Defining the Future of Food Packaging

IFT’s fifth Research Summit identified key research areas such as materials science and sensing technologies for improving food packaging.

Last spring, the Institute of Food Technologists convened a Research Summit on “Food Packaging Innovations: The Science, Current Research, and Future Needs.” Summit Committee Chair John Floros, Professor and Head of Pennsylvania State University’s Food Science Dept. and IFT’s President-Elect for 2006–07, opened the summit by appealing to participants to identify research needs and provide a roadmap for the future of food packaging. Floros challenged the attendees to focus on where packaging should go in the next 10–15 years, given an unlimited world of resources.

Session Topics

Scientists and scholars delivered 10 presentations during four scientific sessions on Food Quality and Safety Needs, Material Science and Technologies, Sensing technologies, and Packaging in the Future. The sessions featured main speakers and discussants who also served as session chairs and breakout group leaders. Research needs were identified through an interactive process involving small group discussions.

• Food Quality and Safety Needs. Food packaging significantly affects quality and safety– related changes in food and has a profound impact on shelf life. These changes result from various reactions that occur in food throughout the supply chain. This session was designed to provide information on the basic need for packaging and to set the stage for discussions on how packaging fits in the big picture of keeping the food supply safe. The speakers focused on reactions that occur after the food is placed in the package, with special attention to reactions that limit product shelf life or create food safety concerns. Reactions occurring at the product/package interface were also addressed, as were relevant regulations.

• Materials Science and Technologies. Novel and advanced polymeric materials are being developed for enhanced food packaging. The development of these materials is based on conventional polymer science methods, as well as newer technologies including biopolymers,nanotechnology and nanocomposites, and active and intelligent packaging. This session featured three presentations that focused on the latest developments in packaging materials. Special attention was placed on how these materials may accommodate antimicrobials and other agents that may extend the shelf life of packaged food.

• Sensing Technologies. This session reviewed the latest research developments in biosensors and other sensing technologies, with specific attention to rapid detection of microbial activity, biochemical activity, and other reactions that cause food deterioration. Potential mechanisms for integration of these sensors into food packaging were also discussed.

• Packaging in the Future. This session used a systems approach to integrate the concepts discussed in the three previous sessions and then presented a thought-provoking perspective about the role of packaging in future food systems. The presentation covered current and future global trends, ranging from social to environmental to technological, and how they affect food packaging. Specific trends included population growth and diversity, lifestyle, and health. The goal was to examine these trends with emphasis on what would determine consumer needs, such as convenience, and what research can deliver. This session also covered opportunities for using the package as a communication tool to convey information to consumers.

--- PAGE BREAK ---

Future Research Needs

The summit participants identified, discussed, and reached consensus on major research and information needs that are necessary to advance the field of food packaging. These needs are summarized below.

• Materials Science and Technologies. Scalping and migration of components, such as flavors, presents major challenges during development of new packaging materials. Participants identified three key research areas—kinetics of release and absorption, permselectivity, and barrier properties—that need further exploration.

Understanding the kinetics of release and/or absorption of the various food components (e.g., flavors and odors) or package components (e.g., controlled-release packaging materials required for active packaging) is critical to the development of appropriate packaging materials for specific foods. A better understanding of the kinetics of release, which varies with compounds, is necessary to develop materials that allow sustained delivery.

Kinetic constants for each component in a multi-component system would be required to identify the optimum packaging materials. Development of a packaging material to minimize absorption of a food component requires knowledge of absorption kinetics to ensure that desired shelf life of the product can be achieved.

Permselectivity is the ratio of the permeability coefficient of carbon dioxide to that of oxygen. The general relationship is that as permeability increases, selectivity invariably decreases. The magnitude of the desired permselectivity will vary with the product as a result of the unique local atmosphere (carbon dioxide/ oxygen) needed to extend the shelf life of each product. Research on development of materials with high permeability, while minimizing selectivity, is needed.

Packaging materials with a range of permselectivity magnitudes (depending on desired shelf life) are needed for improvement of shelf life of a variety of products. For example, materials with high permselectivity are desired for controlled-atmosphere packaging for fresh produce. Development of materials with optimized permeation rates for specific food products is also desired.

Barrier to physical, chemical, and biological influences is an important property of packaging materials. Existing materials could be modified or new materials developed with improved barrier properties. Also, materials that maintain high-barrier properties with changing temperature and humidity are desired.

• Bio-Based Materials. These materials are made from renewable resources such as starch, cellulose, and soy protein. The major driving forces to develop bio-based materials are the rising prices of petroleum and environmental concerns. Bio-based materials offer an alternative for reduced dependence on oil, the primary source of most currently used packaging materials. Bio-based materials based on polylactic acid have been available for some time, but industrial application has been limited. Technical and economic feasibility studies need to be completed to encourage commercial applications.

--- PAGE BREAK ---

Additional research on identification of appropriate additives and processing aids to improve functionality could increase utilization of bio-based materials for food packaging. For example, research should identify appropriate plasticizers for bio-based materials, since these components may differ from those currently used for petroleum-based materials. Other resources should be explored for development of new green polymers with properties to match conventional polymers. The use of waste materials from production of value-added products is encouraged. In addition, research is needed to determine compatibility of these materials with food products.

• Nanotechnology. Nanotechnology has many potential applications to food packaging, especially in development of materials with improved mechanical, thermal, and barrier properties. Although considerable research is underway, more emphasis on safety and risk assessment of nano-scale materials is needed.

• Active Packaging. Commercialization of active packaging technologies, with the exception of moisture and purge control, has been relatively slow. Furthermore, some of the offerings have been poorly tested, or did not function as intended. There is a need for a single independent, unbiased resource to evaluate the value of existing and upcoming food packaging technologies.

Another research limitation in active packaging is associated with controlled-release packaging. The most promising opportunities involve slow release of active compounds such as antimicrobials and antioxidants from the package to food for enhanced quality and safety during prolonged storage. There is a general need to develop materials with the ability to release the active ingredient at rates suitable for various packaging applications. Considerable research has been completed on antimicrobial packaging, especially on the use of nisin to control microbial growth and extend the shelf life of food. Since cost of application seems to be prohibitive, a cost-benefit analysis is needed in an effort to enhance feasibility.

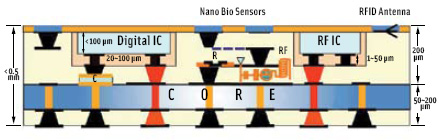

• Intelligent Packaging. Research on the integration of thin-film electronics into food packaging (i.e., system on the package) with accurate monitoring/verification procedures and corrective actions is needed to have broad impact on intelligent food packaging. Low-cost devices are needed to sense volatile organics, time and temperature, humidity, and harmful bacteria and communicate this information to manufacturers and consumers by wireless interfaces such as radiofrequency identification (RFID) tags.

Polymer-compatible, thin-film functional electronic components (e.g., antenna), thin-film embedded actives (e.g., reader, amplifier), and embedded nano-sensing devices will enable the use of low-cost electronic systems in packaging, leading to the implementation of intelligent food packaging.

--- PAGE BREAK ---

• Other New Materials. Research on materials for microwave heating is needed to provide a range of cooking times, uniformity of heating, and improved browning and crisping during heating of large food components, and to cater to increases in microwave wattage. Because of current concerns about obesity and in an effort to promote health and wellness, the foodservice sector has recognized the need to implement portion control, resulting in the switch from bulk to portion packaging. New packaging materials are needed to facilitate this shift.

• Life-Cycle Assessment. Life-cycle assessment for new packaging materials, such as nano-based and bio-based materials, is essential for their success. This is a comprehensive analysis of materials from production to disposal to determine their environmental impact. It involves evaluation of the materials and energy usage in product manufacture and use and evaluation of the type and amount of waste generated.

Uniform criteria or a universal model with standard inputs and outputs is needed to evaluate packaging materials. Analysis of the performance and sustainability of new materials, especially bio-based materials, is also required to document their advantages over conventional petroleum-based materials. Investigations into the compatibility of new materials with food products are important.

• Materials Safety. Safety studies must be completed for all new materials and technologies. For example, the potential release of mutagens/carcinogens needs to be evaluated. Other issues of material use and disposal include the potential safety problems of breakdown products.

• Sensing Technologies. Sensors need to be integrated at the processing stage of the food supply chain, as well as in bulk container packaging or storage facilities. Sensors are a critical component of packaging to maintain flow of information throughout the supply chain and to allow for product traceability. They facilitate in-plant or in-process validation as well as detection of contamination. They may be used in combination with or to complement HACCP programs.

Sensing technologies are readily available, but research on mechanisms for incorporation in food packaging is needed. For example, identification of strategic locations in the sample or package for effective detection is lacking. Research to establish compatibility of sensors with various packaging materials and structures should be pursued.

Sensors should enhance the role of the package as a communication tool for consumers by conveying information on product usage, proper handling, and storage, and as indicators for product rotation in the home pantry or refrigerator.

--- PAGE BREAK ---

• Food Safety and Quality Sensors. Research needs to be conducted on quality and/or safety indicators in food. Models that predict changes in terms of safety, quality, and shelf life of food are important in the development of sensors. Safety-related sensors, including microbiological sensors that detect specific pathogens in food, are a relatively recent development.

Additional research is needed in development of sensors that can detect several different microorganisms simultaneously. For example, a single sensor that could detect the most prevalent foodborne pathogens in a given food would be ideal.

Research is needed on development of quality-related sensors to detect metabolites or byproducts of degradation reactions in food. Other product quality attributes such as pH and staleness could be used as indicators for sensor development.

• Sensing for Intentional Contamination. Intentional contamination must be differentiated from accidental contamination in foods. Sensors used in combination with tamper-evident packaging would be useful. On-going research will develop sensors for detection of chemical contaminants. A universal sensor with the capability to detect multiple toxins would be ideal.

A better understanding of the changes (e.g., quality and shelf life) in food associated with intentional contamination is needed for sensor development. In addition, the development of software or algorithms for data gathering/ collection, processing, and storage to be used in the integration and transmission of information in real time for quick decision making should be given elevated priority.

• Collaboration. Collaboration on packaging research activities is essential to improve decision making and to advance food packaging. There is a need for materials research scientists to reach out to scientists in other disciplines, such as electronics, microbiology, and medicine, to create a multidisciplinary approach for technology development. In addition, there is need to establish a nonbiased group and develop collaboration between industry and academic research groups. Such a system should allow networking and collective thinking in anticipation of key research issues.

--- PAGE BREAK ---

• Education and Communication. Consumer perception is viewed as the most significant factor in limiting the application of new packaging technologies. This is due, in part, to the lack of understanding of the research or misinformation about the technologies. The need to translate technical information into a form that communicates more clearly to consumers should help overcome resistance to new technologies. Consumers need to gain a better understanding of the application and safety of new technologies, such as nanotechnology and use of sensors in tamper-evident packaging. In addition, employee training s necessary to gain a better understanding of new technologies and to properly interpret the technology output.

It is also important to establish a mechanism for exchange of information among all stakeholders, including government, industry, academia, media, consumers, and the groups that represent them. Formation of a consortium or forum to engage stakeholders on food packaging issues would be valuable.

Establishing Priorities

The focus of food packaging is to improve the safety, quality, and shelf life of food products as well as provide consumer convenience and satisfaction. The pressing question is “Where do we go with packaging?” to meet this goal. There is a need to prioritize the identified research areas to come up with packaging solutions that significantly improve the delivery of safe, high-quality food to the consumer.

Summit Presentations Available Online

Participants in IFT’s Research Summit on “Food Packaging Innovations: The Science, Current Research, and Future Needs” included Barbara Byrd Keenan, IFT Executive Vice President; Dennis Heldman, Ph.D., IFT President 2006–07; John Floros, Ph.D., Pennsylvania State University (Summit Program Chair); Jung Hoon Han, Ph.D., University of Manitoba; Francisco Diez-Gonzalez, Ph.D., University of Minnesota; Joe Hotchkiss, Ph.D., Cornell University; Per Nielsen, Ph.D., Technical University of Denmark; Sara Risch, Ph.D., Michigan State University School of Packaging; Kay Cooksey, Ph.D., Clemson University; Kit Kam, Ph.D., Rutgers University; Evangelos Manias, Ph.D., Pennsylvania State University; Amar Mohanty, Ph.D., Michigan State University School of Packaging; Aaron L. Brody, Ph.D., Packaging/Brody, Inc.; Melvin Pascall, P.h.D, Ohio State University; Michelle Stevens, Mocon, Inc.; Joseph Irudayaraj, Ph.D., Purdue University; Mahadevan Iyer, Ph.D., Georgia Institute of Technology; Leslie Cook, Cryovac Inc./Sealed Air Corp.; and Bruce Welt, Ph.D., University of Florida.

Some of their presentations are available online at IFT’s Web site. To view the summit agenda as well as the presentations, please go to www.ift.org and place your cursor over the “Research, Reports, & Policy” button in the blue tint box on the left-hand side of the page, then click on “Research Summits.”

Betty Bugusu, Ph.D., ([email protected]) is Research Scientist and Cory Bryant, Ph.D., ([email protected]) is Senior Research Scientist, Dept. of Science & Technology Projects, Institute of Food Technologists, 1025 Connecticut Ave., N.W., Suite 503, Washington, DC 02236-5422.