PROCESSING

Nanotechnology a Processing Topic This Year

With the changes in the technical program for IFT’s 2006 Annual Meeting + Food Expo® that have been introduced by the special task force in which I participated, there are fewer papers on processing this year than in recent years—a higher fraction of submissions were rejected than in the past to increase quality.

The Food Engineering Division and the Nonthermal Processing Division are presenting some conventional oral sessions, some symposia, and many poster presentations. Nanotechnology, dehydration, nonthermal processing, and ohmic heating are some of the topics of the food processing symposia and papers this year. Here is a brief description of some of them.

Nanotechnology

Bioterrorism, the threat of deliberate contamination of some portion of the food supply, helped inspire an intriguing session, "Nanotechnology for Improved Detection of Bioterrorist Threats to Food Safety," on Sunday afternoon, June 25. Nanotechnology has shown an improved capability in orders of magnitude to detect chemical, biological, radiological, and explosive (CBRE) agents with high sensitivity and selectivity, protect lives from and neutralize CBRE agents, and provide site-specific prophylaxis.

This symposium, session 8, will present the latest developments in nanoscale science and technology relevant to detection of CBRE agents, with particular reference to those that may enter foods and food production and the processing environment.

The session will open with a high level overview of the National Nanotechnology Initiative and its multi-agency efforts on the grand challenge of CBRE detection and protection. It will be followed by discussion of the recent breakthroughs of various innovative nanosensors for detecting pathogenic bacteria. Successful examples of moving a laboratory benchtop discovery to practical commercialization in the private sector will be highlighted.

A related session is session 46, "Nanotechnology in the Delivery of Bioactive Compounds and Micronutrients in Foods," on Monday afternoon. Nanotechnology has the potential to provide new solutions on many fronts. New research into nano-emulsions, liposomes, micelles, and biopolymer complexes can lead to improved properties for protection of bioactive compounds, integration into food matrix, stability through food processing and distribution, masking of undesirable flavors, and modifying of sensory profile. New developments in nanotechnology will allow design of smart delivery systems that can sense and respond to specific stimuli for controlled release with feedback regulation capability.

--- PAGE BREAK ---

The symposium will describe recent developments in potential applications of nanotechnology in relation to functional foods and nutraceuticals. It will focus on fundamental concepts of nanomaterials and engineering approaches for target delivery systems, potential applications of nanomaterials in foods, and methods for analyzing and characterizing these materials.

Immediately following this session will be the Food Engineering Division Distinguished Lecture, "High Pressure–Assisted Processes: Opportunities and Challenges for Food Engineering," by Marcel Loncin Research Prize winner Dietrich Knorr.

Although not part of the Annual Meeting, an International Food Nanotechnology Conference cosponsored by IFT and USDA/ CSREES will be held in Orlando immediately after the Annual Meeting. Details can be found at www.ift.org/nanotechnology.

Dehydration

Drying is a mature and often overlooked technology, but session 3B, "Food Engineering: Drying and Acrylamide Formation," on Sunday afternoon offers 32 poster presentations covering such topics as osmotic dehydration, rehydration, spray drying, acrylamide formation, sorption isotherms for several materials, glass transition phenomena, and edible films made of gellan, zein, and maltodextrin.

Session 24 on Monday morning, "Dehydration Options—New Developments Offer New Choices and New Products" continues the topic. Because energy costs play an important role in determining dehydration processes for products, this symposium will compare energy consumption and savings for the technologies. It also offers a glimpse into new innovations in drum drying, spray drying, and vacuum drying, as well as combinations of processes to optimize products and reduce energy/equipment costs.

Since equipment suppliers, universities, and R&D consultants offer advanced pilot-plant facilities so that companies can shop and compare before they buy the equipment they need or contract for custom processing, this symposium will provide contact information and explain confidentiality, contracts, and costs involved in conducting trials.

Nonthermal Processing

An important aspect of nonthermal processing—and of thermal processing, for that matter—is understanding how the Food and Drug Administration evaluates a submitted process. The suggested approach uses Food Safety Objectives. Session 59, "Conceptual and Mathematical Description of the Food Safety Objectives (FSO)," on Tuesday morning addresses this topic. The FSO formula and its components will be explained from conceptual, mathematical, and statistical standpoints. Each of the components of the formula will be addressed individually and their integration and potential application discussed.

This symposium will address the lethal effects of different processes using diverse lethal agents such as steam, high pressure, gas, radiation, multiple hurdles, etc., and diverse environmental conditions that may influence the presence, survivorship, and growth of microorganisms in foods.

--- PAGE BREAK ---

Ohmic Heating

Ohmic heating is thermal processing, but in an unconventional form. Session 106, "Ohmic Heating: New Technological Developments Spur a Reemergence," on Wednesday morning offers five papers in this area. Ohmic heating saw considerable activity in the early to mid-1990s. Since that time, the number of commercial installations worldwide has grown and new manufacturers have entered the market. With the development of solid-state power supply technology, it is now possible to use ohmic heating in pulse mode, to economically control electrolytic effects to innocuous levels.

A wide variety of potential designs exist for ohmic heaters, depending on the application. Although the sterilization of solid– liquid food mixtures has attracted much attention, other applications have been identified recently.

The interaction of electric fields with biological materials results in interesting effects that have significant economic implications in food and bioproducts processing. These processes, which rely either solely on the nonthermal effects of electricity, or the effects of combinations of electrical and thermal phenomena are loosely described as Moderate Electric Field (MEF) processes, which involve the application of electric fields typically under 1,000 V/cm, with or without heating to accomplish specific objectives.

MEF processes have been shown to permeabilize eukaryotic cells, resulting in increased drying rates and juice expression yield compared to conventional treatments. Extraction of cellular constituents, e.g., betanins from sugar beets, may be enhanced and oil absorption during frying controlled. The lag phase of bacteria during fermentations may be decreased by the application of MEF during the fermentation. Using ohmic heating and the MEF electrical effects, vegetables and fruits may be peeled, with high quality and competitive yield, with minimal use of caustic chemicals, and blanch water use may be potentially greatly reduced.

Other Processing Sessions

The Food Engineering Division will sponsor poster sessions 3C, "Rheology and Texture," on Sunday afternoon; 78D, "Heat Transfer," on Tuesday afternoon; and 78E, "Modeling and Physical Properties," on Tuesday afternoon.

The Nonthermal Processing Division will sponsor oral sessions 26, "Keeping It Fresh—Dealing with Threat in the Global Market," on Monday morning; 17, "Vitamin and Microbial Inactivation Kinetics," on Sunday afternoon; and poster sessions 39J, "High Pressure Processing: Biochemical, Microbiological, Chemical, and Physical Impacts," on Monday afternoon; 39K, "Pulsed Electric Fields, UV, Sonication, Ozone, and Irradiation," on Monday afternoon; and 72, "Physical and Biochemical Changes in Food Undergoing Nonthermal Processing," on Tuesday morning.

The main opportunities for presentation of newly commercialized developments in ingredients, processes, instruments, and functional ingredients are the well-attended sessions organized by the New Products and Technologies (NTP) committee, which is probably more selective than any other programming group, accepting only about 40% of submissions. One of the four NPT sessions, session 33, will focus on "Innovations in Processing, Packaging, and Food Safety," on Monday morning.

--- PAGE BREAK ---

Exhibits

Here are descriptions of some of the processing-related exhibits at Food Expo:

• Twin-screw food extruder, the Buhler BTSK-30, is designed for parameter evaluation, process development, process optimization, pilot plants, and small production requirements. With new counterflow cooling and increased maximum torque, the extruder can provide laboratory quantities or higher throughputs in small production operation. The extruder is designed to allow rapid changeover of barrel length and configuration. Buhler Inc., www.buhlergroup.com, Booth 4432

• Snack food pilot plants in Tampa, Fla., and Firminy, France, can be used to generate new products and ingredients, including unique shapes, textures, and colors. The pilot plants are equipped with R&D and production twin-screw extruders, dryers, and ancillary equipment. On-site process engineers and scientists assist in product development, formulation, and production. Recent developments include coextruded products with novel flavor combinations, bi-colored snacks, and bi-textured varieties, as well as products that incorporate healthy ingredients such as whole grains, natural ingredients, protein, and legumes. Clextral Inc., www.clextral.com, Booth 966

• Thin-film evaporator overcomes the limitations of membrane filtration techniques and traditional multiple-effect evaporators for concentrating dairy proteins prior to spray drying. The Centritherm evaporator facilitates attainment of high protein concentrations and can substantially increase dryer capacity. The resulting protein concentrates are of high quality and functionality, since the thermal impact is negligible due to the short residence times and low evaporation temperatures. FT Technologies, www.ft-tech.net, Booth 1138

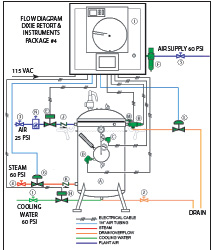

• Retort control system for low-volume processing retorts provides ease of control. After the user enters desired setpoints and pushes the start button, the retort automatically performs all programmed cycles. The new Recipe Download Program allows up to six process recipe downloads to be stored for repeated use or modified as product or processing requirements requirements change. Dixie Canner Co., www.dixiecanner.com, Booth 3517

• Retort control system for low-volume processing retorts provides ease of control. After the user enters desired setpoints and pushes the start button, the retort automatically performs all programmed cycles. The new Recipe Download Program allows up to six process recipe downloads to be stored for repeated use or modified as product or processing requirements requirements change. Dixie Canner Co., www.dixiecanner.com, Booth 3517

• Pilot-plant mixer and/or dryer, the FM-75, can be used for a variety of R&D applications and processes. The 75-L mixer has stainless-steel construction, allowing for easy disassembly and cleaning. The jacket is designed for heating and cooling and is rated at 90 psig at 330°F. Charging is accomplished through a charging door. A high-speed 5-hp chopper is available. Contour door is provided as the standard discharge, with semi-spherical valve or ball valve available as an option. The Filtorr® system for liquid-solid separation may be used in conjunction with the optional valves for many applications, including impurity removal and extractions. Littleford Day, www.littleford.com, Booth 1889

• Mini production processors are laboratory UHT and HTST processing systems that can be used for scaling up and down aseptic, pasteurization, hot-fill, and continuous cooking processes. The PLC-controlled systems feature plate heat exchangers, multiple hold tubes, and an in-line homogenizer, plus extensive datalogging and a complete on-board setup and operation manual. The equipment can produce production-quality samples of milk, shakes, soy milk, juices, puddings, baby foods, and other products right in the lab. Also available are laboratory steam injection, tubular, plate and microwave systems with in-line homogenization, ultra-clean filling, and more. MicroThermics, Inc., www.microthermics.com, Booth 1741

--- PAGE BREAK ---

• Automated hygiene equipment for food processing employees includes the new CleanTech® 500EZ automated hand washing and sanitizing system. The system is all stainless-steel and water-tight with a wall-mount installation. The new ProTech Solution is a high-throughput, walk-through, hand- and boot-washing/sanitizing system designed for areas where a high volume of employees enter a clean area at one time; it washes and sanitizes the hands and boots of approximately 30 employees/min and is also available as a hands-only system. Meritech, Inc., www.meritech.com, Booth 4041

• Ultrasonic processing of low-viscosity liquid samples is provided by the VCF 1500 High Volume Continuous Flow Cell. Designed primarily for dispersing and homogenizing, the unit provides uniform exposure to the ultrasonics, allowing throughput rates as high as 100 L/hr, depending on the viscosity and degree of processing. The flow cell is powered by a 1500-W ultrasonic generator and is easily dismantled for inspection and cleaning. Sonics & Materials, www.sonics.biz, Booth 2991

• Depositor produces center-filled chocolates, hard candies, and caramels and can also be used for new concepts such as honey-filled throat drops, yogurt-filled fruit jellies, or sugar-free hard candy filled with energy gel. Custom dies are available for innovative stripes, swirls, and patterns. The depositor has two or more individually heated and temperature-controlled product hoppers and pump heads. Servo operation for each pump is independent, so the operator can set separate parameters such as up and down speed, start and stop timing, and stroke length. The depositor has many automated features, can store up to 99 recipes, and can also be operated manually. Bottom Line Process Technologies, www.blt-inc.com, Booth 4623

• Adsorbent media in the Amberlite™ FP line are designed for use in processing food products and additives. Applications include citrus juice debittering and deacidifying, demineralization, removal of metals and color, odor reduction and taste improvement, and processing of wines and beers, as well as many large-scale applications in the sugar, starch, and organic acids industries. Amberlite FPX66 is a new adsorbent for purifying plant extracts such as antioxidants and polyphenols. This polymer has large internal surface area very selective of organic molecules and can be applied to great variety of cultivars, including grape, pomegranate, cranberry, cocoa, blueberry, strawberry, and green/black tea. Rohm and Haas, www.rohmhaas.com/ionexchange/nutrition, Booth 1351 and Paper 33-01

• Site location for processing plants in Iowa is one of the services the Iowa Dept. of Economic Development offers. Other services include existing building availability, profiles of existing labor force, and permitting and financing assistance. The department is hosting a reception from 5:30 to 7:30 p.m. on Sunday, June 25, at the Rosen Center Hotel, to tell about Iowa’s advantages. Iowa Dept. of Economic Development, www.iowalifechanging.com, Booth 3203

--- PAGE BREAK ---

• Encapsulation technology provides microspheres and microcapsules for the food, flavor, and other industries. A wide variety of materials can be formed into perfectly round spheres or encapsulated with a host of shell materials, using technology developed by Brace GmbH, Germany. Reduced manufacturing costs, a narrow particle size distribution, and complete control over the release profile of encapsulated materials are major benefits. The new Microsphere and Encapsulation Technology Laboratory features state-of-the-art equipment ranging from bench scale to high-capacity production systems and can be used for development work, testing, and optimization of processes for commercial scale-up. Spheres and capsules may be manufactured in sizes from 50–100 microns to 6–8 mm. Harper International Corp., www.harperintl.com, Booth 3271

• Twin-screw extruders in the Magnum ST Series are available in four sizes with speeds up to 1,200 rpm. They can be custom designed to include new shear and kneading elements for precise control of product shape, texture, density, and cooking time. The DDC preconditioner, mid-barrel and back pressure valves, an external density management system, a new overhead rail system, and a manual or automatic control system are available as special options to customize to product requirements. Wenger Manufacturing, Inc., www.wenger.com, Booth 948

• Processing equipment for drying, granulation, agglomeration, evaporation, filtration, liquid processing, homogenization, packaging, powder handling, tableting, mixing, containment, and dry condensing is offered by Niro, Inc., a member of the GEA Group, a global technology group specializing in process systems and solutions. Niro, Inc., www.niroinc.com, Booth 2551

• Pilot-scale processing system, the FT94, extends the range of the company’s scaled-down HTST/UHT equipment from 10-20 L/hr to 50–100 L/hr, enabling larger batches of material to be prepared for more-extensive product trials. The system offers plate and concentric tubular heat exchanger options. The latest version features a 24-bar pump that enables the tubular heat exchanger to handle more viscous product. The FT94 is designed for operation as both a stand-alone unit and for seamless integration into a full processing system with the capability of aseptic packaging of processed product. Product is pre-heated by a steam-heated water circuit to prevent heat shock, then heated by steam through the heat exchanger surface. Both preheat and heating temperatures are automatically controlled to setpoints defined by the user. The FT94 incorporates full CIP and SIP functions. Also available are miniature-scale processors, including the FT74X HTST/UHT system, the FT74DI direct steam injection system, the FT25BBP margarine crystallizer, the FT80 spray dryer, and the FT102 carbonator/filler. Armfield Ltd., www.armfield.co.uk, Booth 2507

by J. Peter Clark,

Contributing Editor,

Consultant to the Process Industries,

Oak Park, Ill.

[email protected]