Consortium Researches Novel

Thirty-two organizations—30 throughout Europe and two in other countries—joined forces in 2006 in an integrated project, called NovelQ, designed to stimulate innovations in food processing and packaging. Strategic solutions for technical and basic research hurdles were to be formulated for complex food products rather than food constituents.

The main objectives of the project are to substantially extend the shelf life of food products using novel processing; respond to the demands of consumers for food with fresh characteristics that contribute to health, convenience, and well-being; enhance eco-friendly innovative processing methods (reduction of water, energy, chemicals, packaging materials, and fresh produce loss); and solve migration problems.

The NovelQ participants are focusing on high-pressure processing (HPP) for pasteurization and sterilization of food, pulsed electrical fields (PEF) as a pasteurization technology, and cold plasma as a surface-disinfecting method. Other research and development topics include coupling of new packaging concepts to novel processing and hurdles to be overcome regarding implementation of advanced heating technologies such as microwave, ohmic, and radiofrequency heating. The participants are striving for enhancements to the state of the art in the novel food processing area and are demonstrating the potential of novel processing schemes in an industrial environment.

The research focuses on plant-based products, both solid and liquid, including carrot, tomato, strawberry, apple, and broccoli. These commodities have been selected because they integrate food structure issues, color- and flavor-related aspects, health-related components such as allergens, and food safety issues. However, the anticipated results will be applied to other types of products, even whole meals, including regional recipes that are typical of the rich and diverse European cuisine.

Further knowledge of consumer perception is a prerequisite to most effectively addressing opportunities for novel processing methods. The consumer perception of the methods used and the “new” foods delivered will provide important information for food manufacturers and equipment suppliers on how to communicate and operate.

Approach Involves Sub-projects

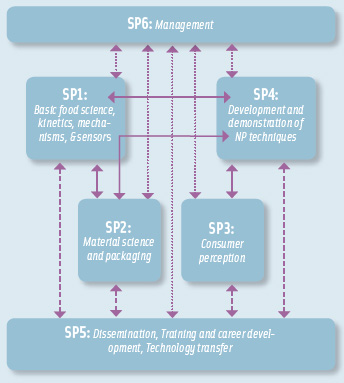

To reach concrete deliverables within NovelQ, two fully interacting approaches have been adopted in sub-projects of the overall integrated project.

• Development of a Knowledge Base. In sub-projects 1 and 2, a comprehensive knowledge base is being developed, offering mechanistic and kinetic insights into the effect of novel processing and packaging materials on the safety and quality of complex food products (solids and liquids) of plant origin. This approach has been adopted, as opposed to the examination of model systems (e.g., buffer systems), because, while the latter is simpler, its results are less readily transferred to industry.

Sub-project 1 focuses on mechanistic and kinetic insights in changes of food components and food products resulting from novel processing. Sub-project 2 focuses on the effects of novel processing on packaging materials and food package material interactions with the food itself (e.g., migration).

• Product and Process Development. Next, an integrated product/process development and demonstration approach has been developed for the range of products mentioned above. The approach embraces reversed-chain thinking; i.e., it starts with market trends and consumer demands and translates them into product characteristics and required engineering methods to produce the required foods.

Sub-project 3 focuses on consumer perceptions of novel processing technologies and the high-quality food products produced with these technologies. For both public and private institutions, a better understanding of factors motivating consumer choice—related to purchased products and underlying processing methodologies—is required.

Sub-project 4 involves carrying out applied science and demonstration activities to transfer knowledge from the basic science domain into the industrial application area. The consortium will address application issues and demonstration of advanced heating technologies in the first few years of NovelQ and of HPP, PEF, and cold plasma in the second half of the project. This sub-project will consider bottlenecks concerning implementation of technologies in the market.

This approach serves two main goals: (1) the importance and advantages of technological innovations in food processing may convince private and public parties to invest in new food processing methods, thereby stimulating the innovation power of the food sector; and (2) obstacles and best practices in the implementation trajectory will serve as input for the more-novel processing methods.

Sub-project 5 covers, in parallel, dissemination of non-confidential outcomes in the public domain, technology transfer to industry, and training and career development of young scientists.

--- PAGE BREAK ---

Sub-project 6 outlines project management, intellectual property rights, legal matters, communication and public relations, and administration. Here, emphasis is put on creating an innovation culture and managing innovation processes in R&D projects covering the entire research chain from basic science to development and implementation.

It should be noted that to manage such a complex project, each sub-project consists of work packages, in which several partners work on a specific research issue, e.g., one on microbial safety and another on texture in sub-project 1, one on packaging materials and another on food–packaging interactions in sub-project 2, consumer perception of technologies and products in sub-project 3, and hygienic design and efficient processing at pilot scale in sub-project 4.

Participants in the Project

The participants in the overall project are organized into several groups:

• Consortium. The consortium consists of partners within NovelQ who have signed the Consortium Agreement and jointly carry out research. For the first time in Europe, NovelQ brings together key experts on novel processing schemes in the research domains mentioned above. The critical mass of the project is substantial, with 30 partners from all over Europe, plus one each from Argentina and South Africa (see table). Many project partners are also engaged in nationally funded projects, and there will be synergistic benefits associated with working at national and regional levels. This situation is consistent with the aims of the European Research Strategy. The NovelQ partnership combines research activities of institutions having internationally recognized experience in basic sciences, applied market-oriented research, industrial research, and non-governmental experience.

• Industry Advisory Platform. In addition to the partners in the NovelQ Consortium, an Industry Advisory Platform has been established to ensure the most-effective transfer of knowledge to potential end-users and technology providers. The so-called cross-sectorial approach—combining food manufacturers with equipment suppliers—is characteristic for NovelQ. As a side effect, R&D spending of two sectors is multiplied.

• Industry Advisory Platform. In addition to the partners in the NovelQ Consortium, an Industry Advisory Platform has been established to ensure the most-effective transfer of knowledge to potential end-users and technology providers. The so-called cross-sectorial approach—combining food manufacturers with equipment suppliers—is characteristic for NovelQ. As a side effect, R&D spending of two sectors is multiplied.

More than 45 companies are members of the Industry Advisory Platform. The platform exploits and promotes results and helps to identify bottlenecks to be examined in the project. Best practices are disseminated in (new) East European member states via established networks, such as the European Federation for Food Science and Technology (EFFoST).

• Scientific Advisory Board. This group consists of a few senior scientists within the NovelQ consortium. Their roles are monitoring and maintaining high-quality research, reviewing draft publications, and keeping contact with experts in other European research projects and research organizations. They also coach and train young scientists within NovelQ.

• Training and Career Development Network. Public and private organizations ask for well-trained new employees with a broad range of expertise and skills. This network has been established to create enthusiasm and self-confidence in the younger scientists and to pass on knowledge to them. The advantage of involving young scientists in European projects is the opportunity to learn from experts outside their direct working environment. The network and its more than 30 members—young scientists, all employed by partners within the consortium—are willing to share their spirit and experiences with organizations outside the NovelQ consortium.

Research is conducted by each consortium partner using their own facilities. In addition, scientists periodically stay in the laboratories of other partners to get joint results. The consortium meets once a year, the sub-projects at least twice, and partners in a work package more often.

Results During the First Year

The consortium has been on stream for more than one year. First results have been delivered, and more than 20 publications have been written and recently submitted for publication. Here are some results:

--- PAGE BREAK ---

In sub-project 1, a systematic analysis of earlier research has been made; it serves as a basis for identification and implementation of proper research protocols describing high-pressure thermal treatments and PEF treatments. The protocols are imperative to equally compare research results and provide a sound science base for the technologies under investigation.

Screening studies on these treatments are followed by kinetic studies. In all work packages, screening studies on the effect of high-pressure thermal processing on spores, allergens, chemical changes, texture-associated aspects, color, and flavor components were initiated. High-pressure, high-temperature (HP/HT) sterilization for shelf-stable foods is being especially researched. For PEF treatments, screening studies have been performed on pathogenic microorganisms, allergens, chemical changes, color, flavor, and enzyme inactivation/activity. First prototypes of mathematical models for process impact analysis of high-pressure thermal processes and PEF processes have been developed. A methodological approach for evaluating a specific enzyme system in terms of its potential as time–temperature high-pressure indicators has been identified and implemented and is being prepared for publication.

In sub-project 2, novel biodegradable films and edible coating formulations based on biopolymers from vegetable sources have been developed. And the relevant functional and structural properties of commercial packaging films to be used for HP/HT and cold plasma treatments have been analyzed. An experimental setup for the migration/scalping phenomena of packaging materials subjected to novel processing treatments has been designed, as first models for viscoelastic, physical vapor transport, sorption, and mass-transport properties of polymeric materials before treatment.

In sub-project 3, a knowledge database of previous research on consumer attitudes toward new technologies in general has been created, including data on genetic modification, irradiation, and other technologies. Input was provided by the food industry via questionnaires. Focus group interviews have been executed in Hungary, Denmark, Slovenia, and Norway to evaluate the role of novel technologies in consumer desires. A general concern from industry is “What can be done to prevent problems before they occur?” At an EFFoST workshop with 40 participants/stakeholders, this concern was addressed and discussed by the Consumer Acceptance Group of EFFoST. The workshop results will be published in February 2008.

In sub-project 4, industrial problems related to integration of continuous processing and packaging equipment have been described, including hygiene design issues, environmental impact via life cycle assessment (e.g., for tomato processing), cost-effectiveness of technologies, scale-up times, etc. In addition, a general design and type of robot vision control system to be used in pilot plants has been sketched and patented. A predictive model describing the effects of novel processing on shelf life and quality and a model for a virtual factory, with pros and cons regarding implementation, have been made.

A database of commercially available equipment and available pilot-scale novel processing equipment has been drafted for members of the NovelQ consortium and the Industry Advisory Platform. Research has been carried out on bottlenecks occurring during scale-up of high-pressure sterilization equipment; the results cover design of vessel, seals, pump, selection of materials, preheating unit, full automation options, semi-continuous operation, and a protocol on how to deal with bottlenecks.

The first three full-demonstration trajectories have been started. The potential of water-immersed radiofrequency heating equipment for several types of food—fluids, particulate fluids, pastes, and solids—has been determined. Software for numerical modeling of microwave treatments on ready-made meals has been developed. For ohmic heating, a new industrial line has been defined and is in operation at pilot scale at Centre Technique de la Conservation des Produits Agricoles (CTCPA) in Avignon, France, again for whole meals. Homogeneity of treatment is a key issue in order to compare end-product quality with conventionally processed foods.

--- PAGE BREAK ---

Plans for the Next Five Years

The ambitious goal of NovelQ is to build up a long-lasting consortium of groups with a wide range of expertise who will jointly strive for a sound-science base and implementation of novel processing methods. This multidisciplinary approach asks for understanding and combining forces beyond each group’s own research targets. New collaborations between natural and technological science groups and between those groups and social science groups will lead to new scientific results and research & development opportunities.

The consortium expects to develop more than 50 draft manuscripts over the next five years and submit them for publication in peer-reviewed journals. In addition, results from demonstration projects will be submitted for publication if confidentiality allows. New software tools will be developed for monitoring, analysis, understanding, and prediction of functionalities, both product and process. At least three validated advanced processing methods—and equipment prototypes—will be demonstrated.

A unified platform for industry and knowledge centers will be created to regularly hold workshops to discuss opportunities and bottlenecks. Scientific and industrial research outcomes will be shared at meetings of the European Technology Platform on Food for Life (http://etp.ciaa.eu/asp/home/welcome.asp), and a young-scientist network will be in operation, initiated and managed by the young scientists themselves and coached by senior experts.

Global Scope

The European Commission Directorate General Research partially funds NovelQ (http://cordis.europa.eu/en/home.html), and the research institutes and companies involved finance at least 50% of their activities by themselves, depending on the kind of activities—a higher percentage for basic science activities than for demonstration activities.

Even though NovelQ is a European-funded project, some of the activities may be addressed in a wider context. All kinds of novel processing schemes that are potentially more eco-friendly deserve attention in view of the global warming discussions. Reduction of the environmental impact of the food production chain is essential. Approaches might include reducing water use (for cleaning, cooling), energy use (via less heating and cooling), product loss (by enhancing shelf life, improving quality), packaging material (by avoiding repacking, using biodegradable materials), etc.

On the global scale, food-related health issues (e.g., obesity) and safety issues (chemical and microbial) ask for multidisciplinary workshops and discussions about the role and impact of novel processing methodologies. The health guidelines require reduction of salt (e.g., in shelf-stable products), higher-fiber products (e.g., novel fruit and vegetable products), and well-balanced fatty acid intake (e.g., fatty fish products). Here, the advantages of novel processing methods need to be considered. Consensus should be achieved on scientific findings—for consumers and the public and private sectors—as pursued by the Global Harmonization Initiative (www.globalharmonization.org).

As an essential part of the entire food production chain, innovation in processing schemes should be periodically related to trends and developments in other parts of the food chain. A broader perspective for novel processing could then be given. Joint meetings of the Institute of Food Technologists and network organizations involved in primary production, distribution, retail, and foodservice—such as the International Agri-Food Management Association and EurAgri (www.ifama.org)—would allow discussion of these trends and developments with input from NovelQ consortium partners.

Huug de Vries, Ph.D., is Project Co-ordinator, NovelQ, P.O. Box 17, 6700 AA Wageningen, the Netherlands ([email protected]). Dietrich Knorr, Ph.D., a Member of IFT, is Head, Dept. of Food Biotechnology and Food Process Engineering, Technical University of Berlin, Königin-Luise-Str. 22, D-14195 Berlin, Germany ([email protected]). Huub L.M. Lelieveld, Ing., a Fellow of IFT, is former President, EUFFoST, Ensahlaan 11, 3723 HT Bilthoven, the Netherlands ([email protected]). Send reprint requests to Huug de Vries.

The NovelQ team thanks EU Project Officers Jürgen Lucas, Jean-Marc Chourot, and Isabelle van Borm for their support in setting up and executing the NovelQ project. More information about NovelQ is available at www.novelq.org.