Discovering Processing Innovation

Exhibitors highlight solutions for food science–related needs and challenges, from small-scale unit operations to commercial-scale equipment lines.

Article Content

This year’s IFT18 food expo was appropriately described as “A Matter of Discovery.” As I walked through the expo, I discovered both traditional and novel food processing equipment for food product developers and engineers.

MicroThermics, a leading provider of small-scale custom pasteurizers and aseptic fillers, highlighted its UHT/HTST/aseptic processors at this year’s food expo.

GEA Group is one of the largest equipment suppliers to the food processing industry. This year at the expo the company showcased its Batch Formula Test Mixer, which features direct steam injection.

Armfield manufactures small-scale equipment ranging from HTST/UHT/aseptic systems to spray dryers and chillers, extractors and crystallizers, oil processors, ultrafiltration devices, and more. Small-scale equipment enables development and optimization of custom processing solutions before scale-up into commercial operation.

Baker Perkins highlighted processing equipment and services for the bread, biscuit, confectionery, snack, and breakfast cereal sectors. One of the company’s innovative technologies is a three-dimensional mold system for high-value, starchless jelly depositing.

Radio Frequency Co. is a leading manufacturer of advanced industrial radio frequency processing systems for the rapid heating, drying, de-infestation, and pasteurization of foods. At this year’s expo, the company showed off its Macrowave CeleroTherm pasteurization system.

A number of companies highlighted processing solutions for sanitation. Meritech featured its ProTech XV, which simultaneously sanitizes both hands and footwear. Safe Sterilization announced a new treatment using heat and steam to improve the safety of dry ingredients without the use of chemicals or irradiation. Klarion exhibited a range of novel spray systems for safe, sustainable cleaning and sanitization. American Ultraviolet designs and manufactures a wide range of standard and custom ultraviolet C sterilization fixtures to protect food and beverages and shared those at the expo.

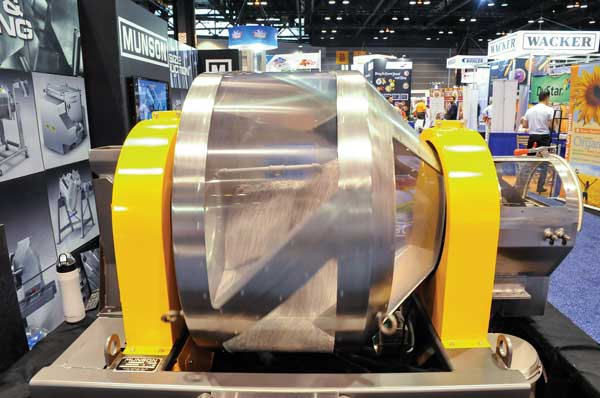

Several companies exhibited a variety of types of mixing equipment. Ampco Pumps highlighted its Shear-max high-shear inline mixer for dispersing, dissolving, homogenizing, and more. Munson Machinery provides low- to high-shear solutions for blending and/or homogenizing dry solids, slurries, and pastes. B&P Process Equipment has developed mixing equipment since the early 1900s and offers a wide variety of mixing equipment to the food industry.

Several companies exhibited a variety of types of mixing equipment. Ampco Pumps highlighted its Shear-max high-shear inline mixer for dispersing, dissolving, homogenizing, and more. Munson Machinery provides low- to high-shear solutions for blending and/or homogenizing dry solids, slurries, and pastes. B&P Process Equipment has developed mixing equipment since the early 1900s and offers a wide variety of mixing equipment to the food industry.

Several extrusion manufacturers exhibited at IFT18. Buhler Group, C.W. Brabender, Clextral, and Wenger Manufacturing featured a variety of extrusion food processing equipment options.

In addition, Porifera highlighted its forward osmosis processing technology, which was the topic of the March 2017 Processing column. This energy-efficient technology is used to dewater and concentrate high- quality liquid foods.

Several Chinese equipment manufacturers exhibited at this year’s expo. One of them was Jiangsu Haitel Machinery, a professional manufacturer of equipment for production of foods, candies, and egg rolls.

Advanced Process Solutions and Blentech offer consultancy services to help guide food processing development. Advanced Process Solutions provides customers with the latest technological developments in valves, controls, actuation, measurement, and instrumentation. Blentech is an application-driven company that provides a wide range of innovative solutions to various processing challenges. Universities and government agencies are other good sources of information for companies interested in novel food processing solutions.

Acknowledging Processing Achievement

Finally, three IFT Achievement Awards related to food processing were presented at the event. The Research and Development Award was granted to The Innovative Infrared Research and Development Team (Zhongli Pan, Tara H. McHugh, Ragab Gebreil, Chandrasekar Venkitasamy, and Hamed M. El-Mashad) of the Western Regional Research Center, U.S. Department of Agriculture’s Agricultural Research Service and the University of California, Davis. This award recognized the development and commercial implementation of sustainable infrared heating technologies for improved food healthfulness, quality, and safety while saving energy and water during processing.

In addition, Pawan Singh Takhar was awarded the Marcel Loncin Research Prize for the use of porous media physics to model multiscale fluid, species, and heat transport processes in foods. This new modeling method promises to be a powerful tool for porous foods.

Finally, Dominique Bounie was awarded the W.K. Kellogg International Food Security Award for finding innovative solutions to humanitarian and emergency feeding problems through the application of food science and technology, including the design of low-cost processes dedicated to the local production of emergency and rehabilitation foods.

In summary, the IFT18 annual event was filled with food processing discoveries, reinforcing the important role of food processing in developing new foods and/or improving food quality, health, and safety while enhancing sustainability in food manufacturing.

Tara McHugh, PhD, is a contributing editor of Food Technology magazine ([email protected]).