The Case for—or Against—Case-Ready Fresh Red Meat in the United States

PACKAGING

Annual Meetings of the Institute of Food Technologists often feature fascinating topics that provide major new information, stimulate new research initiatives, spark debate, clarify complex issues, or become the foundation for exciting new commercial ventures. The subject of case-ready fresh red meat has been discussed by meat and retail store managers and technologists since the corner butcher shop moved into the supermarket back room about 50 years ago. During the late 1990s and now in 2000, a plethora of talk and print pieces suggest that the rumbles are about to convert into commercial reality—or are they?

An IFT Annual Meeting symposium cosponsored by IFT's Muscle Foods and Food Packaging Divisions and co-chaired by me and Melvin Hunt of Kansas State University attempted to state the facts and place them in perspective—if that is possible in this complex environment. Entitled "Factors Influencing the Successful Implementation of Centralized Packaging of Meat and Poultry," the symposium focused on the red-meat core of the issue, virtually omitting any mention of poultry, since the latter long ago converted into centralized packaging, the old nomenclature for case-ready.

An IFT Annual Meeting symposium cosponsored by IFT's Muscle Foods and Food Packaging Divisions and co-chaired by me and Melvin Hunt of Kansas State University attempted to state the facts and place them in perspective—if that is possible in this complex environment. Entitled "Factors Influencing the Successful Implementation of Centralized Packaging of Meat and Poultry," the symposium focused on the red-meat core of the issue, virtually omitting any mention of poultry, since the latter long ago converted into centralized packaging, the old nomenclature for case-ready.

For those unfamiliar with the concept of case-ready meat, it is the integration of technology, logistics, and common sense that moves the cutting and packaging of fresh red meat out of the supermarket back room and into centralized facilities. The latter would be (and in Europe and for poultry around the world, is) more efficient, more cost effective, and more sanitary than the more than 31,000 individual supermarket and club-store back rooms, each under the supervision of a highly paid butcher. Centralized packaging requires that the beef (and it is largely beef involved in this venture, since pork is converting as this is written) be reduced to whole muscle cuts or grind, converted into ready-to-use units, and preserved for a period well beyond the hours or one or two days currently offered by the venerable backroom operations.

Almost every speaker in the symposium enumerated the advantages of case-ready beef: reduction of the almost universal out-of-stock situation at retail level; much-reduced spoilage; significantly reduced labor and space cost; ability to brand and market; and supervision by trained food technologists. But the benefits do not come without some challenges, such as butcher and often retailer resistance (to any change); much higher packaging costs; the need for an effective and reliable preservation technology; and an understanding of how to achieve a specified extended shelf life in a too-variable distribution temperature environment.

A number of issues are involved: Ground beef today constitutes 40% of the total market demand and is both highly vulnerable to spoilage and highly price sensitive. Color—which is unrelated to product quality—is perceived by consumers as critical in their purchase decision. There have been several public health incidents involving E. coli O157:H7 from ground beef and the attendant nudges in the direction of irradiated beef. Additional challenges are the real economics involved, and the steady decline in beef consumption. Countering all these challenges are the announcement by Wal Mart that its superstores will convert to all case-ready beef by the end of 2000, and the several chains that are already using centrally packaged beef. In Europe, much of the beef has been centrally packaged for years, but, as the skeptics assert, Europe is "different."

Market Size. A minor debate on the size of the current United States case-ready beef business resulted in no satisfactory answer: some of the speakers believed that about 10% of all beef is now delivered to retailers in case-ready form, and others placed the proportion higher, perhaps as much as 20%, with ground beef representing a larger share than intact cuts. The growth rate is now well above historical data, but case-ready meat is still not a major proportion of the beef displayed for consumers at retail level. The total retail meat industry is valued at $14 billion plus $4 billion for poultry which, not incidentally, now surpasses beef as America's favorite meat.

The objective of the symposium was to try to enumerate most, if not all, of the technical challenges that must be addressed to nudge the U.S. meat packing and retailing interests to convert from the present archaic methods into modern centralized packaging.

Color. Don Kropf (with co-author M.C. Hunt) of Kansas State University discussed color, indicating that many cumulative variables influence the color of red meat: pigment, pH, species, animal sex, pre- and post-slaughter handling, variability of the cuts, presence of antioxidants (Kropf mused on why antioxidants are not used for ground beef), and oxygen content. Not all of the well-known color reactions are reversible. Maximum production of undesirable brown metmyoglobin takes place at above a 1.4 mm partial pressure of oxygen. In practice, when the vacuum within a package is not drawn effectively, oxygen partial pressure will exceed 4 mm and the rate of formation of brown metmyoglobin will be high.

The retail display life of red meat is inversely proportional to its oxygen consumption rate (OCR), which, in turn, influences oxygen penetration and reaction in the layers of meat: red oxymyoglobin appearing initially on the surface, brown metmyoglobin just beneath, moving to the surface with depleted reducing action, and oxygen partial pressure and internal purple myoglobin. Thus, another variable is the rate of diffusion of oxygen into the meat. For maximum red color retention, ultra-low oxygen, i.e., less than 10 ppm, should be reached very rapidly, followed by reblooming to red oxymyoglobin from purple myoglobin by exposure to oxygen (or air) when needed. Color is compromised at oxygen concentrations greater than 0.15%. An interesting point is that meat will scavenge oxygen up to about 0.5%, i.e., less than 500 ppm can delay metmyoglobin production.

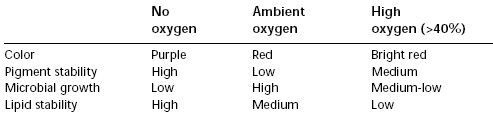

Changes in Meat During Distribution. Louisiana State University's Ken McMillin, an organizer of the symposium, reviewed many of the changes that occur during the shelf life of red meat, in terms of color, drip, microbiological growth, lipid oxidation, and enzymatic changes (Table 1).

An interesting observation was that high oxygen tends to reduce microbiological counts, especially pseudomonads, a finding that agrees with the results obtained by the United Kingdom's Campden Food and Drink Research on fresh lettuce.

At –1.5ºC and reduced oxygen, (rebloomed) red oxymyoglobin color could be retained for up to 46 days (realistically, 18-21 days for ground muscle and 21+ days for intact muscle). A modified atmosphere containing 20% carbon dioxide offered the longest shelf life, and vacuum the second longest at about 28 days. With high-oxygen systems, i.e., 80% oxygen (plus 20% carbon dioxide), 8-10 days of good color retention could be achieved in ground beef (this is the preferred system in Europe and is used in the U.S. for ground beef by some packers). Ten days of shelf life can be achieved with whole muscle cuts at 0°C. Lipid oxidation became a problem in about 6 days with 75% oxygen and after 9 days in air.

The implication is that highly reduced oxygen internal packaging environment offers the longest shelf life, assuming good sanitation and distribution temperature. Reduced oxygen requires a downstream means to convert the myoglobin to red oxymyoglobin, such as passive admission of air through a gas-permeable membrane or even direct injection of oxygen—all of which then permit only a day or two of display time.

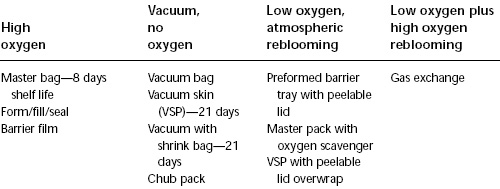

With regard to concepts, systems, and successful implementation of a case-ready system, Central Soya's Brian Smith made two related presentations, one on meat and the other on packaging systems.

Greater than 30% carbon dioxide content in a modified-atmosphere package can lead to package collapse due to gas dissolution. Greater than 50% carbon dioxide tends to inhibit color oxidation. Thus, carbon dioxide tends to be better than vacuum to preserve red meat. Confirming Kropf's data, less than 1% oxygen will be scavenged by the meat, and pigment oxidation takes place at 2-10 % oxygen.

Smith's tabulation indicates about 13 different packaging systems being offered commercially for case-ready beef (Table 2), but his list is still short of all that are present or suggested. Issues include oxygen present in the pores of expanded polystyrene trays, purge, how to achieve the highly reduced oxygen, and, of course, the still unreliable distribution temperature.

Gary DelDuca of Pactiv, formerly Tenneco and Mobil and Amoco Chemical, described his company's new fresh red meat packaging system (PakTech), listed in Table 2 generically as low oxygen, atmospheric reblooming.

Dynamics of the meat market include consumers appearing to demand the bright red color and the "familiar" package, retailer concern about liability and cost, and meat packers' low margins and desire for added value.

Package costs today are about $0.03-0.05 for conventional back-room air packaging, which offers 1-3 days of shelf life; $0.08-0.15 for high-oxygen packaging for "regional" distribution; and $0.14-0.20 for low-oxygen packaging requiring reblooming for either regional or national distribution. These data do not necessarily include labor and other variable costs.

Sources of oxygen that must be addressed by any low-oxygen system include the meat, its package headspace and, as indicated above, air in the package materials. Oxygen removal can be mechanical, but the air in the expanded polystyrene cannot be effectively removed and residual oxygen is emitted over a few days. Conventional oxygen scavenging is too slow to retard formation of metmyoglobin. The PakTech system activates a high-speed/high-capacity oxygen scavenger affixed to the interior of a gas-barrierfilm overwrap containing a standard expanded polystyrene tray overwrapped with PVC film, i.e., a conventional red-meat package. With the highly reduced oxygen, up to 35 days of refrigerated shelf life is claimed. Reblooming requires about 20 minutes after opening the outer barrier bag, thus exposing the overwrapped meat to air through the PVC film.

So, what does the future hold for case-ready beef in the United States? This symposium began with a review of the past and current situation by perhaps the only professional who has been present and involved since the beginning—me. Does a consumer demand or desire exist for centrally packaged red meat? (No, none that can be discerned). Can retailers benefit? (Yes, if the economics are real, as the data from the successful European operations suggest). Can the packers gain an advantage? (Yes, if they go beyond the technology and commodity elements that have been the touchstone of the industry for decades and adopt the marketing philosophy.

Do we need more technologies to reach the shelf life so vaguely defined? None, even those that are in the wings, are nearly perfect. All require a combination of initial meat quality, excellent handling, and—the ultimate challenge—distribution temperature control. If we have all of these indispensables, we can function in today's commercial environment and await whatever innovations are under development in universities or by inventors. And how much "shelf life" is needed? (In Europe, the 6 days for ground beef and 10 days for whole muscle cuts are satisfactory. About 2 weeks works for poultry in the U.S. Why do we persist in the 3- to 5-week shelf life objectives that are repeatedly mentioned in both the technical and trade media?

What more technical information do we need? Based on this symposium and on so many other assemblies on the topic, much is unknown: What are the quantitative effects of temperature on both microbiological growth and color deterioration (and, has it been determined that color is really so vital to consumers, whoever they are?). How much microbiological growth constitutes spoilage? Which red color is acceptable, and what are the precise oxygen partial pressures required—and how can they be achieved in commercial practice? What carbon dioxide concentrations are most effective to achieve what result? Is oxygenation of the meat pigment the best mechanism to obtain the requisite red color—passive, active, or something else?

And what will be the effect of low-dose ionizing irradiation on the meat and its color characteristics, if this means to obviate pathogenic growth becomes a major preservation process? And what package materials and structures will be approved?

We have pondered the issues of centralized packaging of red meat and experienced too many starts—and stops. Just because we do not have all the technical information should not deter commercial development. We have enough scientific knowledge to move, but it is our responsibility to use good information to accomplish our objective, a significant thrust into case-ready red meat.

Products & Literature

PACKAGING MATERIAL FOR PLASTIC TRAYS is supplied in pellet form. The finished trays can withstand temperatures between –40ºF and 400ºF, so the packages can go directly from freezer to oven or microwave for final preparation. The VersaTray program entitles manufacturers and distributors of trays made with the plastic to become licensees of VersaTray by Eastman Chemical Co., and retailers and packer/processors can sublicense use of the VersaTray plastic logo from their tray supplier for use on food packaging. Eastman provides a public relations program to promote the logo so that consumers easily identify the foods packaged in the dual-ovenable tray. The branding program describes the advantages reported for VersaTray: appearance suitable for table use, strength for better product protection, and lots of visibility on television and in print feature stories and ads. The dual-ovenable feature may be important, as a research study from the University of Georgia noted that 92% of consumers chose dual-ovenable packaging regardless of how they planned to cook their meal. For more information, contact Eastman Chemical Co., P.O. Box 431, Kingsport, TN 37662-5280 (phone 800-327-8626, fax 423-229-8595, www.eastman.com) —or circle 322.

ADVANCED GABLE-TOP PACKAGING SYSTEM was designed by an international cross-functional team including experts in packaging, processing, technical service, manufacturing, hygienists, and ESL application advisors. The resulting system, called the TR/18 ESL technology platform, can operate at rates of 14,000 cartons/hr. Products that contain soft particles in sizes to 10 mm diameter can be filled. The unit has two separate lines, so that different products can be filled at the same time, and both lines can apply any of Tetra Rex's closures. Designed to produce packages of low-acid dairy foods with shelf life up to 45 days at 8ºC and 90 days at 7ºC, the unit can produce cartons of high-acid products with shelf life of 120 days at 7ºC. For more information, contact Tetra Rex, Inc., 101 Corporate Woods Pkwy., Vernon Hills, IL 60061 (phone 847-955-6000, fax 847-955-6500, www.tetrapak.com) —or circle 323.

by AARON L. BRODY

Contributing Editor