How Radical Innovation Will Shape the Future of Food

Whether it’s cultivating protein from a primeval microorganism or 3-D printing alternative meat, forward-thinking entrepreneurs are boldly reimagining the way food is made.

Article Content

The future of the world’s food supply may well originate in the turbulent, volcanically heated geysers in Yellowstone National Park. That’s where Thomas Jonas’ team discovered a fungal microbe that has survived for eons in subterranean temperatures of 250˚F. Such microbes are now fermenting in trays in Chicago and being manipulated by food scientists into imitations of chicken and other products, and someday, Jonas believes, will feed huge populations using just a fraction of the land and water resources consumed by traditional agriculture.

Jonas is promising to put the first commercial product on grocery shelves next year under the brand of his company, Nature’s Fynd. Icons of technology and captains of industry already have gotten behind the primeval protein cultures he’s building with Fusarium strain flavolapis. Bill Gates, Jeff Bezos, Richard Branson, and Michael Bloomberg are among funders of a management fund headed by Al Gore that co-led a recent financing round of $80 million for Nature’s Fynd, which will sell the fermented protein created from Fusarium strain flavolapis under the brand name Fy.

“It’s mind-blowing that we’re relying today for food on the same species we started to domesticate when agriculture began 11,000 years ago,” says Jonas, co-founder and CEO of Nature’s Fynd, a Frenchman who previously was a president at packaging giant MeadWestvaco. “Out of the millions of organisms and species on the planet, we have perfected our system around fewer than 10 plants that provide about 60% of our global caloric intake—including the plants that feed the animals that we eat. That’s reaching its limitations in terms of its efficiency and its ability to provide food to all of us.

“So it makes sense to domesticate other species that are coming from nature,” Jonas says. “Fusarium strain flavolapis is not something that we tweaked in a lab. The organism has been there for many thousands of years—it just hadn’t been identified.” (See sidebar NASA Support Helps Propel Startup’s Growth for more details about Nature’s Fynd.)

Jonas is far from alone in his soaring ambitions for futuristic foods. Nature’s Fynd is just one of dozens of companies around the world where entrepreneurs are now seeking to recast food supplies at the most basic levels. These new biological architects are innovating plant-based meat analogues, harnessing obscure or underutilized organisms, radically modifying existing plants and animals, and even creating what amount to new, organism-like animal entities from the ground up—all in attempts to maintain or even improve the traditional attributes of foodstuffs while revolutionizing the way nutrients are produced.

The scientists and entrepreneurs behind these technologies are variously motivated by everything from compassion for the millions around the world who still suffer from hunger to a determination to save the planet from the growing environmental toll of traditional food production. Profit motives also play into it, of course, as well as more complex factors such as a sort of technological determinism that can characterize biological advances as easily as it can propel leaps in digital technology.

In any event, these widespread efforts include four basic areas. The most spectacularly innovative is cell culturing of meat, poultry, and fish analogues, in which technologists nurture animal cells in vitro, instead of from slaughtered animals, and then engineer the cells into imitations of tissue as they grow. A second and sort of complementary technology is 3-D printing of plant-based meat imitations.

Third is gene editing, in which scientists manipulate DNA strands in order to re-engineer existing organisms and even create what arguably are new ones. And a fourth futuristic platform involves developing and scaling up the cultivation of previously obscure organisms to boost food production and make it more environmentally benign.

“We can imagine changing the food production system over the next few decades to confront many of the large issues we’re already seeing as looming, including climate change,” says Trey Malone, a food economics professor at Michigan State University. “The technology has been astounding to witness, and it’s only going to increase.”

At the same time, however, there are skeptics about some of the pie-in-the-sky expectations for futuristic methods—and also about whether some of them are even a good idea in the first place. “There will be a role for some of these new, quite exotic technologies,” says Walter Willett, a world-renowned nutritionist at the Harvard University School of Public Health. “But that said, we don’t actually need them,” he contends. “We can do what we need to do with the foods we have today.”

Julian Mellentin, a global consultant to food and beverage companies on better-for-you strategies, believes that “the future of food is decided not by technologies but by people who decide whether to adopt something. For at least 20 years, people have been telling us that they prefer things as natural as possible, with clean labels and fewer ingredients, and the food industry has been forced to respond to that. And people have said they don’t like eating technology.”

Still, some analysts foresee phenomenal growth for the products of these technologies. Cell-based analogues will snare a 35% share of the global “meat” market by 2040, for instance, predicts consultancy A.T. Kearney. Conventional meats and plant-based analogues will share the rest.

Here are looks at each of these cutting-edge technologies.

Culturing Innovation

Plant-based marvels of food engineering such as Impossible Burger and Beyond Meat are only precursors to a coming vanguard of other “alt-meat” analogues that involve teasing growth out of a group of animal cells and then engineering appearance, texture, and taste that mimic animal flesh. A handful of startups in the United States, Israel, and elsewhere are racing to begin commercializing them.

The methodological starting point for all of these companies is a group of existing cells that may be stem cells, genetically modified muscle cells, or others that can be procured by performing a harmless biopsy on a live animal. They’re fed a nutrient-dense liquid so they reproduce, fermenting in metal “bioreactors” similar to the ones consumers have gotten used to seeing in microbreweries, and producing uniform biomass that mimics ground meat.

From there, some companies and research groups have been introducing matrices of features into the collection of cells, allowing them to form structural components imitating the fat and bone in real meat—in other words, with ambitions to create imitations of cuts of meat rather than a uniform material akin to ground beef. Harvard University researchers, for example, have created gelatin scaffolds that provide physical support to the growing cells and cues for growth, cell orientation, and differentiation.

Like any fledgling, complex, and expensive new technology with the aim of popularization, cost is an issue for alt-meat. The original science a few years ago produced a pound of “beef” that would have been priced at about $1.2 million in a grocery store, according to Billion Dollar Burger, a new book on the industry. By 2017, one startup, Memphis Meats, had gotten the price of its cell-cultured chicken analogue down to $9,000 a pound, and then within a year to less than $1,000 a pound. Now, companies are promising alt-meats within a few years for about $10 a pound.

Future Meat Technologies creates a blend of cultured animal fat and plant-based protein that it plans to sell to food manufacturers globally by 2022. Backed by Tyson, Israel-based Future Meat claims that its production method is highly efficient and low cost, with biomass doubling in size in less than 24 hours because it uses fibroblasts—the fast-growing cells that, for example, quickly close up a paper cut. Bioreactors nurture them into densities that exceed 100 million cells per millimeter.

“We have decades of experience using these kinds of vessels, and they’re highly scalable,” says Yaakov Nahmias, founder and chief science officer. “You don’t need to build a new type of cultivation equipment. Everything is standard and off the shelf.” A Future Meat bioreactor about the size of a standard refrigerator, he says, could produce “half a ton of mass every two weeks. That’s the equivalent of about 500 chickens.”

Nahmias’ method also has a way of dealing with the waste products that all cells, even artificially nurtured ones, generate. A “rejuvenation system” sits outside the bioreactor and acts as a sort of liver to the growing tissue mass, removing the waste products every 48 hours, Nahmias explains.

While Future Meat and other alt-meat enterprises are focusing on imitations of land-based meat sources, other entrepreneurs are looking to the oceans. Wild Type, for instance, was founded by a former U.S. diplomat and by a researcher who was studying how the heart could regrow functional muscle tissue lost in a heart attack. They selected salmon as their first target despite the fact that its cellular biology is much less understood than that of mammals, and there are unique nutritional challenges to replicating salmon meat, such as including crucial omega-3 fish oils.

“We focused on salmon initially in part because of the versatility of salmon, which can be consumed raw or cooked, as lox or salmon steak or in sashimi,” says Justin Kolbeck, Wild Type’s CEO. “Another benefit is that salmon retails for a lot more than meats: three times the price of ground beef and two times the price of chicken.”

BlueNalu is focusing on analogues for higher-priced fish fillets, figuring that they’re a lot more replicable than their similarly pricey counterparts in land-based meats. Its first prototype was medallions of yellowtail, produced in a bioreactor and also employing common food processing methods, including extrusion.

“Picture a virtual rib-eye and picture a virtual bluefin tuna or red snapper or mahi mahi,” says Lou Cooperhouse, CEO of BlueNalu. “Both command the same kind of price point, but rib-eye has marbling, changes color appreciably when you cook it, and has a very complex texture, flavor, and sensory experience. But fish fillet is homogenous and [has] repeated layers of the same structures, muscle, and fat and a much less sophisticated formation.”

There’s even alt-breast milk in the future. Biomilq is a startup in Durham, N. C., that is producing mammary cell–cultured breast milk to provide another option besides traditional formula to mothers who may have trouble with breastfeeding. Breast milk contains thousands of unique molecules blended in perfect proportions to nourish a human through crucial stages of early development, but the company just announced it has raised $3.5 million in funding to advance the idea of Biomilq cofounders Lisa Strickland, a mother of two and cell biologist, and Michelle Egger, an experienced food scientist and avid social entrepreneur, who is CEO.

“We as a company have no interest in replacing the benefits of skin-to-skin contact or the immunological benefits of suckling at the breast,” Egger says. But Biomilq is “produced via the exact cells in the human body that produce breast milk—making the process identical to what occurs in a woman’s body, outside of the body.” Cow’s milk “isn’t designed for human consumption,” she says, and infant formula “isn’t exactly natural, but parents have no better options today.

“We see ourselves as a step closer to breast milk and hope that having another option for parents that is nutritionally superior to infant formula will help increase infant nutrition, decrease trade-offs made by parents, and reduce planetary impacts of dairy production for infant formula.”

Indeed, those impacts are a reason that there’s an almost evangelical fervor to this new business that goes beyond the drive to create foodstuff affordability per se. Founders talk about being able to avoid some of the scourges of relying on real meat, ranging from antibiotics to pathogens such as E. coli. Yet the biggest component of their enthusiasm is this: Whatever the specifics, each startup argues that its method will consume only a fraction of the real estate, energy, water, and other inputs of traditional raising of animals for food—and generate only a fraction of the wastes such as the methane produced by cows.

Take the best known, Eat JUST. It’s the current name of Hampton Creek, a company that Silicon Valley denizen Josh Tetrick created in 2011 to develop plant-based liquid egg analogues. And while over the course of a few years his company managed to market a mayonnaise imitation and plant-based cookie dough, Tetrick wasn’t satisfied. So Tetrick rebranded the company and vowed to become the winner of a global race to bring cultured meat into the mainstream.

“He constantly questioned how much change he was creating” with plant-based products, says Chase Purdy, author of Billion Dollar Burger. “He wanted to branch beyond them, and the cell-cultured-meat proposition struck at the heart of what he always wanted to do, which was end industrial farming. JUST is his way of making a contribution to that movement.”

Similarly, Kolbeck and Wild Type cofounder and research chief Arye Elfenbein argue that cultured-cell salmon beats both wild salmon and aquacultured fish on environmental grounds.

“Overfishing means we’re quickly running out of fish,” Kolbeck says. “And usually the answer is that you don’t have to pull fish out of the sea because of aquaculture. But anecdotally I understand that two-thirds of feed for fish farms comes from wild-caught fish. You need to take boats from shore to the nets in fish farms many times. And as waters are warming globally, fish farms have to keep moving [in order to stay in temperate zones].”

3-D Printing Meat

This technology is revolutionizing everything from the production of auto parts to the repair of human organs, so why not 3-D print food?

One approach is to use such methods to extend the notion of plant-based meat analogues into more sophisticated forms than those that have been produced so far by extruding highly complex slurries, such as Beyond Meat’s burger. Redefine Meat uses 3-D printing to create imitations of cuts of beef rather than ground analogue meat.

“Protein from plants is just powder, and the cells are just a pudding of ‘fat’ or ‘muscle’ cells,” argues Eshchar Ben-Shitrit, CEO of Israel-based Redefine Meat. “How do you create a food product that comes close to meat that has texture and bite and flavors that are released, and imparts juiciness and mouthfeel? You need another technology step that converts [plant] ingredients into ‘meat,’ and our machine is the only thing that I know of that is close to how an animal builds muscle structure.”

Specifically, Redefine Meat has been working for more than two years to perfect 3-D printing of analogue cuts of meat with an architecture that has digitally mapped more than 70 different sensory factors, using vegan components of imitation muscle, fat, and blood. “It’s almost down to the same scale you’d find from a fiber perspective in the muscle of a cow,” Ben-Shitrit says. He foresees large-scale market trials of the company’s first commercial products in Europe by next year.

Gene Editing

Scientists’ precise manipulation of genetic material has gotten exponentially more sophisticated over the past several years, far exceeding anything possibly imagined by Gregor Mendel, the Moravian monk who founded the modern science of genetics in the 1860s.

Using its proprietary technology called TALEN, for example, Calyxt created a high-oleic soybean that has been on the market since 2019, and generated $8 million in sales in its first year. Oil from such beans helps meet the needs of many food industry customers as a trans-fat-free replacement for partially hydrogenated oil. By 2022, Calyxt has announced, it plans to introduce a high-oleic, low-linolenic soybean variety, using TALEN to add another nutritional benefit. (See sidebar CRISPR’s Lesser Known Cousin)

In recent years, a powerful new gene-editing technique known as CRISPR has allowed scientists to use the virus-fighting mechanisms in bacteria to cut strands of DNA out of genomes and swap in other strands, changing how genes are expressed, opening innumerable possibilities for altering natural organisms and for creating essentially new ones.

Rodolphe Barrangou and a team of researchers at food ingredient company Danisco used CRISPR, an acronym for “clusters of regularly interspaced short palindromic repeats,” of DNA in a pioneering initiative in 2007 to alter the immunity to viruses of a bacterium commonly found in yogurt cultures. And while the highest-profile applications of the technique these days are in areas of human biology such as mitigating sickle cell anemia, Barrangou says a flood of CRISPR developments in food are just now beginning.

“It started out with a food company and eventually it will make its way back into the supply chain,” says Barrangou, who now heads the CRISPR lab at North Carolina State University. Russia alone, he says, has announced a multibillion-dollar commitment to use CRISPR-based genome editing on 30 crops and livestock species for commercialization by 2030. And China is considered a world leader in agricultural applications of gene editing.

Gene-editing initiatives and even startup companies are proliferating in the United States and elsewhere as well. Tropic Biosciences has added a proprietary technique it calls GEiGS (for Gene Editing Induced Gene Silencing) to CRISPR, creating lines of coffee with reduced caffeine and increased solubility, and developing novel banana varieties that are resistant to Panama Disease, which experts believe is an existential threat to the banana industry. Next, Tropic is turning its attention to the genomes of rice in an effort to develop varieties that resist the impact of climate change on yields.

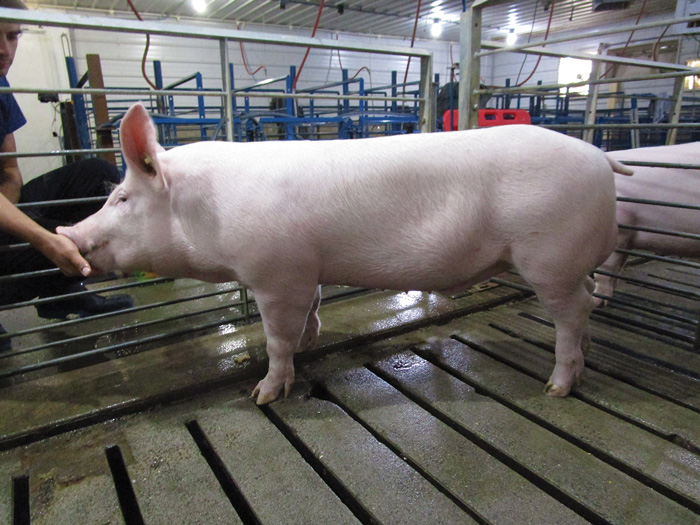

And Genus has harnessed CRISPR to help create resistance in pigs to Porcine Reproductive and Respiratory Syndrome Virus (PRRS), one of the great scourges of pig production around the world, which costs the U.S. pork industry alone nearly $700 million a year, according to an Iowa State University study conducted in 2011.

Elena Rice, chief scientific officer for Genus, notes that the company’s CRISPR process “silences” genes that make pigs susceptible to PRRS and doesn’t insert new genes. “We exact a portion of the specific protein that interacts with the virus, which allows it to enter [pigs’] cells,” she explains. “So the animal will never contract the virus and can’t shed it. It’s not ‘immunity’ per se; they’re just not susceptible.”

Optimizing Organisms

Beyond Nature’s Fynd are other initiatives to discover, experiment with, and more fully harness the capabilities of existing organisms. For example, water lentils—known as duckweed in the United States—aren’t just a component of pond scum. Often mistaken for algae, these very small, light-green, seed-bearing aquatic perennials include high amounts of essential amino acids as well as bioavailable vitamin B12 and lutein, which boosts eye health. And water lentils’ easy cultivation and quick growth allow for frequent harvests.

To what end? Companies including Parabel are fielding powdered supplements based on water lentils and developing food applications. “We have an amino acid score that’s almost impossible for anything else to beat except whey,” says Anthony Tiarks, Parabel’s CEO.

Meanwhile, Joyn Bio is one startup using what it calls “synthetic biology” to reduce needs for chemical fertilizers, pesticides, and fungicides by huge commercial crops such as corn. The company creates symbiotic associations between plants and microbes that can provide crops with nutrients and disease protection.

Joyn’s first project, for example, has been to colonize nitrogen-fixing microbes in corn fields to provide up to half of the plant’s nitrogen needs. Corn requires 70%–80% of its nitrogen in the second half of its life cycle when it is producing ears and uses lots of energy, explains Michael Miille, Joyn Bio’s CEO.

“But it’s hard to refertilize corn after it reaches four to five feet high,” he says. “If we have a microbiome solution that allows cutting fertilizer impact by up to half, that would have a huge impact on the environment. And the economics for growers become extremely favorable.”

“There are no microbes associated with the corn plant that do that” naturally, says Miille. “So rather than wait 200 or 300 years for it to evolve, we’re trying to do it much more quickly.”

He acknowledges that Joyn Bio’s notion of “engineering” of microbes raises suspicions that the company is doing something akin to creating “genetically modified organisms,” the technology perceived as frightening by many consumers even though most scientists are perfectly fine with the safety and efficacy of GMOs. But Miille carefully distinguishes between “speeding up” associations of microbes and crop plants that eventually might occur in nature and “taking a gene from a whole different organism and putting it into a plant” as GMOs do. At the same time, Miille’s acknowledgement of the importance of consumer acceptance of futuristic food technologies is one shared by many working in these fields and by others who observe them.

Conflicting Opinions

Mixed acceptance of GMOs is one thing that proves “humans are irrational biological organisms,” says David Horlock, managing director of the global food and retail supply chain at the British Standards Institute, a century-old organization that first developed manufacturing standards for industrial products such as railway gauges and, most recently, developed the world’s first standards for plant-based proteins.

“So some people will look at the price of cell-cultured meats and if it’s organic and digestible and cheap, they’re in. But other people will say they don’t want to mess with nature and with God. Some others are concerned about displacing proper agriculture and natural ecosystems. And there’s everyone in between.”

Mellentin, the consultant, also has chronicled the rise of better-for-you foods for a quarter-century as publisher and editor of the global magazine New Nutrition Business. He agrees with Willet that alt-meat advocates may be missing something very basic: Why would people want these products at all?

“They’ve failed to give people any good reason to eat it,” Mellentin says. “You’re selling me ‘meat,’ but I’ve already got meat. Or you’re selling me something made out of plants, and I’ve already got plants. I’ve got chickpeas or whatever. They’ve failed to focus on what consumers want to get out of it, and their failure to do so underscores that they have no understanding of humans and history and the determinants of their success.”

Indeed, some of the technologists’ fundamental arguments are open to skepticism. Take their insistence that the full embrace of their products will be nothing but a huge positive for the environment. This logic faces a significant counter similar to the pushback that has been experienced by advocates of all-electric cars, by critics who point out that coal-fired power plants for charging this new generation of vehicles take their own huge toll on the environment, as does the recycling of battery packs.

When it comes to cell-cultured meat, for instance, skeptics wonder things like: What will the environmental impact be of providing energy for potentially thousands of bioreactors, compared with the footprint of producing beef cattle essentially with the solar energy that grows feed? Second, “lab meat” won’t have any soil-health benefits. And, third, alt-meats want to replace an all-in-one animal that provides not only meat but also leather, fat, and many other by-products with “a series of items that have to be produced separately in their own bioreactors,” argues the blog Regenitarianism.

Willett also introduces a concern about the traditional agricultural system that alt-meats would replace. “Technology could play a role in making small-scale farming more efficient around the world,” he says. “But it would be a further step in industrializing a big part of the world’s economy that could have negative sociological implications.”

For hope, practitioners would rather dismiss the concerns expressed by Horlock, Mellentin, and Willett, consumer concerns about GMO-based foods, and other reasons to doubt the embrace of cell-cultured meats and gene-altered crops—and focus on the rapid success of the newest plant-based meats as a model.

“These new technologies may not be palatable to the public at first,” says Barrangou. “But mainly that’s because they don’t understand the rationale or the power or the value of the technology. Then you have an Impossible Burger come in, and people take a bite, and they can’t help but be impressed. That’s what it takes.”