sunday, July 12, from 10:30 a.m. to 12:00 p.m., speakers will discuss and evaluate new trends in food packaging technologies and the strategies the U.S. Food and Drug Administration (FDA) employs to assess the safety of food packaging materials. Timothy Begley will focus on how the FDA evaluates food contact materials, Shehbaz Singh will discuss intelligent packaging for fresh produce, and Eva Almenar will examine a case study in which active packaging and water regulations are being used to extend the shelf life of foods.

Several poster sessions focusing on food packaging will be presented on Sunday, July 12, from 12:00 p.m. to 2:00 p.m. The sessions include a discussion on “Active Zein Coatings on Polylactic Acid Films for the Design of Green Packaging with Antimicrobial and Antioxidant Properties” by Virginia Muriel-Galet, Pilar Hernandez Muñoz, and others. Hernandez Muñoz, Laura Higueras, and others will discuss “Application of the Schiff Base Reaction in the Development of Active Food Packaging Technologies.” Marcela Rangel-Marrón, Enrique Palou, and Aurelio L. Lopez Malo will present “Combined Effect of Modified Atmosphere Packaging and Alginate-Based Edible Coating on Shelf-Life of Fresh Mango Cubes.” Minhyeock Lee and Hyun Park will discuss “Controlled Release System of Thyme Essential Oil Using Halloysite Nanotubes in Food Packaging System.” Jaejoon Han and Sang Eun Lee will describe “Development of Anti-Insect Food Packaging Film Containing a Polyvinyl Alcohol and Cinnamon Oil Emulsion at a Pilot Plant Scale.” Jorge Cardona, Susana Andrade, and others will describe “Effect of Packaging and Storage Temperature in the Postharvest Characteristics of Bell Pepper.”

Session 034, “Innovations in Food Processing and Packaging from an Academic and Industry Perspective,” on Sunday, July 12, from 1:30 p.m. to 3:00 p.m., will feature lecturers from the Food Engineering Division, Nonthermal Processing Division, and Food Packaging Division. Erich Windhab will discuss novel foams and emulsions that use dynamic membrane separation technologies. Carole Tonello will discuss new innovations in nonthermal processing. And Thomas Dunn Jr. will discuss innovations in packaging over the past 35 years.

During session 084, “Antimicrobial Food Packaging Using New Materials and Methods,” on Monday, July 13, from 2:15 p.m. to 3:45 p.m., speakers will discuss the rising consumer demand for minimally processed, ready-to-eat fresh foods and the related need for food packaging that can control microbial growth in such foods. Tony Jin will discuss the three components of antimicrobial packaging and introduce a packaging program that utilizes biopolymers and biobased plastics to improve the safety and shelf life of various foods. Mingming Guo will discuss the application of high pressure homogenization to reduce the particle size of antimicrobial coatings and films. Changqing Wu will examine the potential of using lignin products in biobased antimicrobial and antioxidant packaging. And Kay Cooksey will present the benefits and challenges of the commercialization of antimicrobial packaging in the food industry.

Session 074, “Sustainability in Food Nutrition, Quality, Processing, and Delivery: Let’s Take Action Now!” on Tuesday, July 14, from 1:15 p.m. to 2:45 p.m., will address the challenges of reducing food waste while maintaining sustainability, nutrition value, food quality, processing techniques, safe storage, and delivery. Of the session’s four speakers, one speaker will specifically discuss packaging. Gordon Robertson will talk about the possibility of reaching a consensus about what constitutes sustainable packaging and whether truly sustainable packaging can ever be developed.

Session 118, “Innovations and Trends in Food Product Development: Implementation of Emerging Technologies, Commercialization, and Consumer Acceptance,” on Tuesday, July 14, from 1:15 p.m. to 2:45 p.m., will feature speakers discussing emerging technologies to provide safe, healthy food with high nutritive value. One of the four speakers, Christopher Doona, will focus on innovative technologies that enable extended shelf-life for foods for the military. Doona will present processing technologies developed by the U.S. Army Natick Soldier RD&E Center that have dual-use applications. For example, one of the technologies involves a commercial packaging system used to sterilize medical equipment, and another is an in-package preservation technology that extends the shelf life of fresh produce.

Exhibitor Information

What follows are brief descriptions of some of the products and services available from packaging-related companies that will be exhibiting at IFT’s food expo.

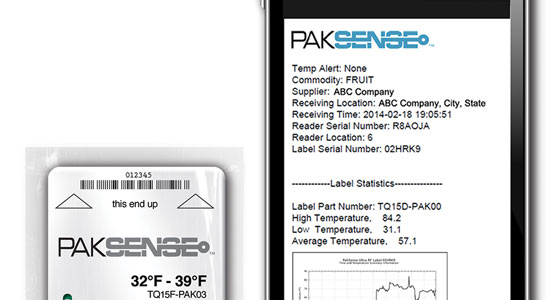

Cold chain solutions from PakSense include automated, wireless, and wired systems as well as single-use temperature recording labels. The company’s wireless AutoSense system delivers cold chain temperature data to smartphones, providing users with a streamlined temperature monitoring option that does not require major information technology support. Its components include PakSense wireless labels and AutoSense readers. The company also recently launched a standalone AutoSense Real-Time unit in conjunction with strategic partner Controlant. As its name suggests, the unit facilitates cold chain distribution by providing real-time access to temperature and location information. PakSense, paksense.com, Booth 4521

A state-of-the-art extended shelf life (ESL) and aseptic beverage contract manufacturer, HP Hood has plants strategically located on both coasts, which allows for efficient national and international distribution. By heating fluid products to a high temperature and packaging them under near sterile conditions, ESL (ultra pasteurization) technology delivers a much longer shelf code than standard pasteurization. The aseptic beverages Hood processes are ultra pasteurized and packaged in HDPE or PET plastic bottles under sterile conditions on a Shibuya aseptic filler. Hood’s facilities meet or exceed U.S. Food and Drug Administration food safety standards and are SQF Level 3 certified. HP Hood LLC, hphoodllc.com, Booth 762

Proprietary CHEP-TRAC software from CHEP Pallecon facilitates electronic capturing and recording of data that is critical for compliance with Food Safety Modernization Act regulations. With CHEP-TRAC, companies can keep track of specific data control points per container instead of per shipment for key factors such as temperature and weight, purchase order numbers, product codes, safety seal numbers, scanner operating user data, sanitation, and loading/ unloading data. In addition to these advanced tracking protocol capabilities, CHEP supplies reusable containers and sanitary liners. CHEP Pallecon Solutions, cheppallecon.com, Booth 131

Proprietary CHEP-TRAC software from CHEP Pallecon facilitates electronic capturing and recording of data that is critical for compliance with Food Safety Modernization Act regulations. With CHEP-TRAC, companies can keep track of specific data control points per container instead of per shipment for key factors such as temperature and weight, purchase order numbers, product codes, safety seal numbers, scanner operating user data, sanitation, and loading/ unloading data. In addition to these advanced tracking protocol capabilities, CHEP supplies reusable containers and sanitary liners. CHEP Pallecon Solutions, cheppallecon.com, Booth 131

The Fluid-Bag system delivers an innovative, safe, and cost-effective flexible container solution for liquid and semi-solid products, including fruit preparations, vegetable concentrates, and bakery fillings. The airtight system prevents contamination and may be used for internal and external logistics. The company also provides equipment for efficient discharge of highly viscous products. Fluid-Bag, fluid-bag.com, Booth 5317

Optimized oxygen absorbers and desiccants from Multisorb to control the internal environment of food packaging help deliver clean label products by reducing or eliminating the need for preservatives or other additives. Oxygen absorbers, including FreshPax, FreshCard, and FreshMax, prevent the oxidation of fats, vitamins, natural antioxidants, flavors, and colors. They preserve food quality and extend shelf life, allowing the use of natural oils without concern about rancidity or reliance on synthetic antioxidants. Multisorb, multisorb.com, Booth 1909

Optimized oxygen absorbers and desiccants from Multisorb to control the internal environment of food packaging help deliver clean label products by reducing or eliminating the need for preservatives or other additives. Oxygen absorbers, including FreshPax, FreshCard, and FreshMax, prevent the oxidation of fats, vitamins, natural antioxidants, flavors, and colors. They preserve food quality and extend shelf life, allowing the use of natural oils without concern about rancidity or reliance on synthetic antioxidants. Multisorb, multisorb.com, Booth 1909

Toni Tarver is senior writer/editor of Food Technology magazine ([email protected]).