The Search for Shelf Life Solutions

LABORATORY

Predicting shelf life is a problem and a challenge, says Juan L. Silva ([email protected]), Professor, Dept. of Food Science, Nutrition, and Health Promotion, Mississippi State University, Starkville. He defi nes shelf life as the time during which a food product stays at its optimum quality and is still safe to eat.

“But the biggest problem is to defi ne exactly the parameters that govern shelf life, such as microbiological, physiological, enzymatic, or oxidative activities, and then test them accurately,” he says.

“But the biggest problem is to defi ne exactly the parameters that govern shelf life, such as microbiological, physiological, enzymatic, or oxidative activities, and then test them accurately,” he says.

Other variables can complicate and compromise shelf life, Silva adds. “A carton of pasteurized milk, for example, has a ‘use by’ date,” he says. “However, season of the year, region, handling, source, and other parameters infl uence the shelf life of the milk, so much so that sometimes it spoils before the expiration date. In part, this can be due to abuse by the consumer.”

According to Silva, determining shelf life in the laboratory includes the use of environmental chambers to control light, temperature, and relative humidity. However, shelf life analysis is only complete when tied to sensory evaluation, he points out. “We have to conduct sensory tests under the same conditions a product will be handled commercially,” Silva elaborates. So many variables make it diffi cult to forecast shelf life, even with all the models available. One can compare evaluation methods, but the ultimate test is through sensory evaluation.”

Sensory-Based Shelf Life Determination

Many physical and chemical factors affect the estimation of consumer sensory-based shelf life, suggests Ted Labuza ([email protected]), Morse Alumni Distinguished Professor of Food Science and Engineering, Dept. of Food Science & Nutrition, University of Minnesota, St. Paul.

Of importance, he says, is the information included on the label, such as “use by,” “sell by,” “best if used by,” or “freeze by” dates.

“This labeling issue is not regulated by the Food and Drug Administration, except that the dates have to be truthful,” Labuza mentions. “However, some 30 states do require date labeling on some categories, dairy foods, for example. The European Union requires all foods to have some type of date labeling, usually a so-called ‘minimum durability date,’ which translated into United States jargon is a ‘best if used by’ date” (Labuza and Szybist, 1999).

The problem with listing a specifi c date is that it will only be true if the temperature in distribution is completely controlled at the temperature at which the study was done, Labuza emphasizes.

“For refrigerated foods, it is usually at ≤4°C to get end of shelf life date,” he says. “Thus, because of the variability in distribution and retail holding, a food company needs temperature distribution data to set a date using a shelf life plot, along with doing some simple integration of the time–temperature plot over time to get the fraction of shelf life left at any time.”

The key then, Labuza continues, is to determine consumer shelf life by some meaningful method, such as using the Weibull Hazard analysis at several temperatures. For example, store individual packages of a refrigerated ready-to-eat food at three temperatures, perhaps 4, 8, and 15°C, and then present the packages to panelists once or twice a day (more often at the higher temperature because of the faster degradation rate).

According to Labuza, the number of testers, and thus number of packages needed, is based on a specifi c formula of increasing the number of people used in the test at each next test time. This is done by adding a constant, for example, one more tester at each next time, plus adding on testers equal to the number of people who scored the product as “failed” once the failure rate is ≥50%. “This means more testers are being used closer to the end of life time,” he explains. “They answer one question, such as ‘is it good or bad or is it still fresh?’”

--- PAGE BREAK ---

Labuza notes that it is diffi cult to understand freshness as a concept. “Freshness may not just be determined by fl avor, but a combination of things, including fl avor, texture, and appearance,” he relates. “For some products we can fi gure freshness out. But for others, the fi nal opinion depends on what the consumer has in mind. That is why a simple Weibull test may be best.”

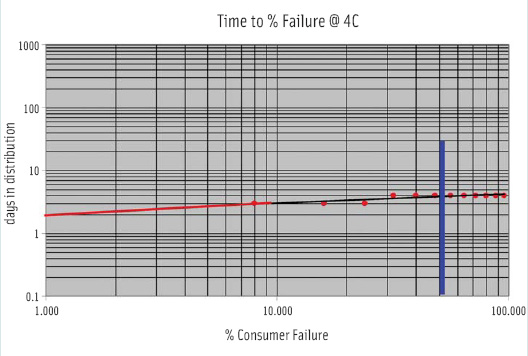

The data from this test are plotted on a log-log plot of time in distribution at some constant temperature vs percent failure (Figure 1).

The data from this test are plotted on a log-log plot of time in distribution at some constant temperature vs percent failure (Figure 1).

“It can be seen that the product in Figure 1 is a very sensitive food,” Labuza says. “So four days in the distribution at 4°C would elicit a 50% failure rate, meaning this product needs help beyond temperature control, such as some gas atmosphere to slow microbial growth. This type of test is very useful to the food processor, and for refrigerated foods takes little time or resources.”

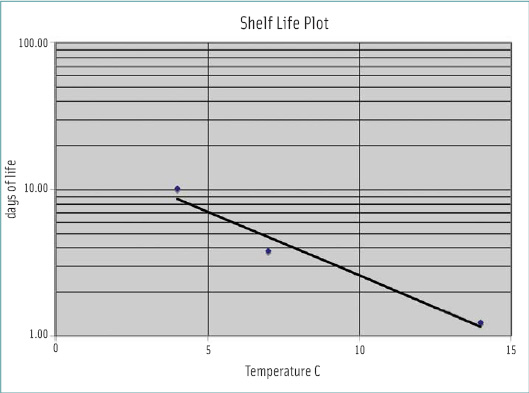

To determine the date that will appear on the food package, the Weibull test also needs to be conducted at higher temperatures to accelerate degradation and measure the effect of the abuse that occurs, Labuza says. “You then can make a shelf life plot with time to some Y% failure—usually 50% is chosen—on a log scale vs temperature, as in Figure 2,” he explains.

To determine the date that will appear on the food package, the Weibull test also needs to be conducted at higher temperatures to accelerate degradation and measure the effect of the abuse that occurs, Labuza says. “You then can make a shelf life plot with time to some Y% failure—usually 50% is chosen—on a log scale vs temperature, as in Figure 2,” he explains.

Generally, Labuza mentions, a fairly straight line is obtained with a high R2, which shows good confi dence in the results. You can then calculate a Q10, e.g., how much faster the product degrades if held 10°C higher than some reference temperature related to the slope of the line. “In this case for Figure 2, it is 7.5 fold, meaning that this product is extremely sensitive to temperature abuse, a real problem in our distribution chain,” Labuza says.

More education is needed on the value of such sensory analysis, he asserts. “It’s all part of traceability and insuring that food is of good quality, including how it applies to safety and gives the logistic managers some direction in how to handle distribution,” he emphasizes. “The math to integrate shelf life as a function of time–emperature history may be diffi cult to understand, but there are simple mathematicals to help, different than the micro models.” For more information, he suggests visiting www.ardilla.umn.edu/00fscn8334-1f/.

Consumer Package Tags

During the 1990s, three companies pioneered chemical-based consumer package tags that changed color at the same rate of shelf life loss as a function of temperature, a concept called time–temperature integration (TTI). These include 3M Co., St. Paul, Minn. (phone 651-733-1110, www.mmm.com), which sells tags called Monitor Mark; TempTime Corp. (formerly Lifelines), Morris Plains, N.J. (www.temptimecorp.com), which offers Fresh-Check; and Vitsab International, Malmo, Switzerland (www.vitsab.com), which produces CheckPoint® Smart Label™.

Labuza has a patent with 3M for FreshnessCheck, which is part of the Monitor Mark line of package tags.

--- PAGE BREAK ---

“The idea was to put words like ‘use by XXX, unless inner circle on tag turned to the same color as outer circle,’” Labuza relates. “Though still in the market, all three companies have found few users because of cost and the fear by food processors of increased consumer sorting at retail level, such as searching for the freshest food. The other problem is the long time needed to fi nd the right chemistry to match the tag’s chemistry to the food shelf life vs time function of Figure 2.”

A simple solution to determining shelf life would involve identifying a “marker”, i.e., a compound that is a result of the chemical reactions causing deterioration that reaches a certain value at end of shelf life. “Many people would love to have a magic wand to rub over food to determine shelf life,” Labuza observes. “Unfortunately, this is wrought with diffi culties because of the complex pathways for many food deteriorative reactions such as lipid oxidation and the Maillard reaction. Both occur in many foods and the multiple pathways have different temperature dependencies.”

So, says Labuza, this marker would likely be different for each food and, importantly, it must reach the same concentration at the point of failure, i.e., the end of acceptable shelf life irrespective of the temperature history that the food experienced. “Hunting for this is too time consuming and wasteful of research efforts,” he insists. “In addition, one would need to open the package to test for the compound, something that cannot be done in distribution or retail.”

RFID Sensor Tags

Labuza believes the future holds promise for the use of active radio frequency identifi cation (RFID) tags to provide up-to-date factory-to-retail information about the effect of temperature conditions on a perishable product as it moves through the cold chain. In fact, he serves as chief scientist and shelf life expert for Infratab, Inc., Oxnard, Calif. (phone 805-986-8880, www.infratab.com), which offers TTI patented technology, including RFID case tags, labels, and software.

According to Labuza, the technology, marketed as Freshtime™, provides low-cost, accurate temperature sensing and recording as well as shelf life left calculation. “This allows for the distributor to change the supply chain logistics management scheme from a fi rst-in/fi rst-out shipping regimen, which allows for signifi cant shrink to occur, such as bad product reaching the retailer, resulting in loss of sales, to a least-shelf-life-left/ fi rst-out scheme,” he explains. “Doing this reduces shrink—no more bad product arriving at retail—and lowers costs, thus paying for itself.” Giannakourou et al. (2000, 2005) determined this in a recent EU-supported study conducted in Greece and Italy with fi sh using the CheckPoint Smart Label.

The advantage of using RFID tags is that one tag fi ts all. “All you need to do is program in one shelf life point and the slope of the line in Figure 2 for the specifi c product, so product—tag match is instant,” Labuza elaborates. “Although it is a case tag, the benefi t to the consumer is that they will get fresher food at purchase, and being on the case eliminates the sorting problem at retail.”

This technology has the potential to infl uence “use by” dates, shipping rates, insurance claims/rates, product recalls, and even perishable pricing (paying less for roses with only two days of vase life vs roses with seven days), Labuza says.

The technology can answer the question “How well has the quality of this perishable been maintained?” he adds. It also serves as an insurance policy in terms of absolutely identifying who abused the product during shipment, as the data is time–temperature recorded. “The problem is getting industry to embrace it and trust it,” Labuza points out.

--- PAGE BREAK ---

Infratab is currently working with or looking for purveyors in key markets such as produce, fi sh, fl owers, pharmaceuticals, and adhesives that want to “push the envelope” in what the company calls product integrity monitoring. “Our current early adopters are quality driven, and are looking at how Freshtime tags and software can provide a competitive edge based on freshness,” Labuza says. “Our fi rst pilots have included both small and large growers, packers, consolidators, truckers, distributors, and retailers. They are testing the tags inside cases as well as on the outside, on reusable plastic containers, on single-use cardboard cases, and as shipping labels. The benefi ts they are getting include insights about quality in the cold chain—about what happened, when, and by whom.”

In April 2007, Infratab, in collaboration with DHL and IBM Corp., captured the Best Service Idea Award from RFID-Journal. Even so, only one food company—a large supermarket chain in Europe—is using the Freshtime product.

“Even though case RFID TTI tagging would reduce shrink signifi cantly and hereby increase profi ts, food companies in the United States are not yet interested in the technology, as has been the case with chemical tags,” Labuza points out. “However, given the problem with the increased number of recent food recalls and the requirement for traceability, as well as country of origin combined with the shelf life knowledge, we are on the cusp of a technology that will revolutionize the frozen and refrigerated food business.”

Safety-Based Shelf Life Models

The recent development of computer models is getting attention in the long-standing world of shelf life analysis, says Donald Schaffner ([email protected]), Extension Specialist, Food Science Dept., Rutgers University, New Brunswick, N.J. “Predictive microbiology researchers are developing computer models so we have them available to design studies for shelf life or avoid shelf life studies,” he says. “Researchers are also trying to develop a model to determine if foodborne pathogens will grow to dangerous levels before the food looks or smells spoiled.”

To launch the concept, scientists in the early 2000s initiated modeling on spoilage of ready-to-drink beverages. Currently, Schaffner and his colleagues are conducting modeling of the consequences of temperature abuse relative to the development of Pseudomonas and Salmonella on raw chicken. “My team has already used the Salmonella model to assist two different companies that approached us when the U.S. Dept. of Agriculture Food Safety Inspection Service questioned them about some temperature control issues,” he mentions.

While use of computer models in shelf life analysis is increasing in commercial applications, Schaffner says some companies are completely misusing the models and coming up with erroneous conclusions.

For example, one company Schaffner worked with several years ago thought that it could safely cool a cooked roast over a 48-hr time period. “I’m still not sure how they came up with that prediction, but it just didn’t make sense microbiologically,” he relates.

A subsequent lab experiment under Schaffner’s leadership showed that the 48-hr cooling was not safe, but further experiments guided by a computer model allowed the company to settle on a cooling regime that was safe, and which they could easily achieve.

“Clearly, you have to understand both the pitfalls as well as the benefi ts to make the most of these powerful modeling tools,” he emphasizes.

Schaffner is currently part a subcommittee of the National Advisory Committee on Microbiological Criteria for Foods working to determine the appropriate criteria that must be considered for a food safety challenge study. “When this report is published, it should include a defi nitive state-of-the-art opinion on how to design effective challenge tests which prove that a given formulation is microbiologically safe, including when it’s appropriate to use mathematical models,” he says. “Challenge testing is similar to shelf life testing, but challenge tests use pathogens to determine safety, while shelf life tests are typically focused on quality.”

by Linda L. Leake,

Contributing Editor, Food Safety Consultant,

Wilmington, N.C.

[email protected]

References

Giannakourou, M.C., Koutsoumanis, K., Nychas, G-J.E., and Taoukis, P.S. 2000. Development and assessment of an intelligent shelf life decision system for quality optimization of the food chill chain. J. Food Protection 64: 1051-1057.

Giannakourou, M.C., Koutsoumanis, K., Nychas, G-J.E., and Taoukis, P.S. 2005. Field evaluation of the application of time temperature integrators for monitoring fi sh quality in the chill chain. Intl. J. Food Microbiol. 102: 323-336.

Labuza, T.P., and Schmidl, M.K. 1985. Accelerated shelf life testing. Food Technol. 39: 57-62, 64, 134.

Labuza, T.P., Fu, B., and Taoukis, P.S. 1991. Time temperature indicators. Food Technol. 45: 70-82.

Labuza, T.P., and Szybist, L. 1999. Playing the open dating game. Food Technol. 53: 70-85.