Electronic Noses and Tongues

LABORATORY

Electronic noses and tongues constitute a young technology and an industry in flux, according to Murat Balaban, Professor, Dept. of Food Science and Human Nutrition, University of Florida, Gainesville. The flux part focuses on the rise and fall of key players in a relatively short time.

"The company I purchased my first e-nose from in 1993 changed names three times by 1999," Balaban says. "New technology brings promotions that go overboard. Companies can’t keep promises, word gets out, and weaker companies filter out while stronger ones satisfy customers’ needs."

Despite those developments, it’s a technology that holds several promises for food-chain stakeholders, Balaban says. "Electronic noses and tongues have the potential to become smaller, faster, cheaper, and easier to operate. That will happen if the industry settles and some problems are resolved."

"I envision a day when every USDA inspector has an electronic nose on his or her belt, and there will be individual sensor sets available for milk, shrimp, and other perishables," Balaban predicts. "Most standard-size electronic noses include up to 32 sensors, but for commodities like milk and shrimp, only three or four sensors are necessary. More research is necessary to refine the technology."

How They Work

R.W. Moncrieff developed an instrument for detecting odors in 1961 and published studies of redox reactions of odorants as an electrode and modulation of electrical conductivity and contact potential by odorants in 1965.

The first practical application of an e-nose was for detection of plastics in landmines by the U.S. Army during the Vietnam War. The concept of an e-nose as a chemical array sensor system for odor classification was presented for the first time by Krishna C. Persaud and George H. Dodd in 1982 (www.aromasciences.com/our-perfumer.asp).

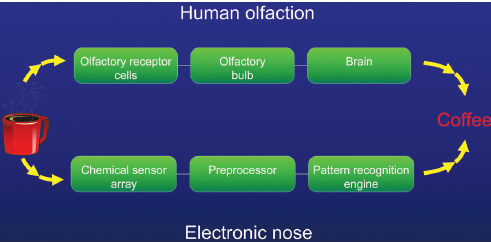

The electronic nose mimics the way the system of interconnected receptors and neurons in the incomparable and irreplaceable human nose interact and respond to vapor molecules. An array of sensors, composed of polymers, for example, expands like a sponge when it comes in contact with volatile compounds in the headspace of a sample, increasing the resistance of the composite. The normalized change in resistance is then transmitted to a processor to identify the type, quantity, and quality of the odor, based on the pattern change in the sensor array.

The electronic nose mimics the way the system of interconnected receptors and neurons in the incomparable and irreplaceable human nose interact and respond to vapor molecules. An array of sensors, composed of polymers, for example, expands like a sponge when it comes in contact with volatile compounds in the headspace of a sample, increasing the resistance of the composite. The normalized change in resistance is then transmitted to a processor to identify the type, quantity, and quality of the odor, based on the pattern change in the sensor array.

--- PAGE BREAK ---

An electronic nose works with the gas phase of a volatile compound, while an electronic tongue works in the liquid phase of a nonvolatile compound.

Electronic noses and tongues can be used to identify flavor variety and geographical origin, composition, aroma intensity, and degree of freshness. Moreover, electronic noses are suitable for measuring release of gases and odors from packaging materials.

Training is the key to using these machines," says Balaban, "training the machines, that is. If, for example, an electronic nose has never smelled bad shrimp, the machine doesn’t know what bad shrimp is. You have to expose it to all the qualities of shrimp so it can formulate a database which will enable it to compare differences in various shrimp samples."

Current issues in e-nose and e-tongue technology, he says, include repeatability of results and reuse of training data. "We need to develop a standard set of data for any commodity we want to measure. At this point, if the same make and model of electronic nose or electronic tongue is used to measure the same sample, the results will frequently vary. To be able to share databases of training data, agreement on standardization methods needs to be established."

"With proper training, electronic noses and tongues will remove the subjectivity from odor and flavor determination and measure objectively," Balaban says. "You can’t say that for human noses and tongues."

Two Major Manufacturers

Alpha MOS (www.alpha-mos.com), headquartered in Toulouse, France, and Hanover, Md., is perhaps the most active player in both the electronic-nose and electronic-tongue industries. Founded in 1994, the firm is still expanding its product range and market coverage, according to George Foster, Business Manager for U.S. operations.

"Our instruments can perform organoleptic analysis correlated with sensory panel, gas, or liquid chromatography techniques, and also chemical analysis."

Utilizing chemical sensors and, more recently, ultra-fast gas chromatography, the firm’s electronic noses are designed to serve as a screening tool for aroma and volatile organic compound analysis. Since an electronic nose can differentiate more than 10,000 scents, there are many applications, Foster points out.

--- PAGE BREAK ---

The company’s electronic tongue measures dissolved compounds responsible for taste in liquids. "The electronic tongue can detect major tastes such as sweet, sour, bitter, salty, and umami, which resembles the effect of MSG, and sub-taste attributes like spicy and metallic," he says.

Electronic Sensor Technology (EST), Newbury Park, Calif. (www.znose.com), established in 1995, developed and manufactured what was the first electronic nose with the ability to identify and measure the concentration of individual chemicals. Known as the zNose®, this real-time electronic device was the first solid-state odor detector to implement gas chromatography, according to Edward Staples, founder of the company and inventor of the zNose. Alpha MOS recently developed the Heracles e-nose, which, like the zNose, is based on ultra-fast chromatography.

How exactly does a more traditional e-nose differ from a zNose? E-noses can only recognize the chemical patterns of odors, Staples says. "Since they cannot measure the concentration of the individual chemicals in the odor, they are not able to separate the chemicals. Separation is what a gas chromatograph does," he explains.

"The zNose can do both," Staples continues, "recognize chemical patterns and quantify the concentration of the individual chemicals in the odor. Furthermore, it does it in 10 seconds, which is 10 times faster than any e-nose."

Currently, the company caters to five markets. "In addition to the food and beverage industries, zNose has applications for clients in the chemical/petrochemical, life sciences, environmental, and security industries," Staples says.

"The zNose sees all and misses nothing," he emphasizes. "It is designed to respond to any chemical that’s volatile. We have added a global positioning system so not only can it quickly and reliably separate chemicals and measure the concentration of each, it can also determine the exact location of the odor."

The zNose has the ability to create two-dimensional images. "This feature is useful when odors mix and it’s difficult to differentiate them," Staples explains. "We can separate odor patterns and create fingerprints, which we call VaporPrints™, that identify the chemicals involved."

Many Applications

E-noses are used for quality control applications in many industries, such as foods and beverages, packaging, pharmaceuticals, flavors and fragrances, chemicals, and petrochemicals. Specific QC applications include conformity control of raw materials, processed or end-products, batch-to-batch consistency, contamination detection, supplier selection, certification of origin, and clean-in-place process monitoring.

--- PAGE BREAK ---

Applications in research and development include new product formulation, selection of raw materials, and competitor benchmarking.

In the pharmaceutical industry, the performances of these taste and odor analyzers are of major interest. "Electronic noses can determine the stability and shelf life of products like cough syrups and throat lozenges," Alpha MOS’s Foster explains. "Since you can’t legally have people sitting around all day tasting drugs that are still in the developmental stages, electronic tongues are the perfect solution to test the palatability of various coatings for tablets or other oral delivery forms. For example, with an electronic tongue, firms can do a complete bitterness assessment of a new chemical entity or active pharmaceutical ingredient of a product using a dedicated scale and index based on more than 20 bitter compounds."

Besides bitterness assessments, electronic tongues can also measure the taste-masking abilities of many delivery forms, including emulsions and orally disintegrating tablets.

"These capabilities speed up drug formulation, which provides an obvious economic benefit to manufacturers of both prescription drugs and over-the-counter products," Foster says.

These days, electronic noses are also finding work in the fields of homeland security, forensics, and environmental assessment. "Our newest miniaturized technologies, which are small boxes including six detectors, can monitor gas and odor emission for indoor air quality, outside air quality, and safety monitoring in sewage plants, composting plants, landfill plants, livestock carcass-quartering sites, and petrochemical plants," Foster adds.

In the food area, C.P. Kelco (www.cpkelco.com) uses the Alpha MOS electronic nose. The Atlanta, Ga.–based company is a leading manufacturer of pectin, xanthan gum, cellulose gum, and gellan gum and also a major manufacturer of carrageenan.

"There are two principal ways in which we use this instrument," says Ross Clark, Distinguished Research Fellow at the company’s R&D lab in San Diego, Calif. "One is in manufacturing and quality control, and the other is R&D. The electronic nose helps us develop a greater understanding of our thickening and gel agents and how they interact with the flavor and aroma of food." Two recent research applications include flavor and texture interactions in model water gels and sensory characteristics of noncarbonated orange beverages.

"Electronic noses can predict certain, but not all, sensory properties," Clark says. "A few flavor and aroma notes can be measured and correlated to what people feel, but electronic noses do not replace human sensory panels. There are still things people notice for hedonic study that technology cannot find."

by Linda L. Leake , a recent graduate of the Professional Master of Science in Food Safety Program at Michigan State University, is a freelance journalist based in Wilmington, N.C. ([email protected]).

References

Luzuriaga, D.A. 1998. Uses of the electronic nose in the food industry. Presented at the Food Science and Human Nutrition Dept. seminar, 1998

Moncrieff, R.W. 1961. J. Appl. Physiol. An instrument for measuring and classifying odors. 16: 742-749.