Use of Starch–Lipid Composites in Low-Fat Ground Beef Products

Novel composites improve flavor and juiciness of low-fat ground beef products

A family of starch–lipid composites, prepared by passing aqueous mixtures of starch and lipid through an excess-steam jet cooker (Fig. 1), offer flavor and texture advantages when combined with food products, particularly ground beef. The jet-cooked dispersions are stable and do not phase-separate even after prolonged standing. They can be drum dried and milled to yield dry powders that are not oily to the touch. The lipid component is dispersed within the starch or starch–water matrix as droplets, about 1–10 microns in diameter.

The products, trademarked Fantesk™, are a new type of starch–lipid composite prepared by a continuous steam jet cooking process. The development of these products resulted from experiments designed to replicate the lipid-based membranes of biological systems using carbohydrates in place of the usual proteins.

After initial attempts to chemically attach lipid materials to starch proved unsatisfactory, the idea arose of physically incorporating lipids into the starch matrix prior to bonding. Past experience taught that jet cooking (Klem and Brogly, 1981; Stover, 1990) would completely solubilize starch, and we correctly assumed that co-cooking starch and lipid would provide an intimate, aqueous mixture of the two components.

The resulting dispersion produced by this method was a creamy, slippery material which did not separate upon standing (Fanta and Eskins, 1995) and was also freeze–thaw stable. Viscosities of these cooked dispersions varied with solids content and, at room temperature, ranged from free-flowing liquids with about 5% solids to soft gels with about 20% solids. Increases or decreases in temperature caused corresponding changes in fluidity and gelling properties, and gels could be easily liquified by heating in a microwave oven. Heating and cooling caused no separation of the oil and water phases.

Dispersions obtained by jet cooking could be drum dried to yield solid starch–oil composites that were not oily to the touch. These solid products could be milled to a fine consistency and when mixed with water yielded dispersions that were similar to the original freshly cooked materials. Extraction of drum-dried products with hexane removed only a portion of the oil, and a significant amount remained tightly bound within the starch matrix (Knutson et al., 1996). Electron microscopy showed that the oil was encapsulated as droplets, about 1–10 microns in diameter, within the starch–water matrix (Eskins et al., 1996). Oil droplets are stabilized by thin films of starch at the oil–water interface (Fanta et al., 1999). Previous work showed that starch is not only solubilized but also reduced in molecular weight by the high temperature and high turbulence of the excess steam jet cooking process (Dintzis and Fanta, 1996).

A variety of starches and lipids have been used to produce these composites, and weight ratios of starch to lipid have ranged from 100:5 to 100:75. Starch sources include corn (with varying ratios of amylose to amylopectin), wheat, rice, and potato. Lipids and lipid-like materials used in these formulations include vegetable oils and fats, animal oils and fats, and various petroleum-based products.

The unusual nature of these composites led us to seek patent protection and to also explore the many practical and commercial applications of this technology. The smoothness and lubricity of these composites immediately suggested their use as thickeners, stabilizers, and fat substitutes in food products. Also, the presence of the oil component in these composites allowed additional lipophilic materials, such as essential oils, volatile food flavoring materials, and antioxidants, to be incorporated within the starch–water matrix without phase separation.

Preliminary experiments with a variety of food products showed that the starch–lipid combinations containing only minor amounts of oil or lipid had the ability to simulate the flavor delivery and mouthfeel of full-fat foods. These observations suggested the use of these combinations in low-fat meats. Preliminary trials with ground beef patties confirmed our initial expectations, and we therefore conducted a detailed set of experiments using a trained taste panel and appropriate controls.

--- PAGE BREAK ---

Composites Prepared

Starch–lipid composites were prepared for use in ground beef patties, using “normal” cornstarch (Pure Food Powdered Cornstarch) from A.E. Staley Mfg. Co., Decatur, Ill.; waxy cornstarch (Waxy No. 1) from Staley; high amylose cornstarch (Amylomaize VII) from Cerestar N.A., Hammond, Ind.; soy protein (Arcon S) from Archer Daniels Midland Co., Decatur, Ill.; wheat gluten from Sigma Chemical Co., St. Louis, Mo.; soybean oil (Wesson Vegetable Oil) from Hunt-Wesson, Inc., Fullerton, Calif.; and beef tallow (Edible Beef Tallow) from H.R.R. Enterprises, Inc., Chicago, Ill. Moisture contents of starches and proteins were determined by vacuum drying at 100ºC, and all weights are given on a dry-weight basis.

Mixtures were formulated from 800 g of starch, 200 g of protein, 320 g of lipid, and 3 L of water. These mixtures were stirred at high speed in a Waring blender, and the resulting dispersions were then passed through a Penick and Ford Laboratory Model continuous steam jet cooker. Steam pressure and temperature within the cooking chamber (i.e., hydroheater) were held constant at 40 psig and 140ºC, respectively. Mixtures were pumped through the cooker at about 1.4 L/min. Hot jet-cooked dispersions were collected in Dewar flasks and dried on a 24-in × 8-in-diameter double-drum dryer heated with 65-psig steam. Dried products were coarsely ground using a Retsch centrifugal grinder.

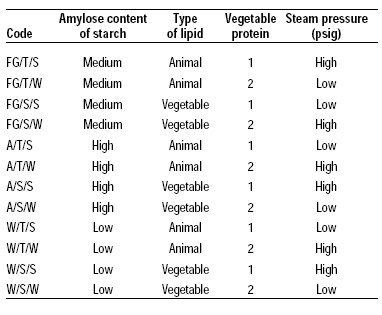

There are a number of variables in the process used to prepare these combination products, four of which appeared to be of major importance. Twelve different composites (Table 1 on page 39) were prepared, according to a statistical design, to investigate the combined effects of these four variables on the sensory properties of ground beef containing starch–lipid as an additive:

• Type of Starch. Since the amylose content of starch influences its rheology and gelling properties, and thus its mouthfeel in food products, we examined different varieties of cornstarch and cornstarch blends having a range of amylose contents.

• Type of Lipid. For this study, we chose animal fat, since its flavor profile was expected to be similar to that of ground beef. We also chose inexpensive and readily available vegetable oil, used previously in many formulations. Lipid was formulated with starch at a level of 40 parts per 100 parts of starch, by weight.

• Protein. Although protein is not an essential component of the formulations, a protein component was included in this series of products, since preliminary experiments had shown that protein helps keep low-fat beef patties intact and reduces crumbling of the patties during cooking. Two commercial vegetable proteins were used at levels of 25 parts per 100 parts by weight of starch.

• Steam Line Pressure (low or high) used during the jet cooking process. Steam pressure within the cooking chamber was held constant at 40 psig. In an excess steam jet cooker, the pressure of the steam entering the cooker is higher than the pressure within the small chamber where the cooking of starch actually takes place (Klem and Brogley, 1981). This results in large amounts of excess steam passing rapidly through the jet cooker along with cooked starch solution. The configuration of the cooking chamber causes this steam flow to create a high degree of turbulence during the cooking process, and these turbulent conditions are severe enough to mechanically degrade starch, lowering its molecular weight (Dintzis and Fanta, 1996). We have shown that at a constant pressure of 40 psig within the cooking chamber, starch is increasingly degraded as the steam line pressure (and the amount of excess steam passing through the cooker) is increased. Since the rheology and gelling properties of both starch and protein are influenced by molecular weight, differences in the extent of polymer degradation caused by variations in cooking conditions might be expected to alter the sensory qualities of these products.

Tested in Beef Patties

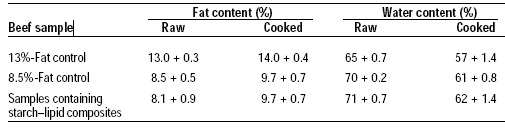

Two ground beef samples with different fat contents were used to make samples for evaluation. The beef for a low-fat product contained 8.5 ± 0.5% fat, and the higher-fat beef sample used as a control had a fat content of 13.0 ± 0.3%. Starch–lipid products were added to the 8.5%-fat beef sample, as follows:

Fresh beef containing 8.5% fat was first coarsely ground. Then dry starch–lipid products were added at a level of 1 part per 100 parts of beef, by weight, and water was added at a level of 10% by weight. The beef samples were then passed through the grinder a second time. Beef patties of uniform size were prepared by weighing 114 g of the beef samples and pressing them into a plastic mold (9.2 cm in diameter × 2.0 cm high).

--- PAGE BREAK ---

Patties were placed on a preheated (170ºC) Toastmaster Model 870G griddle (McGraw Edison Co., Boonville, Mo.) for 13 min (6.5 min/side) until an internal temperature of 76ºC was reached. Patties were cut into 20-g pieces, placed in 50-mL beakers, covered with watch glasses, and presented to panelists for sensory evaluation. They were also analyzed for fat and water content.

Flavor characteristics and texture parameters of ground beef patties were evaluated by a 16-member, trained, experienced analytical sensory panel. Panelists used descriptive sensory analysis techniques to identify flavors, including beef, fatty, sweet, salty, and cereal/grain and were instructed to add any other characteristics not listed on the scoring scale. Flavor intensities were rated on a 10-point scale with 0 = none and 10 = strong. Samples were rated for the following texture parameters: cohesiveness (1 = crumbly, 10 = gummy), chewiness (1 = tender, 10 = tough), springiness (1 = low, 10 = high), juiciness (1 = dry, 10 = juicy), density (1 = light, 10 = compact), and chalkiness (1 = low, 10 = high). All sensory analyses were conducted in a room equipped with individual booths and red lights to mask sample color. Fresh ground beef containing 13% fat and 8.5% fat were used as internal controls at each testing session. Data were analyzed by two-way analysis of variance. Statistical significance is indicated at the 95% confidence level (P ≤ 0.05) unless otherwise stated.

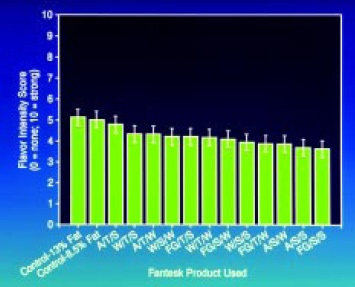

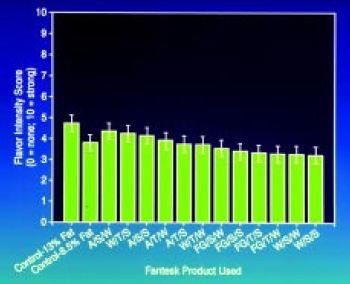

The only sensory characteristics that showed significant differences between samples were beef and fatty flavors and the juiciness and chewiness texture parameters. All other flavors and texture parameters were nondiscriminating. Flavor intensity scores for beef flavor showed no significant differences between ground beef with 13% fat and beef with 8.5% fat (Fig. 2). The effect of oil/fat type was evident when beef patties containing the starch–lipid products prepared from animal fat were compared with the patties containing components prepared with vegetable oil. Five of the six samples of ground beef containing animal fat were not significantly different in beef flavor intensity from the beef control containing 8.5% fat; however, five of the six samples that contained vegetable oil were rated as having less beef flavor than the 8.5%-fat control. As expected, ground beef with 13% fat had a significantly higher intensity of fatty flavor than the beef with 8.5% fat (Fig. 3). Three of the 12 starch–lipid components products (A/S/W, W/T/S, and A/S/S in Table 1) produced fatty flavor intensities that were equal to the beef control with 13% fat. The remaining nine combination products produced significantly less fatty flavor than the 13%-fat control. There was no consistent pattern in the compositions of these materials that would allow us to correlate fatty flavor with the composition of the additive.

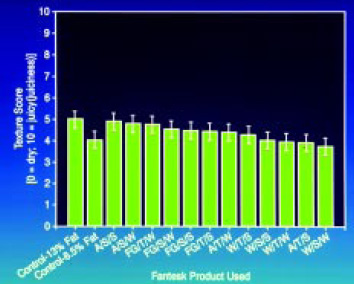

Cooked patties prepared from ground beef with 8.5% fat were significantly less juicy in texture than the patties prepared from beef with 13% fat (Fig. 4). Patties prepared with four of the 12 combination products were also drier. Patties containing two of the combination products that were prepared from the high-amylose starch mixture and vegetable oil (A/S/S and A/S/W) were considered significantly more juicy than the 8.5%-fat ground beef control. In this limited series of tests it was not possible to correlate composition of the added ingredient with dryness of the cooked patty.

Cooked patties prepared from ground beef with 8.5% fat were significantly less juicy in texture than the patties prepared from beef with 13% fat (Fig. 4). Patties prepared with four of the 12 combination products were also drier. Patties containing two of the combination products that were prepared from the high-amylose starch mixture and vegetable oil (A/S/S and A/S/W) were considered significantly more juicy than the 8.5%-fat ground beef control. In this limited series of tests it was not possible to correlate composition of the added ingredient with dryness of the cooked patty.

--- PAGE BREAK ---

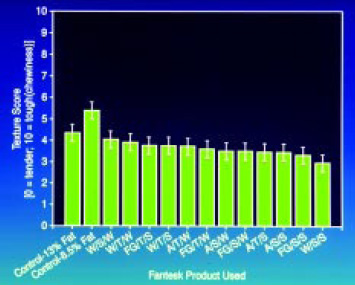

Patties prepared from ground beef with 8.5% fat were significantly tougher in texture than those prepared from beef with 13% fat (Fig. 5). Use of low-amylose starch in formulations slightly increased the chewiness of the cooked patties, compared to the other two starch systems. The starch–lipid product prepared from vegetable oil tended to produce patties that were more tender than those containing the product prepared from animal fat, and five of the six starch–lipid samples containing vegetable oil as the lipid component gave cooked patties that were significantly more tender than patties prepared from the 13%-fat control.

Water contents of cooked and uncooked beef patties were calculated from the loss in weight after freeze drying accurately weighed beef samples. Fat analyses of freeze-dried samples were then performed according to AOCS Official Method Ba 3-38 (revised April 1954 and reapproved 1973). Fat contents of these samples, expressed as weight percentages of the undried patties, are shown in Table 2, along with the water contents.

An Effective Fat Replacer

These results suggest that specific starch–lipid combinations can be effectively used as a fat replacer in low-fat beef patties. Matching the specific formulation to the desired characteristics of ground beef products requires understanding of the role of the starch–lipid components in flavor release and in binding moisture in the product.

This article has dealt with the use of the starch–lipid combination in ground meat products, but the combination is expected to be useful in a wide range of reduced-fat products.

The authors are indebted to A.M. Kelly-Webb (Analytical Chemistry Support Unit) for the fat analyses and to J.H. Salch and S.M. Walker for technical assistance.

Names of products are necessary to report factually on available data; however, the U.S. Dept. of Agriculture neither guarantees nor warrants the standard of the product, and the use of the name by USDA implies no approval of the product to the exclusion of others that may be suitable.

Patented Starch–Lipid Composites Available for Licensing

The starch–lipid composites are described in U.S. patents 5,676,994 and 5,882,713, assigned to the U.S. Dept. of Agriculture. The technology covered by the patents is available for license from USDA. The outstanding characteristics of the ingredients are the ability to rehydrate the product from dry powders, the specific rheology and texture provided by use of the product, and the ability of mixtures containing the product to retain the flavor and texture associated with the full-fat foods. Work is underway to develop use in reduced-fat frozen desserts and other products. For information about licensing the technology, contact Craig Carriere at USDA (phone 309-681-6545, fax 309-681-6682).

Kathleen Warner, Kenneth Eskins, George F. Fanta, Terry C. Nelsen, and Jonathan W. Rocke

Author Warner, a Professional Member of IFT, is Lead Scientist, Food Quality and Safety Research; author Eskins, deceased, was Research Leader, Biomaterials Processing Research; author Fanta is Research Chemist, Plant Polymer Research; and author Nelsen is Assistant Area Director; all at the National Center for Agricultural Utilization Research, Midwest Area, Agricultural Research Service, U.S. Dept. of Agriculture, 1815 N. University St., Peoria, IL 61604. Author Rocke is President, Rocke’s Meating Haus, Morton, IL 61550. Send reprint requests to author Warner.

Edited by Neil H. Mermelstein,

Senior Editor

References

Dintzis, F.R. and Fanta, G.F. 1996. Effects of jet cooking conditions upon intrinsic viscosity and flow properties of starches. J. Appl. Polymer Sci. 62: 749-753.

Eskins, K., Fanta, G.F., Felker, F.C., and Baker, F.L. 1996. Ultrastructural studies on microencapsulated oil droplets in aqueous gels and dried films of a new starch-oil composite. Carbohyd. Polym. 29: 233-239.

Fanta, G.F. and Eskins, K. 1995. Stable starch–lipid compositions prepared by steam jet cooking. Carbohyd. Polym. 28: 171-175.

Fanta, G.F., Felker, F.C., Eskins, K., and Baker, F.L. 1999. Aqueous starch-oil dispersions prepared by steam jet cooking. Starch films at the oil–water interface. Carbohyd. Polym. 39: 25-35.

Klem, R.E. and Brogly, D.A. 1981. Methods for selecting the optimum starch binder preparation system. Pulp & Paper 55: 98-103.

Knutson, C.A., Eskins, K., and Fanta, G.F. 1996. Composition and oil retaining capacity of jet-cooked starch-oil composites. Cereal Chem. 73: 185-188.

Stover, R.D. 1990. The superiority of jet cooking for starch preparation. TAPIK 22: 75-81.