Annual Event Delivers Solutions to Processing Challenges

PROCESSING PREVIEW

The frustration of having so many intriguing scientific and applied sessions and papers that sometimes it’s impossible to fit everything in continues at this year’s annual event as the overall quality of the scientific program continues to improve. Perhaps as a sign of my seniority, fewer of the speakers are familiar names to me, suggesting that the rising cohorts of academics are increasingly pushing the boundaries of our science.

In addition to the symposia previewed here, do not neglect the numerous poster sessions sponsored by every division. Posters offer the opportunity to interact directly with the authors, often graduate students, who treasure the insights and dialogue with more experienced colleagues. I always enjoy the serendipity of browsing posters, not usually knowing what may appear on the next board.

Biocontrol and Inactivation

“Emerging Biocontrol Strategies for Food Safety” is session 003, on Sunday, July 12, from 7:15 a.m. to 8:15 a.m. in room N427a. Traditional means for addressing preharvest control of foodborne pathogens in livestock include adoption of best practices regarding environmental controls, management of pre-slaughter diets, minimizing cross-contamination during transport, and feeding of antimicrobials or probiotics. Approaches for minimizing postharvest microbial hazards in foods or on food processing surfaces include use of traditional processing steps such as heating or application of chemical preservatives, antimicrobials, or sanitizers. In recent years, new approaches for biocontrol—the use of natural or modified organisms or their products for hazard control—have been developed for food safety and related fields. The speakers will discuss use of bacteriophage and probiotics as new hazard controls.

“Shedding Light on Food Safety: Applications of Light-Based Technologies,” session 060, from 10:00 a.m. to 11:30 a.m. on Monday, July 13, is in room S402. Emerging technologies such as UV light, pulsed light, and LED light processing show great promise since they can inactivate the pathogenic microorganisms while preserving the quality of foods. This session will focus on recent advances in light-based technologies for microbial decontamination. Typically, these technologies operate in the UV, visible, and near infrared light range. The identified speakers are experts in light-based technologies.

“Gaseous, Vaporized, and Aerosolized Antimicrobials to Enhance Microbial Food Safety,” session 039, from 1:30 p.m. to 3:00 p.m. on Sunday, July 12, is in room S402. Currently, the fresh produce industry is relying mostly on aqueous sanitizers such as chlorine solutions. However, pathogens on the surface of fresh fruits and vegetables may reside in protected sites such as crevices, stomata, or cracks that aqueous sanitizers cannot reach. Gaseous antimicrobials may be more effective in reaching such sites. Furthermore, gaseous antimicrobials tend to dissolve in wound sites on fruits and vegetables, and microbes in those areas are likely to be inactivated. This makes gaseous application of antimicrobials attractive for fresh-cut produce applications. This session will review the traditional gaseous antimicrobials. Another way of generating vaporous antimicrobials is to vaporize or aerosolize antimicrobials. Ethyl pyruvate, essential oils, and nitric oxide will be discussed.

From 12:30 p.m. to 2:00 p.m. on Monday, July 13, in session 073 in room S504abc, the focus will be on “Nanotechnology-Enabled Technologies for Food Safety Intervention.” This session will highlight some nanotechnology-enabled strategies, ranging from restructuring water to give it antimicrobial properties—with possible applications for fruit and vegetable washing—to new polymer fabrication methodologies that can be used to fabricate surfaces and coatings with bactericidal effects against foodborne pathogens. The speakers are recent grantees of the USDA-NIFA grant program in the area of nanotechnology for food applications and bring a very interesting mix of backgrounds and approaches to solving food safety issues.

“Future of Food Preservatives: Emerging Natural and Potent Alternatives” is session 008, scheduled for 8:30 a.m. to 10:00 a.m. Sunday, July 12, in room N427a. Currently used chemical antimicrobials are not meeting the expectations of a new generation of consumers. These agents also are gradually losing efficacy against targeted microorganisms. New resistant strains of harmful microorganisms are emerging and posing risks in traditionally preserved foods. On the other hand, research for developing effective preservatives and efforts to approve their use at the regulatory level is progressing slowly.

New natural antibacterial and antifungal compounds are needed as alternatives to commonly used chemical preservatives such as benzoates and sorbates. One of the best natural sources for novel antimicrobial agents is bacteria from food and the environment. Although rarely found, certain strains of beneficial microorganisms produce promising bacteriocins and antifungal peptides and lipopeptides. Bacteriocins are ribosomally encoded antimicrobial peptides suitable for use as natural food preservatives. Nisin, a commercially available bacteriocin, was approved in 1969 by the Food and Agriculture Organization and the World Health Organization for use in foods and is utilized in nearly 50 countries as a food preservative. Nisin has been extensively tested in controlling spoilage microorganisms and foodborne pathogens, but the bacteriocin has many limitations.

“Decontamination and Inactivation Strategies to Reduce Pathogens in Foods,” session 058, will take place from 10:00 a.m. to 11:30 a.m. on Monday, July 13, in room S504abc. Foodborne pathogen contamination can occur at any point along the food chain. Traditional physical and chemical interventions, including thermal treatments and antimicrobials, are widely employed during food processing and on food contact surfaces. There has been growing interest in the development of minimal impact and non-thermal decontamination processes that will inactivate pathogens while preserving product quality. This session will begin with an overview of current issues, regulations, and processing practices for the control of Campylobacter and Salmonella in poultry products followed by a discussion of recent advances in cold plasma, high-intensity monochromatic light treatments and other waterless sanitation technologies. Then recent studies of applying electronic beam to inactivate foodborne pathogens in a variety of food matrices will be explored. The session will conclude with an exploration of the effectiveness of isoelectric solubilization and precipitation to reduce microbial pathogens in recovered protein from meat processing by-products.

“Cold Chain for Produce Safety: The Status Quo and Technologies to Minimize Food Safety Risks,” session 087 on Monday, July 13, from 2:15 p.m. to 3:45 p.m. will take place in room S503. Temperature management is critical to ensure the quality and safety of fresh and fresh-cut produce. The U.S. Food and Drug Administration (FDA) has recently updated its Food Code to include cut leafy green vegetables in the time-temperature control for the food safety category, chiefly because these products support pathogen growth. Other fresh produce on this list are cut melons, raw seed sprouts, and cut tomatoes. For cold chain distribution, the FDA Food Code recommends that these products be maintained at or below 4°F. However, adhering to this temperature requirement during transportation and storage at the retail terminus has been a challenge.

This symposium will bring together leading researchers, regulators, and stakeholders in the produce and refrigeration industries to share their knowledge, experience, and perspectives on new technologies/practices to minimize temperature abuse and fluctuations during cold transport, retail storage, and retail display, improvements in food quality and safety, and reduction in operational energy cost. The outcome of this symposium will be a heightened awareness for temperature control in the produce cold chain for compliance with the FDA Food Code, including optimized logistics for refrigerated trucks and the loading/unloading of products, better warehouse management for retail storage, improved performance of commercial refrigerated display cases, and more effective temperature control and monitoring throughout the cold chain. Furthermore, the findings shared in this symposium will provide insights toward new food safety national standards to benefit fresh-cut processors, retailers, and consumers, and facilitate the implementation of the Food Safety Modernization Act.

--- PAGE BREAK ---

The Academic/Industry Interface

Session 045, “Technology Transfer from Academia to Industry: Approaches and Case Studies,” will be held from 1:30 p.m. to 3:00 p.m. on Sunday, July 12, in room S401d. One of the problems with transferring academic results to industry is that scientific projects are mostly conceived by academic scientists who have a different set of goals and targets than industrial scientists. Academic scientists often are interested in learning about fundamental mechanisms and converting these fundamental insights into high-quality publications that contribute to the scientist’s reputation versus the industry orientation of finding solutions to specific problems. This session is designed to illustrate how technology transfer can be done effectively with the goal of stimulating closer cooperation between academia and industry.

“Instructional Approaches to Promote ‘Learning How to Learn’ to Food Science Undergraduate Students,” session 080, will take place from 12:30 p.m. to 2:00 p.m. on Monday, July 13, in room S401abc. Weak learning skills can lead to underperformance among intelligent students and can mean conflicts with instructors. In order to promote successful teaching and learning, learn-how-to-learn skills need to be developed throughout the undergraduate experience. This session will provide some fundamentals on the epistemic learning beliefs of students in order to assist instructors in better designing course materials.

The biosensors industry is now worth billions of dollars and has numerous applications, primarily in the biomedical field. Session 015, “Challenges and Opportunities for Commercial Biosensors,” will take place from 8:30 a.m. to 10:00 a.m. Sunday, July 12, in room N427d. Despite myriad papers published in this area, very few biosensor technologies actually succeed in becoming commercially available, particularly in the area of food applications. This symposium will feature some recent and significant advances in the field of biosensing and its applications to food safety, food quality, and food processing as well as to other biological systems. The speakers will address current challenges in biosensing technologies.

“Global Disasters and Food: An Inextricable Collision” will be the focus of session 122, from 1:15 p.m. to 2:45 p.m. on Tuesday, July 14. As global disasters ranging from superstorm Sandy to the Ebola outbreak continue to present themselves, there is an ever-growing realization that the food system and disasters are inextricable. The food industry and regulators must react to these crises in order to protect public health, and in many cases, the responses must occur within days. This symposium will provide participants with two case studies analyzing the risk assessment, decision-making, and impact of global disasters on the food system. The process of how to assess food risks post disaster will be presented in scenarios delivered to the audience. Finally, presenters will provide insight into using big data and modeling to answer operational questions we have not yet anticipated or planned for.

Just Plain Interesting

The following two sessions promise to be particularly intriguing, and the overall program offers a great deal more that is likely to be just as interesting.

“Applications of 3-D Printing in the Improvement of Food Quality,” session 025, will take place from 10:30 a.m. to noon on Sunday, July 12, in room N427d. The session will bring together three speakers with experience in 3-D printing and potential applications to food. The focus of the session is to identify opportunities in research using 3-D printing to improve quality attributes of foods with specific attention to new and different textures.

“Insect-Based Foods: Views From Different Perspectives,” session 056, will take place from 10:00 a.m. to 11:30 a.m. Monday, July 13, in room N427a. Although billions of pounds of insects have been produced for the pet food and animal feed industry, there is huge potential globally for viable food and ingredient production from insects. This session will cover some of the advances in insect production, supply chain, and processing as well as the regulatory and economic aspects of this emerging industry.

Exhibitor Information

The following are brief descriptions of some of the processing-related exhibits at the food expo.

Miniature-scale research and development systems for the food, beverage, dairy, oils, and pharmaceutical industries are available from Armfield. Equipment is designed to replicate manufacturing processes in a laboratory, permitting R&D teams to test product formulations quickly and easily, using fewer raw materials and saving time, space, and money. Armfield’s product lineup includes UHT/HTST modular miniature-scale process systems (based on plate, tubular, or scraped-surface heat exchangers, direct steam injection, or a combination), sterile fillers, homogenization systems, carbonator/fillers, spray dryer/chillers, inline deaerators, reverse osmosis/ultrafiltration units, multifunction laboratory mixers, and more. Armfield, explorearmfield.com, Booth 1751

Award-winning microwave-assisted aseptic food processing technology AseptiWave from Aseptia creates products that are shelf-stable for 12 months or more while retaining flavor, nutrients, and aroma. The company makes use of patented technology, advanced volumetric heating, and proprietary validation systems that meet FDA protocols. Aseptia’s continuous flow thermal processing technology is used to package a new generation of fruit purees, juices, sauces, soups, and other products. The systems are adaptable, scalable, and standardized for easy integration with upstream product preparation systems and a broad range of aseptic filling equipment. Aseptia, aseptia.com, Booth 232

A colorant concentration system by Ederna uses evapEOs Engineered Osmosis to concentrate at low temperature (down to 10˚C) and pressure, allowing for innovative, cost-effective concentration. No color change, low operating costs, and concentration up to 65% are major advantages over thermal and alternative membrane systems. The system circulates a proprietary draw solution on one side of a specific membrane to attract water from the product circulating on the other side. Sanitation and cleaning are easy, and the fact that no heat is required and low pressure is used produce energy cost savings of 30% to 98% compared to thermal evaporation while ensuring stability of the original color. Ederna SAS, ederna.com, Booth 4913

The lab version of the WaveMix microwave system from Marion Process Solutions is appropriate for applications focused on finish drying, acrylamide reduction, low temperature drying, microbial reduction, microwave drying under vacuum, or change of state. Disassembly, washdown, and reassembly are easy thanks to Marion engineering. WaveMix offers shorter processing time, high energy efficiency, no burning, and no case hardening. According to the company, Marion is the only 3-A Certified horizontal mixing and blending company. Marion Process Solutions, marionsolutions.com, Booth 4518

The lab version of the WaveMix microwave system from Marion Process Solutions is appropriate for applications focused on finish drying, acrylamide reduction, low temperature drying, microbial reduction, microwave drying under vacuum, or change of state. Disassembly, washdown, and reassembly are easy thanks to Marion engineering. WaveMix offers shorter processing time, high energy efficiency, no burning, and no case hardening. According to the company, Marion is the only 3-A Certified horizontal mixing and blending company. Marion Process Solutions, marionsolutions.com, Booth 4518

Precision metering pumps and dispensers for lab, pilot plant, process, and production fluid control are available from Fluid Metering Inc. The company’s patented CeramPump valveless design has just one moving part in the fluid path and inert, sapphire hard, ceramic internal mechanisms. It is well-suited for the accurate addition of colors, flavors, nutrients, enzymes, preservatives, and CIP fluids. Fluid Metering, fluidmetering.com, Booth 3851

--- PAGE BREAK ---

A versatile benchtop pilot unit from Membrane Specialists LLC will make its debut at IFT15. It is designed to accommodate a wide range of membrane geometries, including tubular, spiral, hollow fiber, and ceramic, and can attain the flows and pressures required for reverse osmosis, nanofiltration, ultrafiltration, and microfiltration operation. The company reports that the unit is ideal for investigational and process development projects in food, beverage, and nutraceuticals industries where membrane filtration can provide a solution to separation problems and where relatively small volumes of test materials are available. The company also is introducing a new microfiltration membrane that has been successfully field tested for clarification of highly colored juices. Membrane Specialists LLC, membranespecialists.com, Booth 217

A versatile benchtop pilot unit from Membrane Specialists LLC will make its debut at IFT15. It is designed to accommodate a wide range of membrane geometries, including tubular, spiral, hollow fiber, and ceramic, and can attain the flows and pressures required for reverse osmosis, nanofiltration, ultrafiltration, and microfiltration operation. The company reports that the unit is ideal for investigational and process development projects in food, beverage, and nutraceuticals industries where membrane filtration can provide a solution to separation problems and where relatively small volumes of test materials are available. The company also is introducing a new microfiltration membrane that has been successfully field tested for clarification of highly colored juices. Membrane Specialists LLC, membranespecialists.com, Booth 217

MicroThermics’ small-scale, UHT/HTST and aseptic processors provide easy, affordable accuracy in the processing of juice, soymilk, milk, pudding, and more. Working with MicroThermics helps eliminate failed plant trials while reducing costs. Thermal process matching technology, in-line homogenizers, steam injection, and filling accurately mimic production. New in 2015 are Aseptia microwave processors that feature rapid, controlled heating without fouling. MTI straight line heat exchangers integrate process accuracy with great flexibility. Turnkey services increase efficiency. MicroThermics’ Miniature Plant Trial Services Lab is registered with the U.S. Food and Drug Administration for sample production according to Food Safety Modernization Act requirements. The company is a past IFT Industrial Achievement Award winner. MicroThermics, microthermics.com, Booth 1038

MicroThermics’ small-scale, UHT/HTST and aseptic processors provide easy, affordable accuracy in the processing of juice, soymilk, milk, pudding, and more. Working with MicroThermics helps eliminate failed plant trials while reducing costs. Thermal process matching technology, in-line homogenizers, steam injection, and filling accurately mimic production. New in 2015 are Aseptia microwave processors that feature rapid, controlled heating without fouling. MTI straight line heat exchangers integrate process accuracy with great flexibility. Turnkey services increase efficiency. MicroThermics’ Miniature Plant Trial Services Lab is registered with the U.S. Food and Drug Administration for sample production according to Food Safety Modernization Act requirements. The company is a past IFT Industrial Achievement Award winner. MicroThermics, microthermics.com, Booth 1038

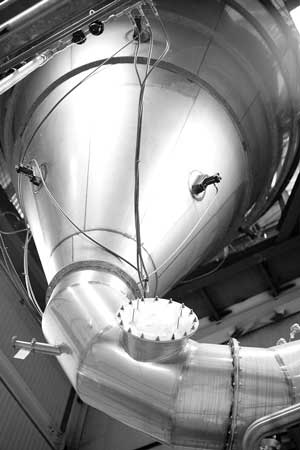

Modern, technologically advanced engineering solutions to retrofit an existing processing system or develop a new plant are available from GEA Group. The company’s extensive assortment of processing equipment includes aseptic equipment, centrifuges, clarifiers, separators, shakers, dryers, evaporators, filtration equipment, homogenizers, instantizers, agglomerators, valves, and more. GEA is committed to helping its customers achieve higher yields, greater product diversity, and improved product quality and consistency at reasonable costs. GEA Group, gea.com, Booth 1512

A manufacturer of microfiltration, ultrafiltration, and nanofiltration membranes and modules, Microdyn-Nadir offers a broad range of membrane configurations, including flat sheet, hollow fiber, tubular, spiral wound, and MBR modules. SPIRA-Cel spiral wound membranes are characterized by high flux, high protein retention, and long lifetimes. Standard and custom sizes that are USDA accepted and meet FDA requirements are offered. Microdyn-Nadir, microdyn-nadir.com, Booth 4634

A manufacturer of microfiltration, ultrafiltration, and nanofiltration membranes and modules, Microdyn-Nadir offers a broad range of membrane configurations, including flat sheet, hollow fiber, tubular, spiral wound, and MBR modules. SPIRA-Cel spiral wound membranes are characterized by high flux, high protein retention, and long lifetimes. Standard and custom sizes that are USDA accepted and meet FDA requirements are offered. Microdyn-Nadir, microdyn-nadir.com, Booth 4634

The patented TempSURE process from Honeyville is a proprietary system that uses an all-natural dry heat process that reduces or eliminates pathogens from dry ingredients. In the process, in which heat probes monitor temperature to assure 5-log pathogen reduction, ingredients remain in their original packaging to prevent contamination. Because no chemical fumigants are employed, the process can be used for organic products. At IFT15, Honeyville will also be highlighting its new gluten-free grain cracking facility designed to eliminate contamination and deliver a contract manufacturing option for companies seeking to expand into gluten-free cereal and breakfast bar categories. Honeyville, honeyville.com, Booth 567

Model 700-TH-40-SS Sanitary Rotary Batch Mixer from Munson Machinery uniformly blends bulk food ingredient batches in parts as small as one per million in less than three minutes, evacuates 100% of the batch, and can be sanitized rapidly without any tools. The unit is designed with a retractable inlet for fast and thorough washdown, a stationary discharge, and a rotating drum with proprietary mixing flights as well as all-stainless contact surfaces. Munson’s product assortment includes rotary batch mixers in capacities ranging from 10 cu ft to 600 cu ft as well as continuous rotary blenders, high intensity blenders, Forberg mixers, and ribbon, paddle, and plow blenders. Munson Machinery Co., munsonmachinery.com, Booth 3906

Model 700-TH-40-SS Sanitary Rotary Batch Mixer from Munson Machinery uniformly blends bulk food ingredient batches in parts as small as one per million in less than three minutes, evacuates 100% of the batch, and can be sanitized rapidly without any tools. The unit is designed with a retractable inlet for fast and thorough washdown, a stationary discharge, and a rotating drum with proprietary mixing flights as well as all-stainless contact surfaces. Munson’s product assortment includes rotary batch mixers in capacities ranging from 10 cu ft to 600 cu ft as well as continuous rotary blenders, high intensity blenders, Forberg mixers, and ribbon, paddle, and plow blenders. Munson Machinery Co., munsonmachinery.com, Booth 3906

Turnkey MOBILEZONE ozone injection system has been designed to quickly integrate into multiple waterlines throughout a process. Its applications include dairy production/processing, food processing and storage, grain and feed remediation, wine and beer processing, and clean-in-place. The compact MOBILEZONE system, which is capable of producing ambient and dissolved ozone, offers 20–40 g/hour ozone production, easy-to-use controls, a central switch to start and stop the system, water flow of 1–25 GPM, an HMI touchscreen, and ozone destruct unit for safety. Ozone Solutions, ozonesolutions.com, Booth 4509

Turnkey MOBILEZONE ozone injection system has been designed to quickly integrate into multiple waterlines throughout a process. Its applications include dairy production/processing, food processing and storage, grain and feed remediation, wine and beer processing, and clean-in-place. The compact MOBILEZONE system, which is capable of producing ambient and dissolved ozone, offers 20–40 g/hour ozone production, easy-to-use controls, a central switch to start and stop the system, water flow of 1–25 GPM, an HMI touchscreen, and ozone destruct unit for safety. Ozone Solutions, ozonesolutions.com, Booth 4509

New extrusion capability will be available to PacMore customers this year. The company is commissioning a 120 mm twin-screw extrusion line complete with ancillary pre- and post-processing equipment as well as a pilot Wenger 57 mm twin-screw extruder. At the IFT15 food expo, PacMore will be sampling a variety of cereal crisps formulated with healthful and trending ingredients. The company’s range of capabilities also includes blending, spray drying, sifting, repacking, and packaging. Its food standard certifications include kosher, organic, gluten-free, halal, and Grade A for dairy powders. PacMore has two BRC A–rated facilities, one in Hammond, Ind., and another in Mooresville, Ind. The company can provide both full-scale and pilot-level spray draying in a single facility. PacMore Products, pacmore.com, Booth 424

New extrusion capability will be available to PacMore customers this year. The company is commissioning a 120 mm twin-screw extrusion line complete with ancillary pre- and post-processing equipment as well as a pilot Wenger 57 mm twin-screw extruder. At the IFT15 food expo, PacMore will be sampling a variety of cereal crisps formulated with healthful and trending ingredients. The company’s range of capabilities also includes blending, spray drying, sifting, repacking, and packaging. Its food standard certifications include kosher, organic, gluten-free, halal, and Grade A for dairy powders. PacMore has two BRC A–rated facilities, one in Hammond, Ind., and another in Mooresville, Ind. The company can provide both full-scale and pilot-level spray draying in a single facility. PacMore Products, pacmore.com, Booth 424

A lab-size reverse osmosis system from Tangent Membranes Inc., the RO Mini can operate up to 1,000 psi on either 110 volts or 230 volts and has a footprint that requires a 12 in square of space. The process uses tangential flow technology that keeps suspended solids moving across a membrane surface while a small amount of fluid travels through the membrane. The system can be loaded with lower molecular weight membranes, allowing for use across a broad spectrum of filtration, including microfiltration, ultrafiltration, nanofiltration, and reverse osmosis. The membranes are spiral wound and available in many different molecular weights. The RO Mini uses a triplex pump than can operate 24 hr a day/7 days a week. Tangent Membranes, tangentmembranes.com, Booth 1864

A lab-size reverse osmosis system from Tangent Membranes Inc., the RO Mini can operate up to 1,000 psi on either 110 volts or 230 volts and has a footprint that requires a 12 in square of space. The process uses tangential flow technology that keeps suspended solids moving across a membrane surface while a small amount of fluid travels through the membrane. The system can be loaded with lower molecular weight membranes, allowing for use across a broad spectrum of filtration, including microfiltration, ultrafiltration, nanofiltration, and reverse osmosis. The membranes are spiral wound and available in many different molecular weights. The RO Mini uses a triplex pump than can operate 24 hr a day/7 days a week. Tangent Membranes, tangentmembranes.com, Booth 1864

A provider of engineering, execution, installation, and testing of sanitary powder processing systems and components, Powder Process-Solutions supplies customized turnkey solutions for the food, dairy, and nutritional industries. At IFT15, the company will be highlighting its recent addition of the MAGNATTACK line of high-strength, sanitary, self-cleaning, and easy-cleaning magnetic separators. BFM fittings will also be in the spotlight at the booth. These tool-free flexible connectors replace traditional flexible sleeves and hose-clamp assemblies by welding formed spigots to each end of equipment and processing lines and installing a snap-in flexible sleeve that seals internally. Powder Process-Solutions, powder-solutions.com, Booth 4433

J. Peter Clark, Ph.D., CFS, Contributing Editor,

J. Peter Clark, Ph.D., CFS, Contributing Editor,

Consultant to the Process Industries, Oak Park, Ill.