Taking a Systems Approach to Clean Label Challenges

A systems approach to clean label can overcome limitations of singular approaches and promote consumer and retailer acceptance via proactive, effective science communication of new ingredient, process, and packaging technologies.

Article Content

Consumers and retailers are increasingly demanding cleaner label products, a trend that is unlikely to go away in the near future. A significant technical challenge to addressing this need is that additive removal often results in shortened shelf life with both economic and environmental implications. While promising, natural alternatives don’t measure up on their own, as such a singular approach in which label-unfriendly additives are replaced with natural alternatives has so far largely had limited success.

A systems approach in which next-generation technologies in packaging and processing work in concert with discovery and validation of clean label ingredients is needed to address these challenges. Systems-wide approaches to reduce and control spoilage organisms and other challenges are also needed. Such integrative approaches are not trivial in an increasingly transdisciplinary food system. Indeed, the complexity of clean label solutions necessitates collaboration among engineers, food scientists, microbiologists, and market researchers, yet such a systems approach is necessary to bridge the gaps between respective disciplines.

Importantly, the systems approaches needed to address these challenges will have to include a renewed farm-to-table emphasis, even for issues where a focused approach was previously effective in a non-clean label world. For example, control of microbial spoilage may have traditionally focused on using antimicrobial compounds in product formulations but may now require a combination of improved systems (e.g., less effective, but clean label, antimicrobial compounds in concert with novel processing technologies) to control product spoilage. Leveraging multifaceted stakeholder input (including consumers who initiate demands for clean label products, retailers who put the pressure on producers with long-range product goals, and producers/suppliers/equipment manufacturers who are left managing a significant technical challenge) will ensure technology development is optimally oriented toward the most impactful outcomes in addressing clean label challenges and ultimately improving the transparency of our food supply.

Product and Ingredient

A primary target in clean label reformulation is replacement of many common synthetic ingredients serving as colorants, flavors, emulsifiers, viscoelastic modifiers, and preservatives with naturally derived substitutes. Such natural ingredients are often perceived by consumers to be of better quality, healthier, and safer (Carocho, Morales, and Ferreira 2015). Consumers expect such natural replacements to have similar or superior sensory and functional (e.g., health-benefiting, antioxidant) attributes compared to traditional ingredients (Kraus 2015). Beyond the goal of limiting the use of synthetic ingredients, the clean label movement also restricts the extent to which ingredients have been modified and demands greater information for the consumer regarding origin of food components and products.

Indeed, substitution of synthetic ingredients is neither straightforward nor trivial and presents a continuous challenge to the food and beverage industry. Naturally derived ingredients often lack the process and storage stability of synthetic counterparts. Further, while synthetic compounds are often well-defined molecules with low batch-to-batch variability, natural ingredients are typically derived from crude sources (e.g., fruit extracts) with complex compositions, adding cost if standardization is desired (Dabas et al. 2011). An excellent example is replacement of synthetic pigments with plant- and algal-derived natural pigments. Efforts are continuously underway to effectively utilize anthocyanins (red to purple), betalains (magenta to red), carotenoids (yellow to red), chlorophyll (green), and even spirulina-sourced phycocyanins (blue) as colorants in foods. Similar to other natural compounds, these pigments are susceptible to degradation under the temperature, pH, light exposure, and oxidative conditions common in processing and storage (Weber and Larsen 2017).

Stabilizing pigments and other labile natural ingredients against degradation by pH, temperature, and oxidative degradation represents a major area of active research and an exciting opportunity for ingredient and product companies. Encapsulation or complexation with protein or polysaccharide-based hydrocolloids and complexation with small molecules that interact with and protect the labile compound represent promising potential stabilization systems (Selig et al. 2017, Chung et al. 2017, Comunian 2017). Enzymatic modification, molecular conjugation, and thermal or pressure treatments are other techniques by which naturally available polysaccharides, proteins, peptides, lipids, fatty acids, flavonoids, and organic acids can be modified to improve their stability while retaining functionality and physical/sensory attributes of the final product. Consideration and awareness of regulatory implications and consumer acceptance of such natural ingredient stabilization technologies will be core to their ultimate adoption.

Processing

In addition to improved and novel ingredients, advances in food processing technologies can make contributions to facilitating clean labels. For example, processing technologies that reduce the likelihood of microbial contamination can reduce or eliminate the need for label-unfriendly antimicrobial compounds. Nevertheless, advances in food processing technologies, despite their potential in addressing clean label demands, are not always well received. The food manufacturing sector continues to face tremendous pressure from consumers to create foods that are minimally processed yet have high nutritional value, flavor, and texture (Pasha et al. 2014, The Hartman Group 2016). Meeting these demands in parallel with simplifying ingredient statements in packaged foods is challenging, yet opportunities exist in integrating emerging food processing technologies with recent significant improvements of traditional technologies. For example, newer cooling and freezing systems reduce the time it takes to decrease food temperature to retain quality, enabling removal of some stabilizers that seek to control moisture migration in products. Also, new sterilization equipment (e.g., agitating retorts) and modern aseptic processing and packaging lines have significantly improved the quality of shelf-stable foods by reducing the amount of heat applied, permitting use of thermally labile natural ingredients.

An exciting area of development in food processing technology is in the evolution of nonthermal technologies such as high pressure processing, pulsed electric field, high pressure homogenization, membrane filtration, or ultraviolet irradiation. Most nonthermal technologies allow foods to better retain their freshness, color, flavor, and nutrients under extended refrigerated storage. The main commercial adoption of these technologies has been for microbial inactivation for food safety and shelf-life extension of refrigerated foods to meet regulatory requirements as well as consumer demand for fresher foods. Interestingly, research is now demonstrating that many nonthermal methods have potential beyond microbial inactivation, as they can achieve new functionality and product characteristics (Cadesky et al. 2017). Combining and integrating multiple technologies into new processing strategies may enable new opportunities in production of foods that cannot be made by traditional methods, decreasing waste by process optimization and improving value-added reutilization of agricultural and food processing by-products. As the availability of novel technologies rises and costs become competitive, the emergence of toll food manufacturing facilities paves the way to commercial adoption of technologies that were out of reach a few years ago.

Packaging

Packaging material selection plays an interesting role in the positioning of cleaner label products. There are logistical considerations; for example, with every reformulation comes a new ingredient statement, which is a practical challenge in terms of changing graphics and material backlog. Further, changing processing, storage, and distribution conditions requires a reexamination of packaging materials to ensure integrity of their thermal and mechanical properties (e.g., glass transition temperature, seal strength) under the new conditions. Consumers are increasingly aware (and uncomfortable with) additives used not just in the food product, but in the package that contains it. Major producers are advertising BPA-free packaging materials and publicly stating their commitments to improving transparency of what is (or isn’t) in their packaging materials (Campbell Soup Company 2016). Front-of-package label claims such as all-natural or non-GMO may promote perception of clean label products, yet producers should be cautious of using as-yet unregulated label claims.

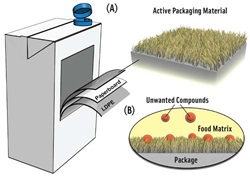

New packaging technologies are being developed that may enable enhanced stability of natural alternatives or removal of some synthetic additives. Improving barrier properties by metallization, inorganic oxide coating, or integration of nanomaterials can help retain quality of products that are sensitive to light, moisture, or oxygen ingress (Lange and Wyser 2003). Another opportunity in clean label packaging lies in active packaging, in which the package performs a function (e.g., antimicrobial or antioxidant) beyond simple containment and protection. While both migratory and non-migratory (immobilized) active packaging technologies are being actively explored, in migratory technologies the active agent ultimately enters the food product or headspace, positioning non-migratory technologies (regulated as indirect additives via the food contact notification program in the same manner as any traditional new packaging material (Koontz 2016)) to be better suited to address clean label demands (Bastarrachea et al. 2015). Certain antimicrobial compounds can retain antimicrobial character after immobilization onto packaging materials and have been shown to delay or prevent growth of pathogenic and spoilage microorganisms (Shin et al. 2016, Saini et al. 2016, Muriel-Galet et al. 2013). Recent work has demonstrated that chelating ligands can be introduced to polymer packaging films and retain ability to bind transition metal ions (e.g., iron and copper) selectively over other cations present in foods (e.g., calcium, magnesium) even under conditions of low pH value and moderate viscosity (Lin et al. 2016; Ogiwara et al. 2016; Tian et al. 2015; Roman, Decker, and Goddard 2015). The clean label movement has shifted the balance between cost and benefit of ultrahigh barrier and active packaging technologies, which have been considered cost prohibitive to date. Further, ongoing research addressing technological and behavioral hurdles to adopting new packaging technologies is helping to lower the barrier to their commercialization (Werner, Koontz, and Goddard 2017).

New packaging technologies are being developed that may enable enhanced stability of natural alternatives or removal of some synthetic additives. Improving barrier properties by metallization, inorganic oxide coating, or integration of nanomaterials can help retain quality of products that are sensitive to light, moisture, or oxygen ingress (Lange and Wyser 2003). Another opportunity in clean label packaging lies in active packaging, in which the package performs a function (e.g., antimicrobial or antioxidant) beyond simple containment and protection. While both migratory and non-migratory (immobilized) active packaging technologies are being actively explored, in migratory technologies the active agent ultimately enters the food product or headspace, positioning non-migratory technologies (regulated as indirect additives via the food contact notification program in the same manner as any traditional new packaging material (Koontz 2016)) to be better suited to address clean label demands (Bastarrachea et al. 2015). Certain antimicrobial compounds can retain antimicrobial character after immobilization onto packaging materials and have been shown to delay or prevent growth of pathogenic and spoilage microorganisms (Shin et al. 2016, Saini et al. 2016, Muriel-Galet et al. 2013). Recent work has demonstrated that chelating ligands can be introduced to polymer packaging films and retain ability to bind transition metal ions (e.g., iron and copper) selectively over other cations present in foods (e.g., calcium, magnesium) even under conditions of low pH value and moderate viscosity (Lin et al. 2016; Ogiwara et al. 2016; Tian et al. 2015; Roman, Decker, and Goddard 2015). The clean label movement has shifted the balance between cost and benefit of ultrahigh barrier and active packaging technologies, which have been considered cost prohibitive to date. Further, ongoing research addressing technological and behavioral hurdles to adopting new packaging technologies is helping to lower the barrier to their commercialization (Werner, Koontz, and Goddard 2017).

Technology Adoption in an Era of Food Technology Distrust

Innovative technologies in food manufacturing have great potential to address challenges in our food systems, including clean label, yet discussion of many new food technology advances often elicits a “not in my food!” knee-jerk reaction from the consuming public (Cardello 2003; Cox, Evans, and Lease 2007; Vidigal et al. 2015). While many of the mentioned technologies have paved the way for new developments in clean label products, numerous recent failures in technology acceptance have demonstrated that once consumer attitudes about risk have been established, they are difficult to change by follow-up information interventions (Fischer and Frewer 2009). This general distrust of food technology has helped spur the trend toward more transparent, cleaner labels; therefore, any technology-driven solutions will have to overcome the trust barrier. Indeed, it has been shown that when consumers are introduced to a technology together with an understanding of the problem it addresses, stigma around new technologies can be mitigated (Yee et al. 2008). Gaining public trust of emerging food technologies therefore begins with proactive, effective science communication by the researcher. Higher education must therefore take the lead in educating next-generation food scientists to be experts not only in their respective fields but also to effectively communicate to a modern public audience, not just other experts in their field (Kuehne and Olden 2015, Dudo 2015, Mercer-Mapstone and Kuchel 2015).

Systems Approach

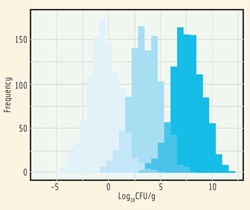

While initial attempts to address clean label challenges leverage a singular approach, such as replacement of a non-clean label additive with one that may qualify, as judged by consumers, as clean label, these approaches often fail. In many cases, the inherent complexity of our food system demands a more comprehensive, systems approach (Hammond and Dube 2012) to effectively develop clean label alternatives that meet performance standards with regard to sensory, flavor, and shelf life. For example, natural colors may not perform as well as synthetic colors, but their reduced stability and performance may be improved by alternative packaging or processing technologies. Similarly, removal of preservatives and antimicrobial compounds typically renders foods more susceptible to microbial spoilage and sometimes even microbial food safety issues. However, controlling microbial food safety and quality issues by a combination approach that uses alternative clean ingredients (e.g., protective cultures), identification and control of environmental growth niches, and application of novel processing technologies (alone or in conjunction with traditional processing technologies) may replicate the level of control achieved by traditional antimicrobial compounds.

Development of effective and economically feasible systems approaches that enable replacement of “non-clean label” additives is typically challenging, particularly since it involves replacing a single, often inexpensive, ingredient, with a set of interventions or control strategies that can be costly. Further, interventions and control strategies may act synergistically (which represents an opportunity) or antagonistically (which represents a challenge). Improved approaches are thus needed to develop and assess different combination approaches that may often involve a combination of interventions that are implemented across the food system, from primary production (farm) to consumer and anywhere in-between.

In order to develop and implement effective systems approaches that address clean label demands, there is a need to move beyond traditional empirical approaches (often described as “cook and look”). Rather, we must leverage science-driven approaches that identify synergistic combinations of treatments and approaches and use mathematical and simulation models to predict the effect of systems approaches to overcoming technical challenges associated with clean label demands. By leveraging systems models to rationally assess combinations of interventions and treatments, optimal strategies can be implemented that meet production needs, economic considerations, and consumer demands. Such transdisciplinary approaches, in which data scientists, behavioral economists, microbiologists, chemists, and engineers work in concert, are critical to overcoming industry-wide hurdles while improving the transparency of our food system to promote public trust, a key driving force of the clean label movement.

The authors gratefully acknowledge PhD candidates Zhuangsheng Lin and Ariel Buehler for Figures 1 and 2. This work was supported in part by the U.S. Dept. of Agriculture National Institute of Food and Agriculture under grant numbers 2016-67017-24635, 2015-67017-26146, and 2014-67021-25613.