Improving Soybean Oil

FOOD SAFETY & QUALITY

Soybean oil, the most abundant vegetable oil in the world, represents about two-thirds of the edible oil consumed in the United States. Oils from common soybean varieties are high in polyunsaturated fatty acids, providing health benefits, but they are easily oxidized and develop objectionable flavors and odors when heated extensively. Partially hydrogenating the oil makes it more stable against oxidation but also results in formation of trans fatty acids, which present coronary health risks.

Consequently, Pioneer Hi-Bred, a DuPont business (www.pioneer.com), and Monsanto Co. (www.monsanto.com) have been developing new soybean varieties to provide oils with improved stability, nutritional value, and functionality.

Pioneer Hi-Bred’s High-Oleic Oil

Pioneer Hi-Bred announced on June 8, 2010, that the U.S. Dept. of Agriculture had approved its Plenish™ high-oleic soybean trait for cultivation in the U.S., allowing the high-oleic soybeans to be grown under contract for ongoing field testing in the U.S. and additional oil testing by food companies. The Food and Drug Administration had completed its review of the soybeans in 2009. Pioneer and its commercial partners will continue to do field testing this year and next, with full commercialization expected in 2012. The company has agreements with 15 oil processors, restaurants, foodservice companies, and food manufacturing companies testing the high-oleic oil in commercial situations.

Pioneer scientists used genetic engineering to suppress a specific gene in the fatty acid pathway of soybean seeds, resulting in increased levels of oleic acid and decreased levels of linoleic and linolenic acid in the seeds and oil. According to the company, extensive testing at both university and commercial pilot facilities has shown that the high-oleic soybean oil is at least 2–3 times as stable against oxidation as regular soybean oil and as stable as commonly used partially hydrogenated oils, while generating less objectionable flavor and odor during frying. It also has 20% less saturated fat than commodity soybean oil.

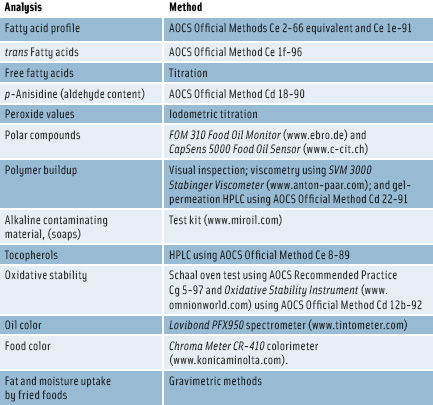

• Analyses. John D. Everard ([email protected]), Senior Research Scientist in Pioneer’s Oil Functionality Laboratory, said that the company uses numerous industry standard tests for oil breakdown and food quality in commercial-scale frying studies (see Table 1). These include methods that measure primary and secondary fatty acid breakdown products such as peroxides, polar compounds and polymers, and other reactive species that reflect the chemical, physical, and sensory properties of the oil.

--- PAGE BREAK ---

• Oxidative Stability. The standard method for measuring oxidative stability of oils, Everard said, is the oxidative stability index (OSI), measured by AOCS method Cd 12b-92. The Oxidative Stability Instrument, developed by Archer Daniels Midland and manufactured by Omnion, puts the oil under extreme stress. A sample is heated to a specified temperature, and air is bubbled through it at a constant flow rate of about 150 mL/min. The effluent is captured and directed into a cell with pure, low-conductivity water. Electrodes in the cell measure the conductivity of the water. As the oil oxidizes, it starts to break down. Since most of the breakdown materials are volatile and conductive, the conductivity increases. There is an initial period in which the conductivity doesn’t change much, but then a very rapid increase occurs as a result of a free-radical breakdown chain reaction. The instrument plots the conductivity vs time and extrapolates back to the point at which the curve becomes exponential. That’s the OSI value, representing the length of time at which the oil becomes unstable.

Pioneer’s test results show that commodity oils typically break down within 6 hr, Everard said. In contrast, the high-oleic oil lasts more than 22 hr. The greater oxidative stability is due to the high oleic acid content (>75%) and correspondingly lower levels of the much more oxidatively unstable linoleic and linolenic acids

• Oil Life Span. Laboratory deep-fat frying studies done by Pioneer’s partners confirm the advantages of high-oleic oil over commodity oil in terms of life span in the fryer, Everard said. Exposing oil to high temperature for extended lengths of time results in generation of a distinct painty odor. This is due essentially to primary oxidation of fatty acids reacting with oxygen and secondary oxidation when those oxidized fatty acid chains break down into lower-molecular-weight compounds with distinctive odors. Some of the breakdown chemicals give fried food a characteristic aroma that people find pleasant, he said, but depending on the balance of chemicals and how oxidized the oil is, the odor can be quite unpleasant.

Another way to determine oil stability is to accelerate the aging of the oil by heating it to moderate temperatures in the Schaal oven test. The oil is generally held at 60°C for 2–3 weeks until the experiment is done, i.e., until off-aromas develop. Then the chemicals responsible for the off-odors are collected, concentrated, and separated on a gas chromatograph, and the chemicals are identified by GC/olfactometry. Instead of using a detector at the exit of the GC, an analyst sniffs the effluent. The retention time—the time when a particular component comes off—can be linked to a particular chemical. The human nose is extremely sensitive to odor chemicals and can detect some of them at the parts-per-trillion level, Everard said.

Test results show that after 3–4 days at elevated temperature, commodity soybean oils have a distinct odor characteristic of rancid oil, whereas high-oleic oils don’t develop those odors, he said.

--- PAGE BREAK ---

• Polymer Buildup. Another consequence of extended heating of oil is buildup of a resin or varnish-like coating on equipment such as fryers. The oxidation of fatty acids and triglycerides leads to polymerization and dramatic changes in viscosity. When the oil is abused by repeated use, the polymerized materials tend to accumulate on the surface of equipment. This buildup on vessels is very obvious to the eye and difficult to remove. Because high-oleic oil has fewer reactive sites (double bonds) in the fatty acids, it has a much reduced capacity to form these resins, Everard said, so the frying equipment is a lot easier to clean.

Measuring the viscosity of the oils gives an indication of accumulation of these polymerized materials, he said, but gel-permeation HPLC is also used to directly measure polymer accumulation.

Monsanto’s Modified Oils

Monsanto is also developing genetically modified soybeans and oils. According to Richard S. Wilkes ([email protected]), Director of Food Applications, oil from the company’s Vistive Gold low-saturate/high-oleic/low-linolenic soybeans will have the lowest saturated fat of any soybean oil, being reduced 60% from commodity soybean oil while maintaining 0 g of trans fat. Testing has demonstrated the oil to have excellent stability and flavor, he added, and when the oil was tested with French fries, saturated fat content was significantly reduced.

FDA has issued a letter of no concern regarding the company’s assessment of the low-saturate/high-oleic oil as generally recognized as safe, and FDA consultation and USDA submissions have been made and are on schedule, he said. The company anticipates commercialization in 2–3 years.

Wilkes said that other soybean trait modifications are also being developed. One, in the very early stage of development, is high-stearate soybeans, with increased stearic acid levels that provide solid fat functionality required in foods such as shortenings, baked goods, and margarines.

Another development, closer to commercialization, is SDA omega-3 soybean oil. This product, being developed in collaboration with Solae LLC and called Soymega, contains 20% stearidonic acid (SDA), which is readily converted into the heart-healthy omega-3 fatty acid eicosapentaenoic acid (EPA). With a neutral flavor that will allow the oil to be added to a broad range of food products, this oil should become the optimal omega-3 ingredient for food, Wilkes said. Commercialization is anticipated in 2–3 years.

For the low-saturate, high-oleic oil, beneficial traits that increase oleic acid and decrease saturate were introduced into the soybean through genetic engineering, and the low-linolenic trait was introduced through conventional breeding, Wilkes said. For the SDA omega-3 soybean oil, enzymes found in common fungi and plants were inserted that result in the soybean’s containing SDA.

--- PAGE BREAK ---

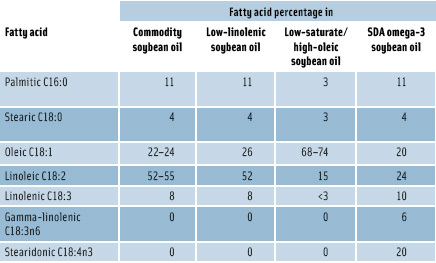

The fatty acid composition of Monsanto’s oils is shown in Table 2.

The modified soybean oils were the subject of several papers at the IFT Annual Meeting in July. In paper 098-03, Wilkes described these enhanced-trait soybeans and their benefits in food product applications. In paper 078-02, he reported the results of frying studies using the Vistive Gold low-saturate/high-oleic oil. Frying studies of French fries and chicken were conducted over an extended frying time (up to 120 hr). Oil quality analysis demonstrated that the new oil extended fry life. Analysis of the fried foods showed that low trans fat levels were maintained and saturated fat levels were reduced. And sensory analysis of the fried foods demonstrated acceptable flavor quality throughout the study.

In paper 167-02, William Harris, Research Professor at the Sanford School of Medicine at the University of South Dakota, discussed the nutritional benefits of the SDA-enriched soybean oil. He said that nutrition studies demonstrate the conversion of SDA to long-chain polyunsaturated fatty acids, including EPA, in animals and humans, and that significant increases in erythrocyte EPA indicate that SDA can improve cardiovascular risk status.

In paper 167-03, Eric A. Decker of the University of Massachusetts described the unique attributes of the processing, chemistry, and stability of SDA for use in functional foods. He said that bioactive lipids such as omega-3 fatty acids are extremely susceptible to free-radical attack, leading to the loss of nutritional quality and the formation of off-flavors. SDA from enriched soybean oil, he said, has advantages over omega-3 fatty acids obtained from some wild-caught fish, including better control of the raw material quality, control of extraction and refining of the oil to minimize oxidative deterioration, utilization of the soybean’s natural antioxidant defense system, and oxidative stability of the fatty acid. These advantages, he said, could result in higher-quality omega-3 ingredients that will increase the shelf life of omega-3 fortified foods and decrease the sensory defects associated with the oxidative deterioration of omega-3 fatty acids.

In paper 167-04, David Welsby of Solae described the shelf stability of the SDA-enriched soybean oil in a range of food applications. He concluded that SDA omega-3 soybean oil has advantages in providing consumer-acceptable, quality foods that provide omega-3 fatty acids that are readily metabolized in the body to EPA.

--- PAGE BREAK ---

High-Oleic Soybean Oil Standard

U.S. Pharmacopeia (www.usp.org) has published a new standard intended to help ensure the quality of unhydrogenated high-oleic soybean oil once it is incorporated into food production. The standard is included in the 7th edition of Food Chemicals Codex, a compendium of internationally recognized standards that designates the quality and purity of food ingredients used by food product manufacturers. The FCC is published by USP. The standard includes specifications that will allow manufacturers to establish the identity, quality, and purity of this new soybean oil, enabling them to differentiate it from other plant oils.

Monitoring Oxidative Stability of Oils

Some additional instruments and methods for monitoring the oxidative stability of oils are being developed and commercialized.

• In paper 070-19 at the IFT Annual Meeting, Meghan Allendorf ([email protected]) and Luis Rodriguez ([email protected]) of Ohio State University reported on studies to evaluate the capabilities of portable handheld infrared and Raman spectrometers combined with multivariate analysis to characterize frying oils and to monitor chemical processes occurring during lipid oxidation. They heated commercial frying oils—corn, peanut, sunflower, safflower, and canola—at 65°C in an oven for 30 days to accelerate oxidation, then measured the fatty acid composition by IUPAC methods 2301 and 2302), peroxide values by IUPAC method 2501 and the FOX method, and acid value by AOCS method Ca 5a-40. They used pattern recognition software, Soft Independent Model of Class Analogy and Partial Least Squares Regression, for spectral analysis and concluded that the handheld IR instrument combined with multivariate analysis showed promise for simultaneous determination of oil quality parameters with performance similar to that of benchtop FTIR units and that its portability and ease of use make them a good alternative to traditional testing methods.

• In November 2009, Ametek Petrolab Co. (www.petrolab.com) announced the availability of the PetroOxy Rapid Oxidation Stability Tester from Petrotest Instruments. The compact instrument features a small hermetically sealed test chamber in which a 5-mL sample is combined with oxygen at a pressure of 700 kPa and heated to 140°C. These test conditions initiate a very fast aging process, which is measured by a pressure drop within the chamber. The time needed to achieve a fixed pressure drop is directly related to the oxidation stability of the sample. Test times can be reduced by elevating the test temperature.

Sniffing Out Undesirable Oil

While high-oleic soybean oil is highly desirable for use in foods, another oil is highly undesirable: the petroleum that has been spewing from BP’s broken oil pipeline in the Gulf of Mexico. But efforts are underway to make sure that the seafood brought to market is safe to consume.

The Food and Drug Administration and the National Oceanic and Atmospheric Administration on June 14 released a joint statement outlining how they plan to tackle seafood safety issues related to the oil spill, including precautionary closures of fishing areas, increased testing of seafood samples, and a protocol for reopening affected areas of the Gulf. FDA and NOAA will also increase inspection of seafood processors to ensure proper documentation detailing the provenance of all seafood entering the U.S. food supply and to stop seafood of unknown origin from coming to market.

FDA sent a guidance letter to the fish and fishery products industry, emphasizing the use of HACCP plans. NOAA’s guidance publication, “Managing Seafood Safety After an Oil Spill” is available at http://response.restoration.noaa.gov/book_shelf/963_seafood2.pdf.

--- PAGE BREAK ---

To help prevent tainted seafood from reaching the market, NOAA created a seafood sampling and inspection plan. Samples are sent to NOAA’s Northwest Fisheries Science Center in Seattle for chemical testing and to the National Seafood Inspection Laboratory in Pascagoula, Miss., where analysts are trained in sensory testing to detect chemicals that are not normal background odors in seafood.

On June 3–4 and 15–17, the International Food Protection Training Institute and NOAA’s Fisheries Service provided seafood sensory training programs for officials in the Gulf states affected by the oil spill. The sessions were held at the National Seafood Inspection Lab and included hands-on training to develop skills in sensory detection of seafood exposed to oil. As of press time, 60 inspectors have been trained to sniff out seafood tainted by oil to make sure that product reaching consumers is safe to eat.

In addition, on July 9, analytical instrument manufacturer Thermo Fisher Scientific Inc. (www.thermofisher.com) announced that its global Food Safety Response Center located in Dreieich, Germany, has developed two new analytical screening methods to detect petroleum contamination in oysters and fish, specifically hydrocarbons and polyaromatic hydrocarbons, resulting from the oil spill in the Gulf of Mexico.

The Center, equipped with state-of-the-art technology and a full-time staff of food safety scientists, was created on April 15, 2010, to reduce the duration, severity, and spread of chemical contamination by accelerating the development and distribution of methods of analysis. The scientists are equipped to analyze any food matrix that contains toxic chemicals, develop a method to test for the contaminants, and deliver the method to food safety regulators, food producers, and independent testing labs.

The scientists used oil samples collected from the Gulf region to develop step-by-step testing procedures that can be quickly implemented by food and environmental laboratories. The procedures are available for downloading from the company’s Gulf Coast Oil Spill Resource Center at www.thermofisher.com. Additional information about Thermo Scientific solutions and food safety applications is available at www.thermoscientific.com/foodsafety.

BY Neil H. Mermelstein,

a Fellow of IFT,

Editor Emeritus of Food Technology

[email protected]