Active and Intelligent Packaging = Longer Shelf Life

PACKAGING

Active and intelligent packaging are two forms of smart packaging. Active packaging employs technology that intentionally releases or absorbs compounds from the food or the headspace of food packaging, which extends the shelf life of products by stalling the degradative reactions of lipid oxidation, microbial growth, and moisture loss and gain better than traditional food packaging. Intelligent packaging communicates to consumers and others throughout the value chain. The two types of smart packaging will advance the packaging sector. Scavengers for oxygen, ethylene, and moisture continue to dominate active packaging, but recent growth in active packaging emitters has been dramatic.

Scavengers

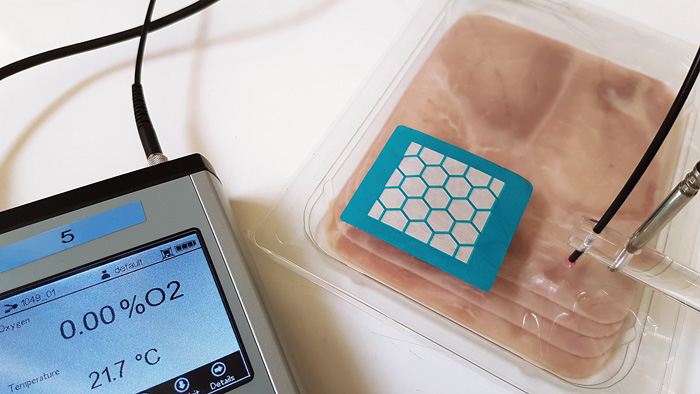

Package scavengers in the form of separate packets or sachets have been around for at least 50 years, but now scavenging technology is embedded within the package structure. This integrated approach reduces costs and enables this form of active packaging to be a cohesive process for production operations and consumers. The combination of intelligent technologies with active packaging allows the gathering of information on how a package is performing.

• Oxygen scavengers. Oxygen absorbers stall oxidation and inhibit microbial growth. The most common substrate in oxygen scavengers is iron followed by ascorbic acid and other substrates. These substrates are incorporated into polymer structures as light-sensitive dyes or sacrificial unsaturated dienes. Oxygen-absorbing liners on the underside of beer closures, such as the Carlsberg FreshCap, are said to increase the shelf life of beer by 15%. The ability for consumers to activate oxygen scavengers within an opened resealable package is an emerging development in this area.

• Ethylene scavenging products. Ethylene scavengers extend the shelf life of produce by slowing the ripening process and senescence. They are typically available in sachet form and can be integrated into the package structure. Regardless of whether ethylene-absorbing sachets contain zeolite or potassium permanganate, they absorb ethylene and moisture to reduce senescence and release sulfur dioxide if water comes in contact with the sachet pads that contain sodium metabisulfite salt. In addition, the compound 1-methylcyclopropene (1-MCP) is commonly used in the washing and processing of fresh produce and to block ethylene receptors and slow senescence. FruitBrite by Hazel Technologies releases 1-MCP to diffuse ethylene blockers within the headspace of packaging during distribution. In addition, the incorporation of 1-MCP in corrugated linerboard eliminates the need for sachets and allows for more seamless and consistent produce distribution. PEAKfresh by PEAKfresh USA, Green Bags by Evert Fresh, Ethyl Stopper by Profresh Systems, and Bio Fresh by Grofit Plastics are other ethylene-scavenging products that are on the market.

• Moisture scavengers. Moisture scavengers control moisture in the headspace of a package and absorb liquid weeping from food, which extends product shelf life. Examples of common commercial scavenger pads and sachets that absorb moisture from food include Dri-Loc by Novipax, absorbent pads by Thermasorb, and MeatPad by McAirlaid’s. There are also various types of absorbent packaging, such as MoistCatch films by Kyodo Printing, desiccant packaging by Onyx Specialty Papers, and FreshWell rigid trays by Aptar. Clays, zeolite, humectants, and other compounds in packaging substrates absorb moisture, but adding high-capacity hydrogels to packaging structures allows for more effective moisture control.

Emitters

Active food packaging emitters lessen the effects of deteriorative reactions from microbial growth, oxidation, or uncontrolled ripening via their direct contact with food and diffusing from the packaging. Packaging materials that do not provide a suitable shelf life of foods can be enhanced with active packaging emitters. For example, when an antioxidant is emitted into the headspace of a package, the required oxygen barrier or the degree of headspace modification (via vacuum or gas flushing) may decrease. This is the case with some packaged cereals in which butylated hydroxyanisole or butylated hydroxytoluene emitted from a relatively low-barrier, low-density polyethylene and polypropylene copolymer stalls lipid oxidation.

The abundance of research on the diffusion of antimicrobials from unrealistic packaging materials has not encouraged commercialization of these materials. This is because many packaging materials have conflicting value propositions. For example, an added layer of the antimicrobial chitosan on fossil-derived compostable polybutylene adipate terephthalate (PBAT) could inhibit some microbial growth on a food product, but it also precludes the compostability of PBAT. However, active packaging emitters can be used with bioderived, recyclable, and reusable polyethylene and polyethylene terephthalate without a conflict in many value propositions. Thus, more research is needed on the diffusion efficacy of antimicrobials and antioxidants from more plausible packaging materials.

The use of antimicrobials does not always mean that microbes are eradicated. The efficacy of antimicrobials is defined by different means, such as whether the microbes are pathogens and, if so, their potency; the microbes render a product unsalable (e.g., unsightly mold); or an antimicrobial is capable of reducing microbial growth by 2 log10 colony-forming units as defined by ISO 22196:2011. The diffusion dynamics of the antimicrobial from the package material to the food need to be controlled and consistent. Thus, much of the development in antimicrobial packaging has relied on polymers or polymer coatings with controlled levels of crystallinity to control desorption from packaging materials.

• Antimicrobial carbon dioxide emitters. Hydrogels and other containment mechanisms for the release of antimicrobial carbon dioxide from packaging materials have been available for at least 30 years. CO2 Freshpads by CO2 Technologies and SuperFresh CO2 Pads by vdP International release carbon dioxide via sodium bicarbonate and citric acid whereas Moxiyo CO2 Packets by Moxiyo and UltraZap XtendaPak by Novipax use other means to release carbon dioxide. Most often, carbon dioxide emitters are used in combination with modified atmosphere packaging gases such as nitrogen.

• Antimicrobial nano-sized metals. The ability of nanoparticles to create a high aspect ratio and efficient dispersion within a packaging substrate increases the efficacy of antimicrobial nanoparticles. The most prevalent nano-sized antimicrobial is silver. By themselves or combined with titanium dioxide and zinc oxide, nano-sized silver particles are effective against Listeria monocytogenes, Salmonella, and Escherichia coli as well as non-pathogenic microbes although silver’s efficacy decreases at cooler temperatures. Applications for antimicrobial nano-sized metals include orange juice, soft cheeses, fresh-cut produce, and deli meat.

Antimicrobials can also be employed to inhibit microbial growth of food in contact with recycled paper-based molded pulp packaging. For example, CoppTech Antimicrobial Solutions has an antimicrobial zinc-oxide blend that is effective at inhibiting E. coli and other microbes at low and ambient temperatures in packaging such as egg cartons and reusable molded pulp packaging.

Other Compounds Used in Active Packaging

The use of spices, essential oils, enzymes, and food polymers in packaging materials is limited by the degree to which the inherent flavors or odors can be transferred to food. To inhibit mold on food surfaces, it is often more effective to apply onto a food product an atomized mist containing a food-grade antimicrobial or add a food-grade antimicrobial to the product’s ingredients. The essential oils of basil, bay leaves, and cinnamon are effective against Clostridium sporogenes and E. coli, and the essential oils of cinnamaldehyde and oregano inhibit L. monocytogenes. Green tea extract stalls lipid oxidation. And orange essential oil inhibits E. coli, Staphylococcus aureus, and Pseudomonas spp.

The synergistic effects of carvacrol, thymol, and other essential oils appear to be quite effective at reducing odor and flavor issues associated with the high concentration of an essential oil. Combinations of thymol-carvacol-eugenol and rosemary-oregano also exhibit efficacy against oxidation. Nisin, a peptide, is effective against psychrotrophic bacteria and anaerobic bacteria. And the food polymer epsilon-poly-l-lysine inhibits microbial growth by disrupting and degrading cell walls. For spices, essential oils, enzymes, and food polymers to be properly assessed as potential antimicrobials in food packaging, research outside of laboratory settings is needed. Compounds used as food preservatives can also be used to limit microbial growth on food and packaging; these include citric acid and allyl isothiocyanate (AITC), potassium sorbate, and other derivatives of sorbic acid. Wasaouro films and labels by Mitsubishi Chemical contain AITC. While AITC and other food preservatives are effective antimicrobials, they must adhere to a wide range of regulations to ensure their use.

Interest in valorizing food processing waste has prompted the use of food processing waste as packaging additives. For example, the polyphenols in olive leaves and grape pomace stall oxidation, and chitosan derived from shells inhibits numerous microbes.