Placing Bar Codes Directly onto Foods

Innovative technology utilizes microscopic, edible bar codes that can be applied directly onto foods to make them more secure, safer, and less expensive.

Invisible, biodegradable markers that can carry up to the amount of information in a bar code and that can be placed directly on or within edible materials could provide several benefits to the food industry.

First, they could be used to make food more secure, by providing proof at any point along the production, storage, and distribution chain that a food product is what the label on its package says it is. Second, they could be used to make food safer, by providing similar proof that a food product has received a particular treatment at a particular time. Third, they could be used to make food less expensive, by replacing “one step forward, one step back” traceability protocols with reach-through and real-time documentation of the origin and subsequent history of a product.

This article describes a technology we have developed (Nightingale et al., 2003) that accomplishes this.

Technology Options

The easiest way to make something invisible is to make its largest internal diameter smaller than the resolving power of the human eye, which is about 0.5 mm (500 μm). The easiest way to make something biodegradable, or edible, is to use materials that are either generally recognized as safe or scientifically proven to be so, blend them with equally acceptable additives that accelerate to the desired rate of spontaneous decomposition of the parent compound under the conditions of intended use, and not expose the mixture during the manufacturing process to circumstances that might alter any of its native properties. The remaining design issues are how to place a very large amount of information on a very small area of a biocompatible material, how to locate and read these markers quickly and reliably, and how to do so at negligible unit cost.

The surfaces of most foods are far too easily deformed to maintain the highly ordered shape required to store a bar code of microscopic size. For this reason, the information has to be encoded on the surface of a fairly rigid microscopic particle, preferably a flat one, and that particle then has to be attached to the food. For most applications, the particles can be attached to the food by either (1) electrostatic attraction, (2) use of wetting agents, proteins, or lipids as adhesives, or (3) simply mixing the particles into a material that is subsequently mixed into or applied to a food. The choice of technique depends on how the subsequent conditions (e.g., temperature or humidity) under which the food is subsequently stored will affect the performance of the adhesive.

Binary codes are generally preferable to analog codes (e.g., codes that use shapes, colors, trace materials, or nucleic acid sequences) for information storage because binary codes are easier for machines to write, store, and read. They become more so as the amount of information encoded goes up and the space into which they are encoded goes down. Binary codes can either be stamped onto a sheet of marker material or scored onto it while it is being extruded into a filament. In the latter case, the code is subsequently revealed when the filament is cut into thin sections perpendicular to its long axis. This approach has substantial economies of scale.

Food markers made by extrusion would have to be made of thermoplastic, easily digested, and non-allergenic materials that can be spun into fibers. One such material is polylactic acid, which has been used for more than 40 years as a component of an absorbable surgical suture and more recently in cosmetic surgery to replace collagen. Another example is celluloses used to coat slow-release enteric pharmaceutical tablets. Their rate of spontaneous decomposition can be accelerated by adding small amounts of a material such as polyethylene glycol. This disrupts the regular internal pattern of the polymer and consequently increases its exposure to environmental agents (such as water in the case of polylactic acid) that break the polymer down into soluble monomers.

Size is the most critical element in the design of food markers. All other things being equal, the larger the marker and the more of them on or in the marked item, the easier they will be to find and read. For food, however, the size and concentration of the markers must be such that they have no detectable effect on the tare or the texture of the marked product. For tare, the markers should constitute no more than 0.1% of the weight or volume of the marked product. For texture, the concentrations should be two to three orders of magnitude lower than this, to roughly the concentration at which a consumer could not detect any effect they might have on the turbidity or taste of distilled water.

--- PAGE BREAK ---

The lower limit to the size of a microscopic marker is determined by the amount of information that it carries. The size of complex patterns on the edible thermoplastic polymers we have examined cannot be reduced much below 4 μm2 per bit of information. This is the size of a circle 1 μm in diameter in the center of a square 2 μm on a side. A bar code that contains 14 digits requires 47 ordered bits for binary representation (1014 is slightly less than 247). The marker has to be asymmetric, so that the order of the bits can be determined regardless of the marker’s orientation to the reader (e.g., top up or top down) and that increases by at least one bit the number of bits a marker must hold. The bottom line is that a marker made of a biodegradable material will need at least 200 μm2 of readable surface area to carry a bar code, and could do with a few more.

Regulatory Issues

When placed on or in food, the markers by definition become Food Additives. These by law must be generally recognized as or scientifically proven to be safe at the maximum amount to which a consumer would be exposed. If the markers were made from a cellulose that was also used as an inert filler for vitamin capsules, it would meet this requirement if the amount of that cellulose in all the markers on all the foods that a consumer might eat in a day would be less than the amount of that cellulose, say 10 mg, in a single vitamin capsule that is taken daily. Since many people take many such capsules a day without apparent harm, and since cellulose is either inert or metabolized to glucose, the regulatory bar for a cellulose-based marker would appear to be within reach. An alternative regulatory approach might be to consider the markers to be Food Contact Substances, although this regulation is intended to cover substances unintentionally incorporated into a food, such as a plasticizer in a packaging material. In addition, the issue of whether a food label would have to disclose the presence of a trace amount of an otherwise acceptable food additive that had been added solely for the purpose of making the food more secure, when that disclosure might compromise the security of the marker, is an issue that in the current political climate is probably negotiable.

Producing, Detecting, and Decoding

Producing, Detecting, and Decoding

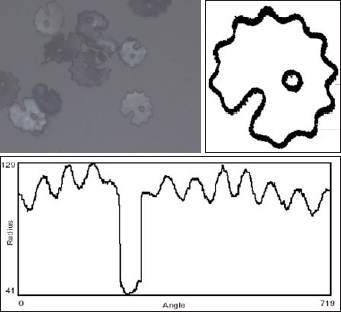

Fig. 1 shows a marker that was designed with the above considerations in mind. It was made by scoring and embedding the asymmetric binary pattern onto and within a fiber made of polylactic acid as it was being extruded into a filament. The filament was made from about 1 kg of the polymer, which produced about 1,000,000 m of fiber about 50 μm in diameter. The filament was spooled into the shape of a bicycle tire about 50 mm × 50 mm in diameter and about 1 m in circumference, so that there were about 1,000,000 revolutions of the fiber in the spool. The filament was embedded in paraffin while it was being spooled so that it could subsequently be cut into thin sections perpendicular to the long axis of the fibers. Fig. 2 shows a block of this spool mounted in a microtome. Approximately 100,000 10-μm-thick sections of this spool were made, yielding 100 billion (100,000 × 1,000,000) markers/kg of polymer.

The easiest way to decode a marker such as this is by direct visual inspection under a microscope. This particular marker has the approximate shape of a head with a mouth and an eye, seen in profile. In addition to the mouth, there are 11 different indentations around the circumference of the marker. Any or all of these 11 indentations can be present or absent. Because the design of the marker is asymmetric, the order of the presence or absence of the indentations is preserved, whether the marker is viewed from the top (e.g., mouth facing right) or bottom (e.g., mouth facing left). For this reason, the marker carries an ordered sequence of 11 ones or zeros, of which there are 211 or 2,048 different combinations. This is slightly less than one-fourth of a bar code. The design of markers such as this can be modified so that they can carry more combinations. Alternatively, more than one marker could be used to carry a larger code, with one or more bits on each marker (or markers of different designs) used to determine the order in which the markers are read.

The easiest way to decode a marker such as this is by direct visual inspection under a microscope. This particular marker has the approximate shape of a head with a mouth and an eye, seen in profile. In addition to the mouth, there are 11 different indentations around the circumference of the marker. Any or all of these 11 indentations can be present or absent. Because the design of the marker is asymmetric, the order of the presence or absence of the indentations is preserved, whether the marker is viewed from the top (e.g., mouth facing right) or bottom (e.g., mouth facing left). For this reason, the marker carries an ordered sequence of 11 ones or zeros, of which there are 211 or 2,048 different combinations. This is slightly less than one-fourth of a bar code. The design of markers such as this can be modified so that they can carry more combinations. Alternatively, more than one marker could be used to carry a larger code, with one or more bits on each marker (or markers of different designs) used to determine the order in which the markers are read.

--- PAGE BREAK ---

There are numerous pattern-recognition algorithms that can be used to decode images such as this automatically. One is to locate the center of the marker, determine the orientation of the mouth to the eye, and then measure the distance in pixels from the center to the circumference of the marker at half-degree rotations around the center, with the direction of rotation determined by the orientation of the mouth to the eye. The output of this algorithm is illustrated in Fig. 3.

There are numerous pattern-recognition algorithms that can be used to decode images such as this automatically. One is to locate the center of the marker, determine the orientation of the mouth to the eye, and then measure the distance in pixels from the center to the circumference of the marker at half-degree rotations around the center, with the direction of rotation determined by the orientation of the mouth to the eye. The output of this algorithm is illustrated in Fig. 3.

Other algorithms, such as pattern-matching algorithms, could be used for this marker, or for other markers of more complex design. In any reading system, it would be preferable to have at least two computationally independent algorithms determine the code on a marker. There is sufficient computational power in currently available laptop computers to decode several images of markers like this per second. It is not necessary or even desirable to write the instruction code for these algorithms from scratch. Several well-validated image analysis programs are available from government or commercial sources and can be adapted, though admittedly with some effort, to this task.

Reading these markers while they are moving is slightly but not prohibitively more complex. For example, if the shutter speed of a camera is set at 1/200 sec and a marker is moving at 1 cm/sec, a marker that is 50 μm in diameter will have moved 50 μm, or one full diameter, during the time the shutter is open. As a result, capturing its image would require a strobe light, which requires more control over ambient light, and more power, than may be available in some field settings. These are, however, easily obtainable in a production line or laboratory setting.

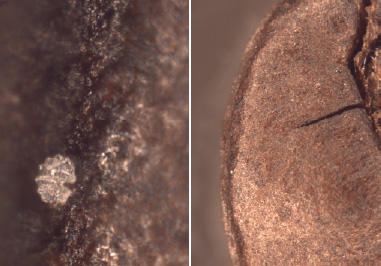

Thin films of highly ordered polymers such as polylactic acid transmit—and, as Fig. 1 also illustrates, polarize—light very efficiently, but they reflect it much less efficiently, in the range of about 1% of incident light. Markers on the opaque and irregular (and therefore light-absorbing and -scattering) surfaces of foods such as meat may therefore require higher concentrations of additives that disrupt the internal order of the polymer and thereby increase its reflectance, or alternately reflect light on their own.

There are other ways the markers can be detected. For example, they can be removed from the surface of the marked item with a detergent and then concentrated in the detergent by centrifugation. Alternatively, as in the case of the 50-μm-diameter particle in Fig. 1, the markers can be filtered out of the detergent with a No. 325 mesh, which retains particles with any internal diameter greater than 44 μm. To extract markers embedded within foods, the food can be disrupted by gentle sonication, to which at least the markers we have examined are relatively immune. When the markers are suspended in a liquid, they can also be identified, and counted, by a variety of particle size measurement technologies.

--- PAGE BREAK ---

Applications

Applications

Figs. 4–6 illustrate various applications of these markers. Fig. 4 shows a marker on a cut of prime beef. The marker was applied by spraying the meat with a dilute acetic acid solution similar to antiseptics that are routinely sprayed on beef, pork, poultry, and fish carcasses to control or eliminate bacterial pathogens such as Listeria and Escherichia coli. The markers could be used to preserve the identity of the carcass from which an individual cut was made in an active meat production facility.

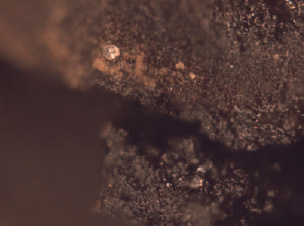

Fig. 5 shows the marker identifying a Perigord truffle, Tuber melanosporum, which retails for about €1,000/kg. France produces about 35 metric tons a year. T. melanosporum is indistinguishable by untutored sensory examination from Tuber indicum, which retails for about €1/kg. France imports about 30 metric tons from China a year. As might be expected, counterfeit truffles have become a problem, and Le Monde reported on January 10, 2003, that the French government has supported the development of a mitochondrial DNA test to distinguish the two tubers. The marker in Fig. 5 provides a comparable degree of authentication at potentially much less expense, thereby illustrating how these markers can increase the security and lower the cost of a food.

Fig. 5 shows the marker identifying a Perigord truffle, Tuber melanosporum, which retails for about €1,000/kg. France produces about 35 metric tons a year. T. melanosporum is indistinguishable by untutored sensory examination from Tuber indicum, which retails for about €1/kg. France imports about 30 metric tons from China a year. As might be expected, counterfeit truffles have become a problem, and Le Monde reported on January 10, 2003, that the French government has supported the development of a mitochondrial DNA test to distinguish the two tubers. The marker in Fig. 5 provides a comparable degree of authentication at potentially much less expense, thereby illustrating how these markers can increase the security and lower the cost of a food.

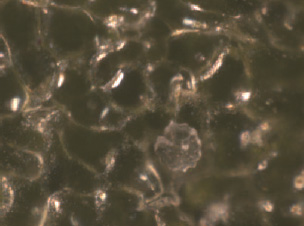

Fig. 6 shows a marker on a leaf of spinach. For this illustration, markers were suspended in Fit®, a cleaning solution for produce distributed by HealthPro Brands, Inc., Cincinnati, Ohio. The presence of the marker documents that the lettuce was sprayed with this solution. The marker could provide additional information about the time or other aspect of the spraying process, or about the origin and provenance of the marked item.

Fig. 6 shows a marker on a leaf of spinach. For this illustration, markers were suspended in Fit®, a cleaning solution for produce distributed by HealthPro Brands, Inc., Cincinnati, Ohio. The presence of the marker documents that the lettuce was sprayed with this solution. The marker could provide additional information about the time or other aspect of the spraying process, or about the origin and provenance of the marked item.

In each of these examples, the person in possession of a food product at any point along its production, storage, or distribution chain has the capacity to encode any and all information that any person who subsequently comes into contact with that product might have about that product. For example, one marker on a piece of meat might indicate that it came from the 1,022th carcass to be processed at a facility on a particular day, and a second marker (with a different pattern) might indicate that the piece of meat was subsequently irradiated at a particular facility at a particular dose on a particular day. The code itself can be open or encrypted; e.g., a marker bearing code 1022 could refer to the 1,022th carcass processed on a day, or it could refer to the 14th carcass if the code were scrambled in that way.

--- PAGE BREAK ---

The markers are not intended, at least initially, to replace the label on a food product. Instead, they are intended to provide the capacity for independent, on-demand validation of the information on a product label, and to serve as a complete backup identification system for a product in the field in case the product label has been corrupted or lost, as, for example, in a theft or product recall.

In some circumstances, it may be useful to use a marker that dissolves after a particular amount of time, or after it has been heated to a particular temperature. These characteristics can be controlled by modifying the polymer(s) from which the marker is made, for example the average length of its chains. Such modifications would also deter attempts to reuse markers for illicit purposes, and to prevent contamination of an environment by markers that may remain after the product they marked has been processed or consumed.

Potential for Industry Acceptance

Public or industry acceptance of any change other than price reduction is rarely instantaneous. Initial acceptance is most likely in specific areas, not necessarily in the United States, where producers and customers would agree that additional product validation is desirable. Traceability of beef comes to mind immediately in this regard.

Broader industry acceptance of direct-marking technologies for foods depends on the answer to three questions:

Will it add sufficient value to justify its cost? The total cost of marking and detecting marked foods will probably be in the range of 1% of the sale price of the marked product, with the majority of the cost in the reader rather than the marker. Some of this might be recouped in reduced costs of tracing products after they are manufactured, both routinely and in the event of product recall. Some might be recouped by deterring or increasing recovery from theft of products. Some might be recouped in the premium that some consumers are now willing to pay for branding of foods with certain “credence” attributes, such as whether it is “dolphin-free,” “organic,” “kosher,” or the product of a particular region.

Will it increase producer exposure to product liability? It would be easier for an individual who became ill after eating a marked item to trace that item to its source. At the same time, it would also be easier for the producer, or a public health official, to trace other portions of that item to other consumers who may or may not have become ill after exposure to it. The net economic result can be argued either way, with the deciding vote cast by the insurance industry.

How durable is the technology? The U.S. Dept. of the Treasury currently estimates the service life of an anti-counterfeiting technology to be seven years. It would be difficult for the food industry to profit from the use of any technology that became obsolete in so short a time. However, some anti-counterfeiting technologies are more durable than others, and durability is a function of the amount of information that a particular technology encodes. The 128-bit data encryption technology used to secure Internet purchases, for example, is in no danger of obsolescence. Markers for food, or for that matter any other product, need not encrypt this amount of information for every application; but the greater their capacity to do so, the longer their survival in the marketplace is likely to be.

Author Nightingale is President, Burntside Partners, Inc., 4703 Broad Brook Dr., Bethesda, MD 20814. Author Christens-Barry is President, Equipoise Imaging LLC, 4009 St. Johns Lane, Ellicott City, MD 21042. Send reprint requests to author Nightingale ([email protected]).

References

Nightingale, S.D. and Tangen, N.M. 2003. Multi-functional product markers and methods for making and using the same. U.S. patent application 10/465,781 and international application PCT/US2003/16227, June 22. A Notice of Allowability for the claims in the U.S. patent application was issued on September 28, 2004.