Packaging That Appeals to Pet Owners

PACKAGING

Pet food packaging has morphed from multiwall paper-based bags to packaging that has a palpable retail presence, enhances consumer convenience, and enables healthier pet food. Packaging that clearly communicates convenience and enables a strong human-pet connection adds value. Innovations in pet food processing continue to expand pet food packaging into new areas.

Packaging for Point of Sale

Package design that promotes products at the point of sale focuses on material innovation to provide brand differentiation, graphics that pop in LED lighting, configurations that enable the use of vertical retail space, and ease of e-commerce and home delivery. Package graphics in pet food drives consumer purchase and assists consumers with product differentiation. Blue Buffalo Co. offers products in packaging with graphics that differentiate between value and premium. To delineate brand value for consumers, package graphics change from a simple high gloss in the Blue Basics line of pet food products to a metallized laminate enclosing the Blue Wilderness premium product. The Blue Earth Essentials pet food line has a matte finish, which implies a more natural product.

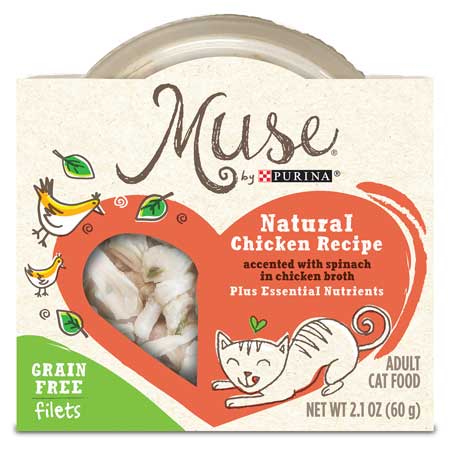

Paperboard sleeves enveloping small single-serve containers provide on-shelf stackability and more branding space. For example, the Muse pet food line by Nestlé Purina comes in polypropylene dishes sealed with metallized lidstock housed in a three-sided 10-point clay-coated newsboard tapered sleeve with a hole in the center that allows for detailed graphics and product viewing by consumers. Likewise, the Nestlé Purina Fancy Feast brand uses a two-sided window-bottom sleeve to deliver branding and viewing of the products in multilayer plastic serving bowls.

Paperboard sleeves enveloping small single-serve containers provide on-shelf stackability and more branding space. For example, the Muse pet food line by Nestlé Purina comes in polypropylene dishes sealed with metallized lidstock housed in a three-sided 10-point clay-coated newsboard tapered sleeve with a hole in the center that allows for detailed graphics and product viewing by consumers. Likewise, the Nestlé Purina Fancy Feast brand uses a two-sided window-bottom sleeve to deliver branding and viewing of the products in multilayer plastic serving bowls.

Retail stores have moved from overhead fluorescent lighting to LED shelf lighting; this accentuates graphics and reduces light-induced lipid oxidation and other degradative reactions. As a result, product manufacturers can now use more clear packaging. Clear packaging invites consumers to see the quality of pet products and reflects the transparency consumers want. Until LED lighting, windows in pet food packaging were not common. Now, a clear arrow on the front of a pouch of Nature’s Variety Instinct Raw Boost Mixers directs consumers to top a bowl of kibble with the freeze-dried product. Other unique products such as Purina Beyond dog treats also feature a window on the front panel. Flat-bottom gusseted bags with clear side panels showcase product as well. Open-air refrigerated cases with LED lights contain pasteurized and preserved products such as the Vital brand in an array of package styles from tubes to doy-style pouches or flat-bottom bags. And LED lighting also illuminates upright freezers with sliding doors containing Nature’s Variety Instinct Raw Boost Mixers. Resealable stand-up pouches with large windows contain 30 sealed thermoformed clear trays of Elive fish foods in individual servings that allow for easy and safe thawing.

Retail stores have moved from overhead fluorescent lighting to LED shelf lighting; this accentuates graphics and reduces light-induced lipid oxidation and other degradative reactions. As a result, product manufacturers can now use more clear packaging. Clear packaging invites consumers to see the quality of pet products and reflects the transparency consumers want. Until LED lighting, windows in pet food packaging were not common. Now, a clear arrow on the front of a pouch of Nature’s Variety Instinct Raw Boost Mixers directs consumers to top a bowl of kibble with the freeze-dried product. Other unique products such as Purina Beyond dog treats also feature a window on the front panel. Flat-bottom gusseted bags with clear side panels showcase product as well. Open-air refrigerated cases with LED lights contain pasteurized and preserved products such as the Vital brand in an array of package styles from tubes to doy-style pouches or flat-bottom bags. And LED lighting also illuminates upright freezers with sliding doors containing Nature’s Variety Instinct Raw Boost Mixers. Resealable stand-up pouches with large windows contain 30 sealed thermoformed clear trays of Elive fish foods in individual servings that allow for easy and safe thawing.

Some retailers are using vertical space to build store-brand pet food dispensers to deliver food by the pound to consumers. This means the function of packaging shifts from protecting product from manufacturer to consumer to protecting product from retailer to consumer. Less compartmentalized packaging and refillable containers are more sustainable.

For the growing number of urban consumers without cars, home delivery of pet food and auto-ship is a tremendous convenience. Home delivery of pet food saves time and energy, removing the tasks of shopping and transporting heavy pet food bags: bulky 24-pound dog-food bags are difficult to transport. Besides facilitating delivery, design innovations in e-retail packaging facilitate consumers’ better understanding of pet food products when purchasing online and extend brand identity and presence to consumers’ homes. This can be accomplished with packaging that interacts with both consumers and their pets. For example, corrugated boxes used for shipping can be folded into fun toys or reassembled into pet gyms.

Packaging That Provides Convenience

Pet food packaging provides convenience by optimizing package sizes and enabling closing and recycling of packages. Major strides have been made in producing value-based pet food packaging that reduces food waste. Extending the shelf life after opening, reducing spillage, and enabling easy storage is critical to retaining product quality and value. Reducing product headspace meets consumers’ need for an intuitive connection between package size and product volume and ensures compliance with federal regulations for nonfunctional slack-fill packaging. Nonfunctional slack-fill can often be addressed with design changes or by enabling consumers to see the product volume. Clear packaging intuitively communicates to consumers how much product is in a package. For example, ShowPack by Printpack (printpack.com) is a flat-bottom bag with clear side panels that allow product transparency; printed front and back panels accommodate branding. Perforations on the side panels of non-paper large dog food bags allow for venting during rapid filling and distribution, reducing the need for excess headspace and increasing production speeds. Correctly sized pet food packaging also decreases package, distribution, and retail restocking costs and increases shelf life and the number of on-shelf facings.

Many consumers attribute anthropomorphic qualities to their pets—selecting, storing, and serving pet food as if it were human food. Packaging helps consumers make this attribution by extending human product aspects to pet food packaging. For example, single-serving retortable bowls with peelable lidstock have a high degree of convenience focused on individual servings, but the bowls are also in shapes and sizes that resemble common kitchen dishes. Anthropomorphic pet food also mirrors human meals with choices such as beef stew, petite pot pie, and tiny Thanksgiving dinners, as in the small-breed dog food line by Merrick Pet Care. Two or more portions of Nutro Petite Eats and Sheba Perfect Portions are within two- or four-compartment in-mold labeled thermoform trays that can be snapped apart to serve the portions. Meal choices can thus be personalized, serving side dishes with a main meal choice with less waste. Seasonal variety cases showcasing holiday food or summer fun food also connect consumers to their pets.

Opening features such as laser scoring and closing features such as zippers and Velcro are standard on some pet food pouches and bags. The disadvantage of these closing features is that they are designed to close at the top of the package, so the headspace within the bag increases as more product is used. This often reduces product shelf life if a product is not individually packaged within a recloseable pouch. Marketing messages are more easily communicated if the bag remains its full length, but this is not optimal for shelf life and consumer storage. Bags and pouch graphics that still communicate product attributes as product volume dwindles are needed. Fold over options include Sealstrip tape by Sealstrip Corp. (sealstrip.com) and large bag clips and metal twist ties.

Pet food is often not well protected from moisture and oxidation by zippers, Velcro, taps, and clips. For this reason, many consumers place pet food within an airtight container after purchase, so product is purchased essentially to refill an existing refillable container. Bridging this gap for consumers by providing more refillable containers with discounted refills or containers that are more airtight after opening is also needed. Natural Aquatic Turtle Food by Zoo Med Laboratories comes inside a polyethylene terephthalate container that is refillable, recloseable, and recyclable. These convenient containers, which are common in human-food packaging, are an area for growth in pet-food packaging. This is especially relevant to dry and hard-to-measure pet food.

Convenience also extends to after-product use. For many pet foods, exceptional flavor, odor, and oxygen barriers are needed. Nanotechnology in the form of additives within polymers and coatings within layers of a homopolymer could enable single-layer high-barrier packaging. Easily separable layers of high-barrier polymers can provide the needed barrier, using paperboard for physical support.

Pet food packaging labeled as compostable or biodegradable often creates confusion. For example, some pet food packaging identified as landfill biodegradable is not biodegradable in every landfill. This happens when the packaging is compliant with ASTM 5511-12 (“Standard Test Method for Determining Anaerobic Biodegradation of Plastic Materials Under High-Solids Anaerobic-Digestion Condition”) but not ASTM D5526-12 (“Standard Test Method for Determining Anaerobic Biodegradation of Plastic Materials Under Accelerated Landfill Condition”). Even when the packaging is compliant to both, few facilities exist that enable biodegradation in a landfill.

Packaging for Natural Pet Foods

Packaging developed for pet food products that do not contain preservatives and for minimally processed products is advancing rapidly. Consumer trends toward clean labels, fewer ingredients, and raw pet foods as well as requirements in the Food Safety Modernization Act and new definitions from the Association of American Feed Control Officials have altered the needs of pet food packaging and processing. This has made the intersection of packaging and processing more acute in pet food.

Limited-ingredient products demand high oxygen barriers and often modified atmosphere packaging to maintain nutrient quality and retain product appeal. Oxy-Guard oxygen absorbing sachets by Clariant (clariant.com), films, carbon dioxide and nitrogen scavengers, and ethanol emitters by Freund (freund.co.jp) extend shelf life by reducing degradative reaction and nutrient loss. Oxygen- absorbing sachets are used in packages for both human and dog beef jerky products. To reduce off odors and flavors associated with oxidation, hexanal—a by-product of lipid oxidation—is often allowed to escape through paper bags or vents.

While retort processing within thermoformed or injection mold bowls or steel or aluminum cans dominates the wet pet-food market, the markets for refrigerated and frozen pet food are growing. Research and development on processing and packaging that facilitates preservation via microwave-assisted thermal sterilization or high-pressure processing (HPP) within a package continues to develop. In particular, the raw category employs HPP, freezing, and freeze-drying to maintain product freshness.

Claire Koelsch Sand, PhD, Contributing Editor

Claire Koelsch Sand, PhD, Contributing Editor

CEO, Packaging Technology and Research

Adjunct Professor, Michigan State Univ. and California Polytechnic State Univ.

[email protected]