The Versatility of Ultrasonic Energy

PROCESSING

Ultrasonic energy is used for a surprising variety of functions in the food and packaging industries. Here we will explain a little about the technology, provide some references and sources, and, hopefully, stimulate some creative thinking.

The Basics

Sound is nothing more than pressure waves in some medium, such as liquid, air, or solids. Human hearing responds to pressure waves between 20 cycles per second (Hertz, Hz) and 20 kilo-Hertz (kHz). Pressure waves between 20 kHz and 1 mega Hertz (MHz) are considered power ultrasound (beyond the range of human hearing and intense enough to deliver energy). Beyond 1 MHz is considered diagnostic and is used for imaging and measurement.

In power ultrasound, many effects are due to cavitation. Cavitation is the formation, growth, and collapse of many very small bubbles in a liquid due, in the case of power ultrasonics, to the relative inelasticity of liquids at the frequencies imposed. As the pressure wave passes, the liquid is literally torn apart, despite the theoretically higher energies required. This occurs, according to a recent volume on the subject (Feng et al., 2011), because most liquids contain some small bubbles or particles that act as nuclei for the formation of more bubbles.

Bubble growth is affected by temperature, vapor pressure, and system pressure. Because of the pressure fluctuations, the bubbles quickly collapse, generating very high temperatures in the vicinity. Growth and collapse is reduced at elevated pressures because this raises vapor pressure. Higher external pressure raises the threshold pressure for bubbles to form but also increases the violence of collapse.

It is generally known that cavitation also occurs in centrifugal pumps and homogenizers, where it can cause damage because of the impact of bubbles and fluid against surfaces. Ultrasonic-caused cavitation can also cause damage, but if controlled, can be beneficial. For instance, ultrasonics can dislodge soils from surfaces and has been used to clean wine barrels and fresh produce. Some research on produce cleaning and sanitizing was performed by Hao Feng at the University of Illinois at Urbana-Champaign, supported by Ash Husain, now Executive Vice President at Cedarlane Natural Foods, Carson, Calif. (phone 310-886-7720, Ext. 7145), while he was with ConAgra. Husain reports that ultrasonics research was discussed at the most recent IFT Nonthermal Processing Division Workshop in Melbourne, Australia.

Effects of Cavitation

In addition to the physical impact on solid surfaces, the extremely high temperatures in collapsing cavitation bubbles can generate chemical free radicals, which can cause both desirable and undesirable reactions. For instance, oils may be oxidized, causing rancidity. But also, microbes can be killed. Metal salts can be reduced to metal nanoparticles. Enzymes can be inactivated, all without elevating the bulk temperature very much.

The formation and collapse of bubbles near a surface can disrupt the heat and mass boundary layers that pose external resistance to heat transfer and drying, thus increasing rates. Both conventional and osmotic drying can be improved by application of ultrasonic energy.

Cell walls of fruits, vegetables, and other foods can be disrupted by ultrasound, enhancing extraction of valuable materials, such as juices and sugar.

In filtration, ultrasound may help keep a screen or filter media from clogging by knocking off trapped particles.

Ultrasound seems to improve freezing rate and quality of soft fruits and vegetables by enhancing heat transfer at the surface, and, possibly, by encouraging nucleation of ice crystals. Many small ice crystals are generally preferred in freezing foods because they cause less cell disruption.

Spraying and atomization of fluids and slurries can be enhanced by ultrasonic nozzles, in which the nozzle tip is vibrated at about 20 kHz. One application described in Feng et al. (2011) is spraying seasoning onto snack chips. The same effect might be beneficial in spray drying, where good control over droplet size distribution is essential.

--- PAGE BREAK ---

Mixing and emulsification are fairly obvious candidates for application of ultrasonics. The ability to generate small droplets without the high pressures used in homogenization should be an advantage.

Ultrasonic waves directed through air have been used to reduce foaming in beverage filling and in chemical reactors. Sound energy is quickly absorbed in air, but enough is left to deflate foam.

How Is Ultrasound Generated?

A source of high frequency and, potentially, high amplitude (or intensity), vibration needs to be coupled to some means of transmitting the pressure waves to a medium—solid, liquid, or gas. The source may be piezoelectric or magnetostrictive. Piezoelectric is more common. The piezoelectric phenomenon relies on special crystals that vibrate when electrically stimulated. The reverse is also true, and is used as the basis for some instruments; when compressed, the crystals produce an electric current. The magnetostrictive phenomenon is similar, but uses an oscillating magnetic field to generate vibrations. In either case, the electric field can be varied to modify the ultrasonic waves.

The source of vibration is coupled to a tool, often made of titanium. Titanium is used, despite its expense and competition from defense uses, because of its low dampening coefficient, which means more vibrational energy is transmitted. Titanium is notoriously difficult to form and machine. Energy is required to move the tool so efficiency of transmission to the medium being treated declines as size increases.

Sealing and Welding

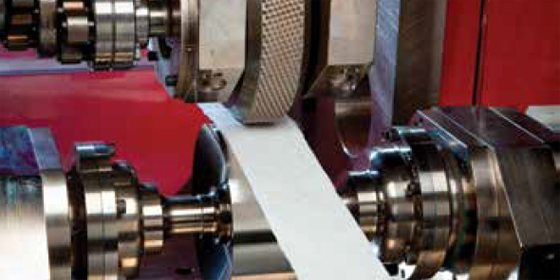

When an ultrasonic tool is pressed against a solid, such as plastic sheet or film, it can rub two pieces together so that frictional heat softens and melts the plastic. This effect can be used to seal flexible packaging materials and weld together thermoplastic parts very quickly. In the case of package sealing, the seal can be formed through contamination in the seal area because the vibrating tool self-cleans the area. A number of suppliers of ultrasonic sealing equipment and systems exhibited at the 2012 Pack Expo presented by the Packaging Machinery Manufacturers Institute (PMMI) in Chicago recently. Aurizon Ultrasonics, Kimberly, Wis., is a spin-off from Kimberly-Clark, commercializing rotary ultrasonic tools for welding and sealing, according to Robert Cool, Executive Vice President (phone 920-750-5081). Rotary motion of the tool is said to offer advantages in many applications.

Sonics & Materials Inc., Newtown, Conn., focuses on plastic welding and assembly, as well as ultrasonic liquid processing and the manufacture of ultrasonic metal welding systems, according to Brian Gourley, North American Sales Manager (phone 203-270-4600). Rinco Ultrasonics, Danbury, Conn., also offers plastic and textile welding systems, according to Gordon Hull, Managing Director (phone 203-744-4500).

How to use these commercially available systems for food applications is an interesting creative challenge. One extension that has been successful is cutting of sticky and fragile foods. For example, sheets of compressed grains with syrup binder can be slit into strips with ultrasonic knives, then cross-cut into bars with guillotine tools, all driven ultrasonically to keep them clean. Fragile cakes have also been cut with ultrasonic knives.

Measurement

Many people are familiar with ultrasonic imaging used to portray a developing fetus in the womb. Such a detailed image takes a long time to develop because of the needed depth of penetration of the waves and the need for low-energy levels. The phenomenon is based on the difference of the speed of sound in materials of different densities and the reflection of waves from some materials. The same concept can be used to detect foreign matter in foods, but at production speeds, there is a limit to about 2 inches depth.

Another measurement concept is flow measurement due to the difference in the speed of sound depending on the flow rate of a liquid or gas. An ultrasonic flow meter can be strapped onto the external surface of a pipe, avoiding the potential for leaks around an inserted fitting. Sound waves are sent across the pipe, usually at several points and at an angle up and downstream of the flow. The speeds of arrival are detected and compared, from which the volumetric flow rate is computed. Mass flow is calculated from known density or density as a function of temperature data, if temperature is not constant.

A Doppler flow meter might be better than a transit time meter for fluids containing bubbles or suspended solids because it relies on a frequency shift in a reflected signal. The frequency shift is proportional to the flow rate of the fluid.

Ultrasound is widely used to examine critical welds in metal pipe, tubing, and vessels. This relies on the differences in sound velocity between solid metal and possible voids or gaps.

Applications for Ultrasonics

Power ultrasound is a solution looking for the right food processing problem to solve. As is so often the case, it has passionate advocates and a gnawing intrigue: It must be good for many things. The practical realities of needing relatively expensive tools and of having some negative consequences, in some circumstances, seem to be inhibiting its rapid adoption in the industry. Clearly, ultrasound has found a few niches in packaging and plastic parts assembly. Are there lessons from those applications that can direct research toward the next big application in food processing? How about meat processing? Tenderizing? Reforming?

J. Peter Clark, Contributing Editor,

J. Peter Clark, Contributing Editor,

Consultant to the Process Industries, Oak Park, Ill.

[email protected]

References

Feng, H., Barbosa-Canovas, G.V., & Weiss, J., eds. 2011. Ultrasound Technologies for Food and Bioprocessing, Springer, New York.