Food Product Traceability: New Challenges, New Solutions

Recent food safety crises highlight the need for better traceability in the supply chain. New software options offer affordable tracking systems, even for small companies.

Product traceability has always been a contentious issue in the food and beverage industry, often pitting manufacturers, packagers, and distributors against retailers, customers, and government agencies. However, recent supply chain wide “meltdowns” have all sides of the issue beginning to agree on the need for better controls. No less important than the need for traceability is the availability of cost-effective and practical solutions. Fortunately, new technologies and techniques are changing traceability from a profit-wrecking expense to an acceptable cost of doing business and, in some cases, even positively affecting the bottom line.

The new focus on traceability has had less to do with new regulations and governmental sanctions than plain old free market pressures. Adam Smith, an 18th century philosopher and author of “The Wealth of Nations,” would be proud.

The new focus on traceability has had less to do with new regulations and governmental sanctions than plain old free market pressures. Adam Smith, an 18th century philosopher and author of “The Wealth of Nations,” would be proud.

To be sure, there is no shortage of governmental traceability edicts. Relatively weak public safety laws existed in the United States prior to the Sept. 11, 2001 terrorist attacks; much more substantial security-related statutes were added post 9/11. But to be blunt, rules such as FDA Bioterrorism Rule 306 (FDA, 2004) have been obeyed about as often as the speed limit on an old country road at 2 a.m. The laws are there, but the enforcement staff is non-existent, and further limitations of enforcement agents to “post-event” inspections (particularly in the U.S.) have pretty well reduced these laws from preemptive safeguards to “after the fact” responses.

Supply Chain Complexities

While governments have been ineffective, the enlightened self-interest of the brand owners has become a driving force for traceability … and with good reason. The simple cup of soup I had for lunch today had over 40 basic ingredients. From previous work we know this cup of soup’s supply chain likely entailed over 500 different companies from all over the world. As we are all too aware, it only takes a problem in one of the 500 chain members processes to damage the entire brand supply chain. And it gets worse, much worse. As the tomato industry (Hedges, 2008), scallion industry (EBSCO, 2006) and other industries can attest, without good traceability systems, the original problem doesn’t even have to be in your industry, let alone your supply chain, to have a devastating effect.

Trade organizations such as GMA (Grocery Manufacturers Assn.) are pushing for expanding the FDA’s funding and extending authority to proactively verify that sites are adhering to FDA 306 traceability and recordkeeping rules. In addition, GMA is recommending the use of technology to aid in traceability and extending traceability down to the farms themselves (Brackett, 2008). Furthermore, influential food retailers such as Wal-Mart (Maestri and Chang, 2008) have joined “commercial” regulatory movements such as GFSI (Global Food Safety Initiative) and are compelling their food suppliers to meet new sets of standards on food safety management and traceability.

--- PAGE BREAK ---

Back in the “good ole days,” if your processes were clean and you could dig around and come up with a list of suppliers and customers, you could claim acceptable traceability. That’s not so anymore. As Mark Twain once famously said, “It ain’t what we don’t know that gets us into trouble. It’s what we know for sure that just ain’t so.” A good portion of the companies that we have talked to about traceability assumed that since they had some form of traceability, they have the traceability they need. But that is just no longer true either legally or commercially. Because of the implications, formal surveys of food manufacturers practicing true product traceability are hard to come by. But significant anecdotal evidence suggest that less than 5% of food manufacturers meet the applicable traceability standards, such as FDA 306 (FDA, 2008), GFSI (CIES, 2008), Can-Trace (Can-Trace, 2008), PTI (Produce Traceability Initiative) (Produce Marketing Assn., 2008; United Fresh Produce Assn., 2008), etc.

As far as we know, there is no one all-encompassing simple definition for traceability that all the various regulations and commercial initiatives agree upon. So rather than attempt to create a definition that is guaranteed to be “exactly” wrong or reproduce thousands of pages of documents, we will use a few simple tests that demonstrate the intent and impact of what most of the rules from the various groups (as listed above) are asking manufacturers and packagers to achieve.

Take the Traceability Test

First, let’s break the concept of traceability into two parts: (1) tracking and recalling “inside the fence line” (i.e., primarily data collection and reporting), and (2) labeling for the supply chain. To see if you meet the traceability standards from the various organizations noted above, please answer the following questions.

• Tracking and recalling.

Given a specific item you sent a specific customer, can you

a. list the specific lot numbers of those items (i.e., specific does not mean that we were shipping these lots that day, so it was probably one of them)?

b. determine the ship dates and the carriers which shipped the items/lots?

c. determine which raw materials went into those shipped items—by internal item & lot and supplier’s item, lot and/or manufacturing date, and container size? … and identify the carrier and the date those items shipped?

Here are some special implications. If a supplier sends you the same item/lot via two different deliveries, they are not the same products from a traceability standpoint. If you are not capturing this labeled raw material when it arrives and re-labeling it with internal lot or container numbers, this information is lost.

Given a specific vendor item number, can you

a. list the specific matching vendor lot numbers and/or manufacturing dates for the items you received?

b. list the carriers that brought those items by date and lot/manufacturing date?

c. list all the finished goods items the specific vendor’s specific item/lot went into and who you shipped those products to (by lot) on which day?

Can you respond to a request for any of the above data in less than 24 hours on information up to two years old?

• Labeled for the supply chain.

1. Do you print the item number and lot number/manufacturing date on your products?

2. Do you differentiate labels by manufacturing plant?

3. Do you use the 14-digit GTIN (Global Trade Item Number) barcode number to record the company and item reference (this is an emerging commercial standard—more on this later)?

If you answered yes to all the questions and your facility is already doing all these things, that’s great! Now all you have to worry about is the 95% of your suppliers and customers who cannot.

One question we are hearing in the marketplace is, “Will better traceability reduce the damage or just better report it?” The track record here, at least for some food products, is clear. Better traceability is better for the public, the brand, and the industry. The better the records, the faster the problems are isolated, the fewer products and lots involved, and the easier it is to locate and test other suspected material. And, of course, the less interested the press is.

--- PAGE BREAK ---

These benefits are not just theoretical. Several meat recalls have taken place over the last few years, intermixed with tomato, lettuce, spinach, etc. But almost no one remembers them. Why? The meat recalls were fast and contained. Meat plant operators gave very exact lot number and manufacturing dates. Those recalls hit the news but the specificity of the information (dates, lots, etc.) made the material easier to locate and gave the public a much better sense of control. Partially because of that, the press got bored and moved on. To be sure, other factors contributed to the difference but better traceability was a big part.

Even in the cases where traceability doesn’t help with “real” physical control, “perceived” control of the supply chain is just as effective with customer and consumer confidence.

Avoid the Paper Trail

While many people think “lawyering” is the world’s oldest profession, civilization didn’t start moving along until the scribes (i.e., data collectors) started documenting events and information. At the very least, we have been counting and collecting data for over 9,000 years. Paper-based systems, like their clay tablet predecessors, are slow, unwieldy, and prone to error. Even a small company creates an incredible number of papers with trace-back information over a two-year period.

In many ways, as FDA Assistant Commissioner for Food Protection David Acheson (2008) reported to Congress, the 2008 Salmonella outbreak caused so much damage and took so long to trace back to the source because so many of the chain members were using paper-based record systems. Mountains of slowly processed and inaccurate records stretched out the research until some evidence was lost. Other data was missing or wrong. The end result is that two industries were severely damaged.

But just buying and installing the latest whiz-bang ERP (enterprise resource planning) or accounting system is unlikely to provide adequate traceability. To be sure, these systems do wonderful things for business administration, but most are not focused on lot traceability, production management, or labeling. A process-oriented warehouse management system (WMS) and/or production management system (PMS) will usually make for a better solution.

Product labeling—and the lack thereof—have also proven problematic. It is often not possible to tie a product back to anything more specific than the vendor and general product description. New standards, such as the Produce Traceability Initiative (PMA, 2008), which includes the GTIN labels, are gaining wide acceptance. PTI requires the packager/manufacturer to include a “refined” version of a UPC code and additional lot information. It has gained broad approval by both purchasers of product and the trade organizations of the producers.

Cost of Implementation

Another question we are getting from the marketplace is, “What is all this going to cost, and how are we going to do it?”

Most of us have always preferred better traceability but costs and implementation difficulties have made it impractical, particularly on a unilateral basis. Two things, however, have changed. First, traceability is now a commercial and legal cost of doing business for everyone, as opposed to a “nice to have” option. Second, the cost-reducing power of the Internet makes traceability affordable, if not profitable.

--- PAGE BREAK ---

As many of us may have witnessed, purchasing a traditional, and sufficiently powerful, inventory management/traceability/labeling system can easily cost more than a company’s annual profits. And writing your own “one-of-a-kind” software is always riskier and almost always turns out to be much more expensive than buying “off the shelf ” products.

Until now, larger companies could justify the investment by distributing the costs over larger volumes. Smaller companies have not had this option. That is, until … enter the power of the Internet and the web-enabled concept of “Software as a Service” (SaaS) (Webopedia, 2008).

The SaaS service provider owns and maintains the software and the computers it runs on, and the user pays a subscription fee to use the software over the Internet. In addition to the subscription, the user only requires an Internet connection to run the SaaS application. The costs are pooled and distributed over a large number of companies/users and so the per user cost is far less than a standalone system, especially for small to mid-size companies. How much is “far less” per user? Full featured WMS, traceability, and labeling systems like Mobia are available starting at $125 per user per month. For just a labeling system, the cost is about $50 a month. Even the once very expensive RFID solutions are available at a very affordable rate.

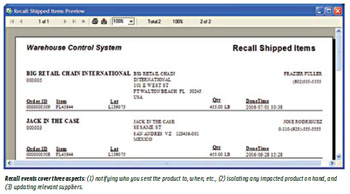

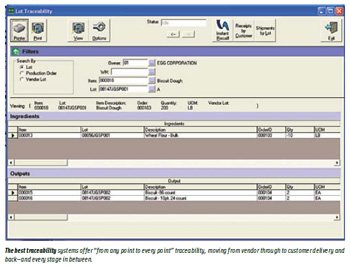

A good “from any point to every point” traceability system can process data retrieval for real or “mock” recalls in seconds and instantly identify and document all the shipments, receipts, customers, vendors, and products involved.

Users have reported that the entire annual cost of their systems were paid for in the labor savings they received from not having to manually collect, organize, read, review, and summarize their traceability data. The benefit of increased customer confidence, while certainly more abstract, is also of some certain value.

As supply chains have grown longer and more interconnected and food products more complex, we have seen that, in the absence of good traceability, failure in even one member of a supply chain can severely damage many supply chains. Brand owners have never been in a more vulnerable position.

For food manufacturers and packagers that plan on staying in business, the question is not “if ” you will comply with the new traceability and labeling requirements but “how”. Fortunately, cost-effective solutions now exist to allow manufacturers and packagers of any size to quickly implement even the most stringent of the currently announced traceability and labeling requirements.

by David Miller is President of Operations Technologies, 150 Executive Center Dr., B30 – Suite 230, Greenville, S.C. 29615 ([email protected]).

References

Acheson, D. 2008. Transcript for Media Briefing on Salmonella Outbreak. FDACDC. Aug. 28. http://www.fda.gov/bbs/transcripts/2008/salmonella08282008.pdf. Accessed Nov. 24, 2008.

Brackett, R.E. 2008. Written Testimony of Robert E. Brackett, Ph.D. Senior Vice President and Chief Science and Regulatory Affairs Officer before U.S. House of Representatives Committee on Energy and Commerce Subcommittee on Oversight and Investigations July 31, 2008. http://74.125.45.104/search?q=cache:C5LJ9zaVyn8J:energycommerce.house.gov/cmte_mtgs/110-oi-hrg.073108. Brackett-testimony.pdf+gma+congress+fda+traceability&hl=en&ct=clnk&cd=5&gl=us. Accessed Nov. 24, 2008.

Can-Trace. 2008. Can-Trace develops traceability standards for all food products sold in Canada. http://www.can-trace.org. Accessed Nov. 24, 2008.

CIES. 2008. Global Food Safety Initiative (GFSI). http://www.ciesnet.com/2-wwedo/2.2-programmes/2.2.foodsafety.gfsi.asp. Accessed Nov. 24, 2008.

EBSCO. 2006. Iceberg Lettuce Seen as Taco Bell E. coli Source. Carl R. Darnall Army Medical Center. Dec. 14. https://healthlibrary.epnet.com/GetContent.aspx?token=c5987b1e-add7-403a-b817-b3efe6109265&chunkiid=170366. Accessed Nov. 24, 2008.

FDA. 2004. Final Rule on Establishment and Maintenance of Records (69 FR 71561). Dec. 9. http://www.cfsan.fda.gov/~dms/frrecord.html. Accessed Nov. 24, 2008.

Hedges, S.J. 2008. Salmonella mystery: the smoking pepper. Tribune’s Washington Bureau - The Swamp. http://www.swamppolitics.com/news/politics/blog/2008/07/salmonella_mystery_solved_the.html. Accessed Nov. 24, 2008.

Maestri, N. and Chang, R. 2008. Wal-Mart says food suppliers to meet GFSI standard. Reuters. Feb. 4. http://www.reuters.com/article/business-News/idUSN0459973720080204. Accessed Nov. 24, 2008.

Produce Marketing Assn. 2008. Produce Traceability Initiative Action Plan (PTI). http://www.pma.com/cig/tech/documents/ProduceTraceabilityInitiative-FinalActionPlanv3102108_000.pdf. Accessed Nov. 24, 2008.

United Fresh Produce Assn. 2008. Produce Traceability Initiative. http://www.unitedfresh.org/newsviews/produce_traceability_initiative. Accessed Nov. 24, 2008.

Webopedia. 2008. SaaS. http://www.webopedia.com/TERM/S/SaaS.html. Accessed Nov. 24, 2008.