Entrepreneurial Approaches Mean Big Wins for General Mills

Open innovation and inviting consumers into the product development process earlier allow the company to unlock new growth opportunities.

In today’s global economic climate where entrepreneurs can win with emerging scale locally, never before has it been more critical to connect with consumers to integrate their voices into product development efforts. General Mills believes that successful consumer packaged goods (CPG) companies will find new ways to nimbly re-center their product development efforts on rapidly changing consumer needs.

If CPG companies are going to be successful and compete with smaller scale start-ups and entrepreneurs, it is critical they find ways to recalibrate product development for smaller launches, both locally and regionally, and be more flexible in how they bring new products or adjacencies to market.

Traditionally, while big companies maintain tremendous expertise and large-scale resources, they have been too laden with bureaucracy and complex internal processes when trying to offer unique and differentiated products that can keep pace with consumers’ rapidly evolving needs. Today General Mills is offering consumers an effective and permanent seat at the table. We have created new mechanisms for involving consumers at each stage of our product development life cycle, including rough prototyping; creating foods together in the kitchen to gain insights from consumers; concept reviews and feedback; and finished product in-store selling to understand food purchasing choices. The value in moving the consumer to the center of our universe has become clearer. We commit to further building on our understanding of consumers’ needs across our value chain, including in our research and development. We can and will deliver foods that not only meet consumer needs, but also promote excitement and build brand loyalty.

Small companies have been doing this well for decades, and we are learning from their approaches in order to provide consumers with what they want and need faster and in a way that builds trust and loyalty. An enormous opportunity exists for us to combine the best of big companies and the best of small companies. And by pursuing the best of both worlds, we are unlocking new growth.

Open Innovation

We believe innovation is at the center of this change and is the principal way forward for General Mills. But our idea of innovation is evolving and is increasingly focused on reinventing the processes and mechanisms we use to create new products by intimately understanding our consumers and capitalizing on innovation and know-how outside of General Mills in order to respond to their needs in less time.

It is becoming more and more evident that a wealth of enabling innovation resides outside our four walls and we will need to effectively access it if we want to be successful. In 2005 we sensed it would be critical that General Mills more effectively connect and build relationships with outside partners, primarily with suppliers and vendors for innovations (product and technology or technical solutions). Over the course of the following years, we encouraged the company to adopt an open innovation strategy to bring outside resources closer to our product development activities.

--- PAGE BREAK ---

Today open innovation is doing this and enabling more robust interaction with consumers in our development processes for iteration and early feedback.

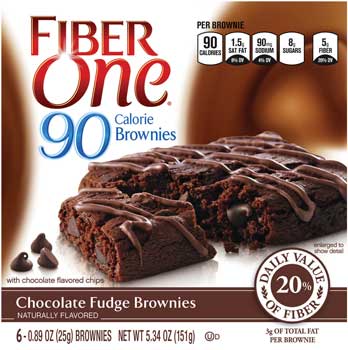

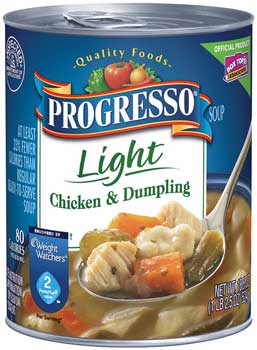

Many of our most successful new product launches since that time—such as Fiber One 90-Calorie Brownies, Yoplait Greek 100, Nature Valley Bistro Cups, Progresso Light Soups, and Nature Valley Protein Bars—have incorporated open innovation. Open innovation and external connections enabled these products to be developed with the unique food qualities they bring to the market as finished products. Those external partnerships contribute unique resources—technical solutions or enabling us to bring on capabilities in process or packaging.

Many of our most successful new product launches since that time—such as Fiber One 90-Calorie Brownies, Yoplait Greek 100, Nature Valley Bistro Cups, Progresso Light Soups, and Nature Valley Protein Bars—have incorporated open innovation. Open innovation and external connections enabled these products to be developed with the unique food qualities they bring to the market as finished products. Those external partnerships contribute unique resources—technical solutions or enabling us to bring on capabilities in process or packaging.

Today our open innovation strategy continues to grow, evolve, and infiltrate nearly every division and function within the company. We believe that we have unique, differentiating capabilities in how we work collaboratively with consumers to understand what is needed and how we can deliver possibilities to meet those needs.

Consumer First Design

At General Mills, we call our effort Consumer First Design (CFD), and it impacts every aspect of how we approach our product development process. It involves a comprehensive set of interactions with consumers at various stages of the product development life cycle supported by individuals embedded within our R&D platforms. These individuals accelerate the rate of learning and facilitate the process of interaction with consumers and developers.

At the core, it begins with an unwavering commitment to build true empathy for our consumers, putting our cross-functional teams in the consumer’s shoes to experience the frustrations, trade-offs, and challenges consumers face in their daily lives. That deep understanding of consumers’ food choices in their context is proving critical as we work to provide new and different solutions to the food “jobs” that consumers need done.

CFD also gives our consumers a much better seat at the table as we turn ideas into products. We’ve incorporated “lean thinking” into our efforts, and we now work collaboratively with consumers in short, iterative learning sprints to get our products right. By interacting with consumers at very early stages in the development life cycle, we learn and can pivot faster to address consumer needs more effectively and precisely. This understanding upfront shortens the overall life cycle and better ensures getting it right the first time. What took us months before, sometimes now takes days as we build new ways to effectively engage consumers.

We also have emphasized the importance of transactional learning, where we learn from real consumers, with real product, in real stores early in the development process.

Recently, we initiated an early in-market learning approach for products we are really enthusiastic about but needed to get a better pulse on what flavors and texture consumers wanted, what they were willing to pay, and if they would find value and convenience in the product. This simple and quick approach, which we’ve termed “Lemonade Stands,” helps us engage with consumers and proved hugely valuable in the recent development and launch of Nature Valley Bistro Cups. Our R&D team spent two weekends in two Minneapolis area Target stores sampling and learning from consumers. We learned that consumers were very excited about using their single-serve brewers for other things besides hot beverages. We also gathered feedback on flavors, textures, and even packaging.

This early interaction with consumers on the concept led to insights and validation on the product that, without the interaction, we could only speculate about. The Lemonade Stands allowed us to gain early consumer feedback, which led to better alignment of a product that consumers wanted. All of these learnings helped quickly pivot the product into one that consumers embraced, all in a time frame that previously was difficult to achieve.

Over the last few years, we’ve charged our teams to get the product to the point where it is just “good enough” and then test it with our consumers by actually trying to sell it in the very early stages of product development. R&D teams develop food-safe, rough prototypes that allow them to interact with consumers in order to learn about their purchasing choices and their reasons for choosing foods in the category. Our goal is to learn if real consumers will spend their money on these products and, if so, what motivated them, what they liked about the product, and what could be improved. This provides us with the empathy and understanding needed in the iterative product development cycle to deliver the finished food product to delight and nourish our consumers’ lives.

Over the last few years, we’ve charged our teams to get the product to the point where it is just “good enough” and then test it with our consumers by actually trying to sell it in the very early stages of product development. R&D teams develop food-safe, rough prototypes that allow them to interact with consumers in order to learn about their purchasing choices and their reasons for choosing foods in the category. Our goal is to learn if real consumers will spend their money on these products and, if so, what motivated them, what they liked about the product, and what could be improved. This provides us with the empathy and understanding needed in the iterative product development cycle to deliver the finished food product to delight and nourish our consumers’ lives.

Giving consumers not only a seat at the table earlier in the process, but spending time with them, has taught us many valuable lessons and allowed us to create new best practices that we continue to incorporate in our product development approaches today. We learn upfront before spending too much time perfecting a product so that when we are in the final stages of perfecting it we have ensured it is accurately and precisely addressing the consumer need. This is now a best practice within our R&D organization: “consumer first” learnings, finished product second.

--- PAGE BREAK ---

Functioning Small While Remaining Big

We see future success coming from combining the scale and rich resource base of the large company with the nimbleness that, to date, only smaller companies have mastered. Large companies historically have not been known for their speed to market. More often, large company product development was wrought with numerous iterations before consumers even saw prospective new products on store shelves. These iterations were designed to optimize the product before the company even knew if the total offering was something consumers would be motivated to buy. This, of course, added time and slowed the process. However, we’ve learned—particularly over the past few years—that CPG companies can continue to optimize and evolve a product after it enters the market and the sooner consumers see it, the more likely it will end up being successful. We conduct short-term trials in store with consumers having the option to buy our product. Once learnings are gained and the product is launched, we then have similar mechanisms for learning while the product is in the market. From that data, we can pivot or make necessary adjustments in order to ensure we are meeting consumers’ needs.

Take, for instance, the Nature Valley Bistro Cup single-serve oatmeal. With the resources of our entrepreneurial-like business development unit called 301 Inc., this product went from ideation to store shelves in six months. Flavor offerings were modified and added after consumers had a chance to sample, react to the current product iteration, and provide critical feedback on likes and dislikes about taste at the Lemonade Stands. Still today, Nature Valley Bistro Cup Oatmeal, which began appearing at retail in June 2014, is the only oatmeal in the market made using a single-serve brewer.

Take, for instance, the Nature Valley Bistro Cup single-serve oatmeal. With the resources of our entrepreneurial-like business development unit called 301 Inc., this product went from ideation to store shelves in six months. Flavor offerings were modified and added after consumers had a chance to sample, react to the current product iteration, and provide critical feedback on likes and dislikes about taste at the Lemonade Stands. Still today, Nature Valley Bistro Cup Oatmeal, which began appearing at retail in June 2014, is the only oatmeal in the market made using a single-serve brewer.

In recent years, larger companies like General Mills have been outflanked by smaller companies that are quicker to market because they are led by passionate entrepreneurs who make products they want to buy themselves. By building our intuition and our empathy for our consumers, and leveraging early in-market learning, we can become passionate entrepreneurs as well.

Speed to Market

Speed is more and more of a factor in our industry as we compete with small, nimble companies who may be less adverse to risk. To compete in this changing landscape and unlock new growth, we need to combine the “spirit of the small” with the “power of the big.”

The recent development and launch of Gluten Free Chex Granola, which hit store shelves in January, is a perfect example of how a solid idea packaged with a skilled team and engaged consumers can accelerate product timelines. Armed with an entrepreneurial mindset and approach, a very talented team within our cereal business worked on the product from start to finish with our innovation support teams, but most importantly with consumers. The product is the company’s first gluten-free granola and went from ideation to creation of our total product offering—flavors, cluster size, ingredients, etc.—in a mere 45 days. We spent seven months from ideation to full production at the plant and a total of nine months from ideation to launch in December.

The recent development and launch of Gluten Free Chex Granola, which hit store shelves in January, is a perfect example of how a solid idea packaged with a skilled team and engaged consumers can accelerate product timelines. Armed with an entrepreneurial mindset and approach, a very talented team within our cereal business worked on the product from start to finish with our innovation support teams, but most importantly with consumers. The product is the company’s first gluten-free granola and went from ideation to creation of our total product offering—flavors, cluster size, ingredients, etc.—in a mere 45 days. We spent seven months from ideation to full production at the plant and a total of nine months from ideation to launch in December.

The product development team enlisted “agile design” methods, a process that originated in the IT industry more than a decade ago and is now used across many industries. Agile design allows teams to innovate iteratively with greater speed. Agile design is a software development process or approach that enables quick testing and learning in order for developers to make changes in the development process in an iterative way. This is something we have externally benchmarked and adapted these methods and contextualized them to food product development.

Throughout the 45-day process, the team created more than 80 varieties of the granola before landing on the perfect one, and connected with consumers both face-to-face and online, extending our ability for consumer input on many key questions throughout the development process. We connected through a prototype fair, focus groups, online communities, and our Lemonade Stand (in-market purchase test). We answered questions about what job this does for consumers, who the target consumer is, flavors, ingredients (e.g., quinoa or no quinoa), brand name, how we talk about it, and even the nutrition label. The combination of these consumer touch points allowed us to work with more than 1,000 consumers to help co-create this product. They were with us every step of the way and the learnings from each interaction enabled us to make adjustments and then re-engage. That’s the spirit of agile.

This was definitely a nontraditional approach to how our company has done development in the past, but those on the team said that using agile design methods proved to be energizing and enabled them to make important decisions more quickly than is typical. This approach helped answer key questions faster and with really close fingertips on the consumers’ wants and needs. With such frequent interactions, we were able to consistently check in with internal key stakeholders on what new things we’ve learned and why, and then align on the decisions. One example is on the inclusion of the Rice Chex pieces. Even decision making was agile, and everyone was on this journey together in a short time frame. Consumers helped us answer those critical questions and do what was best for them.

If we challenge ourselves to think and execute in ways that the most successful small, entrepreneurial companies of our day operate, we believe we’ll be more in touch with our consumers and better able to meet their rapidly changing needs. Our vision is to leverage the outside world, where science and technology are connected globally, with our new iterative, consumer first product development methods internally; we are nourishing lives in new ways as the new “Best Big Small Company.”

Peter C. Erickson, a member of IFT, is executive vice-president,

innovation, technology, and quality, General Mills

([email protected]).