Nonbrowning apples move closer to market; Microwaves ‘gently’ pasteurize milk

CUTTING EDGE TECHNOLOGY

Nonbrowning apples move closer to market

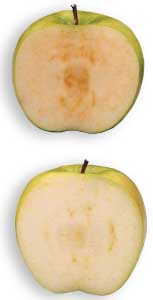

Nonbrowning apples move closer to marketTwo varieties of biotechnology-derived nonbrowning apples appear to be closer to commercialization and may be deregulated in the United States in early 2014. The U.S. Dept. of Agriculture’s Animal and Plant Health Inspection Service (USDA APHIS) has opened the second, and final, public comment period for Okanagan Specialty Fruits’ biotech-enhanced nonbrowning Arctic apples. APHIS has posted their Environmental Assessment and Plant Pest Risk Assessment for Arctic Golden and Granny apples, and is requesting public comments until the December 9, 2013 deadline.

The Canadian fruit company uses apple gene sequences to silence the genes that produce polyphenol oxidase (PPO), which contributes to browning when the apple cells are fractured, such as during cutting. Field tests over 10 years show that the Arctic apples’ fruit is compositionally and nutritionally similar to conventional apples. In addition to its aesthetics for consumers when cut or bitten, the new apple varieties offer advantages to fruit producers/packers and processors as well as retailers. Arctic apples won’t show minor bruising as easily as conventional fruit, resulting in less culling and higher pack-outs. Retailers may see less shrinkage. For processors of juice and sauce, the apples retain their natural color without the use of antioxidants.

Microwaves ‘gently’ pasteurize milk

Researchers at the University of Hohenheim and Fraunhofer Institute IGB in Germany, along with several European small-to-medium entrepreneurs, have joined forces to develop a novel method for pasteurization of milk with microwaves. The “gentle” treatment helps to preserve the nutritional components of milk and is suitable for heating viscous and concentrated dairy products due to minimal fouling of equipment surfaces. Thus, cleaning operations and its associated use of water and cleaning/sanitizing agents may be reduced.

Called MicroMilk, the EU project is funded within the scope of the 7th Framework Research Program of the EU (Grant Agreement No. 606321). It has produced a prototype system for continuous microwave pasteurization with a throughput of 400 liters/hr of milk, which has been integrated into an existing pasteurization process at a dairy station at the University of Hohenheim.

Experiments on the system have revealed several benefits. Reduction of fouling has enabled extended operating times between system cleanings, thus saving water and detergents. The system’s ability to heat milk with a pasteurization step from 68°C to 72°C not only results in a more homogeneous temperature gradient, but is also three times faster than with a plate heat exchanger. Due to this extremely rapid heating, the milk is exposed to high temperatures only for a very short time.

“Much of the valuable and heat-sensitive substances, especially milk proteins and vitamin B, remains undenaturated,” declared Ana Lucia Vásquez, who coordinates the project at the Fraunhofer Institute IGB. “A very promising characteristic of microwave pasteurization is that we can also handle viscous products with a high content of solids, such as whey concentrates. Existing pasteurization plants are susceptible to fouling and have to be cleaned frequently.”

The core of the microwave method and a result of extensive simulation is a compact reactor, which is divided into different compartments. Each compartment is equipped with its own magnetron generating electromagnetic waves. The microwaves are coupled into a waveguide, which simultaneously acts as the heating chamber. Through this chamber, the milk flows in a special pipe. The pipe material does not absorb the microwaves, but is resistant against heat and pressure.

“During this passage, the milk is heated directly, and, unlike the plate heat exchanger, it is not heated from the outside to the inside, but volumetrically—when the electromagnetic waves are absorbed by the polar molecules of the milk, this makes the molecules oscillate over the entire volume and thus homogenously generating heat,” explained Vásquez.

If you are working on or know of some cutting edge technology that you would like to be featured in this column, please send an email to [email protected].