Forum Provides Information on Extrusion and Drying

PROCESSING

Extruder manufacturers offer not only equipment but also expertise to food manufacturers. For example, Wenger Manufacturing, Inc., Sabetha, Kans., recently held a two-day extrusion research forum for users of its equipment, including universities, consultants, and some university processing centers.

Gordon R. Huber, Wenger’s Director, New Concept Development (phone 785-284-2133), said that the forum was held in Kansas City, Kans., in November 2000 to improve communication and relationships between industry and institutions and to update the participants about the company’s latest technologies in extrusion, drying, and food processing systems. The forum also gave the participants the opportunity to tell the extruder manufacturer what developments and changes they would like to see in the future.

Among the new developments discussed at the forum were the Optima II single-screw extruder, the Magnum II twin-screw extruder, the QuikChange™ rapid changeover system, the Phase Transition Analyzer, and the Vacuum Microwave Dryer.

· Optima II Single-Screw Extruder. This extruder, introduced in June 2000, features a new drive and a new design of the screw flighting and barrel ribbing that provides advantages over the Optima I, Huber said. The combination of flight depth, pitch profile, and effective helix angle optimizes the conversion of mechanical energy into heat through friction while minimizing shear damage, providing a 30-50% increase in production capacity, improved control of product texture and bulk density, and reduced processing costs. The Optima line is used primarily for producing pet foods and aquatic feeds.

· Magnum II Twin-Screw Extruder. This extruder, introduced in November 2000, features high-speed drives variable from 350 to 1,200 rpm, various length/diameter ratios, screw diameters of 57, 85, 115, 144, and 168 mm, and a hydraulically removable barrel. It provides higher speeds, increased power, and greater production output rates than the previous version. The extruder can be used for production of premium pet foods and aquatic feeds, specialty animal fees, textured vegetable proteins, and starch-based industrial products.

Deeply flighted screw segments provide increased free volume in the barrel, resulting in greater capacity, and varying the location and configuration of shear and kneading elements provides product and process versatility. Extrudate pressure is distributed uniformly around each screw, providing uniform support of the screws and shaft within each barrel channel. Uniform pressure at the die face results in more uniform product shape, size, definition, and length.

The extruder’s Automatic Process Management (APM) System automatically controls startup, operation, and shutdown. It regulates throughput, process temperatures, and addition of liquids, and monitors post-extrusion functions designed to optimize quality and efficiency.

· The QuikChange™ Rapid Changeover System for Extruders. This system enables the processor to change from producing one extruded product to another without shutting down the extruder. The die has two extruding heads, allowing the operator to prepare the die to extrude a second product during operation. During a product change, the extruder’s APM system changes the die position to extrude through the second die within a few seconds. The extruder continues to operate at capacity during the change, virtually eliminating downtime and product waste, Huber said.

In operation, product A passes from the supply bin through the extruder and die and into the cooler and dryer. As the raw ingredients for product A in the supply bin run out, the ingredients for product B are fed into the extruder, creating a small quantity of mixed product AB in the extruder, followed by the new product B. The APM system keeps track of the small quantity of product AB as it passes through the drying phase, and separates it to be used as desired by the manufacturer.

· The Phase Transition Analyzer (PTA). Extrusion causes complex chemical and physical changes in ingredients to produce final products with desired characteristics. By measuring these changes and correlating them with desired properties in finished products, it is possible to predict processing effects and to more accurately formulate products and automated processing parameters.

According to Brian Plattner, Process Engineer, changes in physical properties as a biopolymer passes through its glass transition temperature (Tg) and its melt transition temperature (Tm) can be measured by various analytical techniques, including differential scanning calorimetry (DSC), dynamic mechanical thermal analysis (DMTA), thermal mechanical analysis (TMA), and dielectric thermal analysis (DETA). However, these techniques have limited ability to measure Tg and Tm for the complex recipes used in food extrusion. Capillary rheometers yield the controlling Tg and Tm for complex mixtures but are not widely used.

The PTA overcomes these problems, Plattner said. It is a closed-chambered capillary rheometer that uses a combination of pressure, temperature, time, and moisture to predict the Tg and Tm of a given biopolymer. It differs from other capillary rheometers in that it applies a constant pressure to the sample instead of a maintaining a constant volume in the sample chamber. By maintaining a constant pressure on the sample, the PTA is able to more accurately determine the Tg and Tm for a given biopolymer.

The PTA has been introduced through a series of papers and presentations and will be available for sale in the first quarter of 2001.

· The Vacuum Microwave Dryer (VMD). Although Wenger is known for its extruders, it is also one of the three largest manufacturers of dryers for the food industry and has been manufacturing convection dryers since the early 1960s. According to Robert Sunderland, Technical Service Representative, in June 2000, Wenger signed a 10-year agreement with the Canadian firm, EnWave, to jointly design, manufacture, and sell commercial vacuum microwave systems.

Wenger’s new VMD has advantages over traditional hot-air convection dryers. By combining the rapid heating ability of microwaves with vacuum—reducing the pressure to 40 Torr or 0.8 psi—helps to retain volatile flavor components. Reducing the pressure lowers the boiling point of water, so lower process temperatures may be used for drying. Drying temperatures less than 120°F are common with the VMD, compared to 160–200°F in typical hot-air dryers. The overall result is greater retention of flavor and heat-sensitive components. Another advantage is speed, he said. The drying rate is very fast, so products that normally require 18 hr in a freeze dryer can be dried in minutes in the VMD.

A test unit was installed in Wenger’s Technical Center in Sabetha, Kans., in December 2000 and will be used for testing customers’ products, as well as for scale-up studies. The test unit delivers 15 kW of energy, compared to 0.75 kW in a large home microwave oven. The dryer is more expensive per unit throughput than conventional dryers and is more complicated, but the product quality is much better.

Sunderland sees the process as a competitor to freeze drying. The VMD produces a product that is very close to freeze-dried products at almost half the cost. He also foresees installations that couple both conventional and VMD dryers. Products such as fruits and vegetables can be dried from about 80% moisture on a weight/ weight basis to 35–40% in a convection dryer, then be passed into the VMD for finish drying.

Other topics discussed during the forum included scale-up, mass and energy balance, and control systems. The forum was a followup to the company’s previous research forum held in 1996. Plans are being made to hold the next forum in 2002.

R&D Extruder to Be Installed in U.S.

A 32-mm extruder in the Evolum series of twin-screw extruders manufactured by Clextral, Inc., Tampa, Fla., will be installed in the United States in the next month or two, the first such installation in the U.S. Designed for research and development on all kinds of extruded products, it can produce 20-200 lb/hr, depending on the product, and is scalable to full-size production, according to Gilles Maller, Sales Manager (phone 813-854-4434).

The Evolum extruders feature optimized temperature control, using a new barrel design offering improved cooling efficiencies, plus PLC control for immediate and accurate temperature management. The new barrel design—a product of extruder heat transfer research conducted by Clextral, Inc., Tampa, Fla., and the University Institute of Industrial Heat Systems (IUSTI), Marseilles, France—provides optimum temperature control along the entire screw profile.

The extruders provide advantages in the production of ingredients such as pregelatinized flour, caseinate, and flavors. For production of pregelatinized flour, widely used in baby food, instant beverages, convenience foods, sauces, and extruded products, the extruder provides maximum control of the degree of gelatinization to achieve the precise level required for each product. Clextral’s Rapid Viscosity Analysis (RVA) technique is used to analyze and compare gelatinization from various production sets and control the process to ensure maximum quality.

For production of caseinate, twin-screw extrusion offers a continuous, controllable method of combining casein and alkali with a small amount of water to produce a dry, mixable powder utilized in food production for its binding and emul-sifying properties. The Evolum extruders use a fraction of the water required for traditional caseinate production, reducing the energy requirement and offering improved quality, solubility, and flavor.

For flavor development, the extruders can encapsulate flavors in a sugar or starch matrix, or accurately control the Maillard reaction for flavor development. The PLC-based operating software ensures extremely accurate and immediate response for all production parameters and captures all data for historical analysis.

The Evolum extruders were first introduced in early 1999, one size at a time. They are available with screw diameters of 32, 53, 88, and 145 mm, all of them fully scalable to production-size units. The 32-mm unit is a compact, stand-alone machine, with all electrical connections and controls on the unit. It has a screw speed of 1,200 rpm, provides high pressure and high torque, and can be set up with different barrel lengths, with L/D ratios ranging from 12 to 48, giving it a lot of flexibility, Maller said. The company has two 53-mm units in its research center in Firminy, France, near Lyons, and will install another in its research center in Tampa, Fla., later this year for use in product development and testing.

PATENTS

Food sanitizing apparatus. U.S. patent 6,150,663, filed 2/8/1999, issued 11/21/2000 to R.A. Rosenthal. Describes a process for sanitizing fresh foods and beverage products using multiple stages of exposure to different wavelengths of ultraviolet, near infrared, and infrared light, without altering the nutritional or organoleptic qualities of the product. The food or beverage is exposed to ultraviolet light at germicidal wavelengths to inactivate undesirable microorganisms on the product. The UV exposure damages the organoleptic qualities, which are subsequently restored by exposing the product to polychromatic near-infrared light. In addition, prior to the inactivation of microorganisms, the food or beverage may be exposed to infrared light to inactivate enzymes responsible for decomposition of the product.

Method for treating a liquid egg product. U.S. patent 6,149,963, first filed 9/21/1995, issued 11/21/2000 to J. Cutler et al., assigned to Cutler Egg Products, Inc. Describes a method for treating a liquid egg product containing egg white and/or egg yolk to extend shelf life. The liquid egg product is steam heated at 78.degree. C. or higher for about 1.5 seconds or less, cooled by more than 30.degree. C. in 0.5 second or less, then held at about 60.degree. C. or more for a time sufficient to pasteurize it, e.g., a few minutes.

Process for preparing dockered potato products. U.S. patent 6,149,959, filed 11/20/1998, issued 11/21/2000 to K.E. Dayley et al., assigned to Miles Willard Technologies,L.L.P. Describes a process for preparing potato products, such as potato chips, cottage fries, and French fries, that includes placing raw potato slices on a moving conveyor belt; dockering the potato slices by moving them under a rotating brush having flexible bristles; then cooking them. The finished products are said to have fewer pillows and blisters, lower moisture contents, and reduced cooking times. Blistering and pillowing in some food products can be reduced by perforating the product with openings, a process known as dockering. The openings provide conduits for venting steam, thus preventing formation of the pillows and blisters.

Method of manufacturing an expanded, extruded food product. U.S. patent 6,146,679, filed 3/31/1998, issued 11/14/2000 to T.C. Heyhoe, assigned to Koala Property Limited. Describes a method of manufacturing an expanded, extruded, reduced-fat or low-fat food product, without loss of flavor and color. Normally, as a rice or other cereal-based pre-mix is passed through an extruder, it loses flavor and color because of the heat of extrusion and the sudden pressure change. The extrudant is generally coated with color and/or flavor additives, resulting in the completed food product’s having a high concentration of color additives on the surface which can be picked up on the consumer’s fingers. In this process, flavor and/or color compounds are added to the initial mix prior to being fed into a screw extruder, and further flavoring and/or coloring compounds are added at an appropriate stage during extrusion so that the food products, when extruded, are ready to eat.

Method for the preparation of a foodstuff. U.S. patent 6,156,367, filed 10/28/1997, issued 12/5/2000 to R.D. Keenan et al., assigned to Good Humor-Breyers Ice Cream, div.of Conopco, Inc. Describes a process for preparation of an ice confection having an aqueous phase and a fat phase. The confection comprising in the aqueous phase at least 1 wt % micellar casein and sufficient total sugars so that a protein gel is formed on application of ultra-high pressure. The confection is not subjected to a freeze concentration step prior to the ultra-high-pressure treatment If micellar casein is present in the aqueous phase at less than 2 wt %, the confection includes a stabilizer. The ice confection is not subjected to a freeze concentration step prior to the ultra high pressure treatment.

Molded pizza crust. U.S. patent 6,156,364, filed 3/9/2000, issued 12/5/2000 to R.L. Meibach, assigned to Kraft Foods, Inc. Describes a method and apparatus for forming proofed dough for baked goods in a predetermined shape. The method includes transporting proofed dough from a pressurized dough mixer through a dough transporting device to the injection molding device. The injection molding device fills the injection mold with dough when it is connected to the dough transporting device, thus forming one or more pieces of dough having the predetermined shape within the molds. The injection molds containing the dough may then either be conveyed into an oven to form a baked piece of dough having the predetermined shape, or conveyed into a freezer to form a frozen piece of dough having the predetermined shape.

PRODUCTS & LITERATURE

Extrusion Services offered to help food specialists transform their product ideas into reality include not only testing at the Buhler Extrusion Services laboratory but also extensive counseling. This includes not only the preparation and the setup of the tests but also definition of the appropriate variations in the process parameters, recording of test data, and analsis of the results. The laboratory includes twin-screw extruders and upstream and downstream unit operations for the conditioning of the raw material and the final treatment of the product. In process development, attention is focused on linking these process units according to specific requirements and reproducibility of results, and the throughput capacities of the individual system elements are carefully matched. The services provided enable international customers to run tests and carry out development projects. For more information, contact Buhler AG, CH-9240 Uzwill, Switzerland (www.buhlergroup.com) —or circle 300.

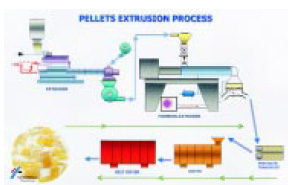

Complete Extrusion Processing Lines are being offered for production of a variety of human and pet foods. The turnkey systems are designed to help manufacturers scale up to full production in less time. Since the beginning of 2000, turnkey systems have been supplied in the U.S. and Europe for production of such products as breakfast cereals, snacks, snack pellets, and meat analogs. In the snack area, the pellet processing line shown in the accompanying illustration makes snack pellets that can be finish-cooked at a retail or foodservice outlet by frying, hotair puffing, or high-density microwave expansion. Complete processing lines include bulk product storasge, dry material feeder, twin-screw extruder, former, cutter, and ancillary equipment, plus all conveyor and equipment interfaces. For more information,contact Clextral, Inc., 14450 Carlson Cl., Tampa, FL 33626 (phone 813-854-4434, fax 813-855-2269) —or circle 301.

Batch Mixer, the FKM Ploughshare®, provides high-performance mixing of dry and wet materials with high homogeneity and short mixing and granulating times. The mixer handles capacities from 35 to 9,250 gal and can be equipped with chippers to aid mixing and injectors to moisten and condition products. Various options are available. For more information, contact Lödige Process Technology, 1 Greentree Center, Suite 201, Marlton, NJ 08053-3105 (phone 856-988-5579, fax 856-596-1324, www.loedigept.com) —or circle 302.

Meat Slicer, the Stackrite Hyspeed Model 1090SS, can produce slices ranging in thickness from shaved to 5/8 in at up to 800 slices/min, with a maximum stack height of 3-1/4 in. An optional shingler/indexer can produce up to 1,000 slices/min. Typical products include lunch meats, boneless meats, natural-shaped briskets, sausages, cheeses, poultry products, processed and restructured items, baked goods, seafood, and vegetable products. For more information, contact Great Lakes Corp., 2500 W. Irving Park Rd., Chicago, IL 60618 (phone 773-478-3625, fax 773-478-7647, www.greatlakescorp.com) —or circle 303.

Potato Slicer, Model GRL, strip-cuts plain and crinkle-cut potato strips. It helps processors avoid product loss and increase cut length by minimizing transverse fracturing and feathered edges. The machine accepts potatoes up to 9 in long and produces uniform slices up to 9/16 in thick. Flat or crinkle cuts are produced by dialing a different slice thickness and by changing the crosscut spindles. The machine features continuous operation and simplified design for ease of cleaning and maintenance. For more information, contact Urschel Laboratories, Inc., P.O. Box 2200, Valparaiso, IN 46384-2200 (phone 219-464-4811, fax 219-462-3879, www.urschel.com) —or circle 304.

In-Line Mixers provide efficient and hygienic mixing. The precision-engineered rotor/staor workhead cas the capacity to mix, emulsify, homogenize , solubilize, suspend, disperse, and disintegrate solids, reducing processing times by up to 90%. Product cannot bypass the intense mixing zone of the workhead . Single- and multi-stage units are available. For more information, contact Silverson Machines, Inc., P.O. Box 589, East Longmeadow, MA 01028 (phone 800-204-6400 or 413-525-4825, fax 413-525- 5804, www.silverson.com) —or circle 305.

by NEIL H. MERMELSTEIN

Senior Editor