How Tofu Is Processed

PROCESSING

This month’s Processing column will continue the theme of “How Is It Processed?” The column will focus on tofu, which is sometimes called “the cheese of Asia.” It is a nutritious, protein-rich bean curd made by coagulating soy milk. There are many different types of tofu, and they are processed in a variety of ways. Methods to produce various types of tofu will be described, as will effects of processing on the final product properties of this healthy food.

History, Market, and Nutrition

Tofu originated in China. It is thought to have been developed first by Liu An, a Han Dynasty prince who lived during the second century B.C. During the 1960s, the Japanese Food Research Institute recommended modernizing and standardizing tofu production throughout Japan. This effort led to significant advances in tofu processing. Although tofu has been made in the United States since the beginning of the 20th century, its consumption didn’t increase rapidly until around 1970.

Today, the United States is one of the largest producers of soybeans in the world. Yet tofu is consumed at relatively low levels in the United States compared with other countries. Tofu sales during 2014 were $274 million in the United States, according to the SoyFoods Association of North America. Tofu is largely consumed as an ethnic food or as a high protein, vegetarian alternative to meat and cheese. Tofu can also be found in a variety of other foods including hot dogs, burgers, ice cream, sauces, desserts, and shakes.

There are numerous types of tofu, including extra firm, firm, soft, and silken tofu. Extra firm and firm tofu have textures similar to cooked meat and raw meat, respectively. Their rigidity lends them to use in stir-fry dishes, grilling, and soups. Soft and silken tofu are fragile and have soft and silky textures. Soft and silken tofu can be blended into sauces or used as desserts or drinks. Other types of tofu include fermented tofu, flavored tofu, fried tofu, and frozen tofu.

Nutritionally, tofu is cholesterol free, low in saturated fat, and high in protein. On a moisture-free basis, tofu contains about 50% protein and 27% fat, most of which is polyunsaturated fatty acids. Tofu is also a good source of calcium. The U.S. Food and Drug Administration approved a soy health claim in 1999, and tofu has been shown to have numerous health benefits (Rekha and Vijayalakshmi 2013).

Tofu Processing

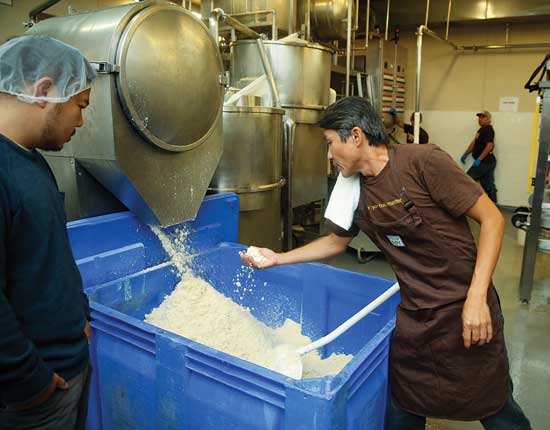

• Soaking, Grinding and Cooking the Soybeans. Tofu production begins with soaking and grinding the soybeans. Soybeans can be soaked anywhere from 9 to 10 hours at lower temperatures (22°C) or 4 to 6 hours at higher temperatures (32°C). If the beans are ground prior to soaking, the soaking time can be reduced. In some cases, soybean hulls are removed prior to grinding. Dehullers use soft, rotating rubber rollers to remove the hulls. This improves the color and reduces the beany flavor of the final tofu (Kang et al. 2014). In addition, soybeans can be pretreated with sodium bicarbonate to decrease beany flavor and increase smoothness of the final tofu (Rekha and Vijayalakshmi 2013). Grinding can be performed using a variety of types of equipment, including micro-cutters, hammer mills, and other similar devices. The more thoroughly ground the slurry, the more protein extracted and the better the yield. Next the ground slurry is cooked, typically to 100°C to 110°C for 3–10 min. This process denatures the soy protein and removes volatile beany flavors.

• Separating the Soy Milk. Then the soy milk needs to be separated from the solid soy pulp or fiber, also known as okara. This can be done through centrifugation and/or filtration. Alternately, the soy milk can be separated from the okara prior to heating. In some cases, the soy milk is concentrated prior to coagulation. This can be performed though a variety of processes, including heat, reverse osmosis, vacuum evaporation, or nanofiltration. The texture of the final tofu depends largely on the solid content of the soy milk prior to coagulation. Soy milk can be concentrated to between 10% and 22% solids (Kang et al. 2014).

• Separating the Soy Milk. Then the soy milk needs to be separated from the solid soy pulp or fiber, also known as okara. This can be done through centrifugation and/or filtration. Alternately, the soy milk can be separated from the okara prior to heating. In some cases, the soy milk is concentrated prior to coagulation. This can be performed though a variety of processes, including heat, reverse osmosis, vacuum evaporation, or nanofiltration. The texture of the final tofu depends largely on the solid content of the soy milk prior to coagulation. Soy milk can be concentrated to between 10% and 22% solids (Kang et al. 2014).

• Coagulating the Soy Milk. The coagulation step is the most important step in the manufacture of tofu. Its purpose is to coagulate the protein and oil in the soy milk. Different coagulants are used to produce different types of tofu. The three main categories of coagulants that are commonly used are salts, acids, and enzymes. They can be used alone or in combination. Coagulants are typically added at concentrations between 1.5 and 5.0 g/kg while stirring the soy milk at temperatures between 60°C and 90°C. Stirring the milk for the first 5 seconds of coagulation improves yields (Rekha and Vijayalakshmi 2013).

--- PAGE BREAK ---

The two most commonly used salt coagulants are 1) calcium sulfate (gypsum) and 2) magnesium chloride combined with calcium chloride (nigari salts). Calcium sulfate is the most traditional and widely used coagulant for tofu. It is chosen as a coagulant primarily because it does not mask the taste of the soybeans, allowing premium tofu makers to preserve and highlight the flavors and fragrances of beans prized in Asia. Magnesium chloride and calcium chloride salts are more soluble than calcium sulfate and produce smoother-textured tofu. In Japan, nigari, which consists primarily of magnesium chloride, is produced from seawater. Sodium chloride is removed and water is evaporated to yield the nigari white powder. Nigari may also contain small amounts of magnesium sulfate, potassium chloride, and calcium chloride depending on how it is made. The variable composition of nigari can be a challenge for large-scale tofu manufacturing.

Edible acids can also be used to coagulate tofu. The most commonly used acid is glucono delta-lactone (GDL). GDL is specifically used for silken or soft tofu because it coagulates rapidly, allowing silken tofu to be made inside the container without an air-gap, which prevents the silken tofu from breaking during transport. Prior to the invention of GDL and its use in silken or soft tofu, tofu makers couldn’t reliably transport soft tofu. GDL is commonly used with soy milk having high solids levels (10%–13% instead of 5%–10% in regular tofu). Soft and silken tofu filled containers are heated in a water bath at 80°C–90oC for 40 to 60 min to allow the GDL to transform into gluconic acid, which causes the protein to coagulate as a homogeneous gel, with no whey separation (Berk 1992). GDL leaves a slight sour taste in the finished product. It can be used in combination with calcium sulfate to produce a soft and smooth textured tofu. Other acids such as acetic and citric acid can be used as well, but they frequently leave undesirable flavors.

Enzymes may also be used as coagulants. Papain and proteases (alkaline and neutral) are possible coagulants. These enzymes catalyze crosslinking between amino acids in the proteins.

A variety of other factors affect the coagulation process. One of these is the addition of natural oils in combination with the coagulant using a high shear mixer to produce an emulsion or suspension containing the natural oil prior to coagulation (Kang et al. 2014). The protein subunits present in the soybeans also affect coagulation. Tofu made from soybeans having high 11S/7S subunit ratios has a hard texture at lower coagulant concentrations than tofu produced from soybeans having low 11S/7S ratios. These require more coagulant for the maximum hardness (Onodera et al. 2009).

A variety of other factors affect the coagulation process. One of these is the addition of natural oils in combination with the coagulant using a high shear mixer to produce an emulsion or suspension containing the natural oil prior to coagulation (Kang et al. 2014). The protein subunits present in the soybeans also affect coagulation. Tofu made from soybeans having high 11S/7S subunit ratios has a hard texture at lower coagulant concentrations than tofu produced from soybeans having low 11S/7S ratios. These require more coagulant for the maximum hardness (Onodera et al. 2009).

• Pressing the Tofu. Traditionally, tofu curds were pressed with hand-turned screw presses or simple lever presses. Modern systems use hydraulic presses or centrifuges. For standard firm and extra firm tofu, the soy curd is pressed to release the excess liquid (whey permeate) using cheese cloth or muslin. The curd is pressed to varying degrees depending on the desired final tofu texture. Firmer tofu is pressed with higher loads than less firm tofu. Tofu can then be cut into its final piece sizes and flavored or further processed as desired. Soft and silken tofu does not require pressing. In these cases the tofu is coagulated directly in the final package as described earlier.

• Pasteurizing the Tofu. Pasteurization is frequently used to extend the shelf life of the final tofu product. Tofu can also be processed using ultra high temperature (UHT) technology and packaged aseptically to further extend shelf life.

Recent Innovations in Tofu

Recent research has focused on better utilization of the coproducts of tofu processing. These coproducts contain healthy proteins and fats that taste good and can be beneficial to human health. Methods to stabilize wet okara in an efficient manner are being studied, as are value-added final product uses for okara in foods. Better utilization of soy permeate in foods is also being explored. Finally, sprouted tofu is gaining popularity. This is tofu made from soybeans that have germinated. Sprouted tofu has a less beany/grassy flavor and better aroma. As worldwide needs for more sustainable protein sources continue to rise, tofu represents a versatile, nutritious processed food that is ripe for innovation and expected to continue to grow in popularity during the years ahead.

Tara McHugh, PhD, Contributing Editor

Tara McHugh, PhD, Contributing Editor

Research Leader, USDA Agricultural Research Service, Albany, Calif.

[email protected]

References

Berk, Z. 1992. Section 9.5. http://www.fao.org/docrep/0532e/t0532e10.htm#9.5.

Kang, C. S. et al. 2014. Tofu Manufacturing Process. U.S. Patent Application 20140302199 A1.

Onodera, Y. et al. 2009. “Homogeneity and Microstructure of Tofu Depends on 11S/7S Globulin Ratio in Soymilk and Coagulant Concentration.” Food Sci. Tech. Res. 15(3): 265–274.

Rekha, C. R. and G. Vijayalakshmi. 2011. “Influence of Processing Parameters on the Quality of Soycurd (Tofu).” J. Food Sci. Technol. 50(1): 176–180.