Annual Meeting Papers Address Minimal Processing

1999 IFT ANNUAL MEETING & FOOD EXPO

There is a continuing trend toward fresher, less processed, safe foods. This is illustrated by the continued use and introduction of minimally processed foods and extended-shelf-life refrigerated foods/sous vide products.

It is also illustrated by the continuing and increased research and development activities regarding nonthermal methods of processing. Although thermal processing of foods provides a high degree of safety, it tends to degrade the quality of foods to some extent. Among the nonthermal methods being investigated, and in some cases commercially applied, are high-pressure processing, irradiation, ohmic processing, pulsed electric field processing, pulsed light processing, ultraviolet light processing, and others. Microwave processing, although it is a thermal processing method, is rapid and can thus help minimize thermal degradation.

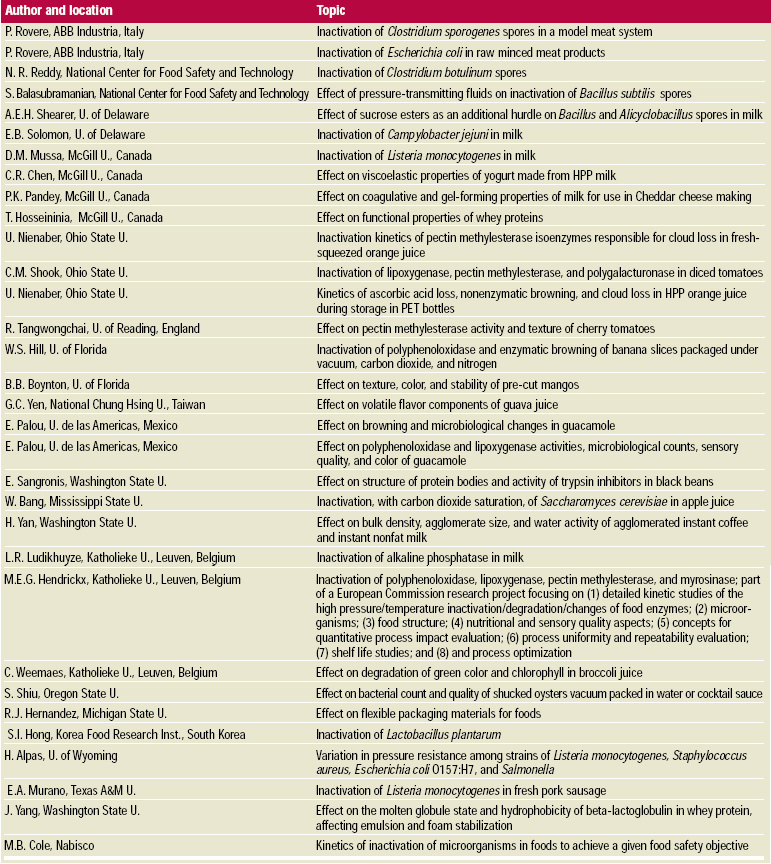

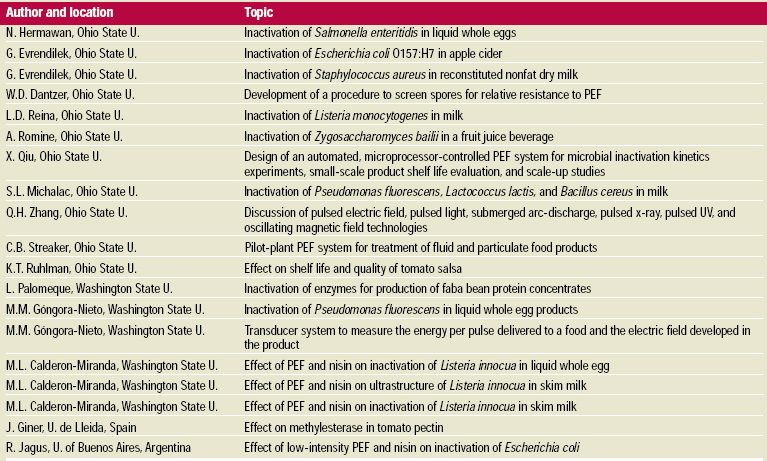

At this year’s IFT Annual Meeting & Food Expo, held in Chicago, Ill., July 24–28, 1999, many papers were presented on emerging technologies. For example, 30 papers were presented on high-pressure processing (HPP), and 19 papers were presented on pulsed electric field (PEF) processing. Both have fairly recently begun being used commercially, and research on applications is increasing. Tables 1 and 2 give an idea of the various applications discussed at the Annual Meeting.

At this year’s IFT Annual Meeting & Food Expo, held in Chicago, Ill., July 24–28, 1999, many papers were presented on emerging technologies. For example, 30 papers were presented on high-pressure processing (HPP), and 19 papers were presented on pulsed electric field (PEF) processing. Both have fairly recently begun being used commercially, and research on applications is increasing. Tables 1 and 2 give an idea of the various applications discussed at the Annual Meeting.

As a technology is being developed, research and development is conducted on the technique itself, then the equipment, then the effectiveness in model systems, and then application to foods. For example, the papers on HPP discussed primarily applications, whereas the papers on PEF, a newer technique, also discussed engineering aspects, such as developing methods for measuring the delivered dose.

Irradiation is another method for minimally processing foods. Although it has been around for many years, consumer wariness has led to its not being used much. Three types of irradiation—gamma, electron-beam, and x-ray—are being studied and used; see the Processing column in this issue (p. 140) and the August 1999 issue (p. 88). However, interest in nonradioactive methods, particularly electron-beam irradiation, may lead to increased acceptance by the consumer. Ultraviolet light processing is also reaching commercialization (see the Processing column in this issue (p. 140)

Another indication of the increasing interest in nonthermal methods of food preservation is the recent establishment of the IFT Nonthermal Processing Division, which was granted probationary status in December 1998. Information about the Division is available on the Internet at www.ift.org/divisions/nonthermal. The division sponsored or cosponsored two symposia during this year’s IFT Annual Meeting: “Nonthermal Food Preservation: From Concept to Market” (session 30) and “Regulatory and Intellectual Property Aspects of Novel Food Processing Technologies” (session 59). This sidebar article will discuss these and other symposia and papers presented at the Annual meeting that pertained to minimal processing of food. Audiotapes of these presentations and others are available (see ad within this issue).

Nonthermal Food Preservation

In the symposium, “Nonthermal Food Preservation: From Concept to Market” (session 30), J. Larkin of the Food and Drug Administration pointed out that development of nonthermal processes requires consideration of their impact on organisms of public health significance, the procedures used to establish the process, the ability to identify the critical factors of the process, uniformity of the process treatment or identification of the minimum treated portion, and the ability to document that an adequate reduction process has been delivered to the product.

--- PAGE BREAK ---

Q.H. Zhang of Ohio State University said that all pulsed power technologies have one commonality—the treatment dosage is not continuous. In general, the microbial destruction follows first-order reaction kinetics with respect to the peak intensity of the treatment dosage. Therefore, the efficiency of microbial destruction increases with increased peak intensity, but physical and chemical limitations may restrain the maximum peak intensity.

M.E.G. Hendrickx of Katholieke University, Leuven, Belgium, studied the effects of high pressure and temperature on kinetics of inactivation of enzymes and showed that the kinetic effects are largely dependent on environmental conditions. M.B. Cole of Nabisco reviewed microbiology issues in nonthermal food processing, and C.P. Dunne of the U.S. Army Soldier Biological & Chemical Command reviewed nutritional, chemical, and biochemical factors guiding nonthermal food preservation. He showed that sensory acceptability of selected acid foods treated by PEF or HPP could be maintained for more than a year at 80°F. Some sugar–acid reactions occurred after processing, he said, but, overall, chemical and nutrient content changes were less than in thermally processed products.

Regulatory Aspects

In the symposium, “Regulatory and Intellectual Property Aspects of Novel Food Processing Technologies” (session 59), G.V. Barbosa-Cánovas of Washington State University said that high-intensity PEF, oscillating magnetic fields, and HPP are promising nonthermal technologies which can inactivate microorganisms and enzymes, but that process effectiveness must be determined and verified and worker safety and environmental and economic issues must be addressed.

He also said that each nonthermal technology has specific applications, in terms of the type of food that can be processed. For example, HHP, oscillating magnetic fields, antimicrobials, light pulses, and hurdle technology are useful in processing both liquid and solid foods, whereas PEF is more suitable for liquid foods and irradiation for solid foods. Furthermore, light pulses, irradiation, and magnetic fields can be used to reduce the risk of cross- or post-process contamination in prepackaged foods. Thus, each type of nonthermal process has its merits and limitations.

Although the commercialization of foods processed by nonthermal methods is a definite possibility in the near future, he said, it may take some time, since regulatory approval is still an unresolved issue. Some questions that must be answered include finding the inactivation mechanisms, specific microorganisms resistant to a particular nonthermal method, and those microorganisms that may not follow a linear and predictable inactivation course during the nonthermal processes.

D. D’zurilla of Legal, Oblon, Spivak, McClelland, Maier & Neustadt discussed intellectual property protection for new food processing technologies. P.A. Hansen of FDA said that the processing of foods by various nonthermal methods has become increasingly popular as a means of offering foods that retain more of the qualities associated with “freshness” but which also have extended shelf life. Many of these technologies also have the potential to significantly reduce levels of foodborne pathogens. These food processing methods encompass a wide variety of technologies, raising a variety of regulatory issues. And T. Wilson of the University of Missouri-Columbia discussed use of electronic pasteurization and polylactic acid treatment on beef to reduce Escherichia coli counts.

Fresh Fruits and Vegetables

A symposium entitled “Intervention Strategies to Improve the Safety of Fruits and Vegetables” (session 29) was sponsored by the IFT Fruit & Vegetable Products Division. R.L. Buchanan of FDA pointed out that recent outbreaks of foodborne disease associated with consumption of fresh produce and unpasteurized juices have increased interest in the development of new intervention technologies that reduce risks from foodborne pathogens while retaining the “fresh” character of the food. R.E. Carver of Carver Research Associates, Inc., said that good manufacturing practices are very important to ensure the safety of fresh fruits and vegetables but are only part of the overall puzzle of safe food processing. Fundamental programs and HACCP are also important.

--- PAGE BREAK ---

C.E. Sizer of the National Center for Food Safety and Technology said that consumer demand for fresh or fresh-like produce has increased significantly over the past two decades. Industry has responded by developing minimal processing technologies that achieve a significant biological reduction, increase the shelf life of the produce, yet maintain the delicate characteristics of the fresh product. These minimal processes, he said, represent a significant challenge, since overprocessing frequently results in damage to the produce, while underprocessing may present a public health problem.

J.P. Cherry of the U.S. Dept. of Agriculture said that use of sterile water and antimicrobial compounds (such as chlorine, chlorine derivatives, and organic acids) in fruit and vegetable processing is being reevaluated. Well-known and new chemicals, alone and in combination, are being examined under different processing conditions for more effective control of spoilage and pathogenic microorganisms. Chemicals used in combination with newly developed cold pasteurization techniques such as PEF and HPP in place of heat treatment to sterilize foods have attracted interest. L. Xu of Praxair, Inc., discussed use of ozone instead of chlorine compounds in fruit and vegetable processing.

D.W. Thayer of USDA said that application of ionizing irradiation to extend the shelf life of fresh fruits and vegetables such as strawberries, lettuce, sweet onions, and carrots is well documented but that relatively little effort has been applied to the control of foodborne pathogens. He mentioned that ionizing radiation has been used to eliminate E. coli O157:H7 from apple juice, Toxoplasma gondii and Cyclospora cayetanensis from raspberries, and E. coli O157:H7 and Salmonella from seeds and sprouts, and combination treatments with other processes such as chlorination seem especially promising.

Stressed Pathogens

In the Food Microbiology Division symposium entitled “Stressed Pathogens Compromise the Safety of the New Generation Foods: Assessment and Control of Pathogens” (session 43), A.E. Yousef of Ohio State University pointed out that while the emerging technologies such as HPP, PEF, pulsed intensive light, biopreservation, and ionizing radiation can be used to eliminate molds, yeasts, and non-spore-forming bacteria from food, they are less effective against bacterial spores. Mild treatment of food by the minimal processes, he said, is likely to injure or stress microbial cells rather than kill them, and when conditions are favorable, stressed cells may develop a stress adaptive response which protects them against more severe treatments and may compromise the safety of the product.

J.N. Sofos of Colorado State University pointed out that contamination of foods with stressed microorganisms that have developed resistance to traditional food preservation hurdles, such as heat, cold, acidity, and antimicrobials, is especially undesirable, considering the sensitivity to foodborne pathogens of at-risk populations. Resistant strains of pathogens should be included in food product development studies, he said. In addition, where feasible, food processing and preservation systems should be modified to minimize potential for resistance development, and microbial control approaches should employ multiple hurdles that prevent resistance development.

E.A. Johnson of the University of Wisconsin, V.K. Juneja of USDA, C. Keler of USDA, and C. Hill of the National University of Ireland also discussed various aspects of environmental stress and resistance of pathogens.

Ozone in Food Processing

Various papers presented during the technical program addressed use of ozone, which has been declared by an expert panel of the Electric Power Research Institute as a GRAS substance for disinfecting and sanitizing food products. Ozone can be used to sanitize equipment, wash fruits and vegetables and seafood, and disinfect poultry chill water.

S. Deng of the University of Minnesota in paper 83A-12 said that ozone, a strong oxidizing agent, is a potential replacer for sanitation because it destroys both bacteria and viruses, while chlorine is not very effective against viruses, and ozone reacts much faster and is more environmentally friendly than chlorine. Ozone is generally dissolved in water, and the resulting ozonated water is applied to the surfaces of foods and food processing facilities. The author reported on design of an automatic system for continuous generation of ozonated water and its use to clean food and food processing facilities.

--- PAGE BREAK ---

A roundtable (session 72) on “Regulatory Issues with Ozone Use in Food Processing” was cosponsored by the Food Laws & Regulations Division and the Food Engineering Division. D. Graham of R&D Enterprises discussed the affirmation of ozone as GRAS for use in food and agriculture, B. Loeb of Praxair-Trailigaz Ozone Co. discussed the safety and enviromental issues involved with ozone use, D. Armstrong of FDA reviewed regulations regarding ozone use in food processing, and R. Carawan addressed Environmental Protection Agency regulations regarding ozone applications in food industry wastewater treatment.

Safety of Meal Solutions

In the symposium, “Safety Strategies for Meal Solutions” (session 73), cosponsored by the IFT Food Microbiology, Food Packaging, and Refrigerated & Frozen Foods Divisions, L.G.M. Gorris of Unilever Research said that hurdle technology—combining several preservation technologies—is receiving increasingly more attention as a preservation concept that fits perfectly well with the consumer demand for minimally processed foods.

L. Jackson of FDA said that the very nature of extended-shelf-life refrigerated foods—foods that have received minimal processing or precooking and use refrigeration as the primary means to ensure safety, including luncheon meats, vegetable salads, fresh pasta and pasta sauces, entrees, side dishes, and complete meals—presents challenges to ensure their microbiological quality and safety. The primary microbiological concerns associated with these products are psychrotrophic pathogens, which can grow at refrigeration temperatures during periods of extended storage, and mesophilic pathogens, which can grow during conditions of moderate temperature abuse. Ensuring the quality of raw materials, equipment usage, equipment design, facility and equipment sanitation, and hygienic practices of all employees is pivotal to food production, she said. The hurdle concept will also assist in the control of microbiological hazards.

J. Humber of Micro-Logics, Inc., said that to reduce the probability of pathogenic microbiological incidents in commercially distributed chilled prepared foods, microbiological challenge tests offer a means to predict problems, and he presented a protocol for such tests.

M.G. Roman of Kraft Foods said that the success of the chilled foods industry will continue to depend on technologies which provide effective hurdles to microbial growth while still providing a high degree of organoleptic quality to the products throughout their shelf life. A degree of safety must be built into the product to safeguard against temperature abuse. M. Mitchell of Certified Laboratories, Inc., stressed the importance of maintaining the cold chain.

L. Bell of Fresh Express Farms, Inc., said that the critical variables that impact food safety in the processed/preserved segment of the food industry are well defined because they have been researched and standardized over the past 100 years. In contrast, the emerging fresh-cut and packaged produce industry and the processes being developed to sustain freshness are in their infancy.

I.R.T. Martens of Alma Sous Vide Competence Centre, Belgium, reported that a European Union effort has been underway for several years to establish standards to eventually serve as uniform regulations throughout Europe.

Time/Temperature Specifications in Distribution

A Special Forum entitled “Retail and Foodservice Time/Temperature Food Safety Specifications” (session F-1) was presented by the IFT/National Restaurant Association Strategic Alliance. It included, among several topics related to food distribution, use of mathematical models to predict microbial behavior.

by NEIL H. MERMELSTEIN

Senior Editor