Intelligent Packaging Advances to Meet New Needs

PACKAGING

Intelligent packaging conveys multifaceted information for different entities in the value chain. Brand owners, processors, distributors, and retailers use intelligent packaging to detect fraud and contaminants, ease loading and stock rotation, and enhance marketing. Consumers expect integrity, freshness, and authenticity. Post-consumer package processors require material identification and sorting assistance for efficient reuse and recycling. Essentially, intelligent packaging measures and communicates. Value chain needs, food laws and regulations, and food sourcing and security challenges have led to major innovations in intelligent packaging. Favorable value propositions in intelligent primary, secondary, and tertiary packaging are now possible as technology advances at a dramatic pace. Intelligent food packaging is poised for further applications that communicate shelf life; identify fraud, authenticity and contamination; and enhance the image of food brands.

Communicating Shelf Life

Food spoilage is often dependent on time and temperature because food deterioration occurs as products age and temperatures rise. Lipid oxidation, enzymatic browning, nonenzymatic browning, and microbial growth escalate with increased temperature and time. Time and temperature indicators (TTIs) communicate this deterioration, and although chemical indicators dominate the field, TTIs have grown to include enzymatically and biologically based indicators. The drive toward packaging with integrated sensors and enhanced communication continues with sensors that detect spoilage and then act to ameliorate it.

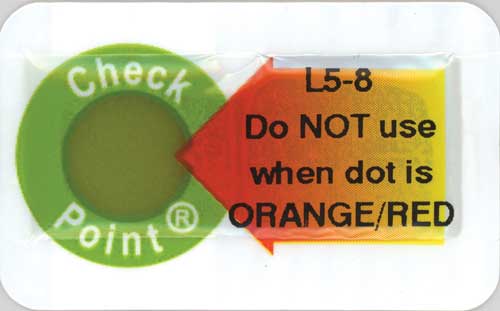

Patrons of Fresh & Easy grocery stores can see the OnVu TTI by Freshpoint, Nesher Haifa, Israel (freshpoint-tti.com), turn from blue to gray via benzopyridine photo-activation as time and temperature increase, indicating that foods are past their shelf life. Food handlers see a similar color indication on food past its shelf life with FreshPoint’s CoolVu when an aluminum layer thins, causing a reaction. Labels such as FreshCode by Varcode Ltd., Ra’anana, Israel (varcode.com), and Tempix by Tempix, Stockholm, Sweden (tempix.com), allow the barcode to fade, inhibiting business-to-business transfer or consumer purchase of poor quality products. When time or temperature abuse has occurred, value chain entities see an irreversible color change from the enzymatic hydrolysis of triglyceride on scallop packages containing the L5-8 Smart TTI Seafood label by VITSAB, Malmo, Sweden (vitsab.com).

Patrons of Fresh & Easy grocery stores can see the OnVu TTI by Freshpoint, Nesher Haifa, Israel (freshpoint-tti.com), turn from blue to gray via benzopyridine photo-activation as time and temperature increase, indicating that foods are past their shelf life. Food handlers see a similar color indication on food past its shelf life with FreshPoint’s CoolVu when an aluminum layer thins, causing a reaction. Labels such as FreshCode by Varcode Ltd., Ra’anana, Israel (varcode.com), and Tempix by Tempix, Stockholm, Sweden (tempix.com), allow the barcode to fade, inhibiting business-to-business transfer or consumer purchase of poor quality products. When time or temperature abuse has occurred, value chain entities see an irreversible color change from the enzymatic hydrolysis of triglyceride on scallop packages containing the L5-8 Smart TTI Seafood label by VITSAB, Malmo, Sweden (vitsab.com).

Sensors detecting degradation by-products and microbial growth provide a direct connection to product condition. These sensors are specific to the food and deteriorative reaction and are ideally integrated into package structure. For example, microbial growth in meat alters certain metabolites that can be measured and indicated by intelligent packaging sensors. SensorQ by Food Quality Sensor International, Lexington, Mass. (fqsinternational.com), determines meat spoilage by measuring total volatile basic nitrogen, and indicators by UPM Raflatac, Helsinki, Finland (upmraflatac.com), sense cysteine loss via hydrogen sulfide generation. Indicators by CheckPack, Brussels, Belgium (checkpack.ugent.be), also measure volatiles released by deteriorating products.

Sophisticated sensors that can be seamlessly integrated into packaging are needed to enhance effective communication within the value chain. Indicators from that incorporate antibodies (for detection) within polymer films. Using this technology, an entire package film that changes color due to the presence of degradation volatiles is possible. A sensor that detects volatile amine formation based on trimethylamine oxide is pending for fish. Consumers can replace sniffing milk to determine whether it is spoiled with seeing a shift from blue to red (at a pH of 6) on a package indicator developed by researchers Abdennour Abbas and John Brockgreitens at the University of Minnesota.

Carbon dioxide sensors such as those made by Transia, Ober-Morlen, Germany (transia.de), indicate loss of freshness as produce respires. Topcryo by Cryolog, Nantes, France (cryolog.com), is a sensor that contains Carnobacterium maltaromaticum and an indicator that changes color as microbial growth increases. Measuring Campylobacter, Salmonella, and Shigella is accomplished with phage receptor binding protein (RBP) sensors. These RBP sensors hold distinct promise due to their environmental stability versus sensors based on optics, bioluminesence, fluorescence, and oscillation. More sophisticated sensors convert biochemical signals to electrical responses that show remaining shelf life. For example, biosensors by Bioett AB, Lund, Sweden (www.bioett.com), are linked with chip-less radio frequency identification (RFID) for readable temperature recording in a manner similar to CoolVu by Freshpoint. The high surface-to-volume ratio of nanofibrous membranes and electrospun sensors and the accompanying advances in graphene printing and conductive polymers also have merit within the entire value chain. More advances in intelligent packaging that detects then reduces deteriorative reactions through the detection of carbon dioxide, antioxidants, or a change in pH are needed.

--- PAGE BREAK ---

Preventing Contamination and Fraud

U.S. and international regulations that focus on reducing food fraud have fueled food packaging innovation that detects contamination and fraud and ensures authenticity. While more predictive techniques to identify potential sources of fraud are being developed, the potential for economically motivated fraud is vast and very much a moving target. Innovations in tracking and tracing in medical packaging detect contamination and ensure authenticity to thwart fraud. These advances are reducing costs, making the technology more viable for the food industry. The cost is ideally shared by those who benefit within the entire value chain from brand owners to consumers. The anti-counterfeit food and beverage market is expected to increase 16% to $62.5 billion. Timestrip PLUS by Timestrip Ltd., Cambridge, England (timestrip.com), Best-by by BASF, Florham Park, N.J. (basf.com), and Novas by Insignia Technologies, Lanarkshire, Scotland (insigniatechnologies.com), indicate the elapsed time since package opening through the use of seal indicators. Since high oxygen levels within a modified atmosphere package often indicate a leak, distributors and retailers are assured of package integrity via oxygen sensors. A fiber tear on paper has been used extensively to indicate that a seal is broken.

Covert and Overt Assurance of Authenticity

Intelligent packaging technologies that verify authenticity throughout the complex value chain of multi-ingredient food products take many forms. When assessments of vulnerability to food fraud identify risk, food packaging can offer reliable control measures. Covert methods of detection include FluxSecure by Schreiner ProSecure, Oberschleissheim, Germany (schreiner-prosecure.com); it is a thin (less than 0.05 mm) customizable glass-coated metal thread that can be inserted in polymer layers, corrugated cases, and folding cartons. The high temperature and environmental resistance of silicon dioxide micro-tags from TruTag Technologies, Kapolei, Hawaii (trutags.com), and tags by Flint Group, Luxembourg (flintgrp.com), and Spectra Systems, Providence, R.I. (spsy.com), can be incorporated into most package forms.

Labeling and printing advances beyond traditional ink, dyes, watermarks, and taggants continue to emerge. SigNature by Applied DNA Sciences, Stony Brook, N.Y. (adnas.com), works with numerous package printers to print plant-based DNA markers for barcodes, watermarks, and microdots. This is a cohesive approach to covert packaging. DNA verification methods based on GenomeTrakr from the National Center for Biotechnology Information will soon be available. Alpvision Fingerprint, Vevey, Switzerland (alpvision.com), offers digital signatures within molded caps and bottles that provide true tracking and tracing of packages. And Unisecure by Systech International, Princeton, N.J. (SystechOne.com), relies on imperfection tracking without disrupting rapid line speeds and allows authenticity to be easily assessed with a five-megapixel smartphone camera.

Overt methods discourage fraud and increase confidence throughout the value chain. Tracking and tracing have been the main focus of overt packaging to prevent food fraud. The return on investment of seafood traceability has been refined by the Global Food Traceability Center’s Seafood Traceability Financial Tool. The benefit of traceability provides rationale for investment in an increasing number of instances. An intelligent fish box with an RFID-integrated TTI by Craemer Group, Shropshire, England (craemer.com), complies with European regulations for tracking seafood to ensure authenticity. A plethora of companies offer tracking and tracing via RFID and near field communication (NFC). Companies that have refined the industry, lowered costs, and improved readability include Alien Technology, San José, Calif. (alientechnology.com); CAEN RFID, Viareggio, Italy (caenrfid.com); Changzhou Institute of Printed Electronics, Changzhou, China (en.czipei.com); Convergence Systems, Hong Kong, China (convergence.com); TempTRIP, Broomfield, Colo. (temptrip.com); Quad Industries, Sint-Niklaas, Belgium (quad-ind.com); and Zebra Technologies, Lincolnshire, Ill. (www.zebra.com). Value chain entities and consumers (who are not often equipped with RFID or NFC readers) can use verification code concepts such as those by authentiQ, San Jose, Calif. (au.thentiq.com); Sicpa, Lausanne, Switzerland (sicpa.com); and VerifyMe, New York, N.Y. (verifyme.com). These codes are increasingly common within the alcoholic beverage industry.

Enhance Brand Identity

Enhance Brand Identity

The increase in the purchasing of food online and delivery services has made maintaining brand presence in consumers’ homes more important. Intelligent packaging is evolving to enable advances in meeting consumer needs and marketing brands. Intelligent packaging takes a fun twist as it enables embodied cognition (unconscious decision making) using sights, sounds, and temperature. Sounds of a solid seal with the “pop” translate to product freshness, but intelligent packaging can do much more to purposefully enhance brand image and market products more effectively to consumers. The motion sensor of CapriSun Monster Alert is integrated into a corrugated shipping case and responds to approaching consumers with sounds and lights that attract attention. Thermochromatic inks change color and reveal images when the product is at the proper temperature to drink or eat.

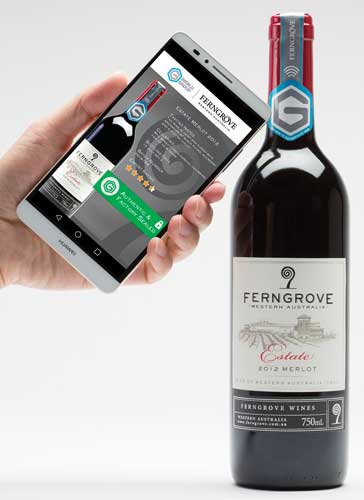

Interactive communication is realized with intelligent packaging. When the NFC OpenSense sensor by Thinfilm Electronics, Oslo, Norway (thinfilm.no), on Johnnie Walker Blue Label Whiskey and Ferngrove wine is tapped with a smartphone, it verifies authenticity and divulges recipes and marketing promotions. The rewritable memory of thin film intelligent packaging allows for usage tracking and data recording, enabling consumers to track product use for dietary and repurchasing needs, and assists with recycling and reuse. Applications within the food industry have the potential to shape brand identity. Brands with a sustainable identity can apply intelligent packaging as well. Recent research by the Polymark Consortium (polymark.org) improves upon existing fluorescence-based detection systems for sorting food-contact polyethylene terephthalate from waste streams to enable efficient reuse and recycling. Intelligent packaging enables recycled content confidence and assurance of sustainability through ease of recyclability and reuse. Information in the form of ultra-variable packaging, in which smart devices communicate to packaging, is poised to revive brand image and address consumer needs.

Claire Koelsch Sand, PhD, Contributing Editor

Claire Koelsch Sand, PhD, Contributing Editor

President, Packaging Technology and Research

Adjunct Professor, Michigan State Univ.

[email protected]