Packaging That Communicates Freshness

PACKAGING

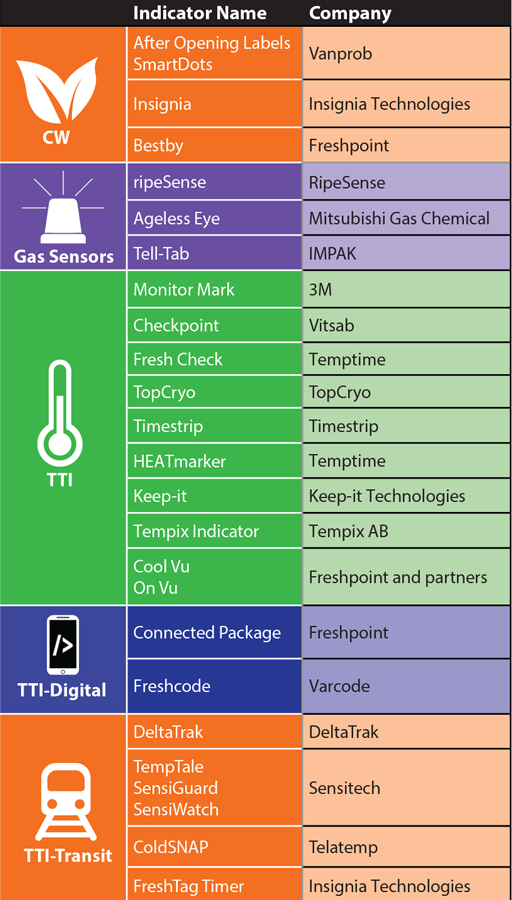

Intelligent packaging communicates to packaging converters, food manufacturers, distributors, retailers, consumers, and post-consumer package handlers. Freshness indicators are used in some intelligent packages to communicate the shelf life of products within the value chain. However, because much food waste occurs after the purchase of food products, it is essential to ensure that freshness indicators also communicate to consumers. The use of freshness indicators that indicate shelf life after opening and freshness can be expanded to decrease food waste and increase the value of packaging.

Intelligent packaging communicates to packaging converters, food manufacturers, distributors, retailers, consumers, and post-consumer package handlers. Freshness indicators are used in some intelligent packages to communicate the shelf life of products within the value chain. However, because much food waste occurs after the purchase of food products, it is essential to ensure that freshness indicators also communicate to consumers. The use of freshness indicators that indicate shelf life after opening and freshness can be expanded to decrease food waste and increase the value of packaging.

Shelf Life

Research indicates that the incidence of food waste would be reduced if the shelf life of food products were not guesswork. Intelligent packaging containing consume-within (CW) technology can communicate to consumers the shelf life of products after they are opened. Many types of indicators exist to communicate this type of information. Insignia carbon dioxide indicators convey freshness after a package is opened. This indicator has polymer-based labels embedded with a colorimetric carbon dioxide indicator that is activated upon opening. After a product is opened, a color change from beige to purple occurs in four days due to the temperature-dependent desorption of carbon dioxide at 41° F. The indicators Food Fresh and BestBy convey shelf life of products after opening in a similar way. Research continues to advance on indicators that communicate time until the end of shelf life to consumers. For example, one indicator is activated by peeling off its ammonia-charged layer to start temperature-dependent diffusion of ammonia. The indicator can be stored for six months and is reusable. An anthraquinone-based and ultraviolet light–activated oxygen indicator changes color from yellow to green in 42 hours at 40° F. These innovations in on-package indicators will compete with products that provide consumers an indication of meat freshness, such as FOODsniffer.

Freshness

In-package freshness prior to opening is determined by different markers that indicate the onset of spoilage. These markers include pathogens, amines, degradation byproducts, carbon dioxide, and oxygen. There are various intelligent packaging technologies that detect and communicate product freshness.

Biosensors such as ToxinGuard and Food Sentinel System are very promising; however, there has been no commercial application of these types of biosensors. Likewise, concepts such as SensorQ, an anthocyanin-based pH sensing technology with the ability to measure volatile amines from microbial activity, have lacked solid commercialization. Indicators developed to monitor the shelf life of fish communicate when spoilage occurs and feature colorimetric sensors to monitor volatile amines, pH and conductivity electrodes to monitor volatile amines, and anthocyanin-based dyes. Research on and development of indicators placed on packages is producing new technologies such as an indicator that employs vanillin for the detection of several species of molds, yeasts, and bacteria.

Ethylene gas, optical sensors, acetaldehyde, and acetic acid are being used in intelligent packaging sensors that indicate the ripeness of fresh produce. For example, a bromophenol blue–embedded bacterial cellulose membrane senses ripeness in guava. And RipeSense can detect the optimal ripeness of pears based on pH-based color change.

Microbial spoilage, fermentation, ripeness, and degassing can all cause changes in the level of carbon dioxide in food packages, which is why carbon dioxide indicators are suitable for monitoring the freshness of many food products. High-moisture products are the best candidates for dye-based carbon dioxide–indicator applications, but phenol red or M-cresol purple printed on cellulosic and plastic layers do not require moisture when non-volatile phase transfer agents are used. Dyes on paper-based structures are more accurate than dyes printed on polymer structures. Interestingly, wheat-gluten carbon dioxide sensors have been found to possess unique dielectric properties.

Oxygen indicators are used to monitor integrity throughout the supply chain. For example, they are used in modified atmosphere packaging to detect leaks in the seals and structure of packages. Oxygen indicators such as AgelessEye and Tell-Tab tablets detect oxygen within a package. Titanium oxide–based, ultraviolet light–activated, and inkjet printable colorimetric oxygen indicators suitable for products with reduced-oxygen with high-moisture content such as fresh meat also have potential.

Time and Temperature

Because time and temperature govern many degradative reactions in foods, there are many intelligent packaging indicators that assess these parameters. These indicators monitor temperature with upper or lower limits or integrate time and temperature to indicate the cumulative effect on the freshness parameter of interest. Color development, decomposition, and mechanical deformation translate into an indicator that can be visualized. The working principles of time and temperature indicators are based on temperature-dependent enzymatic, chemical, mechanical, physical, or microbiological action. Major concerns associated with time-temperature indicators are related to activation mechanisms and false indications. The time-temperature indicators that remain available have optimal costs and functional capabilities, and more are in development.

Indicators that show when temperature has exceeded appropriate values are temperature-abuse indicators. They are often placed on the outside of individual product packages or tertiary packaging such as corrugated boxes. They assist in monitoring the actual temperatures that products experience in distribution and convey whether temperatures have extended beyond a specific temperature range. For example, produce needs to be kept within a certain temperature range to control maturation and product quality. For products such as seafood, ensuring the temperature stays below a certain value is a food-safety requirement.

Time-temperature indicators rely on the cumulative effect of temperature and the Arrhenius relationship of reactions in food. Diffusional time-temperature indicators contain a microporous structure. Commercial examples of diffusional time-temperature indicators include MonitorMark, which employs fatty-acid ester diffusion on a wick, and Timestrip, which regulates the flow of a blue dye through a membrane at different rates in solid and liquid form. Even though the commercial viability of diffusion-based time-temperature indicators is great, they do have functional issues such as aging of the porous diffusion wick and color discharge. For example, the evaluation of a time-temperature indicator based on the diffusion of isopropyl palmitate on a microporous film to determine whether it matched the total count of aerobic bacteria in juice suggested that the indicator was viable only at inappropriate temperatures above 56° F.

FreshCheck and TOPCRYO are often used for frozen foods. CoolVu indicators measure the time that is remaining in days or years. Keep-it indicators show the number of days until shelf life ends, beginning when they are applied at the manufacturing sites. TempixAB inhibits consumer purchase by making the barcode unreadable when a defined time and temperature have been reached. Photochromic time-temperature indicators such as OnVu are activated by ultraviolet light and have applications for meat that is shipped while frozen and displayed in refrigerated cases at retailers.

Enzymatic-based time-temperature indicators offer advantages such as low cost, stability, and control. Enzyme type, substrates, and activating agents such as coenzymes, pH, and buffer solutions are finetuned to represent actual degradation in foods. Modification of enzyme types and substrate concentrations enable enzyme-based time-temperature indicators to reflect shelf life. CheckPoint is a lipase-mediated time-temperature indictor based on hydrolysis of lipids creating a temperature-dependent color change. CheckPoint can be used on food items that are stored up to 1-1/2 years at 40° F. And microbial-based time-temperature indicators can convey the degradation kinetics that occur in foods. For example, a lactic acid bacterium within certain time-temperature indicators detects the onset of off-flavors and microbial growth. Even though these types of time-temperature indicators can measure variables that indicate the degradation of food quality, accurate analyses are often challenging due to the complex nature of food matrices. Time-temperature indicators such as FreshCheck and HEATmarker, which have acetylene polymers, are widely used; however, polydiacetylene compounds may have toxicity issues and are adversely affected by light.

Product Tracking

Indicators communicate time and temperature as well as provide track and trace information. Time-temperature indicators can be combined with other technologies such as near field communication (NFC), radio frequency identification (RFID), and barcodes to enhance an expanded value chain. Manufacturers and retailers can benefit from the tracking, inventory control, direct marketing, and increased sales due to differentiation while consumers can get information on freshness, shelf life, product origin, and promotions. For example, a digital time-temperature indicator records time and temperature throughout the value chain using the barcode system. Other indicators that monitor cold chain include Delta Trak, TempTale, and ColdSNAP. FreshPoint combines on-package indicators with technology links to smartphones to provide brand and freshness information.

NFC-enabled packaging applications offer flexibility and do not require smartphone applications. For example, consumer engagement with packages of cheese and cookies increased when audio-enabled silicone NFC tags were employed. Additionally, about a third of the engaged consumers converted this into an action, such as downloading a recipe. When time-temperature indicators are combined with RFID and inventory algorithms, price and freshness can be monitored, and costs and benefits are dispersed throughout the value chain. Linking cold chain, logistics and security monitoring provides for an integrated approach using the Sensitech system. Nanomaterials, photonic crystals and printable electronics will expand the commercial application of freshness indicators.

Claire Koelsch Sand, PhD, Contributing Editor

Claire Koelsch Sand, PhD, Contributing Editor

CEO, Packaging Technology and Research

Adjunct Professor, Michigan State Univ. and California Polytechnic State Univ.

[email protected]

Ziynet Boz, PhD, is a food packaging engineer and associate consultant at Packaging Technology and Research, LLC ([email protected]).