Cold Plasma Technology Close-Up

PROCESSING

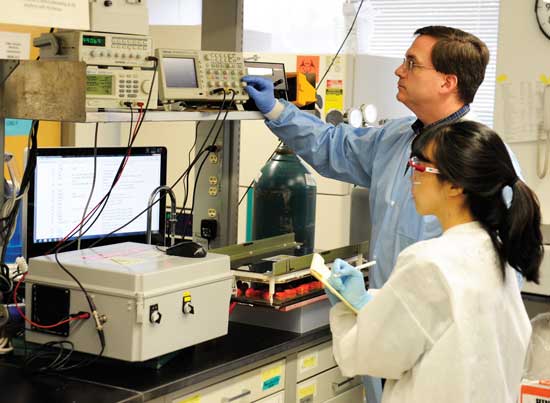

This month’s column discusses cold plasma, an emerging technology that has potential applications as an antimicrobial process for fresh and fresh-cut fruits and vegetables, low-moisture foods, and food contact surfaces. Brendan A. Niemira, the coauthor of this month’s column, is the research leader of the Food Safety and Intervention Technologies Research Unit at the U.S. Dept. of Agriculture’s Eastern Regional Research Center in Wyndmoor, Pa. He and his team have been actively developing and evaluating cold plasma technologies independently and through collaborations.

An Introduction to Cold Plasma

An Introduction to Cold Plasma

Although plasma is a fourth state of matter, distinct from the solids, liquids, and gases of everyday experience, for practical usage it may be regarded as a form of ionized gas. Such plasmas are generated by energizing gases or gas mixtures, usually with high voltage electricity or microwaves. Unlike more familiar hot plasmas, such as flames or electric arcs, the plasmas generated for use in food processing are designed to operate as nonthermal antimicrobial interventions (i.e., at temperature ranges close to room temperature), which do not rely on heat for inactivation and which are typically gentler on treated foods. A variety of terms are used to describe plasmas of this type: dielectric barrier discharge plasma, nonthermal plasma, atmospheric cool plasma, etc. Here we use the general term “cold plasma” with additional specification as needed.

Cold plasma’s antimicrobial modes of action are primarily related to 1) chemical reactions with cellular structures, 2) ultraviolet (UV) damage of cellular components, and 3) UV-mediated DNA strand breakage. The predominance of one mode in a mixed reaction response depends on a number of factors, including the energy state of the cold plasma, the conditions of treatment, the feed gas used to generate the plasma, the atmospheric pressure of the treatment environment, and the electrode shape and design. These factors, in addition to the varying influence of the commodity and the specific pathogen being targeted, have made investigations into the mode of action one of the key areas of ongoing cold plasma research.

Equipment

A wide array of technologies and equipment designs to generate cold plasma are being actively developed and evaluated. The general principles are that energy is applied to a gas in order to ionize it to plasma, which serves to sanitize the target. There are many factors that determine the operation and efficiency of any given gas ionization process, a complexity that warrants caution in making generalizations about cold plasma systems. However, these can be roughly divided into two classes: those that operate at atmospheric pressure and those that rely on applying a partial vacuum. Gases are more readily ionized at lower pressures; this allows a greater volume of plasma to be generated at a given voltage. Offsetting the advantage in power is the additional equipment required for partial-pressure chambers and associated controls. The gas to be used for cold plasma process is also a critical factor. Some gases, such as helium, argon, and neon, ionize more readily than other gases, such as oxygen, nitrogen, and air. Thus, helium cold plasma can be created with less electricity than air plasma. In this case, the tradeoff is in the enhanced antimicrobial efficacy of cold plasmas, which contain oxygen ions and monoatomic oxygen singlets.

With these factors in mind, cold plasma systems intended for food processing can be further categorized. If the reactive species created in the plasma ionization process do not have the opportunity to react with the food target, they will, in the course of moving away from the electrodes, recombine with other chemical species within the plasma plume. Therefore, these systems can be understood based on where the food is with respect to the point of cold plasma generation, and therefore the different levels of reactivity observed when the food is 1) at some significant distance from the point of generation, 2) relatively close to the point of generation, or 3) within the plasma generation field itself. Systems in the first category rely on moving the cold plasma to the food, using airflow, magnetic fields, electrical potential, or other means. Electrodes are physically separate from the food, which can simplify design and operation and increase the flexibility of the shape of products to be treated. However, during the time of flight, the most reactive chemical species are lost to recombination, leaving a “quenched” plasma composed of lower activity, longer-lived chemical reaction products. Systems in the second category apply active plasma directly to the commodity. A much greater number of plasma products are available for interaction with the food, with greater potential for antimicrobial efficacy. For systems in the third category, the food is positioned between the plasma generation electrodes, exposing it to the highest possible intensity of free electrons, radicals, ions, and UV radiation. A challenge with these systems is that presence of the commodity within the plasma field alters the ionization pathways between the electrodes and can lead to stray discharges across the surface of the product or even through the product itself. Crucial for this type of approach is the design of electrodes, including their shaping, material selection, spacing, operational voltage control, and other factors.

Cold Plasma Applications

Cold Plasma Applications

Plasmas have been used in a variety of industries, including textiles (improved dye adhesion to fabrics), printing (improved ink adhesion), materials processing (mating of incompatible laminate polymers), electronics (chemical-free cleaning), and many others. Adapting these technologies to the needs of the food industry presents unique challenges. The fragility, heat sensitivity, sensory and nutritional standards, and throughput requirements for food commodities set performance criteria that are unlike those of other industries.

Much research has been devoted to cold plasma–mediated inactivation of human pathogens such as Salmonella, Escherichia coli O157:H7, non-O157 STECs, Listeria monocytogenes, and norovirus. Results reported with different types of equipment vary in maximum kill obtained, speed of treatment, and sensory impact on food. Probable cost of scale-up to pilot-scale or commercial development is based on feed gas and equipment used. While this creates a challenge in evaluating and comparing new research results as they are reported, it also indicates the diversity of cold plasma technologies that are under investigation. Depending on the necessary performance criteria and the requirements of time, space, and throughput for a given commodity, there is an array of technologies that may be suitable for optimization. Unlike aqueous sanitizing solutions, cold plasma is a waterless process.

The time required for a given target level of microbial inactivation is strongly dependent on the nature of the cold plasma system used, the condition of the target organism, and the circumstances of application. For example, a recent study using a quenched “afterglow” corona discharge apparatus demonstrated D-values for human pathogens on the order of hours: 3.6 hr for E. coli O157:H7, 7.8 hr for Salmonella typhimurium, and 11.8 hr for L. monocytogenes. In this system, cold plasma was generated via a high-voltage electrode array at a distance from the bacterial target and blown into a closed chamber with a fan system. Over the 24 hr course of the study, maximal reductions of 3.5 logs were obtained. It should be noted that while such extended times would not be readily compatible with in-plant processing, they may be suitable for incorporation into a treatment applied during cold storage or shipping. Another study used a more direct treatment by corona discharge to reduce aerobic bacteria and molds on dried seaweed by approximately 2 logs in 20 min. Still another recent study using a gliding arc plasma jet, an apparatus that deposits cold plasma onto surfaces more forcefully than corona discharges, showed that even very short treatments (15 sec or less) led to significant inactivation of pathogen biofilms on inert surfaces. Salmonella biofilms were reduced by 2.1 logs, while E. coli O157:H7 biofilms were reduced by 3.0 logs. This type of treatment may be suitable for food contact surfaces and for incorporation into plant sanitation protocols.

In-Package Treatment

One developing area of cold plasma technology is systems designed to generate plasmas inside packaged foods, operating as a terminal processing step. The advantage of this approach is that it serves as an additional sanitizing hurdle after the risks of contact cross-contamination are eliminated. Studies with externally energized electrodes were able to create antimicrobially effective plasmas for packaged strawberries and romaine lettuce, yielding ~2 log reductions of E. coli O157:H7 and aerobic bacteria following a treatment of 5 min. These reductions were obtained without sensory impact on the produce.

The Future of Cold Plasma

Although recent results are promising, continued research and development efforts are needed for cold plasma to move toward commercialization. Some key areas include determination of modes of action; optimization of gas mixtures to balance power consumption, antimicrobial efficacy, and feed gas cost; and improving speed, efficacy, and compatibility with existing food handling and packaging systems. Parallel research tracks will see the development of cold plasma systems intended to sanitize packaging materials and in areas where sanitizer-resistant pathogen biofilms form, such as food contact surfaces, drains, and conveyor belts. With these developments on the horizon, cold plasma is positioned to be a flexible, effective sanitizing process for the food processing industry in the near future.

Tara McHugh, PhD, Contributing Editor

Tara McHugh, PhD, Contributing Editor

Research Leader, USDA Agricultural Research Service, Albany, Calif.

[email protected]

Brendan A. Niemira, PhD, is research leader of the Food Safety and Intervention Technologies Research Unit at the U.S. Dept. of Agriculture’s Eastern Regional Research Center in Wyndmoor, Pa. ([email protected]).