Selecting an Outside Food Testing Laboratory

LABORATORY

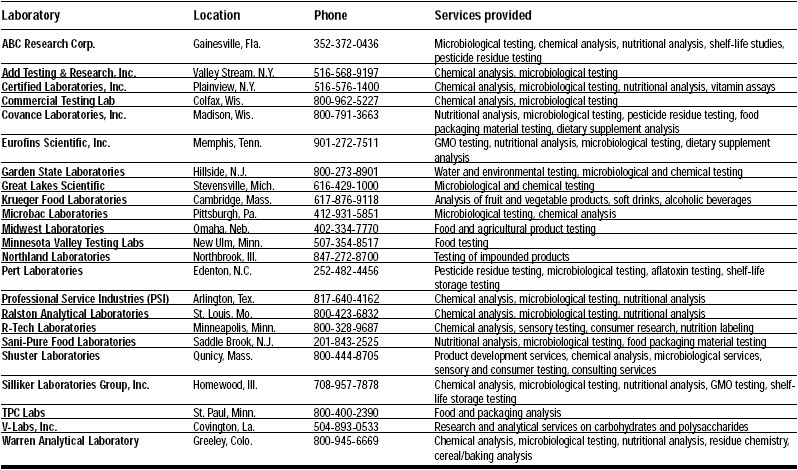

It has been a common practice in the food processing industry to use outside laboratories. These outside laboratories provide a variety of services such as microbiological testing, chemical analysis, nutritional analysis, shelf-life studies, pesticide residue testing, dietary supplement analysis, genetically modified organism (GMO) testing, sensory analysis, and other research.

These outside labs allow food processors to focus on their core activities while benefitting from economics of scale, experienced expertise, and overhead reduction. Some testing has become so specialized that creating and retaining in-house personnel in the area would be prohibitively expensive. One example would be testing for GMOs. The outside lab is often better equipped and more knowledgeable about their specialized branch of testing. However, food processors should be aware that they lose in-house skills, confidentiality, and the ability to closely control costs when using outside vendors. The best processes for outsourcing are ones that are standardized and well defined and require little active control.

Outside labs will often have testing knowledge and experience that come from working with a broad range of clients. In the food industry, regulatory requirements are especially important. Knowledge and experience of meeting government approvals (such as Food and Drug Administration or U.S. Dept. of Agriculture requirements) or compliance standards (such as Good Manufacturing Practices and Good Laboratory Practices) can be an important asset that labs offer. In addition, since many regulatory requirements are particular to separate industries (e.g., meat and poultry processing, baking, beverage processing), experience with these helps with timely and cost-effective management.

For a relationship with an outside supplier to be successful, both partners need to have shared objectives, mutual respect and trust, and commitment. The successful selection of an outside testing laboratory depends on the identification of internal performance requirements as well as the lab’s ability to meet those requirements. See the sidebar for a checklist to help determine if an outside laboratory is a good match.

PRODUCTS & LITERATURE

Meat Drug Residue may be checked with the Meatsafe® B-Lactam. The company claims that it is the only pre-slaughter screen to predict whether dairy or beef animals will pass the drug residue test at slaughter. The single-use unit is self contained and disposable. It may be used to detect more than 25 brands of penicillin, amoxicillin, amipcillin, hetacillin, and cloxacillin in urine. In less than 10 min, blue lines signal either safe or unsafe residue levels. For more information, contact Silver Lake Research Corp., P.O. Box 686, Monrovia, CA 91017 (phone 888-438-1942)—or circle 310.

Food Package Gas Analyzer may be used to measure oxygen and carbon dioxide in soft packages or rigid containers. Perishable foods are frequently packed under controlled or modified atmospheres to prolong shelf life and maintain product quality. Analysis of gases within the package is made to ensure that the packing machine is working properly. This instrument also ensures that the correct gas mixture is used and the packaging material and seal are of good quality. Three gases are commonly used in these packages: oxygen, carbon dioxide, and nitrogen. This instrument can measure oxygen and carbon dioxide in food packages with a free gas volume as small as 2.5 mL. It uses discrete measurement modules to provide an oxygen or carbon dioxide measurement in the range of 0–100%. Each measurement is displayed on a separate display and is also provided as non-isolated 0- to 1-V DC signal output. The analyzer is supplied complete with an accessory kit containing sample filters, needles, calibration nozzle, syringe, sample probe, self-adhesive sample seals, and septa. It comes in either rack mount or benchtop versions. For more information, contact Servomax Co., Inc., 90 Kerry Pl., Norwood, MA 02062-4733 (phone 781-769-7710; fax 781-769-2834)—or circle 311.

--- PAGE BREAK ---

Digital Hygrometer allows the user to check temperature and humidity levels throughout any structure. It is said to be ideal for use in assessing heating and cooling needs in processing and storage areas. The instrument features a large, easy-to-read LED display and minimum and maximum temperature memory. For more information, contact Goodway Technologies Corp., 420 West Ave., Stamford, CT 06902-6384 (phone 203-359-4708; fax 203-359-9601)—or circle 312.

Oxygen Demand Publication offers the wastewater industry information on measurement methods. The 16-p brochure presents thorough coverage of three different methods for measuring oxygen demand: Chemical Oxygen Demand (COD), plus two alternatives—Total Organic Carbon (TOC) and Biochemical Oxygen Demand (BOD). The brochure includes information on how to choose a method, with an entire page devoted to a comprehensive table outlining various parameters of the different methods, including regulatory status, most suitable use, advantages, considerations, and other factors. The brochure outlines the following methods of wastewater measurement: the Dichromate COD Method; the TOC Direct Method; a comparison of COD and TOC together; the BOD Dilution Method; TOC and COD vs BOD; colorimeters and spectrophotometers; and the COD Reactor. For a copy of the brochure, contact Hach Co., P.O. Box 389, Loveland, CO 80539 (phone 800-227-4224; fax 970-669-2932)—or circle 313.

Particle Sizer, the Malvern HPPS, may be used to measure particles in solutions. It covers an application range currently requiring three conventional dynamic light-scattering systems. Applications include the measurement of sub-nanometer-size particles as small as 0.6 nm and molecules in solution (including highly absorbing samples) through to the analysis of particles up to 6 microns. It is said to be especially suited to the measurement of colloidal systems and proteins and macromolecules in solution. For more information, contact Malvern Instruments, Ltd., Enigma Business Park, Grovewood Rd., Malvern, Worcestershire, WR14 1XZ UK (phone +44-0-1684-892456; fax +44-0-1684-892789)—or circle 314.

Outside Laboratory Checklist

The following checklist can help you determine if an outside laboratory is right for you. The checklist was provided by Philip Katz, president of Shuster Laboratories, a leading food product development and testing laboratory located in Canton, Mass.

Is the laboratory qualified to conduct the analysis or service that you require?

Are the laboratory personnel proficient in the testing or service that you require?

Does the laboratory have the appropriate facility, equipment and methodology to conduct the services that you are requesting?

Are the methods intended to be used to meet your requirements suitable and accepted by industry and the regulatory agencies?

Does the laboratory have accreditation or certification pertinent to the food industry?

Does the laboratory have written procedures?

Does the laboratory have an internal quality assurance program to ensure adherence to written procedures?

Are there adequate procedures in place for the receipt, handling, and retention of your samples?

Are there adequate means in place to address your needs regarding communication and turnaround?

Are comprehensive reports provided that document sample identification, data, methods, and interpretation of results?

What are the laboratory’s lead time requirements?

Is the pricing competitive?

by JAMES GIESE

Internet Editor