Food Traceability R&D in Norway

Norwegian research focuses on establishing an electronic infrastructure for exchanging food safety and quality data across the entire food value chain.

Several product transformations and processing steps take place during industrial production of food. These transformations alter food composition and, if not monitored properly, can affect food quality as well as food safety. Little research has been conducted that involves simultaneously recording information related to food product integrity and processing techniques and their affect on food quality and safety. To perform efficient traceability, there is a need to integrate this information into a framework through which a problem caused due to processing or handling/logistics can be identified and traced back to the source. Two Norwegian traceability implementation projects engaging these strategies show great promise: eSporing and eTrace.

The Norwegian eSporing (eTraceability) Project

The Norwegian eSporing (eTraceability) project began in 2007 in response to an Escherichia coli outbreak in food. The 2006 outbreak pinpointed the importance of food traceability as one of many tools to support the process of identifying unsafe food and to track and trace unsafe food on the market. The eSporing project is a collaboration between the Norwegian government, food safety authorities, and companies within the food value chain. The Norwegian Ministry of Food and Agriculture, the Norwegian Ministry of Fisheries and Coastal Affairs, and the Norwegian Ministry of Health and Care Services own the project.

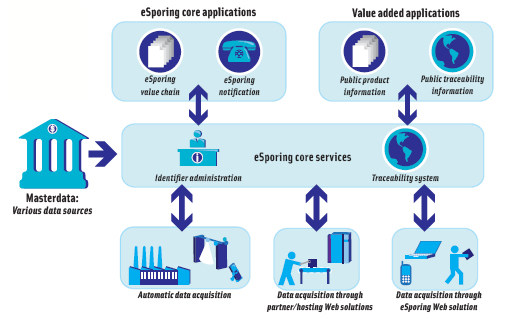

The goal of the eSporing project is to establish an electronic infrastructure for exchange of information in the food value chain. The establishment of the electronic infrastructure (the eSporing solution) should support efficient track and trace in the food value chain, enabling tracking and tracing from beginning to end. This infrastructure should also help identify the source of unsafe food and increase preparedness for such measures.

One of the main focus areas of the eSporing project has been to facilitate and encourage traceability discussions and traceability projects within various subsectors in the food value chain, aimed at finding efficient, cost-effective ways to implement better traceability. The subsectors have organized their work as independent traceability pilots, working in close collaboration with the eSporing project. This part of the work has focused on specific challenges related to traceability. The eSporing solution should be an efficient traceability tool for companies in the food value chain. The eSporing project has a greater aim than the one-step-back/one-step-forward focus in European Union (EU) food law since eSporing will establish a traceability system for the entire chain. The use of the eSporing solution is not compulsory; company participation is based on interest.

--- PAGE BREAK ---

The eSporing sector pilots are beef, grain, produce, grain, wild-caught fish (white fish and pelagic fish), and milk and dairy products. These pilots cover major subsectors in the food value chain in Norway and represent wide collaborations. During 2007 and 2008 the eSporing project conducted several research and development activities to establish principles for an electronic infrastructure for the exchange of information in the food sector. These activities were conducted in close collaboration with research institutions working on traceability.

Method

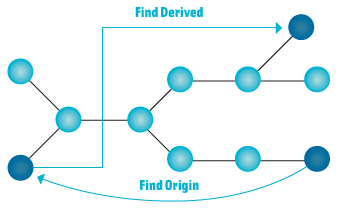

According to the International Organization for Standardization (NS-ISO 8402), traceability is the ability to trace the history, use, and localization of an entity through recorded information. The entity or item that should be traced can be physical or virtual, and all items must have a unique identification. The eSporing project allows companies to use globally or locally unique identifiers to identify company items. eSporing will convert locally unique identifiers to globally unique identifiers, enabling individual companies to use existing systems for identification of items.

The eSporing solution exceeds EU food law in that companies participating in eSporing are required to have some level of internal traceability. The internal traceability links the items received by a company to items sold by the company. Internal traceability information does not necessarily have to be uploaded to eSporing on a routine basis as the solution has a notification system to notify and call for information when a situation involving unsafe food arise. Companies participating in the eSporing solution have been encouraged to upload external traceability information to establish chain traceability on a routine basis. Smaller companies could use eSporing to establish a system for internal traceability, uploading internal traceability directly to the system.

The eSporing solution exceeds EU food law in that companies participating in eSporing are required to have some level of internal traceability. The internal traceability links the items received by a company to items sold by the company. Internal traceability information does not necessarily have to be uploaded to eSporing on a routine basis as the solution has a notification system to notify and call for information when a situation involving unsafe food arise. Companies participating in the eSporing solution have been encouraged to upload external traceability information to establish chain traceability on a routine basis. Smaller companies could use eSporing to establish a system for internal traceability, uploading internal traceability directly to the system.

The Electronic Product Code Information Services (EPCIS) standard was chosen as the standard for the eSporing solution, making extensions solution has a strict authorization system: Only authorized users of the company owning the information can access data. External users can access data only if the owner company specifically grants permission.

Outcome

Version 1.0 of the eSporing solution was completed in September 2011. The experience demonstrates that it is possible to establish a common electronic traceability solution for all subsectors. The ability of a food value chain to participate in such a system varies tremendously. Most companies are able to meet all of the requirements. Nevertheless, an electronic infrastructure for traceability will provide standardized information when companies need to track and trace, enabling better preparedness and rapid results. The eSporing solution is now being tested by other companies in the food value chain. The results will determine whether the eSporing solution needs further development before the food industry can use it as a tracing tool.

--- PAGE BREAK ---

The eTrace Project

Led by SINTEF Fisheries and Aquaculture in Norway with research partners in Iceland and Sweden, the eTrace project was designed to specify, develop, and evaluate an electronic traceability system involving the integration of food safety information sources and suitable enterprise management systems. eTrace provides efficient traceability operations so that precise and reliable recalls can be performed during a food scare.

To accomplish this objective, eTrace had to define how integration between a generic infrastructure for traceability and information harvested by different means could improve documentation and operations related to food safety. eTrace also had to determine how management systems and an EPCIS traceability infrastructure could combine to provide high quality traceability information to ensure continued food safety through the food value chain. In addition, eTrace analyzed and specified functionality for a decision support system for the food value chain to ensure reliable and effective food safety monitoring and control.

Method

A new methodology for modeling this traceability information using the EPCIS framework and Unified Modeling Language state-charts was introduced. A generic state-transition model for food production was developed and applied to two pilot chains: fish supply chains in Sweden and those in Iceland. The emphasis was on identifying both traceability transitions and food safety, and quality data were developed. Application of an existing EPCIS framework for managing food traceability information was presented by mapping the transitions identified in two product chains to EPCIS events: ObjectEvent and AggregationEvent. The corresponding states where the quality parameters are recorded were also identified and linked to these EPCIS events. The food safety information included time-temperature data linked to tagged items as well as information about the catch vessel, nutritional information about fish caught in a particular catch area, results of unwanted substances in catch area, and a chain-of-custody certification scheme.

Fish units (vessel tubs, production units, packaged boxes, etc.) were labeled with radio frequency identification (RFID) tags, and as tagged items moved through production, handheld RFID readers captured data. The goal was to track fish as it moved through the supply chain. The pilot in Sweden focused on chain traceability (fish from vessel to production and retailer) and the pilot in Iceland focused on internal traceability (tracking through all stages in production from receiving the catch to final shipment of packed fillets).

Fish units (vessel tubs, production units, packaged boxes, etc.) were labeled with radio frequency identification (RFID) tags, and as tagged items moved through production, handheld RFID readers captured data. The goal was to track fish as it moved through the supply chain. The pilot in Sweden focused on chain traceability (fish from vessel to production and retailer) and the pilot in Iceland focused on internal traceability (tracking through all stages in production from receiving the catch to final shipment of packed fillets).

The data from RFID readers was uploaded to an EPCIS repository provided by TraceTracker. A local server received uploaded data and handled all parts of the communication between the EPCIS and the computer with the data files. There was no need for human operators to be involved. A Traceability Information Exchange (TIX) stores and manages standardized event data related to individual items. For example, when a box of fish is scanned and information is uploaded from the RFID reader, the TIX records the unique identification of the box, its location, and other relevant information such as the processing step and time.

--- PAGE BREAK ---

Outcome

With the regular reading and data uploading from the fishing and processing to the final product, EPCIS repositories enabled improvements in communication between parties within the food value chain. EPCIS-based traceability systems would open up new possibilities for internal and supply chain optimization if such systems were widely used by all value chain stakeholders. Automatic reading stations in processing plants instead of handheld scanners provided a faster, efficient way to capture and exchange information. The user interface created from the EPCIS repository carried views that rely on the traceable entities defined in the underlying model. The graphic representation of the model enabled visualization of relationships between various units such as the catch, fish boxes, processing, and retail boxes with fish product. The generic EPCIS modeling has no corresponding view that aggregates information from multiple events.

One of the main objectives of this project was to integrate food safety and quality information into the EPCIS system and link these parameters to tagged items that could be tracked throughout the supply chain. The quality and safety parameters selected for this were data on temperature (both product and ambient), redfish nutrition, and undesirable substances in Icelandic waters. All information was stored and available to be exchanged in the EPCIS repository.

Internal traceability was improved by use of the EPCIS system and the production process became more visible. The traceability units (TUs) at each stage in production were clearly identified, and corresponding product parameters were linked to these TUs. The transformations for each TU were modeled in this project and could help in tracing the cause and tracking the extent of a food safety related event.

The EPCIS repository developed in this project also included mechanisms for information exchange between different organizations using different traceability systems. To be able to use this system, the sender had to indicate which item he sent to which customer, and the receiver had to indicate which item he received from which supplier. These two were then matched by a hub infrastructure, leading to a link being created between the same items at the two parties.

The Future

With the regular reading and data uploading from fishing and processing to the final product, EPCIS repositories enable improvements in communication between parties within the food value chain. In the future, EPCIS-based traceability systems will create new possibilities for internal and supply chain optimization if such systems are widely used by all food value chain stakeholders. The installation of automatic reading stations in processing plants instead of handheld scanners will also provide a fast, efficient way to capture and exchange information. Future work should also focus on secure information access and automatic integration of food safety information (it was done manually for the pilot).

Based on this system, chains of companies can be linked together, resulting in the all-up/all-down traceability needed for end-to-end traceability. EPCIS technology combines the advantages of a standard system with features for tying independent systems together in chains that mirror the physical relationships between companies. This allows easy deployment and efficient use of end-to-end traceability in chains for production of food.

Maitri Thakur, an IFT member, is Research Scientist, SINTEF Fisheries and Aquaculture, SINTEF SeaLab, Brattørkaia 17C, 7010, Trondheim, Norway ([email protected]).

Astrid Merethe Karlsen is Team Manager of Traceability, Det Noske Veritas, P.O. Box 200, 1322 Høvik, Norway ([email protected]).

Eskil Forås is Research Manager, SINTEF Fisheries and Aquaculture, SINTEF SeaLab, Brattørkaia 17C, 7010, Trondheim, Norway([email protected]).