Formulating With Animal-Free Ingredients

Novel protein sources hold the key to creating an innovative, appealing, and sustainable array of new meat, egg, and dairy alternatives.

Article Content

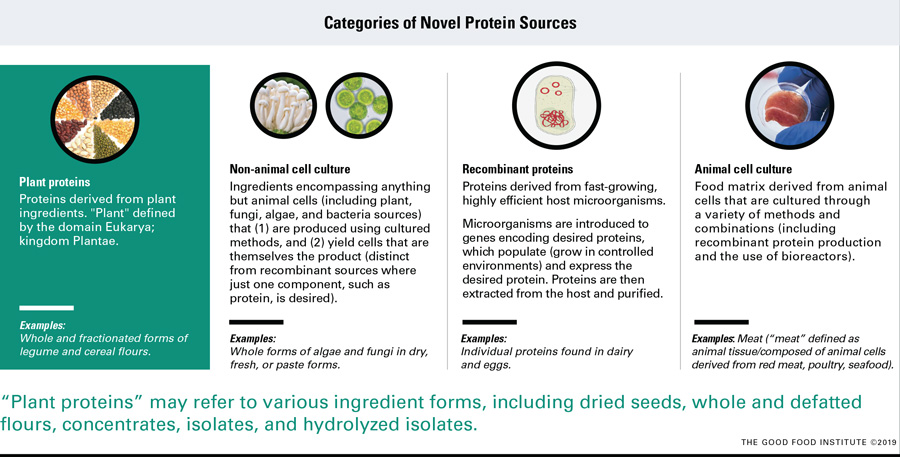

What are novel animal-free proteins? In looking at the space outside traditional animal-based proteins, novel protein sources fit into one of four categories from a production, cost, and infrastructure perspective: plants, non-animal cell culture, recombinant, and animal cell culture. The focus of this article encompasses the ingredients derived from plants, non-animal cell culture, and recombinant proteins, which together include the seeds of cereal and legume crops (plant proteins); forms of fungi, algae, and bacteria (non-animal cell culture); and animal proteins (such as casein, whey, and ovalbumin) produced without the animal (referred to as recombinant proteins). Further to our focus are formulation strategies using these ingredients for creating animal-free meat, egg, and dairy alternatives (Figure 1).

What Is Plant-Based?

Proteins may be differentiated on the basis of their plant, non-animal cell, and recombinant protein sources, but “plant-based” may encompass one or a combination of these sources to create a sans-animal product. Accordingly, “plant-based” may mean something different to everyone. Aimed at a future where plants supersede animal-based products, plant-based is designed to at least meet the organoleptic experience (i.e., flavor, aroma, texture, bite, moisture, mouthfeel, appearance, and color) of its animal-based counterpart. For example, plant-based meat alternatives may offer a fibrous texture similar or even identical to that of the striata of whole muscle or a crumbled or bound texture aligned with preformed patties and ground meat. Products replacing the emulsifying properties of eggs may yield spreads and dressings of comparable color, stability, and creaminess. Lastly, plant-based dairy alternative products may offer the signature white color and smooth, creamy mouthfeel of milk (and subsequently, of yogurt and cheese).

Traditional meat, eggs, and dairy have dominated and continue to dominate our food landscape. Animal-based products undeniably meet the three primary drivers of consumer eating and purchasing behavior, whether trained or instinctual: taste, price, and convenience. The success of plant-based products depends on their ability to deliver on these three drivers. Viewed another way, animal-based products are the template for a food revolution that advances sustainability and innovation by incorporating one or a combination of these novel animal-free proteins.

Plant-Based Formulation

If there is one rule to food innovation, it is to deliver on taste. Taste may be defined by a plethora of attributes that constitute a product’s organoleptic experience. For plant-based products, formulation aims to at least reach organoleptic equivalence to their animal-based counterparts. Ultimately, the aim of many modern plant-based companies is to create a product that is so superior in taste to the animal product it intends to replace that consumers will always opt for the plant-based version.

What this means for the food scientist is striking the right balance between the project’s parameters and the functional and nutritional quality of non-animal ingredients. To best do this, formulators will benefit from the big picture of plant proteins and the incorporation of non-animal cell culture ingredients and recombinant proteins in creating new products or enhancing existing ones.

Animal-Free Ingredients

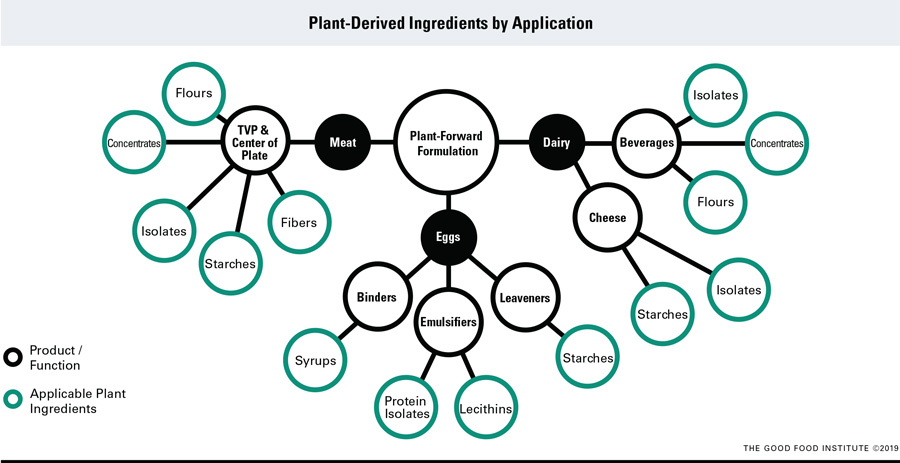

The real strategy behind plant-based or animal-free formulation is understanding the unique functionality offered by ingredients and their components and how this functionality is influenced by the ingredients’ inherent genetic material as well as processing methods. This section explains plants, non-animal cell culture, and recombinant proteins with formulation strategy and considerations in mind. It emphasizes plant proteins and derivative ingredients due to their current commercial availability (Figure 2).

Plant Proteins

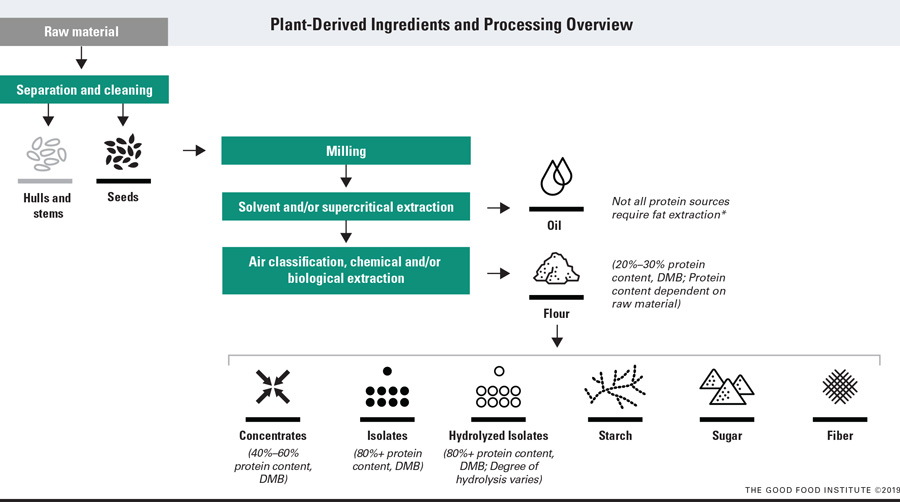

Plant proteins are mainly derived from cereal and legume crops and offered in whole and fractionated ingredient forms. Fractionated protein forms may encompass flours, concentrates, isolates, and hydrolysates. As a result of various approaches in physical, chemical, and biological processing, plant protein sources will gain further traction through their ability to meet key parameters in industry adoption, such as neutral color, odor, and taste; high protein content; amino acid diversity; and vast functional uses across commercial applications and processes.

In their flour, concentrate, isolate, and hydrolysate forms, plant proteins may impart the full range of functional characteristics, including solubility, viscosity, gelling, emulsification, foaming, and dough formation. Their strengths in any one function will be influenced in part by protein purity, which plays a dual role in aroma and flavor. Generally, the closer the finished material is to its native form, the more apparent its aroma and flavor (e.g., beany notes in legume-derived protein sources decrease from flour to isolate forms).

Alongside aroma and flavor, some plant proteins are known to negatively influence mouthfeel (the detection of sand-like particulates). To a large extent, these obstacles can be addressed through hydration, shearing, and cooking, which in combination can yield smooth, neutral-tasting, and white plant-based beverages and spreads. Hydration, shearing, and cooking are also characteristic of extrusion, which has been valuable in reducing undesirable aromas and flavors in the creation of plant-based meat.

The creation of hydrolyzed proteins (aka protein hydrolysates) from isolate fractions also aids protein functionality. Hydrolysates are accomplished by chemical hydrolysis, enzyme hydrolysis, or a combination of the two processes. The end product is measured as a percentage of peptide bonds cleaved, termed its degree of hydrolysis (DH). The DH influences not only functional quality but also nutritional quality and flavor (yielding optimal biochemical absorption but bitter flavors).

Hydrolysates are spray-dried and supplied as a dry powder for high-protein applications that require solubility but minimum water hold, viscosity, and gelation functionality. The value of hydrolysates is their ability to fit a lot of protein into a small space while imparting the least viscosity. Notable in ready-to-drink sports beverages, hydrolysates may also be of value in yielding or exceeding protein equivalence to animal-based counterparts.

Starch and Fiber

To believe that only protein fractions held the solution to innovative plant-based food products would be a major misconception. Major components of plant protein sources—starches and fibers—can deliver on some of the same functionalities while filling in where proteins fall short. As the demand for plant proteins (specifically, fractionated concentrates and isolates) continues to rise, so too will the supply of these coproducts, due to their majority composition.

Traditional starch applications highlight viscosity (thickening) but not necessarily gel strength, stabilization, or unique textural influences. New sources of starch, especially the derivatives of legume proteins, present unique characteristics that may translate to clean label, functional alternatives to hydrocolloids. In their native forms, legume-derived starches (such as pea starch) present functionality that other starches lack.

For example, the amylose content of field pea (with a smooth seed surface) is in the range of 30%–40% and is even higher for wrinkled pea (in the range of 60%–76%) (Ratnayake, Hoover, and Warkentin 2002). With an amylose content double that of traditional and common starch sources (e.g., corn, wheat, tapioca, potato, rice), field pea–derived starch imparts gel strength, film formation, and crispness (features advantageous to replicating the texture of meat products—namely, the “snap” of a cooked sausage or the bite of a chicken breast, cut of pork, or beef).

Further, starch contributes a means of reducing and controlling expulsion of free water or brine (a process formally referred to as syneresis). As it relates to seafood products like surimi, starch (native and modified forms) contributes water management alongside texture, process improvement, and cost reduction (Luallen 2004).

Lastly, fiber offers a new means of imparting viscosity, gelation, and stringiness while addressing clean label concerns and yielding nutritional benefits. Soluble fibers generally create viscosity or a gel when exposed to water (which may prove beneficial in at least hydrocolloid replacement). Further to its influences on texture, fiber’s linear structure may be of benefit in the creation of extruded plant-based meat products (which may aim for a fibrous composition comparable to that of animal-based meat cuts) (Figure 3).

Plant Protein Opportunities

New and emerging plant proteins will follow a template laid out by their still-popular predecessor, soy. The soy template provides a roadmap to low cost and optimal product utilization, which fall hand in hand. For example, soy’s ingredient dominance is in large part the output of several optimized functions: crop utilization, raw material utilization, and end product optimization. This is to say that soy yields maximal edible product per acre and offers an inherently high protein content and a diverse amino acid profile. Further, all parts of soy are reliably used across human and animal nutrition, and soy’s functionality through processing is so dialed-in that soy can be used across numerous applications. These are all parameters yet to be fully applied to new and emerging animal-free ingredients—namely, plants other than soy.

A variety of companies are working to expand our ability to use plant-based proteins. For example, Chile-based startup NotCo recently secured $30 million to further develop its machine learning platform that maps the molecular properties of plants. The company uses this database for comparison to the molecular structure of animal-based foods, determining which plant-based proteins can replicate the original structure in color, taste, and texture.

Current crops have generally been optimized for other purposes (e.g., oil production, feeding animals, baking) rather than for the best molecular structure and mix of amino acids to make plant-based meat. Accordingly, we at The Good Food Institute have prioritized funding open-access research into optimizing crops for plant-based meat alternatives. Through our inaugural Competitive Research Grant Program, we recently awarded $3 million to plant-based and cell-based meat research. Unrestricted access to the research will benefit the entire scientific community and food industry. Plant breeding companies, such as Equinom and Benson Hill Biosystems, are also developing crops optimized for plant-based meat, egg, and dairy applications.

Further opportunity for industry is in finding value-added uses of all parts of the plant. The protein content of plants, like that of animals, ranges generally between 20% and 30% of the edible portion’s weight. The question then is this: what becomes of the remaining 70% to 80%? Just as industry has created a use for every part of the animal, industry will create a use for every part of the plant, sprouting more possibilities for ingredient and product innovation.

Non-Animal Cell Culture

Non-animal cell culture is vast. Encompassing anything but animal cells, its sources can include plants, fungi, algae, and bacteria that 1) are produced using cultured methods and 2) yield cells that are themselves the product (distinct from recombinant sources where just one component, such as protein, is desired). Due to the limited commercial availability of these ingredients, non-animal cell culture products will be discussed in a high-level overview that touches on mycoprotein and algae sources.

Mycoprotein is derived from the fungi family and presents a wealth of advantages in its nutritional profile, structural and textural influences, flavor (umami), and efficient processing methods. On a dry-matter basis, mycoprotein’s whole form, specifically Fusarium venenatum, PTA-284 (the organism behind Quorn-branded products), is composed of 45% protein, 25% fiber, 13% fat, and 10% carbohydrates. Its filamentous nature is desired in at least the creation of meat-like textures and through controlled heating and freezing, can create a fiber-gel composite (of entangled fibers and gelled protein) that emulates the fibrous texture of whole muscle meat.

The wet weight (solids content of about 25%) of Quorn’s PTA-284 product is the form currently utilized in commercial food manufacture (essentially a paste) and is yielded following the collection and centrifugation of fermenter broth. For manufacture, an inoculum of pure culture is introduced to a fermentation vessel. There, a medium containing carbohydrates (among other necessary ingredients) is fed through a process of continuous fermentation, resulting in the growth of mycelium. This mycelium, in combination with its medium, is centrifuged to yield the finished paste (Finnigan, Needham, and Abbott 2017).

Like mycoprotein, algae is manufactured through a closed fermentation process requiring consistent conditions and nutrient supply. Its unique adaptability varies its nutritional composition to yield a high-protein or an oil-containing product within even the same species (dependent on the type and quantity of nutrients it is fed). In the case of protein, finished ingredients are likely to exist in whole-cell algal forms that are simply washed, dried, and reduced to uniform particle size (yielding a high-protein flour). When not utilized as a protein ingredient, its oil content is extracted (Klamczynska and Mooney 2017).

Opportunities in Non-Animal Cell Culture

The inherently higher protein content of mycoprotein and algae, combined with their processing efficiency, presents advantages over plant sources. Despite their promising functional and nutritional characteristics, the obstacle of non-animal cell culture is its lack of commercial availability. While no commercial products exist today, bacteria and plants can be used in the same way as fungi and algae in non-animal cell culture. Further, the limited commercial availability does not imply current species or strains (such as Quorn’s Fusarium venenatum) are the only sources; rather, there is a huge opportunity in expanding strain diversity. Though the creation of a finished paste may be ideal for Quorn’s manufacturing setting, it may not be suitable for optimal ingredient transport, shelf life, or costs. And though algae has yielded dry finished ingredients, its flavor and color may hinder adoption by limiting application versatility. Ultimately, opportunities exist in the realm of non-animal cell cultured ingredient sources, finished ingredients, their processes, and their functionality in commercial food products.

Recombinant Proteins

Recombinant proteins used in foods may be more accurately viewed as non-animal cell culture undergoing recombinant production methods. This is because non-animal cells (or hosts, such as yeast) are utilized to grow or multiply individual proteins. Specifically, DNA sequences are created and inserted into non-animal cells, which feed on other components and create individual proteins via fermentation. Acellular products—namely, individual proteins—are the ingredient output of recombinant protein technology and (in food) may include the proteins casein and whey (proteins in dairy) and ovalbumin (a protein in eggs), among many others.

Recombinant proteins would be utilized for the specific functional abilities imparted by a specific individual protein. To form a finished product, they would be combined with other components (e.g., fats, carbohydrates) derived from non-animal sources (plants and non-animal cell culture). Historically, recombinant proteins in foods have served as processing aids (such as chymosin, referred to as “vegetarian rennet,” or amylase and lipase enzymes). Using this production method to make the proteins casein, whey, gelatin, and ovalbumin changes that paradigm. In these examples, the outputs (of recombinant proteins) do not act as processing aids but as primary and functional ingredients within the final product.

To clarify, recombinant proteins serve as both an end product and a production method. The fundamental difference between this major protein category and both non-animal and animal cell culture (responsible for “clean meat”) is that the end product is an isolated individual protein (not cells), whereas in non-animal and animal cell culture, the cells themselves are the product. Further, recombinant proteins do not require any animal involvement.

Recombinant Protein Opportunities

Recombinant protein technology entails sourcing a desired gene sequence from a publicly accessible genome database (virtually all common food-relevant species are already sequenced), synthesizing it, and then inserting it into a non-animal host cell designed to make the protein. Perhaps the most prominent example of this in the plant-based meat alternative product space so far is by Impossible Foods. The company uses yeast to produce leghemoglobin, a molecule found in soybean plants. This iron-containing heme—identical to the heme in animal meat—adds to the Impossible Burger’s “meaty” taste.

Heme is just the tip of the iceberg. There is a lot of room for the creation of high-value ingredients, enzymes, and biomaterials using recombinant production methods, the outputs of which may serve as finished food ingredients or as processing aids to improve ingredient functionality.

Envisioning a Plant-Based Future

As we look to a future of animal-free food formulation, we need all our ingenuity to address the challenges of new and emerging ingredients, the processes responsible for their manufacture and functionality, and their ultimate application to a diversity of traditional food products. Plant-based products can be created from a host of ingredients that include, but are certainly not limited to, the protein fraction alone. As the demand for plant-based protein ingredients increases, so too will the supply of their coproducts and opportunities for their value-added utilization. Formulators today are on the front lines of revolutionary product innovation that supports a positive effect on our climate, food security, human health, and animals.

What we can create today without animals is truly astounding, though this is not to say that the science behind our capabilities is new. Rather, the timing is right. Our technologies and understanding have advanced such that we can now imagine replicating all products currently derived from animals. However, to make this vision a reality, significantly more research is required. We need more biologists improving plants, fungi, and bacteria for protein production, more biochemists and biochemical engineers optimizing ingredients, and more food scientists combining these ingredients in novel ways to produce plant-based foods that offer consumers familiar products with superior taste at improved prices.

About the Author

MJ Kinney, a member of IFT, is a food scientist with The Good Food Institute ([email protected]).

Food Technology Articles

Better Juice and Ingredion Collaborate and More Ingredient News

News about food industry suppliers

How to Formulate for Food Intolerances

In this column, the author describes the global prevalence of food intolerances and provides insight into state-of-science ingredient replacement and removal methods when formulating gluten-free and lactose-free foods.

Vickie Kloeris Shares NASA Experiences in New Book, Consumers Are Confused About Processed Foods’ Definition

Innovations, research, and insights in food science, product development, and consumer trends.

Top 10 Functional Food Trends: Reinventing Wellness

Consumer health challenges, mounting interest in food as medicine, and the blurring line between foods and supplements will spawn functional food and beverage opportunities.

Keeping Chocolate Sweet While Cutting Sugar

Penn State food scientist Gregory Ziegler experiments with substituting rice flour and/or oat flour to reduce the sugar content of chocolate.

IFT Podcasts

Episode 33: Global Food System Challenge Growth Grant Winners

Join us to celebrate the Global Food System Challenge Growth Grant Winners. Representatives from Food Systems for the Future (FSF Institute), iDE Global, and the African Center for Technology Studies discuss their work and the role that the generous funding from Seeding The Future Foundation plays in helping to make healthier diets more accessible and empowers consumers to make choices benefitting both personal and planetary health.

Episode 32: Global Food System Challenge Grand Prize Winners

Join us to celebrate the Global Food System Challenge Grand Prize Winners. Representatives from the International Rice Research Institute, Solar Freeze, and WorldFish discuss their work and the role that the generous funding from Seeding The Future Foundation plays in helping to make healthier diets more accessible and empowers consumers to make choices benefitting both personal and planetary health.

EP 7: Microalgae - Modern Uses of an Ancient Ingredient

Microalgae: Modern uses of an ancient ingredient.