Sustainability: A New Buzz in Food Packaging

PACKAGING

For those who have been following the impending adoptions of nanotechnology, radio-frequency identification, super barrier, active components, intelligence, sensing of specific pathogenic microorganisms, and the like intruding into our universe of food packaging, welcome to another innovation: sustainable packaging.

The Sustainable Packaging Coalition (www.sustainablepackaging.org) consists of organizations from the entire spectrum of packaging, including converters of package materials and structures, large food manufacturers and retailers, and major foodservice chains.

The Sustainable Packaging Coalition (www.sustainablepackaging.org) consists of organizations from the entire spectrum of packaging, including converters of package materials and structures, large food manufacturers and retailers, and major foodservice chains.

According to the organization, sustainable packaging meets the needs of the present without compromising the ability of future generations to meet their own needs. Sustainable packaging systems do not deplete the planet’s natural resources—oxygen, water, petroleum, plant life, animal life or its subset, human life.

According to the organization, sustainable packaging meets the needs of the present without compromising the ability of future generations to meet their own needs. Sustainable packaging systems do not deplete the planet’s natural resources—oxygen, water, petroleum, plant life, animal life or its subset, human life.

Cradle-to-Cradle Approach

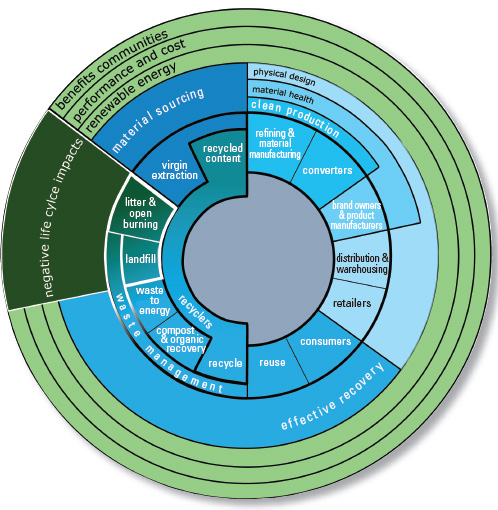

Sustainable packaging adherents advocate cradle-to-cradle cycles for materials rather than a cradle-to-grave approach.

Cradle-to-grave concepts assumed that we could account for all the energy and mass differences from product—and, in our context, packaging—from the moment of its inception until its disposition. By applying the ill-defined rules of this concept, we could quantify the metrics of one alternate vs another. The concept accepted that energy is required and lost (the third law of thermodynamics, which is not refutable) and that eventually the mass may be discarded and not necessarily reused or recovered. Package materials could enter into landfills and sanitary landfills for practical purposes never again to be seen. Under this scenario, some account was taken of future land use of the landfill or energy recovery via burning of waste.

The cradle-to-cradle, or sustainability, approach embraces the notion that all things on this planet are totally renewable, that there should be no waste of energy or mass. Obviously, this is the reality of the universe.

--- PAGE BREAK ---

With regard to packaging cradle-to-cradle, package manufacture precedes the packaging operation and distribution to retail and consumers who acquire and use the contained product. The spent package is recovered and is the input to either a technical nutrient flow (recycling or reuse) or a biological nutrient flow (composting or resource growth). The output of this recovery effort enters into new raw material processing, which in turn feeds the package material converting, starting the entire cycle again—with no losses.

Cradle-to-cradle cycles reduce overall use of finite resources and minimize waste—with an ultimate goal of zero waste—through flow of materials and a 100% effective recovery infrastructure. The entire supply chain is controlled to include economically viable recovery systems to recover value.

Today, cradle-to-cradle encompasses biological recovery, through such measures as managed composting to recover the nutrient value of basic biological materials such as paper and paperboard and wood; technical recovery, i.e., recycling and reuse, to recapture value such as for glass and metal; and energy recovery, through waste to energy, to recover value from spent package materials, a chain that is not necessarily sustainable but is better than landfill, incineration, or litter.

Considers All Materials

Sustainability further fosters the thought that all materials—not just packaging—are the object of perpetual reuse and recycling; agriculture should eliminate the use of "chemical" pesticides and fertilizers, and food processors should never apply "chemical preservatives." The forces of sustainability compel us to look far, far beyond petroleum energy sources to solar, hydroelectric, biomass, geothermal, and wind energy; toward compostable and biodegradable package materials; and to plastics that can be reused forever.

Sustainable packaging is:

• Made using clean production technologies; conserving raw materials, water, and energy; eliminating toxins and waste; reducing risk to humans; reducing environmental impact; increasing efficiency; and ultimately reducing costs.

• Made from materials healthy on all end-of-life scenarios to conserve human and ecological health; eliminate harmful emissions and migrants such as inks, coatings, solvents, and adhesives, especially at the end of life; and ban unsafe materials from packaging.

--- PAGE BREAK ---

• Engineered to optimize materials and energy—supported by the assertion that 70% of the impact of the material is determined during the design phase. The food packaging technologist is directed to imbed into his or her strategies design for the environment, for disassembly, and for source reduction. We might infer from this call for action that food packaging technologists have not heeded these needs until now, a supposition that is far from fact.

Benefits of sustainable packaging include the following: safe and healthy to society; meet market criteria for performance and economics; maximize the use of renewable resources; are physically engineered to optimize materials and energy; foster social equity; close the loop on package materials; create economically viable recovery systems; eliminate waste; and facilitate growth while delivering the benefits of packaging without negative impacts.

These and other objectives represent a powerful dynamic for industrialized society at this instant; in an ideal world, etc., if we were starting over, etc.; if we had infinite resources to change the world, etc.

The food science and technology community, recognizing the present and future needs to sustain the world food supply for this grown and growing population, has long worked toward reductions in package mass and energy usage. Examples of our successes have included aseptic packaging, in which the thermal energy to sterilize in ultra-high-temperature processes is many times less that post-fill retorting, and in which the mass of paperboard/ plastic is 10 times less than that of the metal cans or glass jars they replaced, and retort pouches, whose heat and materials contents are orders of magnitude less than those of the traditional metal can.

Responsibility for Eco-Efficiency

Eco-efficiency means to do more with less of our resources. For decades, food packaging technologists have been systematically reducing the mass of package materials required to protect the food supply by converting from glass to metal, from metal to plastic, and from rigid plastic to flexible and reducing the gage and weight of plastic and paperboard. But plastic is not as sustainable as cans and glass bottles, almost all of which can be recycled back to metal and glass.

Eco-efficiency further suggests using materials that disintegrate instead of littering and defacing and contaminating the environment. It also discourages multiple or multilayer materials, since they are more difficult to recycle, and encourages returnable reusable materials and structures.

--- PAGE BREAK ---

Among the claims of the Sustainable Packaging Coalition are that glass is sustainable because some finite fraction is recycled (and in other venues is reused); that paper and paperboard derive ultimately from virgin trees which are replanted on approximately 25-year cycles; that aluminum cans are recycled at a nearly two-thirds rate; that steel cans are recyclable into automobiles and appliances; and that polypropylene plastic can be extended by admixing it with minerals such as calcium carbonate.

Summed together, it appears that all package materials are sustainable if the definition is expanded sufficiently. All of which belies the question of what is sustainable—that which supports our advocacy, or that which is truly returned to continue the Earth, or something between?

Product Stewardship

Sustainability implies that all of us, not just the package converters or the food packagers, are responsible for eco-efficiency. However, someone must manage the entire system, and that someone is not government—even though government’s responsibilities involve doing for people collectively what individuals cannot do for themselves. That someone must be the business organizations which initiate the use of mass and energy, prodded and supported by their consuming public. In simple terms, it is your responsibility and mine.

Dozens of companies and organizations, major and minor, users and suppliers, distributors and consumer groups, have joined the Sustainable Packaging Coalition to promote its fundamental tenets. Those in a position to do so have initiated actions to spur adherence to those elements that can be accomplished immediately; all must incorporate the principles into their long-term strategies.

But how many of these strategies are real, and how many are technically feasible in a real world in our time horizon? And how does sustainable packaging address the use of petroleum as a fuel, the three-fourths of municipal solid waste that is not packaging, and conspicuous consumption by consumers?

Nearly 40 years ago, we scientists and technologists began the drive toward reducing the packaging solid waste stream. We were able to solve the easiest problems very quickly, but as we did so we encountered the real challenges that are so visible today.

Packaging cannot be eliminated, nor can it be compromised; our food supply depends on it. Think about it!

by Aaron L. Brody,

Ph.D., Contributing Editor ,

President and CEO, Packaging/Brody, Inc., Duluth, Ga.

[email protected]