Addressing Produce Loss Knowledge Gaps

FOOD SAFETY AND QUALITY

Wasted food is the largest single category of materials occupying our ever-expanding municipal landfills. It’s not surprising when you consider that approximately 31% of food was discarded at retail and consumer levels in 2010, according to estimates from the United States Department of Agriculture’s (USDA) Economic Research Service (FDA 2021).

The USDA, the Food and Drug Administration (FDA), and the Environmental Protection Agency (EPA) have all made food waste a priority through a 2018 joint agency formal agreement that primarily emphasizes education to reduce post-retail consumer food waste. But food loss, which occurs prior to food reaching the consumer, is another essential aspect that involves economic importance and agricultural sustainability. Very little attention has been paid to understanding loss at the farm level (Dunning et al. 2019). It’s a part of food dissipation that should garner more attention from government agencies, researchers, buyers, growers, and food processors.

Food Loss vs. Food Waste

Food loss is an “unintended result of agricultural processes or technical limitations in storage, infrastructure, packaging, and marketing” (Johnson et al. 2019). With fresh fruit and vegetable crops, food is lost in the field due to economic reasons or weather constraints. It’s lost elsewhere in the supply chain because of culling, slicing, dicing, and chopping during processing and reaching the expiration date while still on grocery shelves.

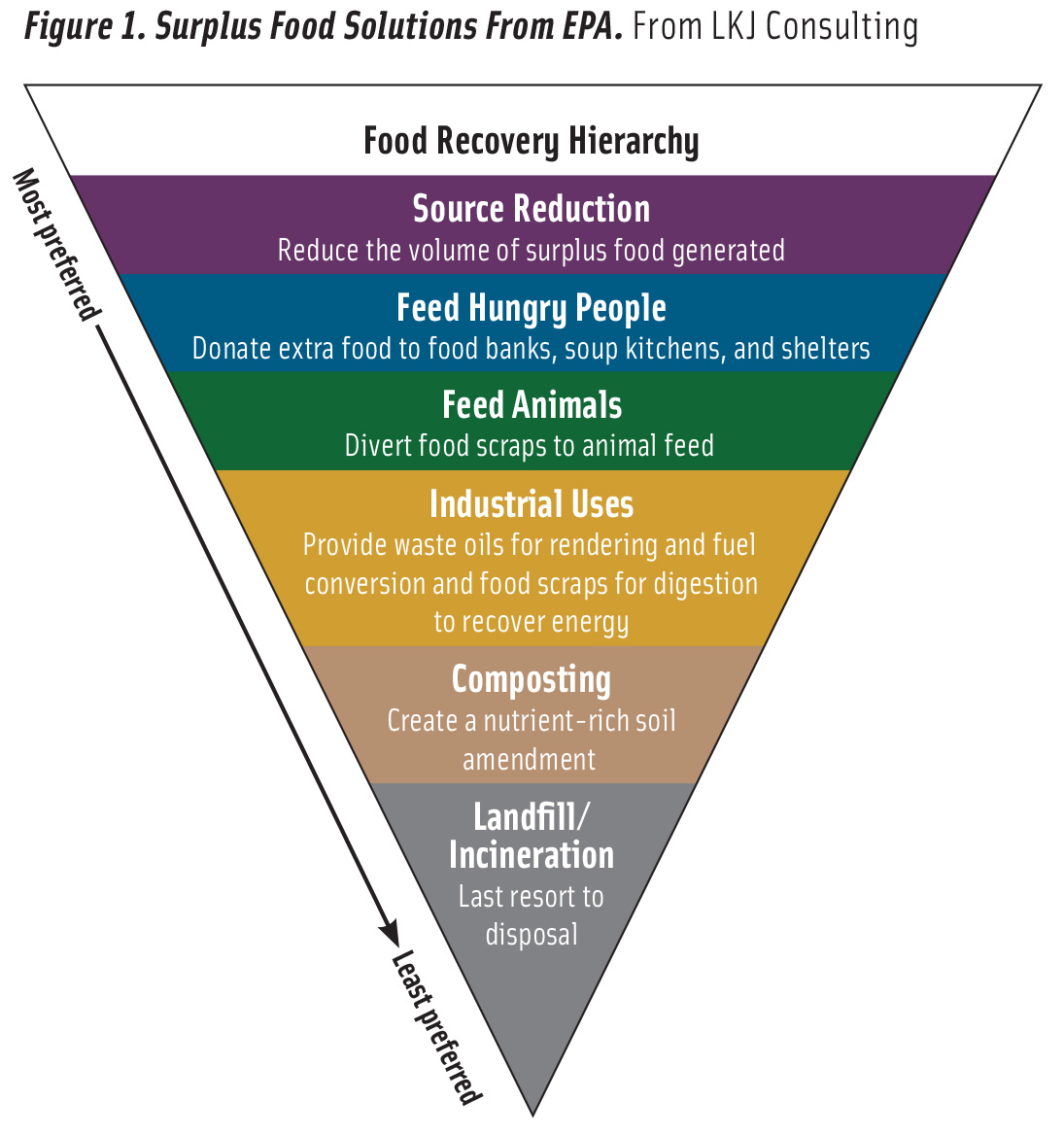

Because food loss has been relatively unstudied and unquantified, significant knowledge gaps persist at the farm level. Qualitative studies have determined that many significant factors driving food loss are beyond growers’ control, including stringent quality standards imposed by buyers and low prices that don’t cover harvest costs (Johnson et al. 2019). The EPA did create a food recovery hierarchy in 2015 to address food waste, but it can’t be directly applied to agricultural production (EPA 2016) because it was developed without input from growers and farmers (Figure 1).

Food Recovery

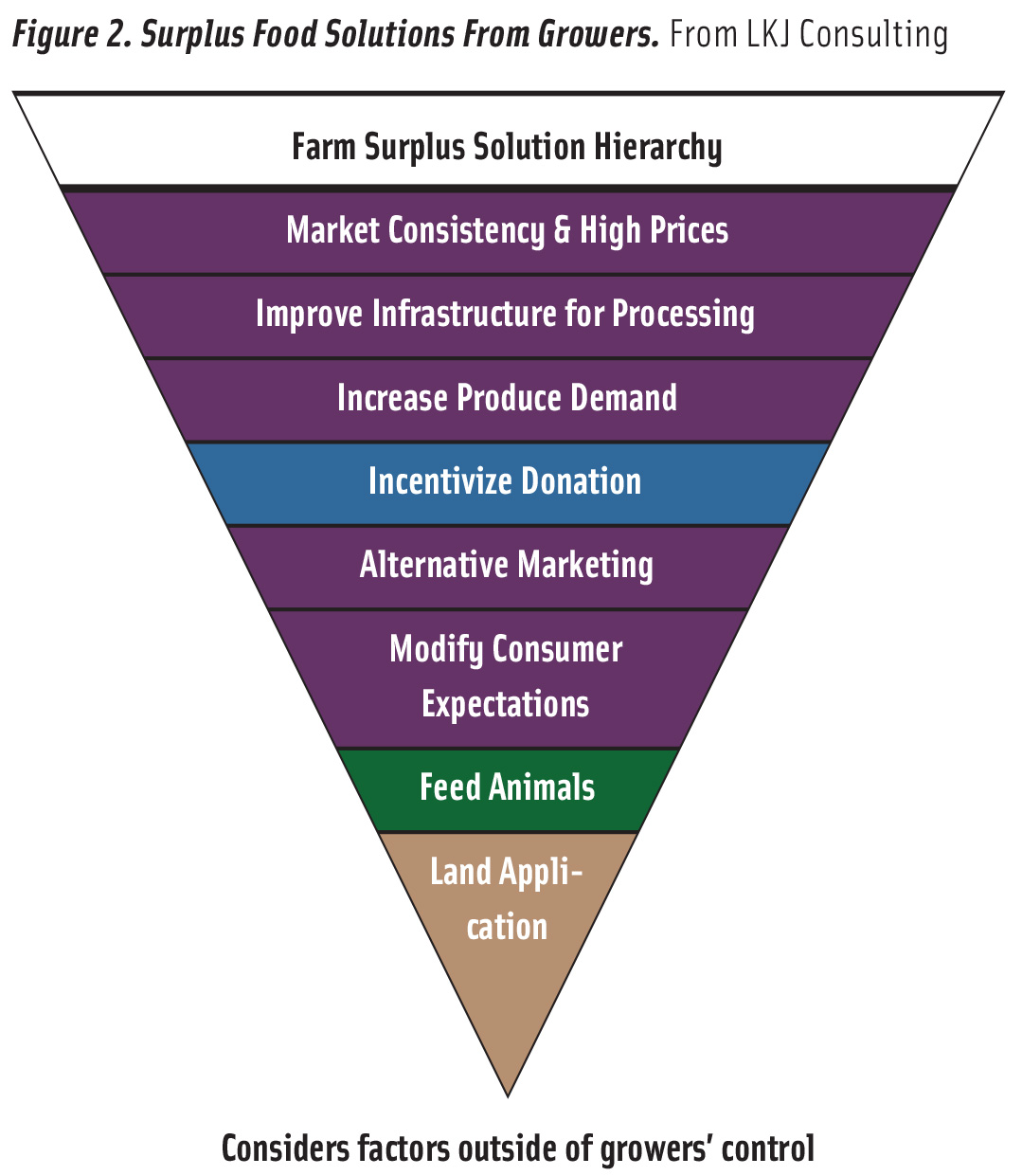

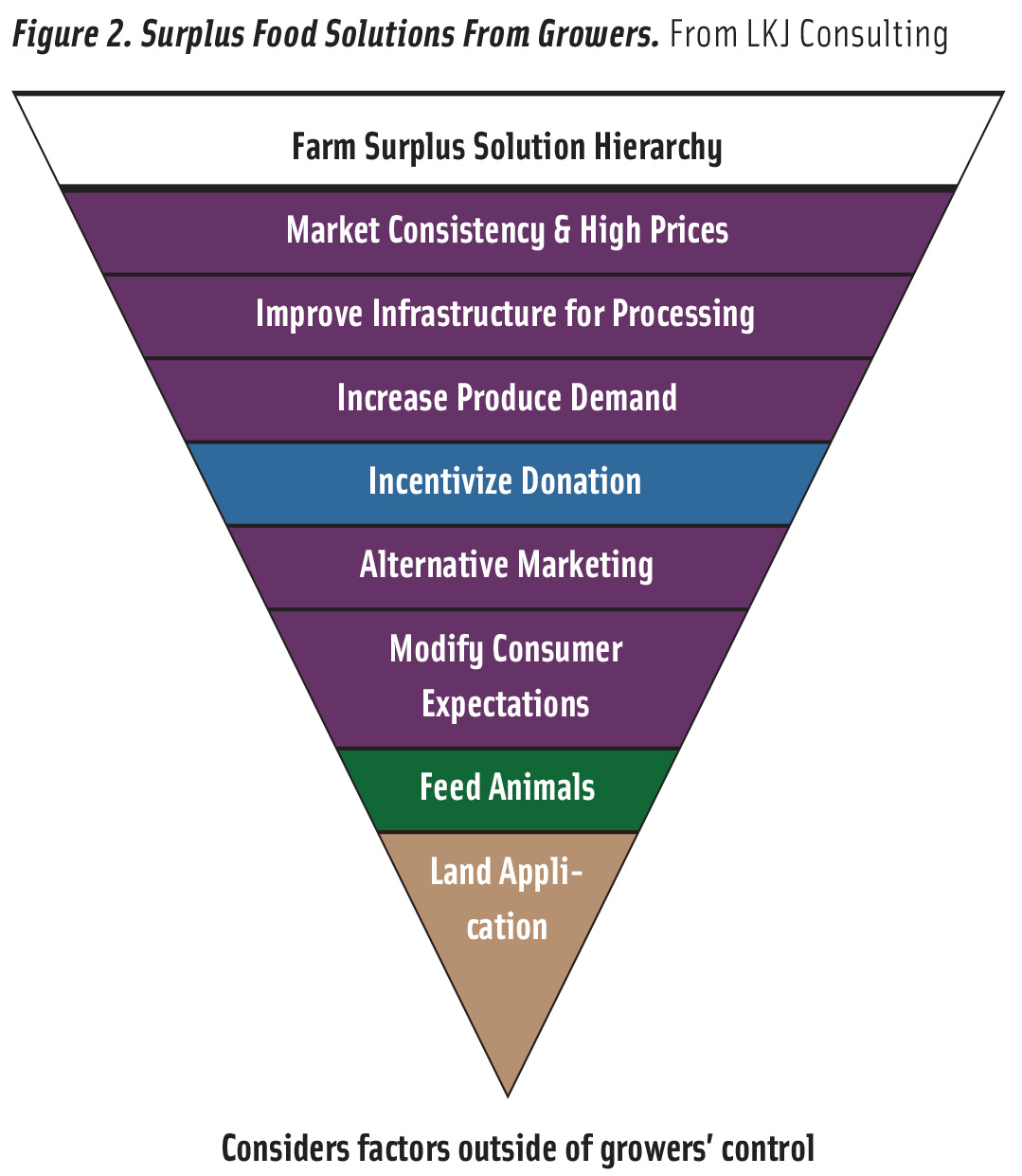

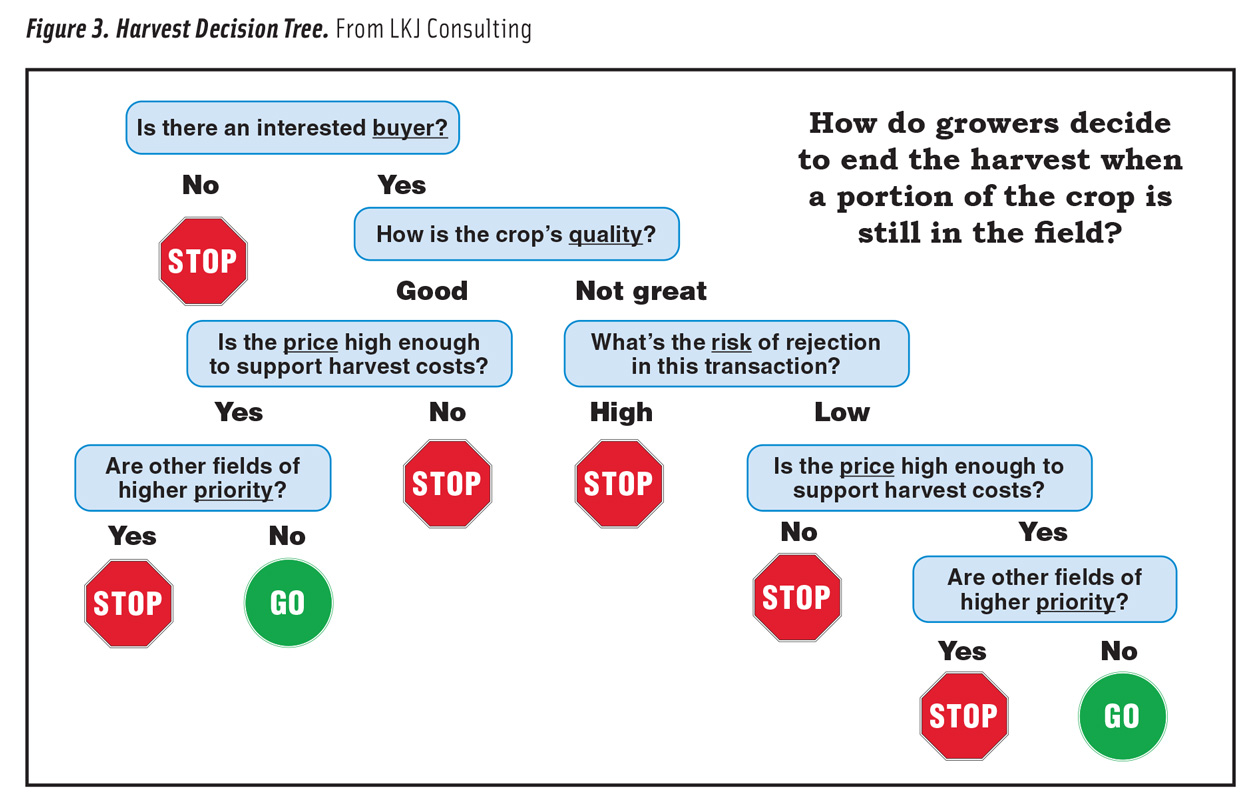

“I got interested in quantifying food loss during my graduate studies at the University of Georgia when I realized there was a huge knowledge gap,” says Lisa K. Johnson, an independent food and agriculture consultant for LKJ Consulting. Collaborating with other investigators at North Carolina State University, Johnson has created an alternative food recovery hierarchy (Figure 2) and a harvest decision tree (Figure 3) based on interviews with and inputs from commercial fruit and vegetable growers with medium to large North Carolina farms (Johnson et al. 2019).

Unlike the EPA model, which recommends source reduction and food donation to the needy, the grower-conceived pyramid’s highest priorities are facilitation of high prices and market consistency for produce (Figure 2). Source reduction, the goal at the top of the EPA hierarchy, is based on the unproven idea that farmers overplant to reach production or quality goals (Figure 1). But this is not always the case, Johnson found through grower interviews. Growers said they based their production on historical data from previous seasons and tried to avoid overplanting. Other recommendations from growers, in order of diminishing preference, included:

- improving infrastructure for processing

- increasing produce demand

- incentivizing and facilitating donation

- supporting alternative marketing strategies

- modifying consumer expectations

Some producers were concerned that flooding the market with “ugly” or lower-quality produce would negatively affect the market price of their higher-quality offerings. They considered food donations a viable option if more economic incentives, such as government tax credits, were provided to cover their pick and pack costs. Industrial uses, such as conversion to energy or bioactive compounds, were not suggested by the growers. And, as in the EPA pyramid, growers were open to feeding surplus produce to animals, along with carrying out land applications like composting.

More studies are needed to quantify actual food loss in the field, since growers often are too busy to emphasize estimation of this parameter (Johnson et al. 2018). In addition, flowcharts like the harvest decision tree will need to be updated when new sources of revenue are created by technology, alternative processing, or marketing opportunities.

Fermentation Strategies

For centuries, fermentation has safely reduced waste and prolonged food shelf life. Recent studies in the online open access journal Frontiers in Sustainable Food Systems examined the safe reuse of food byproducts and waste in a circular food economy, using microaerobic fermentations of mixed food waste and beer mash as biostimulants for citrus nursery stock (Pagliaccia et al. 2020). Digestates from the food waste and mash were applied to irrigation water, and within 48 hr, bacterial diversity was reduced in favor of growth of beneficial host-associated microbes such as Pseudomonas putida. The digestates increased the concentration of some plant nutrients without adding toxic elements.

Cereal byproducts such as the germ, bran, and spent grains from brewing end up as feed, fuel, or wastes (Verni et al. 2019). However, new fermentation technologies are increasing the nutritional and functional features of cereal byproducts, including synthesis of bioactive compounds acting as antitumoral, antimicrobial, and antioxidant agents (Verni et al. 2019). Other researchers in the field have provided a mini review on increasing the nutritional value of vegetable wastes using bacteria other than lactic acid bacteria, as well as fungi (Sabater et al. 2020). Bacteria including Bacillus subtilis, Rhizopus oligosporus, and Fusarium flocciferum are used to produce protein extracts with high biological value. Aspergillus, Yarrowia, and Trichoderma species can produce a wide variety of functional carbohydrates and glycosidases.

Prospecting novel microbial strains is necessary to economically harvest bioactive ingredients from food waste (Patel and Shukla 2017). Finding higher value for food wastes and byproducts can drive a circular food economy where low-value alternatives such as animal feed may fail. Traditional fermentations should be reconsidered and products expanded, such as Ham Farms’ Covington vodka, produced from fermented sweet potatoes.

Composting Food Material

“If it lives, it can be composted,” says Noel Lyons, president of McGill Environmental Systems. McGill employs 100 people worldwide and annually turns approximately 500,000 tons of organic waste—a good portion of which is food waste—into 400,000 cu yd of compost through aerobic digestion. Aerobic digestion differs from anaerobic processes like fermentation and anaerobic digestion because appreciable amounts of alcohol or methane are not produced.

McGill employs a modified aerated static pile process for composting. While no microbial starter cultures are used, reseeding with previously composted materials is a key step in the process. Rather than turning the materials to oxygenate, the company forces ambient air through the 1,000-cu-yd batches in a highly controlled manner via a temperature feedback loop. This optimizes bacterial and fungal growth, which rapidly decomposes the raw materials.

Controlled composting is a forgiving process that can manage a variety of wastes simultaneously. The EPA requires a time-temperature treatment of 131°C continuously for 72 consecutive hr to ensure the safety of aerobically composted materials. With a target moisture range of 55%–60%, this process can compost plant materials as well as meat and dairy.

After the biodegradation is complete, the compost must meet certain specifications regulated by the EPA. The compost is analyzed for micro- and macronutrients, biological stability, pH, moisture, heavy metals, and percentage organic matter. Salmonella or fecal coliforms are measured to ensure microbial safety.

The final product’s particulate size is important and dictates use. For example, compost functions as an amendment to turf such as golf courses and soccer fields and as an enhancement of agricultural soils. Due to sustainability demands in the present market, many companies are eager to pursue green initiatives. “If composting is equal to or close in price to other options, most companies will lean to green,” says Lyons. “The combination of landfill diversion and the carbon sequestration value of compost makes a great case for green-minded generators.”

Fresh Opportunities

The high cost of hand harvest and the relatively low economic value of produce left in the field create a huge barrier to distribution and use. Expensive transportation costs, lack of available processing facilities, and food safety concerns make distribution and marketing this produce too costly for growers.

But there are opportunities for entrepreneurs willing to explore the unique challenges of each produce type. Beyond the fresh market, further processing could provide secondary uses such as juice, dried produce, and shelf-stable ingredients. Fermentation and aerobic digestion products offer possibilities for upcycling and may provide price incentives for harvesting and distribution or opportunities for green initiatives. Lower-quality produce can be acidified or fermented for value-added products with longer shelf lives or bioactive compounds. Retailers could be encouraged to buy entire fields, a motivation for them to market the entire crop and make sustainability claims to consumers and investors (Baker et al. 2019).

There is no simple, one-size-fits-all solution to produce loss in the field (Baker et al. 2019). But through processing, recycling, marketing, and logistics solutions, researchers and innovators may be able to develop new niches to exploit produce loss and to sustain agricultural practices that benefit growers, create new markets, and feed hungry people.

REFERENCES

Allen, A. J. 2021. “Environmental buzz words: Sustainability vs. greenwashing.” Food Safety News, March 30. https://www.foodsafetynews.com/2021/03/environmental-buzz-

words-sustainability-vs-reenwashing/?utm_source=Food+Safety+News&utm_campaign=ae39b59452-RSS_EMAIL_CAMPAIGN&utm_medium=email&utm_term=0_f46cc10150-ae39b59452-40169867.

Baker, G. A., L. C. Gray, M. J. Harwood, et al. 2020. “On-farm food loss in northern and central California: Results of field survey measurements.” Resour., Conserv. Recycl. 149: 541–549. doi: https://doi.org/10.1016/j.resconrec.2019.03.022.

Dunning, R. D., L. K. Johnson, and K. A. Boys. 2019. “Putting Dollars to Waste: Estimating the Value of On-Farm Food Loss.” Choices, Quarter 1. http://www.choicesmagazine.org/choices-magazine/theme-articles/food-waste-reduction-strategies/putting-dollars-to-waste-estimating-the-value-of-on-farm-food-loss.

EPA. 2016. “America’s Food Waste Problem.” April 22. https://www.epa.gov/sciencematters/americas-food-waste-problem.

FDA. 2021. “Food Loss and Waste.” https://www.fda.gov/food/consumers/food-loss-and-waste.

Johnson, L. K., R. D. Dunning, C. C. Gunter, et al. 2018. “Field measurement in vegetable crops indicates need for reevaluation of on-farm food loss estimates in North America.” Agric. Syst. 167: 136–142. doi: https://doi.org/10.1016/j.agsy.2018.09.008.

Johnson, L. K., J. D. Bloom, R. D. Dunning, et al. 2019. “Farmer harvest decisions and vegetable loss in primary production.” Agric. Syst. 176: 1-11. doi: https://doi.org/10.1016/

j.agsy.2019.102672.

Pagliaccia, D., S. Bodaghi, X. Chen, et al. 2020. “Two Food Waste By-Products Selectively Stimulate Beneficial Resident Citrus Host-Associated Microbes in a Zero-Runoff Indoor Plant Production System.” Front. Sustain. Food Syst. 4: 593568. doi: https://doi.org/10.3389/fsufs.2020.593568.

Patel, S. and S. Shukla. 2017. Fermented Foods in Health and Disease Prevention. Cambridge, Mass.: Academic Press.

Sabater, C., L. Ruiz, S. Delgado, et al. 2020. “Valorization of Vegetable Food Waste and By-Products Through Fermentation Processes.” Front. Microbiol. 11: 581997. doi: https://doi.org/10.3389/fmicb.2020.581997.

Verni, M., C. G. Rizzello, and R. Coda. 2019. “Fermentation Biotechnology Applied to Cereal Industry By-Products: Nutritional and Functional Insights.” Front. Nutr. 6: 42. doi: 10.3389/fnut.2019.00042.