Structural changes in fried foods; Bilberry byproduct adds fiber

NEWS

Structural changes in fried foods

Structural changes in fried foods

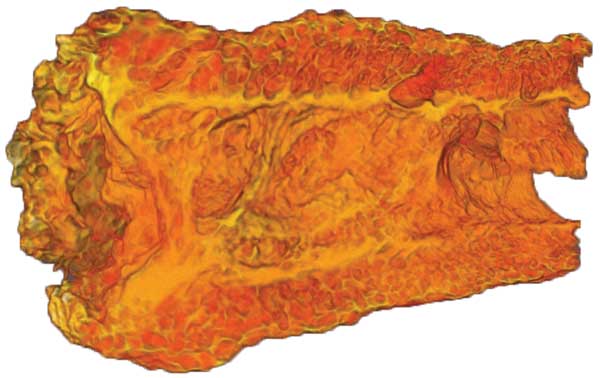

A study published in the Journal of Food Science took an in-depth look into the microstructural changes that occur when foods are fried.

During deep frying, as food is immersed in hot oil, water in that food quickly evaporates and steam pressure builds. This pressure affects the microstructure, including the porosity—the number and size of pores in the food as well as the twistiness of the pathways between those pores (tortuosity). This determines how and how much oil gets taken up into the food.

To understand the distribution of oil better, the researchers conducted a study using X-ray microcomputed tomography (micro-CT) to gain 3-D images of the microstructure of fried potato disks after they had been fried for various lengths of time. The researchers observed that as frying time increased, pore size increased, allowing for greater uptake of oil. They also saw a correlation between oil content and how the network of pathways between the pores changed throughout the frying time. These pathways act like channels for water and vapor flow and oil penetration in the food.

“Our long-term goal is to provide fundamental information that [the] food industry can utilize to reduce the fat content of fried foods without compromising with taste and texture,” says Pawan Singh Takhar, one of the study’s authors. Though the researchers did not specifically focus their study on how to make fried foods healthier, Takhar says that consumers can reduce the amount of oil that ends up in their foods by blotting fried foods with paper towels and being careful not to cook them for too long.

“For frying each food there is some optimum time that depends upon the type of food, its structure, initial moisture content, frying temperature, and etc.,” he explains. “Frying longer than the optimum time could result in greater oil uptake and undesirable taste and texture in the food.”

Identifying gluten from specific sources

Accurate labeling of the gluten content in food products is crucial for gluten-intolerant consumers, such as those with celiac disease. The tests available for detection, however, primarily focus on detection in wheat, but it’s just as important to accurately measure gluten coming from sources like rye and barley. A recent Journal of Food Science study examined the creation of immunoassays utilizing grain-specific antibodies and calibrators that may help improve gluten quantitation and characterized the polyclonal antibodies developed for grain-specific gluten detection.

In the study, the antibody cross-reactivity to proteins from grains of wheat, rye, barley, oat, and corn was assessed by Western blot. The researchers found that grain-specific antibodies (anti-gliadin, anti-secalin, and anti-hordein) exhibited high reactivity toward their respective grain proteins with negligible immunoreactivity to other grain proteins, meaning that it was possible to isolate gluten coming from each source.

“Identifying the source of the gluten could help in the future in more accurately quantifying gluten in a food because accuracy can be unreliable when multiple grain sources are contained in a food, whether intentionally or by cross-contamination,” says Girdhari Sharma, one of the study’s authors. Being able to accurately quantify gluten levels in foods is especially important for consumers with celiac disease, for whom the presence of gluten interferes with nutrient absorption and damages the small intestine.

--- PAGE BREAK ---

Bilberry byproduct adds fiber

Bilberry byproduct adds fiber

A byproduct of bilberry juice production can be used to add fiber to food products, according to research conducted by research and technology company VTT Technical Research Centre of Finland.

Bilberry press cakes, which are left over from pressing bilberry juices, are an underused, low-cost raw material. Dry bilberry press cakes can contain up to 59% dietary fiber, most of which is insoluble. Researchers found that press cakes could be used to substitute whole berries in muffin applications for a 6% dietary fiber content without compromising sensory qualities and added to extruded snack products to create a crispy product. In addition, bilberries contain high levels of anthocyanins, which have anti-inflammatory properties.

Food safety no longer ‘business as usual’

The Food Safety Modernization Act and its final rules will render business as usual in the food industry obsolete, according to Stephen Ostroff, who spoke at the 2016 National Food Policy Conference in April and who assumes the position of deputy commissioner, foods and veterinary medicine, U.S. Food and Drug Administration (FDA) in June.

“It is important to educate well before we regulate,” said Ostroff, explaining why the FSMA rules have taken so long to implement fully.

In addition, he said that the success of FSMA depends on sufficient funding. Ostroff said that besides ensuring the safety of the U.S. food supply, the FDA is also committed to addressing the injudicious use of medically important antibiotics in food animals in order to stem the tide of antimicrobial resistance, reducing the amount of sodium and added sugars in foods, and decreasing the incidence of obesity among U.S. consumers.

Vegetable surfaces resist pathogens

The microscopic structure of different types of vegetables affects how pathogens adhere to the produce, according to a study that appeared in PLOS ONE.

In the study, researchers exposed 24 of the most common salad vegetables in the United States to a swine virus that mimics rotavirus. They found, perhaps counterintuitively, that vegetables with three-dimensional crystalline wax structures on the leaf cuticle harbored significantly fewer virus particles after rinsing. Researchers had expected the virus would be able to hide within the structure, but on the contrary, the waxy layer made the vegetable surface more hydrophobic and encouraged the pathogens to bond with OH groups in the rinse water, making them easier to wash away.

“Viruses are literally everywhere, causing many opportunities for infection. But the information from this study can be used down the road to select or breed for varieties that might have the capacity to reduce adherence of these particles,” says University of Illinois geneticist Jack Juvik, one of the study’s authors.

The researchers are currently conducting experiments to determine what factors control sanitation efficacy for produce contaminated with viruses, according to study author Helen Nguyen, a University of Illinois associate professor. She adds that certain vegetables such as kale, which have been identified as superfoods, naturally resist pathogens, and consumers should be encouraged to eat this kind of vegetable.

News Bites

• American Egg Board named Anne Alonzo as its president and CEO.

• Archer Daniels Midland Co. has named Erik Heggen the new president of Refined Oils. It also opened a state-of-the-art flavor creation, application, and customer service facility in Cranbury, N.J.

• Aseptia completed the sale of its Wright Foods and Carolina Dairy manufacturing operations.

• Barry Callebaut Group announced it has completed an expansion project at its chocolate factory in American Canyon, Calif.

• Batory Foods will break ground on a 678,000-square-foot facility in Wilmington, Ill.

• Corbion completed the pre-engineering for a polylactic acid polymerization plant and is entering the basic engineering phase. It also announced the opening of an advanced R&D and applications laboratory in Gorinchem, the Netherlands.

• General Mills plans to more than double its organic acreage sourcing for ingredients to reach its goal of 250,000 acres by 2019.

• ICL Food Specialties opened its newly expanded research and development center in St. Louis.

• Ingredion was recognized by the Ethisphere Institute, a global leader in defining and advancing the standards of ethical business practices, as a 2016 World’s Most Ethical Company.

• Lawrence Foods received a 2015 Quality and Service Award from Dot Foods.

• Leatherhead Food Research completed the first phase of its headquarter relocation in Epsom, Surrey, England.

• Nellson Nutraceutical announced a reorganization of its facilities, including relocating its corporate headquarters to Anaheim, Calif., and transferring the Salt Lake City powder operations to the Anaheim manufacturing facility.

• Nestlé will build an R&D center in Askeaton, Ireland, to develop new powdered milk-based products for infants and mothers. In addition, Nestlé Vietnam began construction on a new factory in Hung Yen province.

• Nous Sustainable Food Innovation received FSSC 22000 Food Safety System certification.

• Palsgaard A/S achieved CO2-neutrality at its Danish plant during 2015.

• Salt Works launched a brand-new B2B wholesale website, seasalt.com/wholesale/ingredient-salt.

• Sensient Natural Ingredients earned Non-GMO Project Verification for its California-grown garlic, onion, and parsley.

• Solazyme announced that it is focusing the company exclusively on food, nutrition, and specialty ingredients to harness its algae innovation platform and changed its name to TerraVia.

• tna opened a new 950-square-meter facility in Mexico City that includes a state-of-the-art demonstration center.

Melanie Zanoza Bartelme, Associate Editor

Melanie Zanoza Bartelme, Associate Editor

[email protected]