Innovations in Fresh Prepared Meal Delivery Systems

PACKAGING

Until that magic day when a favorite chef is omnipresent for almost all of our eating occasions, almost all of us will depend on one of just a few alternatives for delicious, nutritious, and safe food.

Contrary to Time magazine’s recent imaginary planet on which each of us grows our own tomatoes, oranges, and lettuce in backyard plots and bikes to a nearby farmers market that miraculously supplies vanilla beans and corn produced on a suburban truck farm, we shall drive to a supermarket or convenience store of our choice and select components that will eventually blend to become an eating experience.

Contrary to Time magazine’s recent imaginary planet on which each of us grows our own tomatoes, oranges, and lettuce in backyard plots and bikes to a nearby farmers market that miraculously supplies vanilla beans and corn produced on a suburban truck farm, we shall drive to a supermarket or convenience store of our choice and select components that will eventually blend to become an eating experience.

And the components of the meal will be obtained from packaged products. Even if the result is a combination that began with “fresh,” almost all were in some form of package early on in the distribution process. The other day, I witnessed hundreds of men and women in a recently opened neighborhood international supercenter driving away with dozens of corrugated fiberboard cases and polyethylene bags brimming with bok choy, sugar cane, soft shell crab, star fruit, peaches, and broccoli.

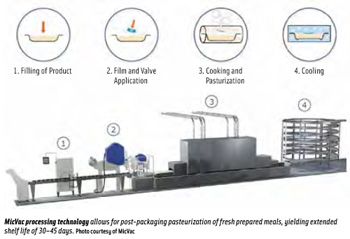

In the supercenter, shoppers were filling their baskets from hundreds of cases of retort pouched and frozen meals. Fresh knows no bounds in a land of prepared, and prepared knows no bounds in a land of fresh. Beyond the fully processed and packaged were the assortments of chilled prepared foods packaged so that with mere placement in a microwave oven and the push of a button, a rethermalized meal is available within three minutes. In all industrialized countries, fresh product and the freshly cooked are shelved side by side.

Fast Food (Delivery) Options

Obviously, restaurants or your friendly on-site culinologist can deliver your favorite meal in a few minutes (the international supercenter cited above indeed housed that option in many different ethnic varieties within its food court). And most large retail groceries are home to kitchens in which cooks follow recipes and chill their meals or meal components quickly for display and sale. If the turnover of back-of-store-prepared chilled products is not rapid, these products are discarded by retailers for fear of pathogenic or other spoilage. Freshly cooked is the objective for quality and safety, but can packaged offer this option? Must we really need to revert to locally grown to enjoy true fresh flavor and nutrition? Certainly, canned and frozen are options, but not for “freshly cooked.” Are the chilled meals from back-room kitchens, which are higher-cost due to low volume and distribution complexities, viable alternatives? Are the short-shelf-life sous vide, cook/chill, or shelved chilled meals really as good and safe as “freshly cooked,” the goal to which all food scientists, technologists, and packaging professionals are striving? And can we deliver these foods to the consumer—without extreme processes such as slack out, thermal pasteurization, or crust freezing? Is modified atmosphere really the route as with wet pasta? Must every ingredient be sterilized before aseptic incorporation? Where will the fledgling ultra high pressure processing technology take us?

Fraunhofer Institute Approaches

To respond to this litany of legitimate questions about the role of food and food packaging technology in the spectrum of consumers’ desire to move closer to fresh eating, we offer you one group’s intriguing perspectives: Double Fresh from Fraunhofer Institute in Germany (ivv.fraunhofer. de), a contract research and development organization. Double Fresh is a collaborative international project involving foodservice, food processors, and research organizations. The objective of the project is to develop so called “ready-to-eat- meals” with improved quality, greater freshness, and longer shelf life. The project has two main areas of focus: Double Fresh meals, which are made from fresh ingredients and heated in a microwave before being eaten, and “freshly cooked meals.” The aim for these ready-to-eat-meals is to subject them to a gentle thermal or nonthermal treatment and attain storage stability on refrigerated shelves similar to that of pasteurized foods, but simultaneously with higher quality.

--- PAGE BREAK ---

Double Fresh Meals

Because only fresh ingredients are used in Double Fresh meals, the work of the Fraunhofer Institute has focused on the hygienic preparation of the raw ingredients and their quality preservation. On being washed with 1% hydrogen peroxide solution, varieties of different vegetables show drastically reduced microbial counts. Clean implements and appliances and a clean workplace are key prerequisites for minimizing subsequent contamination during processing. The use of gels as edible coatings compensates for vegetable quality losses caused by color and structure changes. The raw meat component in these meals is the most sensitive component from a microbiological perspective. The microbial level can vary greatly depending on the preceding slaughter and cutting of the animal, distribution, and the hygiene in the meat suppliers’ processing plants. Studies are being conducted to reduce microbial contamination and retard growth using active antimicrobial substances in combination with physical methods.

Freshly Cooked Meals

This subproject investigates the suitability of gentle thermal and nonthermal methods as well as active packaging for stabilizing ready-to-eat-meals, thus prolonging their shelf life in refrigerated distribution. Novel high-frequency heating methods for reducing microorganisms in packaged foods are applied. Features of the method are the combination of high-frequency electrical fields and water baths for efficient and even interaction of the fields with the packaged food. Among the foods that have been studied are ready-to-eat-meals consisting of several solid and liquid components in a plastic dish—for example, noodle dishes with sauce and small pieces of vegetables. The technological challenge here is to heat the ready-to-eat-meals to the requisite final temperature in a rapid, uniform, and reproducible manner.

Preservation Processes

The aim of rapid high-frequency (microwave or radio frequency) heating is to improve the sensory qualities of temperature-sensitive meal components such as vegetables while maintaining microbiological safety. This should allow the production of ready-to-eat-meals with improved freshness for the standard chilled food distribution chain.

The consortium is investigating microwave sterilization and pasteurization, pulsed electrical field processing, advanced heating, ultra high pressure, modified atmosphere, and combinations of these technologies as in the American PATS (pressure-assisted thermal sterilization)—ultra high pressure is applied with heat to inactivate spores, i.e., achieve sterility with minimal heat. Commercially, ultra high pressure is employed for ready-to-eat meal pasteurization—Double Fresh. Among the meals that have been studied for chilled distribution by collaborator Wageningen Agrotechnology and Food Sciences Group (www.wur.nl) are Boeenkool (mashed potatoes with cabbage and sausage) and spaghetti Bolognese. All were observed to enjoy firmer texture and appearance as well as reduced microbial count.

--- PAGE BREAK ---

Packaging Systems

The Dutch collaborators have also reported on the packaging system aspects of this program. They noted that modified atmosphere mixtures optimum for fresh meat and seafood, e. g. 60% O2/ 30% CO2, increased vegetable deterioration by carbon dioxide damage and increased respiration. On the other hand, optimal gas combinations for fresh vegetables, e.g., 5% O2/1% CO2 led to increases in meat and seafood spoilage. They also concluded that the better the initial quality of the fresh ingredients, the better the final product, hardly a surprising finding. But in the arena of chilled fresh foods for cooking, the balance is indispensable—little compromise on initial quality is permissible to achieve the goal of two weeks of safe chilled shelf life. Ingredients are minimally processed, such as marinade for the protein foods and blanching for vegetables.

Muscle foods are packaged under 60% O2/30% CO2 in barrier packages. Blanched vegetables may be included in such packages. Fresh vegetables, however, must be packaged independently in gas permeable packages to permit increases in carbon dioxide to enhance the preservation effect at chilled temperatures. The researchers reported that the cut vegetables they have incorporated include onions, lettuce, endive, and eggplant. Only white meats, such as chicken and fish, are eminently suitable; raw red meat appears purple. Thus, where appearance and fresh-to-be-cooked are critical, limitations remain. Steam-assisted microwave heating is satisfactory for fresh food meals. But high quality preheated and pasteurized meals in microwaveable polypropylene trays can be produced applying minimum heat load, e. g. for post-pasteurization during processing.

Thus, two basic directions are developing—no post-packaging pasteurization employing ultra-clean techniques, hot filling, and modified atmosphere packaging and mild post-packaging pasteurization applying currently expensive ultra high pressure or microwave heating. Both deliver excellent products, but only when coupled with controlled temperature distribution. Essentially, with either option, we are experiencing the quantitative application of hurdle technologies in which a number of mild treatments are integrated into the total system to act as the surrogate for your personal culinologist.

Is the final product “safe?” Is any food product ever safe? Was our food system safer when we grew our own on our farms two generations ago? The meager records of those bygone days suggest otherwise. By applying multiple scientific barriers, we are minimizing the probabilities of risk—which is all we can ever achieve. But we are offering ourselves a wide variety of really good-tasting, nutritious foods without all the hassle of going into the field on a snowy winter’s night.