New E-Beam Research Facility Exemplifies the Value of Pilot Plants

PROCESSING

Pilot plants—essentially small production plants—are essential steps in translating laboratory results to full-scale production. Most companies have pilot plants for their own use, but many also offer them to potential customers for use in evaluating their products and processes. Many universities are also doing the same, especially now that universities are forming alliances with industry.

One example is a facility being constructed at Texas A&M University, College Station, dedicated to electron-beam irradiation of foods and food ingredients. Scheduled to open next summer, the facility is the result of a strategic alliance between Texas A&M’s Institute of Food Science & Engineering (IFSE) and SureBeam Corp., a Division of Titan Corp., San Diego, Calif. As part of the 10-year, $10-million alliance, SureBeam will provide two linear accelerators for e-beam treatment of foods and food ingredients to kill microorganisms and a third for high-energy X-ray treatment, which provides deeper penetration into products.

SureBeam will also provide a 10-year grant to IFSE to staff the facility with full time operators and management. Operating hours will be shared between SureBeam researchers and Texas A&M researchers. At the end of the alliance, all facilities and equipment will be solely owned by Texas A&M.

According to Mark McLellan (phone 979-862-2032), Professor and Director of IFSE, “This partnership is a clear example of the opportunities for visionary teamwork while meeting the needs of industry and supporting the goals of higher education.”

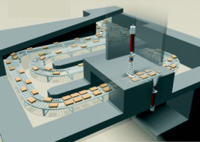

IFSE’s facility—an existing pilot plant originally designed for dairy work—is undergoing a $6 million renovation to form a complete food irradiation research center. A 5,000-sq-ft addition will house a shield room with walls up to 12 feet thick. The facility already has loading docks, refrigerators, and freezers attached and will be entirely chilled to cold-room conditions. It will have a fully automated control and carrier system so that all samples are treated in a highly controlled manner (Fig. 1). The facility will be used only for research on food and food ingredients and the food irradiation system. The only other facility anything like it, McLellan said, is an old system at Iowa State University, Ames, but that facility is devoted to research only, whereas the IFSE facility will be used for both research and pilot plant production studies.

Tentatively called the Texas A&M Electron Beam Food Research Facility, the IFSE center will feature a fully automated system, with very tightly controlled dosage so that all research projects will have assured treatment and assured quality. If a system is not designed and operated right, McLellan said, variations in dosage can adversely affect samples and could make results of evaluation studies questionable.

The center will be staffed with full time Texas A&M operators, to ensure accuracy and quality in the way products are treated. That differs from a more-usual approach to pilot-plant studies, in which the professor and his or her students conduct the experiment. In this facility, they will do the product preparation work and analyses, but the actual operation of the irradiation equipment will be done by the full-time professional staff, under very carefully controlled conditions of experimentation, with fully documented protocols.

Texas A&M and SureBeam will share use of the facility. For every operating day (8:00 a.m. to 5:00 p.m.), university researchers will have exclusive use of the center half of the time, and SureBeam the other half. The facility will be capable of operating 24 hours a day, but SureBeam will be limited to 10 out of every 24 hours, the other 14 being available to the university researchers. SureBeam will also be limited in total production capacity to 25%, for market research purposes, to ensure that the facility remains a research-only pilot plant.

McLellan said that both the faculty and the company will be working with potential customers. Some funding sources prefer to have research done by faculty because of their expertise in such areas as packaging, fat chemistry, carbohydrate chemistry, etc. In other cases, companies may prefer to work through SureBeam.

The center will be used for studies on food safety, packaging, quality, formulation, system design and control, and other aspects of food irradiation.

McLellan said that one of the reasons that SureBeam decided to partner with Texas A&M is because the university has 115 faculty across three colleges focused on food and food-related issues in the IFSE. “It’s hard for any company to find that kind of research talent focused on food and willing to work on contracts and grants from outside the university,” he said. The Institute’s multidisciplinary Project Bright Star team led the partnership presentations and negotiations with SureBeam and included experts in such areas as food safety, consumer behavior, process handling and packaging systems, packaging materials, fruit and vegetable product quality, e-beam measurement and control, and others. While this facility will be owned by Texas A&M, McLellan added, it expects to host academic researchers from institutions around the world interested in pasteurization of foods using electron beams.

According to Dennis G. Olson (phone 402-390-0141), SureBeam’s Vice President, Product Applications, the facility will be similar to the company’s Sioux City, Iowa, production facility (see Food Technology, August 1999, p. 88 and July 2000, p. 88). As shown in Fig. 1, packaged products—individual or in bulk—are put on a conveyor system that moves them in a serpentine manner into the treatment area and through the electron beam or X-ray beam, then returns them to the product handling area. The dose the product receives depends on several factors, but the primary control is speed of the conveyor: for a high dose, the conveyor moves at a slow speed, and for a low dose it moves faster. Through testing and qualifying products and facilities, the company has learned what speed gives what dose.

Formerly director of the irradiation facility at Iowa State University, Olson said that that facility is primarily a research facility used to demonstrate the e-beam and X-ray technology. It has continuous throughput as in commercial facilities but in small volumes—hundreds of pounds of product—whereas the Texas A&M facility will be able to handle thousands of pounds and more. The latter is more commercial-like in design and capable of market research projects.

SureBeam chose to partner with Texas A&M rather than build its own facility, for several reasons, Olson said. The company was interested in having different facilities in different parts of the country; the university has a good reputation; it provided a unique facility; the building was available; and Professor Elsa Murano, one of the leaders in food irradiation, is on the faculty of the Institute.

While the company does testing in its current facilities, they will become less available as the demand for products increases, he said. SureBeam will consider the Texas A&M facility as the primary focus for irradiation research and technology transfer. It will play a key role in bridging the gap between the volume of research that has been done over the past 40 years and industrial applications. It will address some important research issues, he said, but as consumers become more accepting of irradiated products, there will also be more applications. In addition to technology, there are also consumer aspects, he added, including consumer education and perception. There are research opportunities not just for food scientists but for sociologists as well.

University pilot plants provide great benefit to the industry and to the university, said Olson, former director of the meat laboratory pilot plant and food crops processing pilot plant at Iowa State University. In the meat industry, for example, there are ingredient manufacturers, casing suppliers, and equipment manufacturers. All of their products have to be tested in meat products before they can be introduced into the marketplace. This can be very expensive because the meat company may not have a need for constant use of the equipment. Meat and poultry processing requires inspection, a lot of cleanup, sanitation requirements, etc., so for any one company to hire staff to do that is not very economical if it is using the equipment only 3–4 hours a week. So access to these pilot plants is very important. Olson said that three companies use the Iowa State pilot plants almost daily, other companies once a month or every other month.

The pilot plants at Iowa State are also coupled with short courses that teach the technology of meat and poultry production. Universities can have a pilot plant where they can make product and demonstrate the technology, something that is very difficult to do in a commercial facility. If a company has its own pilot plant, it won’t let competitors in there. No one company makes all equipment, so the pilot plant can offer a variety of equipment, featuring the latest technology. The pilot plants generally have the latest equipment because equipment manufacturers want to expose their equipment to the industry and to students. Students benefit because when they go to employers they can show that they’ve learned on different kinds of equipment. They no longer make “beaker sausage” but instead use real-world equipment.

The pilot plants also provide a public relations benefit. Universities get a tremendous number of visitors, including prospective students, parents, and international delegations. Most classrooms and laboratories look the same, he said, so tour groups are generally taken through pilot plants.

McLellan said that pilot plants allow investigators to take a concept from the benchtop and approach a fully processed product scaleup, produce market research quantities, and explore all of the engineering quality and safety characteristics of the product.

In addition to the Electron Beam Food Research Facility, Texas A&M also has a meat processing pilot plant operating under HACCP certification and USDA inspection. The university also has a pilot plant dedicated to processing of grains that can do any type of grain processing, including milling, dough evaluation, and production of tortillas, chips, breads, snacks, and other grain-based products. And the Food Protein R&D Center’s research and development pilot plant is well known for its oilseed extraction and separation capability, as well as other unit operations.

Texas A&M is also home to the national training facilities of the U.S. Dept. of Agriculture’s Food Safety and Inspection Service. “We expect interaction between the FSIS training center and the new Electron Beam Food Research Facility to be a unique opportunity for regulators, industry, and academia,” McLellan said.

Texas A&M is also laying plans for a new 5,000-sq-ft pilot plant for general processing purposes. It has obtained an existing air-conditioned engineering research facility and will equip it with traditional unit operations equipment, such as retorts, heat exchangers, and pumping systems. Following the model used at Cornell University, where McLellan was professor and chair of the Food Science Dept. before joining Texas A&M last year, the university will be seeking companies to provide equipment as either a straight donation or a long-term loan. That gives the equipment suppliers a high degree of exposure to the companies, and allows students to become familiar with their equipment. The facility will be a neutral site, where food companies can become familiar with the equipment and eventually buy it. That’s different from going to an equipment manufacturer to use their equipment or bringing the equipment into the food company’s own pilot plant for evaluation, he said.

McLellan thinks that alliances such as that between Texas A&M and SureBeam are the way things are going to go in the future. “Companies are not going to simply write a university a $10-million check,” he said. “That kind of cash flow is very difficult to secure. It’s going to take this type of partnership agreement to get this scale of new industrial support in the future."

High-strength-electric-field pumpable-food-product treatment in a serial-electrode treatment cell. U.S. patent 6,110,423, filed 2/6/1998, issued 8/29/2000 to A.H. Bushnell et al., assigned to PurePulse Technologies, Inc. Describes a system for deactivating microorganisms, such as bacteria, viruses, fungi, protozoa, parasites, and the like, in pumpable food products, such as milk products, natural fruit juices, liquid egg products, and pumpable meat products, such as ground beef or turkey, by passing them through a high-strength electric field system treatment employing serial electrodes separated by an insulating section.

Process for preparing fully cooked packaged shelf stable or frozen noodles. U.S. patent 6,110,519, filed 12/ 28/1998, issued 8/29/2000 to P. Meyer et al., assigned to Nestec S.A. Describes a full-moisture, shelf-stable or frozen noodle product having a dry matter content between about 30 and 45% by weight. The noodles, known in Southeast Asia under the name of “Beehoon,” contain a cooked flour or semolina of a starchy plant such as rice, softened water, a cooked starch, an ionic gelling agent, an emulsifier, a cation which has formed a gel with the ionic gelling agent, and an oil. If desired, an acid can be included to provide a pH of about 3.7–4.5. The noodle is formed by cooking-extrusion of the mixture, bringing the noodle product into contact with water containing a cation which forms a gel with the ionic gelling agent, dewatering the noodle product, cutting and portioning it, packaging it, and in-pack pasteurizing it. The noodle does not require the consumer to cook it before consumption, but rather to simply heat it for a short time.

Method for preparing quick-reconstituting foodstuffs which includes subjecting such foodstuffs to freezing followed by thawing and then at least one sequence of freezing and thawing prior to drying. U.S. patent 6,110,518, filed 3/12/1998, issued 8/29/2000 to K.L. Cooper et al., assigned to Basic American, Inc. Describes a method for producing a quick-reconstituting foodstuff that involves thawing and refreezing a previously frozen foodstuff a number of times, then removing moisture from the multiply frozen and thawed foodstuff to produce a finish-dried product which has a moisture content of less than about 12% by total weight and a rehydration ratio representing the replacement of at least 95% of previously removed moisture after reconstitution for less than about 10 min in simmering 205°F water.

Method for making a cylindrical food consisting of a plurality of concentric cylindrical layers. U.S. patent 6,106,880, filed 10/29/1998, issued 8/22/ 2000 to M. Harada et al., assigned to Kabushiki Kaisha Kibun Shokuhin. Describes a method and apparatus for making a hollow cylindrical food. Food paste is shaped into rectangular sheets and conveyed to a transverse bar that winds the sheets successively. The apparatus can be used to produce a new type of “Chikuwa” which consists of three concentric cylindrical layers, i.e., innermost and outermost layers of fish paste, and a cheese paste layer embedded between the outermost and innermost fish paste layers.

Products & Literature

MEMBRANE FILTRATION PILOT PLANT, Model R, is capable of testing all membrane technologies (microfiltration, ultrafiltration, nanofiltration, and reverse osmosis) and many membrane types and configurations, including polymeric or inorganic membranes, spiral-wound or tubular, under a wide range of operating conditions. It can be operated in batch, semibatch, or feed-and-bleed mode and features a single-stage recirculation loop. The pilot plant is skid mounted with all components required for quick installation and easy operation. For a 2-p data sheet describing the unit, contact Niro Inc., Filtration Div., 1600 O’Keefe Rd., Hudson, WI 54016 (phone 800-367-6476 or 715-386-9371, fax 715-386-9376, www.niroinc.com) —or circle 320.

SLIDE RULE for calculating vibrator feeder tray capacities can be used to find the capacity of an existing installation as well as aid in the specification of new equipment. The slide rule is calibrated in both English and metric measurements. Also included is a chart of available vibratory feeder models to assist in proper equipment selection for the intended application. For a free slide rule, contact Eriez Magnetics, P.O. Box 10608, Erie, PA 16514-0608 (phone 888-800-3743 or 814-835-6000, fax 814-838-4960, www.eriez.com) —or circle 321.

MEMBRANES AND ION EXCHANGE RESINS are described on new Web sites, www.filmtec.com and www.dowex.com. They offer recommended operating conditions for FilmTec® membranes and Dowex™ ion exchange resins, as well as access to ROSA and CADIX software for the design and evaluation of reverse osmosis and ion exchange systems. The Web sites include supporting engineering information for designing systems, with unit conversion tables, conductivity curves, pH solutions, regenerant concentration, and density table. For more information, contact Dow Chemical Co., 1691 N. Swede Rd., Midland, MI 48674 (phone 517-636-9086) —or circle 322.

EDIBLE OIL ANALYSIS is simplified by use of the 3M Shortening Monitor, a paper test strip that the foodservice worker dips into liquid shortening to determine when the shortening should be discarded. The nontoxic paper test strip features four colored bands. The color change in the bands indicates the degree of liquid shortening breakdown. For more information, contact 3M Food Service Business, 3M Center, Bldg. 223-4N-15, St. Paul, MN 55144-1000 (phone 800-698-4595, www.3M.com/foodservice) —or circle 323.

SCRAPED-SURFACE HEAT EXCHANGER, the Contherm™, can treat products with particles, high viscosity, and a tendency to create a film when heated. It is vertically mounted and designed for the heating and cooling of particulate, sticky, viscous, and crystallizing/phase-change processes. It is available in three sizes and can serve in a wide range of processes, including heating, cooling, slush-freezing, pasteurization, sterilization, and crystallization. Product is pumped into the lower end of the unit and is removed from the walls by the scraping blades as it flows through the cylinder. This scraping action results in product heating or cooling with a high heat transfer rate without fouling. For 2-p data sheets describing its use in production of rice pudding and bread, contact Alfa Laval Thermal Inc., Food Center, 111 Parker St., Newburyport, MA 01950 (phone 978-465-5777, fax 978-465-6006, www.us.thermal.alfalaval.com) —or circle 324.

by NEIL H. MERMELSTEIN

Senior Editor