Packaging Shapes Up and Feels Great

PACKAGING

Communication through packaging is challenging in crowded dynamic and digital retail environments. The ability of a package to influence consumer purchase and product enjoyment has been qualitatively and quantitatively explored. Packaging is again adding value with innovations in shape and texture. Recent research demonstrates that package shape and texture alter the consumer product sensory experience in 85% of analyses. New research methods, insight into the complexity of consumer research, computing power, and an intense need have breathed new energy into this almost 100-year-old area of packaging research. Specific package textures and shapes implicitly connect with consumers to communicate product characteristics such as flavor, health, and sustainability. This added package value is appreciated by consumers and brand owners alike. Packaging can also enhance the rational consumer assessment of products and drive improved decision making. Interestingly, texture and shape both guide consumer preferences. This is an area of research with expertise in marketing, packaging materials, neuroscience, and consumer and sensory psychology.

Shaping Up

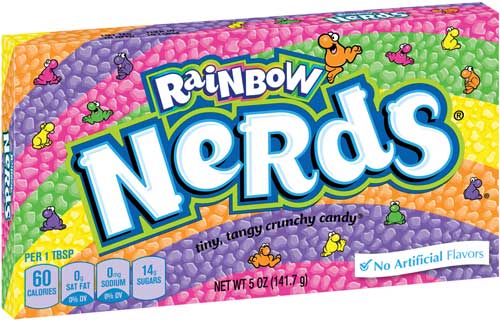

Research has shown that package shape can convey product information and influence taste perception. This is a motivated area of research since package shapes can give subtle clues to consumers making purchase and use decisions. Carlos Velasco, cofounder of Neurosketch, Bogota, Colombia (neurosketch.co), and assistant professor at BI Norwegian Business School in Oslo, Norway, provides an analysis that connects specific food elements to package attributes. “Cross-modal research involving visual/spatial, texture, auditory, and smell can guide package design decisions,” Velasco states. “The connection between taste and shape shows that at an implicit level, consumers match sweetness, friendliness, harmony, and approachability with rounded shapes and sour or bitter notes with rough textures and angular shapes.” Angular and tall packages are associated with bitter, salty, and sour tastes and create the perception of toughness, energy, and strength. Using package shape to convey more specific product attributes deepens the complexity of shape choice. For example, lemon yogurt packaged in a square container was perceived to have a more intense flavor than lemon yogurt packaged in a rounded container.

The ability of the shape of a package to define product perception led to Velasco’s passion for industry-focused multifaceted consumer package research. Early in his career, Velasco was confronted with the challenge of communicating the unique flavor of Colombian fruits that were unfamiliar to non-native packaged juice markets. He realized that the shape of a package could be used to define consumer expectations of the taste, smell, and flavor of juices made from exotic Colombian fruits. Since then, using a refined understanding of the level of congruency between what is expected and what is detected, affective mediation, semantic knowledge, and intense computing power, Neurosketch is developing an expert system of sorts to guide package design decisions. Velasco explains the subtle influence of a package in guiding consumer choice: “For example, consumers have knowledge of what a ketchup bottle shape typically looks like and they recognize it from the shape outline even if it is not labeled. Subtly altering a ketchup bottle to exemplify a new flavor, spicy note, healthful choice, or more sustainably sourced ketchup can be done using color, shape, fonts, sound, and textures. This is the realm of multisensory or synaesthetic packaging design and is packaging design that is based on the systematic connections that exist between the senses.” The potential of synaesthesia in food packaging is high: Desserts by Gu, London, United Kingdom (gupuds.com), are sold in packaging that utilizes synaesthesia, communicating color, shape, texture, and motion.

The ability of the shape of a package to define product perception led to Velasco’s passion for industry-focused multifaceted consumer package research. Early in his career, Velasco was confronted with the challenge of communicating the unique flavor of Colombian fruits that were unfamiliar to non-native packaged juice markets. He realized that the shape of a package could be used to define consumer expectations of the taste, smell, and flavor of juices made from exotic Colombian fruits. Since then, using a refined understanding of the level of congruency between what is expected and what is detected, affective mediation, semantic knowledge, and intense computing power, Neurosketch is developing an expert system of sorts to guide package design decisions. Velasco explains the subtle influence of a package in guiding consumer choice: “For example, consumers have knowledge of what a ketchup bottle shape typically looks like and they recognize it from the shape outline even if it is not labeled. Subtly altering a ketchup bottle to exemplify a new flavor, spicy note, healthful choice, or more sustainably sourced ketchup can be done using color, shape, fonts, sound, and textures. This is the realm of multisensory or synaesthetic packaging design and is packaging design that is based on the systematic connections that exist between the senses.” The potential of synaesthesia in food packaging is high: Desserts by Gu, London, United Kingdom (gupuds.com), are sold in packaging that utilizes synaesthesia, communicating color, shape, texture, and motion.

In a highly visual world, the shape of a package and its design elements can guide consumer purchase, consumption decisions such as sugar or sodium intake, food waste, and sustainable choices. For example, when packages with curved or symmetrical labels that are associated with fitness (in the minds of consumers) are used to label products near the end of their shelf life, consumer purchases increase and this decreases food waste. The subtle suggestion of fitness drives purchases. Subtle cues from angular package elements can influence caloric intake and perhaps decrease overconsumption and obesity. Explicitly labeling a product low-fat decreases taste expectations and perceptions. So package shape can convey low fat in a positive manner. And likewise, a message to consumers that a food is low in sugar, conveyed in a manner that is functionally subliminal (or implicit) using the package, sets up positive subconscious expectations in the minds of consumers.

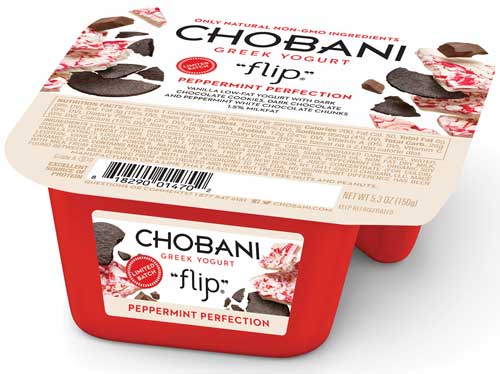

Shape can also enhance decision making. Atypical package shapes have been shown to enhance cognitive processing. When exposed to weak claims, consumers explore product labeling in a more discerning manner. For example, weak claims such as “best choice” or “new formula” or incongruent health claims were refuted by consumers more often when the product was in an atypical package. This means that, for a truly unique product, an atypical package is best since atypical packaging increases the persuasive effect of strong claims on quality judgment. Similarly, a unique package can direct consumers to explore the label of a sustainable innovative food product. For example, Chobani Flip yogurt clearly communicates to consumers that the product has two textures. Studies suggest that consumers are aware of their shortcomings in assessing package sustainability. So research to assess how shape can be used to guide sustainable choices is needed. Further research is also needed to determine how package shape can assist with product comprehension for people who do not understand the language on a package.

Shape can also enhance decision making. Atypical package shapes have been shown to enhance cognitive processing. When exposed to weak claims, consumers explore product labeling in a more discerning manner. For example, weak claims such as “best choice” or “new formula” or incongruent health claims were refuted by consumers more often when the product was in an atypical package. This means that, for a truly unique product, an atypical package is best since atypical packaging increases the persuasive effect of strong claims on quality judgment. Similarly, a unique package can direct consumers to explore the label of a sustainable innovative food product. For example, Chobani Flip yogurt clearly communicates to consumers that the product has two textures. Studies suggest that consumers are aware of their shortcomings in assessing package sustainability. So research to assess how shape can be used to guide sustainable choices is needed. Further research is also needed to determine how package shape can assist with product comprehension for people who do not understand the language on a package.

As urban populations increase, human migration patterns alter due to climate and economic opportunity changes, and migrants resettle in areas with unfamiliar languages. Thus, the need to communicate by package sensory features increases. Interestingly, Velasco’s preliminary research on the cultural impact of package shape on food taste hints that shape-taste associations are universal. Research is evolving rapidly with shape and gustatory connections research by associating research to industry decision making. Research continues in the realm of the homeostatic state of people and the connection between what the body does to prepare to taste, chew, and digest food based on visual assessment of a packaged food.

Texture

Package texture is also extrinsic since it is independent of the physiochemical aspects of food. Use of package texture in food packaging is increasing with the advancement of technology to enable texture and research methods to assess and direct texture. Textures and imagery that encourage touch convey brand image and foster an emotional connection that saves consumers time in supermarkets and at home as it promotes rapid decision making. Textures are also a rational connection to consumer use. For example, textures direct consumers to the locations of package opening and resealing features, and textures can make packages easier to grip. Technology in printing and package fabrication is allowing a focus on the tactile value of packaging. For example, SkinSleever, Morangis, France (skinsleever.com), uses a tactile varnish to define 3D images, and Think4D, Altoona, Manitoba (think-4d.com), uses printed plastic sheets to create textured deep-draw thermoform containers, folding cartons, and labels. These make a direct connection to consumers that is different than traditional surface embossing.

The printing of textured labels using technologies such as the digital N610i UV Inkjet Printer by Domino Printing Solutions, Cambridge, England (dominodigitalprinting.com), provides the agility of printing during manufacturing. Direct laser engraving of ethylene-propylene elastomers offers depth control to tight specifications, and this technology is replacing photopolymers. A joint initiative of HELL Gravure Systems, Kiel, Germany (hell-gravure-systems.com), and ContiTech, Hanover, Germany (contitech.de), engraves elastomers using high-speed dual-beam engraving technology. ContiTech recently demonstrated the flexographic printing of solar cells, which has much potential in packaging.

Methods to assess the impact of texture are pinpointing exact textures to match a brand or consumer need. For example, electroencephalograms can measure cognitive activity, electrocardiograms can measure favorable responses, electromyography can determine positive facial muscle reactions, and psychogalvanic analysis can measure a person’s level of interest. These new test methods are moving from experimental status to actual package design. Because these methods can provide specific direction, package design decisions will be less iterative and hesitant. This can save time and resources spent on the package design process while enhancing the value of the package. For example, research on package texture indicates that roughness and suppleness are associated with natural products. Thus, a package that exhibits these textural attributes would implicitly communicate to consumers that a product is natural.

For products that are contained in packages while they are consumed, packaging that aligns with the product has a major impact on consumer perception. For example, research shows that packages with rough texture translate to more favorable crunch ratings on a crunchy product. Likewise, when texture conveys health, it is a more positive connection than the negative perception created by the term “low fat” stated on a label. Employing new research methods and technologies to refine package texture and shape will drive consumer choice.

Claire Koelsch Sand, PhD, Contributing Editor

Claire Koelsch Sand, PhD, Contributing Editor

President, Packaging Technology and Research

Adjunct Professor, Michigan State Univ.

[email protected]