Food Technology Magazine | Applied Science

Ensuring Quality and Safety in Fried Foods

In this column, the author describes basic principles for maintaining frying oil quality and safety.

© KPS/iStock/Getty Images Plus

Nutritionists and proponents of healthy eating may condemn fried foods as having too much fat and empty calories, but the process of frying foods is not going anywhere for several reasons. First, fried foods taste good. There is a rich aroma and mouthfeel, a satisfying “crunch,” and a wonderful flavor. Second, frying is a very efficient means for cooking food. Cooking a chicken breast in an oven could take 45 minutes whereas placing that same product in a fryer will take 5 to 6 minutes. And one can literally fry anything: pastries, meats, potatoes, vegetables, and even items such as ice cream or candy bars. Yes, visit one of the state or county fairs around the country and marvel at what is offered.

The Evolution of Frying as a Science

The understanding of the science and technology of deep-fat frying has made great strides in the past 35 years. One of the drivers of these changes was Michael Blumenthal, an oil chemist at Rutgers University who developed the surfactant theory of frying, but other researchers and organizations around the world helped turn frying from what many perceived as an art to a science. In fact, in the late 1980s, a frying short course was sponsored through the extension group at the University of California, Davis. One of the speakers, Jim Grob from Frymaster, stated that many felt frying to be a form of art.

Blumenthal participated in the UC-Davis program plus a number of frying programs sponsored by the Institute of Food Technologists’ (IFT) Continuing Education Committee. In fact, if one is interested in learning more about frying, Food Technology magazine published a series of papers presented at a frying symposium held at the 1990 Annual Meeting. Blumenthal’s presentation was entitled, “A New Look at the Chemistry and Physics of Deep Fat Frying,”

Another driver of change and improvement has been the Deutsch Gesellschaft fur Fettwissenschaft (DGF, or German Society for Fat Research). To date, they have sponsored 11 two- to three-day symposia on the subject. The most recent was held in Hamburg, Germany, in March 2023.

IFT’s contribution to frying goes back even farther, however. Back in 1967, in the January issue of Food Technology magazine, Canadian scientist C.J. Robertson proposed several basic principles for maintaining frying oil quality:

- Proper design, construction, and maintenance of equipment

- Proper cleaning of equipment

- Minimize exposure to ultraviolet light

- Keep salt and other sources of metal away from oil

- Filter regularly

Robertson’s principles remain valid today, more than 50 years later. Many also believe that it is important to monitor oil quality during frying. It is also essential to maintain and monitor oil temperatures. Keeping a fryer at elevated temperatures during extended downtimes can severely damage frying oil.

Following these basic principles will help ensure that oil quality is properly maintained, allowing processors and restaurant operators to maximize usable oil life and ensure the food is of good quality. In fact, at the 3rd International Symposium on Deep-Fat Frying sponsored by the DGF in 2000, the organization’s first recommendation focused on the food: The principal index for deep-fat frying should be the sensory parameters of the food being fried, they stated.

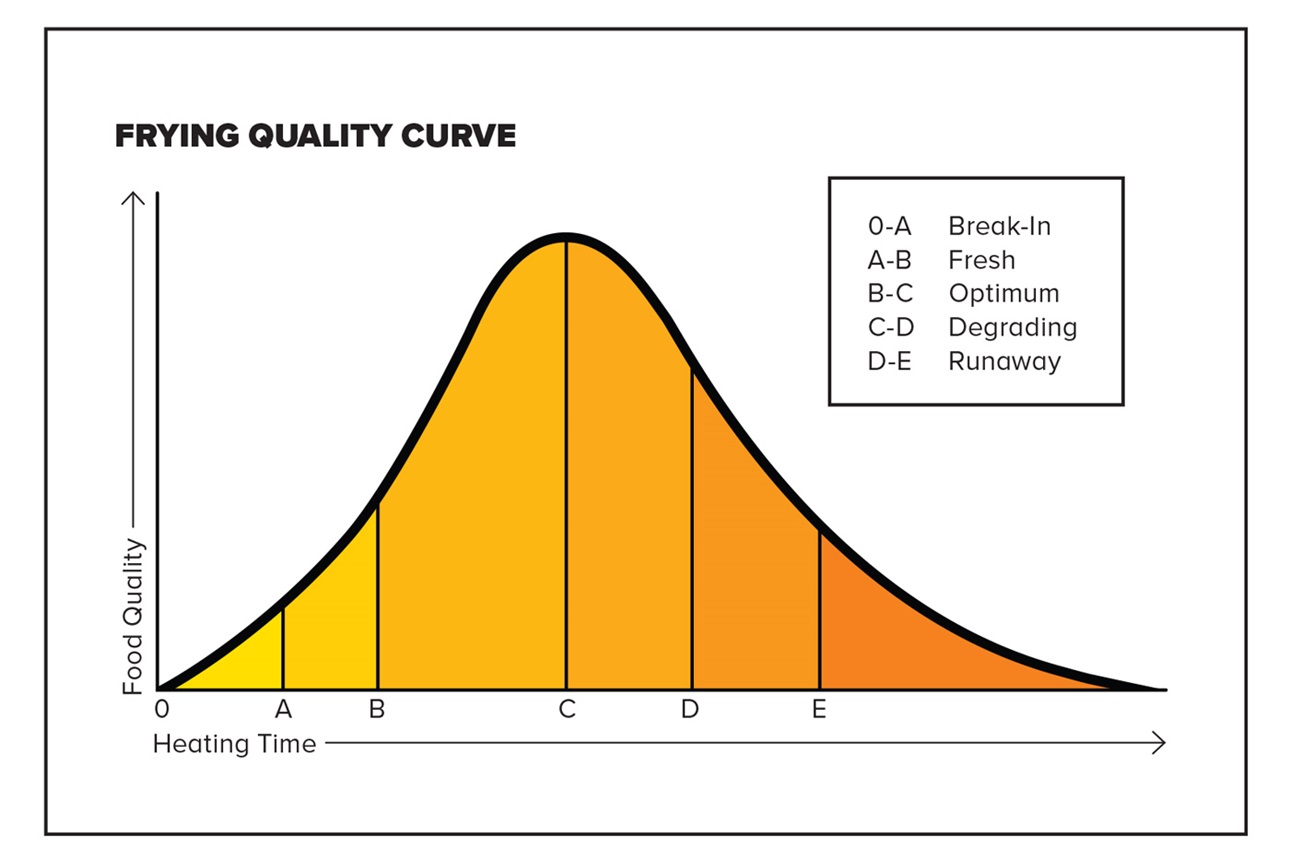

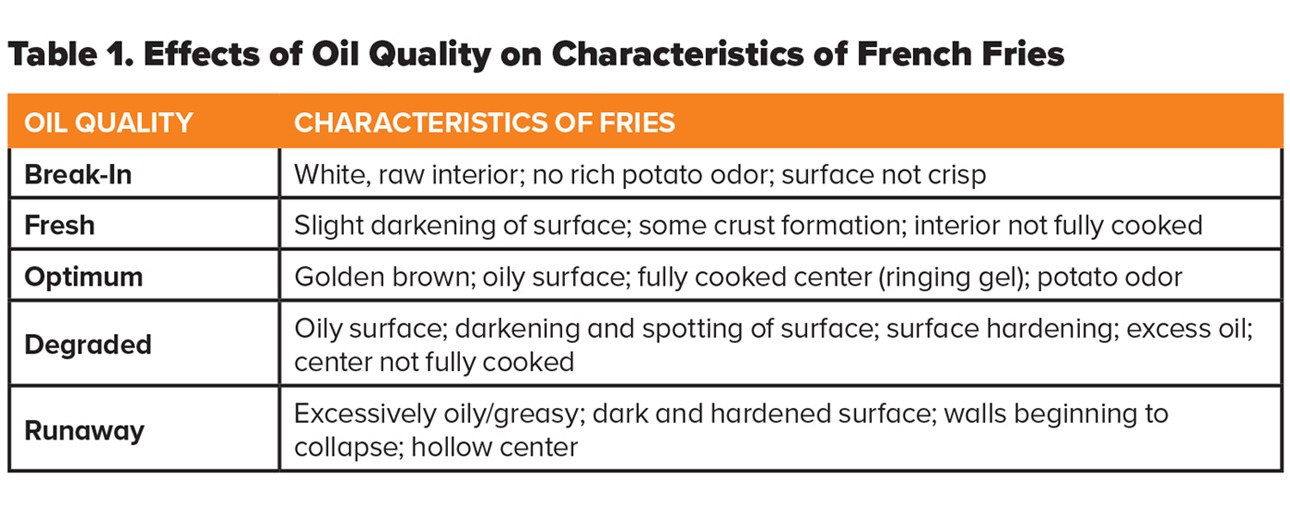

Blumenthal also developed another tool that can help processors to better understand frying called the Frying Oil Quality Curve (Figure 1). The curve describes five stages of oil degradation: break-In, fresh, optimum, degrading, and runaway (Table 1). If one looks at French fry cooking, the process of product changes can be seen throughout the life of the oil. When frying is initiated in a clean fryer with fresh oil, fries are light in color and do not have the rich smell one would expect in the product. This fresh oil has few surfactants, so the oil and food do not remain in contact long enough to properly cook the food. Water that is escaping from the potato pushes the oil away from the surface of the product so that the surface does not brown and the interior is not properly cooked. This is why “old-time” bakers often added a cupful of abused oil to fresh oil. They were “breaking the oil in.”

As surfactants build in the oil, food quality increases to where the oil reaches the “optimum” stage. This is where one gets the best quality fried foods. The goal for both industrial and foodservice frying is to maintain the oil in this condition for the longest possible time. This is easier to accomplish in industrial operations, especially when cooking foods that absorb a great deal of oil such as potato chips. Such operations literally reach a steady state and can be maintained. If users allow the oil to go beyond this stage to either the degrading or runaway stages, food quality becomes progressively worse. Products become darker, surfaces are case hardened, coatings are lost, and taste is poor.

Maintaining Frying Oil Quality

The use of oil treatments or filtration systems is regarded by many as the most important quality principle for maintaining oil quality. Oil must be treated from the very beginning so that breakdown components of the oil, which act as catalysts for further oil degradation, are continuously removed and do not accumulate in the oil. There are two types of oil filtration systems: passive and active. Passive systems simply remove particulates; that is, they simply filter the oil, acting as sieves to remove particulates. These systems include metal screens, rolling (indexing) paper filters, paper cones, plastic cloths, plate and frame systems, systems using diatomaceous earth, and leaf filters.

Active systems, also called treatments by some, remove specific oil-soluble chemical compounds from heated oils. These active filters or systems remove or trap not only the particulates, but also remove or reduce the formation of non-filterable chemicals or breakdown compounds. There are pros and cons to adopting an active filter system. Potential benefits of filtration include reduced energy usage, improved food quality, reduced oil usage and an improved food fried to oil used ratio, enhanced shelf life of products, reduced downtime, oil life extension, reduced cleanup time, the use of healthier oil for frying, and the potential for having a safer and more comfortable workplace. When evaluating any filter material, examine these benefits and work to put numbers on them.

Potential concerns with oil treatments are leaching of powders into the oil, leaching of metals into the oil, the lack of good filtration equipment, potential legal issues in different countries, the capital expenditures, and safety of the system. With foodservice or restaurant frying, there is another issue that needs to be factored into the equation: the worker. Any system that is introduced into a restaurant must be easy to use and field-rugged. Just as one must look at the benefits, it is essential that one must look at the negatives. The bottom line is, do the benefits outweigh the costs? The supplier of the system needs to work closely with the vendor to evaluate costs and benefits. Why? The oils used for frying and foods that are fried affect how these systems perform, but more importantly, only the user understands what constitutes quality fried food in their business.

Fryer operators at both the industrial and restaurant/foodservice level must also properly clean their fryers. Cleaning fryers includes multiple steps once the oil has been drained from the system:

- Rinse with water to remove crumbs.

- Boil out the fryer with alkali to remove polymer buildup.

- Rinse with water to remove the alkali.

- Use an acid rinse to neutralize any residual alkali.

- Apply a water rinse to flush any chemicals from the system.

If an operator fails to properly remove the caustic chemicals, the residual can destroy the oil. They react with water and free fatty acids to form alkaline soaps. The author witnessed such an incident one time: the oil literally turned into a gel.

Safety Aspects

One would think that frying foods in oils that range in temperature from 350oF–400oF would be a no-brainer when it comes to food safety. What self-respecting pathogen could survive such temperatures? However, although there are no documented pathogen outbreaks that have been attributed to fried foods, there may be potential concerns. For example, there is a concern with battered products and the formation of Staphylococcal enterotoxin in the batter if temperatures become too high. Staph toxins are heat stable and could potentially form and survive the frying process. As with any other food processing operation, processors and foodservice operators need to take a Hazard Analysis and Critical Control Point (HACCP)–based approach to the potential risks associated with frying operations and the foods being fried to determine if there are any significant risks.

In response to two outbreaks of salmonellosis attributed to consumption of raw almonds in 2001 and 2004, the Almond Board of California (ABC) has established a program to validate the effects of different processing methods on almonds, including frying. Operations processing almonds must work with an ABC-approved process authority who does the validation studies that must show a minimum of a 4-log reduction of Salmonella surrogates. The process authority then submits the validation work to the ABC’s technical experts for review.

There are several potential chemical safety issues associated with frying oils and fried foods. In the early 1970s, German regulatory agencies received complaints from consumers about fried food quality, most of which were related to gastrointestinal distress. This prompted scientists in that country to initiate studies into the quality of oil in restaurant frying. Researchers were never able to establish a direct link between abused oil and a health problem, but they did determine that many operators were abusing their oil. This work was presented at the 1st International Symposium on Deep-Fat Frying in 1973 and set the stage for the establishment of both regulations and guidelines for restaurant/foodservice frying in Europe.

The most common regulatory index of oil abuse is total polar materials. The simplest definition of polar materials is the non-triglyceride materials found in heated oils. Fresh oils are almost pure triglyceride. If an operator abuses oil to the point that the operation is out of compliance (24%–25% polars), there is a very good chance that the food produced will be of very poor quality. Many operations around the world now utilize polar materials as their marker for oil degradation.

Acrylamide is also a concern. This chemical forms in the foods being fried, not in the oil. Since the April 24, 2002, announcement by researchers at the Swedish National Food Administration and Stockholm University that acrylamide can be found in a variety of fried and oven-baked foods, scientists from all over the world have joined hands to look at how this compound forms in foods and determine whether it is truly a risk. The initial Swedish research indicated that acrylamide formation is particularly associated with traditional high-temperature cooking processes for certain carbohydrate-rich foods. Processors and research scientists are looking for ways that will effectively reduce the formation of acrylamides in fried foods. They are looking at changes in formulations, the use of additives, and changes to the process itself. Factors such as the presence of low molecular weight protein components (amino acids), reducing sugars, and low water availability all affect acrylamide formation in some way. However, these materials are also crucial components in Maillard browning, which is essential to production of baked and fried food traits that are desirable. Reducing frying temperature can reduce the concentration of acrylamides in foods. This is also a step that can help minimize damage to the oil. To date, there is no definitive answer on acrylamide control. The most important piece of the puzzle is that based on consumption data, the compound does not appear to be a significant risk at this time.

What may pose a greater potential risk in frying is food allergens. At the 5th International Symposium on Deep-Fat Frying in 2005, the author warned that allergens could pose a potential risk in frying, especially restaurant operations that fry different products in a single fryer. There is, therefore, a potential that allergens from one food may be transferred to the oil and onto some other item. These concerns were echoed by allergen expert Steve Taylor of the University of Nebraska in 2006 at a short course on deep-fat frying sponsored by IFT. According to Taylor, there have been allergen incidents that have been linked to foodservice frying. These are anecdotal and very few are cited in the literature. Both experts urged that the industry conduct studies to determine what kind of risk such operations do pose and whether there are processes that might minimize risk.

The most obvious preventive controls to reduce the risk of allergen cross-contamination include ensuring that foods are fried in separate fryers and that operators pay close attention to cleanup operations. Risks in industrial frying would be less, but there is still a chance for cross-contamination; for example, if a fish processor reused old oil from shellfish frying when frying a fin fish. One possible means of reducing allergen risks is filtration. There are industrial operations that do practice allergen management. One of these is the nut processing industry. Oils are changed and fryers and processing lines completely cleaned whenever they switch from one nut variety to another. And, of course, whenever allergens are present in a restaurant or industrial operation, the operators must implement and maintain programs to prevent cross-contact.

The Wrap

Frying produces foods that taste and smell great. It is also a rather low-risk operation from a food safety and quality perspective. If operators at the foodservice and industrial level develop, document, implement, and maintain programs to monitor and maintain their oil quality it will be reflected in the food quality—and hopefully, in increased sales and repeat business. And frying may have an added benefit to the environment in the future. Used frying oils can be converted to biofuels so that cars and other vehicles could be powered by fries in the future.ft