Annual Meeting & FOOD EXPO® Preview—Packaging

PACKAGING

Variety of Packaging Papers to be Presented

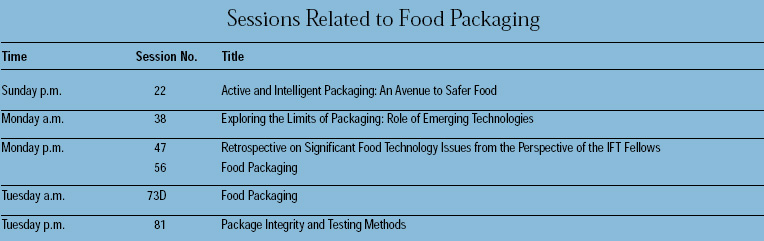

This year’s technical program contains several symposia and sessions on food packaging. Here are short descriptions of some of the papers that will be presented. Also included is a sampling of the exhibitors who will highlight new packaging, processing, and services.

R.T. Albright of Arca Systems will discuss a reusable folding bulk container made of high-density polyethylene (HDPE). Called the Gemini container, the integrated pallet design allows for bulk shipments of food product without the need for separate wooden or plastic pallets. Paper 13-6

A. L. Brody of Rubbright•Brody, Inc., will present an overview of active and intelligent packaging. Active packaging is engineered to sense changes in the in-package environment and to change some property to alter that environment. Examples include oxygen, moisture, and odor removal; and oxygen, aroma, and antimicrobial addition. The best-known are oxygen scavengers which now include compounds incorporated into the package structure as well as sachets of reactive compounds. Intelligent packaging to date has been devices that measure and integrate, but do not respond. Examples include locators, theft and counterfeiting deterrents, and time-temperature integrators. Paper 22-1

R. Clarke of Landec Corp. will discuss intelligent packaging for safeguarding fresh produce quality including membranes that can be used in packaging fresh produce to create and maintain the specific atmospheres required to preserve fresh fruit and vegetables, even through temperature abuse. Paper 22-2

T. Gautreaux of Maxwell Chase Technologies LLC will discuss pads, pouches, and trays which absorb and retain moisture within a food package, thus keeping excess moisture (purge) and spoilage organisms away from contact with the food product and the consumer. Paper 22-3

M.L. Rooney of Food Science Australia will present an overview of the development of new scavenging technologies for removing oxygen from packages containing sensitive foods and beverages. The technologies include sachets containing iron and plastics-based systems. Paper 22-4

F.W. Reimers of H.E. Butt Grocery Co. will discuss using automatic temperature monitoring systems for retail food stores. Lack of time and temperature control has been one of the key contributing factors to foodborne illness. Improved control systems for monitoring time and temperature within a retail store’s refrigeration system can control the growth of not only pathogens, but also spoilage bacteria that can affect quality, therefore reducing product shrink. Paper 22-5

B.P.F. Day of Campden & Chorleywood Food Research Association will present an overview of active packaging applications in the European food market and highlight new developments. Active packaging refers to the incorporation of certain additives into packaging films or within packaging containers with the aim of extending food product shelf life. 22-6

A.L. Brody of Rubbright•Brody, Inc. will present an overview of the next generation of packaging technology. As foods have become more complex, consumers have become more demanding, and distribution channels have changed, the traditional role of packaging as a barrier and physical protector has been altered. In the future, package structures will be multipurpose for preservation, distribution, automated preparation, and ease of consumption, to satisfy the demands and desires of processors, marketers, retailers, and consumers. Paper 38-1

P.J. Slade of the National Center for Food Safety & Technology will discuss the potential for enhancing food safety and shelf life by using combinations of novel technologies and modified-atmosphere packaging (MAP), including the use of MAP in conjunction with irradiation, UV and visible light, microwaves, ultrasound, and HPP. Paper 38-2

G. Sadler of the National Center for Food Safety & Technology will discuss the effects ultra-high pressure and pasteurizing doses of irradiation have on packaging. Issues such as changes in bulk properties and microleaks will be addressed. Paper 38-3

L.K. Cook of the Cryovac Div. of Sealed Air Corp. will discuss antimicrobial food packaging. Consumers continue to demand foods that are minimally processed and appear to have a fresh quality, while modern distribution systems require adequate product shelf life. The idea of combining antimicrobials with packaging films to control the growth of microorganisms in foods could have a significant impact on shelf life extension and food safety. Paper 38-4

B.P.F. Day of Campden & Chorleywood Food Research Association will discuss the guidelines for high-oxygen MAP of fresh prepared produce. During recent years there has been an explosive growth in the market for fresh prepared fruit and vegetables. However, these items are highly perishable and prone to the major spoilage mechanisms of enzymatic discoloration, moisture loss, and microbial growth. Good manufacturing and handling practices, along with the appropriate use of MAP, are relatively effective at inhibiting these spoilage mechanisms, thereby extending shelf life. Paper 38-5

J.H. Han of the University of Manitoba will describe the physical and chemical properties of pea-protein-based edible films and their film-forming mechanism. Edible protein films were produced from concentrated and isolated proteins from yellow field peas to improve the quality of packaged/coated foods and reduce the uses of synthetic packaging materials. To determine the film-forming mechanism, the effect of heat denaturation treatment on chemical conformation of pea protein isolate was examined. Paper 56-1

C. Perez of the Ecole Nationale Supérieure d’Agronomie et d’Industries Alimentaires (ENSAIA) will discuss the thermal behavior of sodium-caseinate-based edible films. Proteins are interesting raw materials for industry applications in the food and non-food areas because of their thermoplastic properties. The suitability of sodium caseinate is based on its functional properties for effective performance in edible films. Paper 56-2

D.E.N. Amako of the University of Kentucky will describe the influence of heat sterilization on thermal characteristics and nutrient retention in conduction-heated foods, such as chili con carne, contained in plastic trays. The effects of temperature–time and residual air volume on process parameters, quality factors, and nutrient retention were studied. Paper 56-4

S.A. Desobry of ENSAIA will discuss the modeling of volatile compound migration from wooden packaging into spherical foods. For food safety, molecular migration from packaging to food is of primary importance. Analytical and numerical methods were applied to solve partial finite difference equations for the diffusion problem. Paper 56-5

C. Perez of ENSAIA will discuss the functional properties of sodium caseinate films, including the effect of plasticizer hydrogen bonding capability on the molecular structure of sodium caseinate (SC) in SC/glycerol and SC/sorbitol systems. Paper 56-3

J.H. Choi of Korea University will discuss the diffusion behavior of potassium sorbate in biopolymer-based films. Incorporating potassium sorbate as a preservative into biopolymer-based films is an appropriate way to solve food spoilage problems, so it is important to determine its diffusivity and temperature dependence. Paper 56-7

Y.M. Kim of Kyungnam University, South Korea, will discuss the use of bacteriocin-coated antimicrobial films in packaging fresh oysters and ground beef. A packaging film containing an antimicrobial agent in its polymeric surface structure may contribute to the preserved quality of packaged food by suppressing microbial activity on the food surface. The use of biologically derived bacteriocins as antimicrobial additives in the films is desirable because of their potential safety advantages. Paper 73D-1

J.H. Choi of Korea University will discuss antimicrobial films based on sodium (Na) alginate and kappa-carrageenan. The use of natural hydrophilic polymers as film materials has received considerable attention in the past few years, especially from the viewpoint of costs and environmental and safety concerns. Food-grade antimicrobial agents (lysozyme, nisin, grapefruit seed extract, and EDTA) incorporated with Na alginate and k-carrageenan films can be used effectively in food packaging. Paper 73D-2

Y.S. Park of the Korea Health Industry Development Institute will discuss release control of antimicrobial agents from biodegradable films. Since potassium sorbate and sodium benzoate have a wide range of bacteriostatic and mycostatic properties, the biodegradable films of methylcellulose/hydroxy-propylmethylcellulose (MC/HPMC), chitosan, or k-carrageenan incorporated with potassium sorbate or sodium benzoate can be used as potential antimicrobial packaging materials. Paper 73D-3

P.G. Veiga of the State University of Campinas, Brazil, (UNICAMP) will discuss the antimicrobial activity of xanthan gum and cassava starch coatings. Antimicrobial substances are widely used by the food industry to preserve products that are usually perishable. Recent studies have incorporated these substances into the packaging material, creating active packages that could possibly extend the shelf life of foods. Paper 73D-4

S.A. Desobry of ENSAIA will discuss mathematical modeling of volatile compound migration into wrapped cylindrical food via package-free space. During storage periods, some volatile molecules migrate from packaging material through the air to food. To predict migrant concentration in food at a given storage time, the migration was modeled as dependent on two-dimensional transient diffusion and solved by finite difference method. Paper 56-6

C.T. Kim of the Korea Food Research Institute will describe the characteristics of antimicrobial edible films derived from cellulose-based materials and incorporated with propolis extracts. The antimicrobial edible film is one of the most promising applications of active packaging, where the antimicrobial substance is released from the film onto the food surface and inhibits the microbial growth. Ethanol-extracted propolis has strong antifungal and antibacterial activity. Paper 73D-5

N.B. Franklin of Clemson University will discuss the use of nisin-containing packaging film to reduce Listeria monocytogenes outgrowth in ready-to-eat food products. Paper 73D-6

P.P. Leung of Ohio State University will discuss the use of nisin, a commercially valuable bacteriocin, to coat polymeric packaging films to inhibit bacterial growth and extend shelf life of foods. The efficacy of nisin-coated antimicrobial packaging film is dependent on the binding affinity of nisin to the synthetic polymer. The proper combination of treatment conditions, such as contact time, nisin concentration, and solution pH, are required to maximize the attachment of nisin to a flexible packaging film. Paper 73D-7

D.S. Cha of Korea University will discuss the preparation of nisin-incorporated antimicrobial films and their diffusion rates. The antibiotic nisin consists of more than one polypeptide with a low molecular weight. Nisin is heat-stable but degraded by proteolytic enzymes in the human intestinal tract. Its incorporation into biodegradable films may have great potential in active packaging systems. Paper 73D-8

T.D. Knight of Texas A&M University will discuss the effect of chlorine-dioxide-releasing packaging film on the microbial and sensory quality of beef during refrigerated storage. Paper 73D-9

S. Chen of Fu Jen Catholic University, Taiwan, will describe MAP of ready-to-eat food stored at ambient temperature. The efficiency of modified atmosphere to restrain microbial growth relies on temperature control. Low temperature is typically employed to store ready-to-eat food; however, starch undergoes retrogradation at refrigeration, resulting in a loss of quality. Since carbon dioxide has a bacteriostatic effect and ethanol is a vapor-phase microbial growth inhibitor, using them in combination may be beneficial. Paper 73D-10

P.S. Taoukis of the National Technical University of Athens, Greece, will discuss how packaging and storage conditions affect the shelf life of bottled tomato ketchup. Carotenes and xanthophylls contained in tomato, especially lycopene, slowly oxidize during long ambient storage, gradually changing color from bright red to dark brown. Higher oxygen availability and high temperature storage accelerates the change. Switching from glass to polymer packaging for cost reduction and functionality must be evaluated with regard to its effect on shelf life. Paper 73D-11

V. Chonhenchob of Kasetsart University, Thailand, will discuss extending shelf life of chilies using perforation MAP. The effect on quality maintenance was studied by varying diameter, density, and distribution of perforations. Shelf life was assessed by evaluating microbiological quality, sensory characteristics, firmness, and browning or darkening. Paper 73D-12

C.I.G.L. Sarantópoulos of the Food Technology Institute, Brazil, will describe the effects of different slicing methods and passive MAP on the quality and shelf life of collard slices. Using MAP may control the stability and quality of fresh-cut produce by regulating the gas composition around the product. Paper 73D-13

E.A. Miller of the National Center for Food Safety & Technology will discuss the changes of volatile compounds in ethylene vinyl alcohol (EVOH) with irradiation. Before irradiation can be implemented with full versatility, there is a need to increase the number of polymers available to food irradiators. Additional information on the formation of radiolytic compounds must be determined for many new polymers crucial to optimal food packaging. Paper 73D-14

V. Komolprasert of the National Center for Food Safety & Technology will discuss the migration of nonvolatile compounds from irradiated semirigid copolyesters into food-simulating solvents. The results are necessary to determine the suitability of the materials for prepackaged irradiated foods. Paper 73D-15

J. Hannecart of the National Center for Food Safety & Technology will discuss the GC/MS analysis of gamma-irradiated EVOH. A food that is irradiated inside a sealed package would prevent recontamination resulting from subsequent handling. However, irradiation of a packaging material may theoretically lead to the creation of undesirable radiolytic compounds. Paper 73D-16

Q. Wang of University of Illinois will discuss the effect of ionizing radiation on tensile properties of zein films. Previous research has indicated the potential of corn zein films for use as biodegradable food packaging. However, improvements to their physical properties are necessary to increase serviceability. Ionizing radiation, routinely applied for polymer modification, offers the possibility of cross-linking effects without the addition of non-food-grade chemicals. Paper 73D-17

Y.S. Song of the National Center for Food Safety & Technology will discuss the effect of ozone treatment of drinking water on plastic packaging materials. Some anecdotal evidence suggests that ozonated bottled water has more off-taste than nonozonated bottled water. This may be attributed to residual ozone attack of chemical double bonds, which may degrade the polymers to impart a unique organic background to water. Paper 73D- 18

B.F. Ozen of Purdue University will describe the effect of ozone gas on mechanical, thermal, and barrier properties of plastic films used in food packaging. Due to its oxidizing and disinfectant properties, ozone has recently received attention for the treatment of foods as well as food processing equipment and packaging materials. Since it is a very strong oxidizing agent, ozone might cause changes in some of the properties of polymeric materials. Paper 73D-19

D.S. Lee of Kyungnam University, South Korea, will discuss the use of Na2CO3-based CO2-absorbent systems to alleviate pressure buildup and volume expansion of kimchi packages. Kimchi, a lactic-acid-fermented vegetable dish, is usually packaged without pasteurization and produces a lot of carbon dioxide inside its package during storage and marketing. The overproduced CO2 from the stored products causes pressure buildup in rigid packages and volume expansion in flexible packages. Paper 73D-20

C.R.F. Grosso of UNICAMP will describe the application of wheat-gluten edible films to strawberries. Edible wheat gluten coatings are applied to reduce the loss of weight and firmness during storage. Strawberries, as typical soft fruits, have a high physiological postharvest activity, so prolonged storage life is a challenge. Paper 73D-34

Y.S. Song of the National Center for Food Safety & Technology will discuss the effects of polypropylene film barriers on fatty and high-moisture food packaged with recycled paperboard. Interest in the use of recycled pulp in packaging microwavable foods with high fat and moisture has increased. These applications require a plastic layer between the paperboard and food to provide the necessary barrier properties. The safety evaluation of recycled paperboard may depend on the effectiveness of the functional barrier. Paper 73D-21

S. Chen of Fu Jen Catholic University, Taiwan, will discuss the use of biodegradable films to form sachets containing functional ingredients in active packages. Biodegradable films have environmental advantages, but their use as primary packaging materials is limited because of their sensitivity to water. Applying biodegradable films to take up water which is then used to initiate necessary reactions would be a novel utilization in active packaging. Paper 73D-22

H. Yang of Pennsylvania State University will discuss depth profiling of a heterogeneous food package using Fourier transform infrared photoacoustic spectroscopy (FTIR-PAS). Paper 73D-23

S. Min of Ohio State University will describe the effects of package size and wall thickness on the shelf life of orange juice. Higher barrier properties from a barrier layer would be achieved by increasing wall thickness of laminated containers. Paper 73D-24

K.N. Turhan of the University of Mersin, Turkey, will discuss a simple method for determining the light transmittance of transparent polymer films used for packaging foods. Food components may undergo degradation under light. Food packaging materials can slow down the degradation by not transmitting a portion of the incident light. Understanding the transmittance of food packaging materials is important in estimating the shelf life of foods. Paper 73D-25

A. Chandrasekar of the National Center for Food Safety & Technology will describe the development of a mathematical model to define a functional barrier. Qualification as a functional barrier depends on such properties as the diffusion coefficient of organic compounds in a polymer, the solubility constant of the contaminant for the anticipated time, and the storage temperature. Paper 73D-26

C.W. Olsen of the USDA-ARS Western Regional Research Center will discuss the microbial safety of solution-cast edible films. Edible films are commonly made through a solution-casting process where the films are dried from 2 to 18 hr. Given the neutral pH and high water activity and/or moderate temperature conditions present during dehydration, the potential for microbial growth exists, but has not been previously studied. Paper 73D-27

R. Sothornvit of the University of California–Davis will discuss the oxygen permeability and mechanical properties of plasticized beta-lactoglobulin films. No research has been done on plasticizer composition, size, and shape influence on the ability to disrupt protein-chain hydrogen bonding, including the ability to attract water to protein films. Paper 73D-28

S.Y. Lin of the University of California–Davis will discuss the improvement of paperboard packaging performance by incorporating whey protein concentrate coating. Paper 73D-29

S.Y. Lee of the University of California–Davis will describe modeling shelf life of whey-protein-coated peanuts analyzed by static-headspace gas chromatography. Lipid oxidation in peanuts results in flavor-fade and off-flavor development. WPI-based films have been found to be excellent oxygen barriers, and WPI films formed as coatings on peanuts may reduce peanut lipid oxidation. Paper 73D-30

K.M. Kim of the University of Nebraska will discuss the plasticizing effect of a mixture of aqueous and crystalline sorbitol on the physical and barrier properties of soy protein isolate (SPI) film barrier properties. Soy protein films have poor moisture barrier properties because of the hydrophilic nature of the protein and the substantial amounts of hydrophilic plasticizer used in film preparation. Use of glycerin as a plasticizer not only increases flexibility, but also results in very high water vapor permeability. Paper 73D-31

C.R.F. Grosso of UNICAMP will discuss the enzymatic reaction temperature effect on mechanical and barrier characteristics of native films, films modified by the enzyme, and films without the enzyme which had the same thermal treatment as that of the films modified by the enzyme. Utilizing the transgluta-minase enzyme produces cross-links in the film matrix that may improve its permeability. Paper 73D-33

P. Hernandez-Muñoz of Michigan State University will describe developing edible films from different wheat gluten protein fractions and the effects of film composition on mechanical and barrier film properties. Paper 73D-36

E. Bosquez-Molina of the Universidad Autonoma Metropolitana-Iztapalapa, Mexico, will discuss improving the moisture barrier properties of mesquite gum–candelilla wax edible emulsion coatings. Paper 73D-37

M.S. Chinnan of the University of Georgia will discuss the characteristics of corn zein and methyl cellulose bi-layer edible films as affected by preparation protocols. A considerable amount of information is available on protein and cellulose-based films, but not on protein and cellulose-based composite films. Paper 73D-38

K.C. Heo of Mokpo National University will describe the characteristics of edible films based on pullulan, an extracellular bacterial polysaccharide produced from starch by Aureobasidium pullulans. Paper 73D-39

S. Min of Ohio State University will discuss the wall thickness distribution in thermoformed food containers. The nonuniformity of wall thickness distribution and delamination of sheets are major limitations in thermoforming of laminated food containers. These defects affect the shelf life of foods, with decreased mechanical and barrier properties. Paper 73D-40

S. Min of Ohio State University will discuss solid phase microextraction gas chromatography analysis of orange juice flavor compounds absorbed by a polymeric packaging film. The absorption of orange juice flavors by polymeric packaging materials may result in imbalances of flavor profiles, which makes the product less acceptable to consumers. Paper 73D-41

J.E. Marcy of Virginia Polytechnic Institute & State University will discuss the application of fluid modeling to determine the threshold leak. Paper 81-1

S. Franks of T.M. Electronics, Inc. will discuss using pressure/vacuum decay for nondestructive package testing. Flexible packages present formidable challenges for package integrity testing. Of the techniques available, pressure or vacuum decay are direct and quantifiable; however, obstacles in testing are present in relating package design to fixture design. Paper 81-2

A. Draaijer of the TNO Nutrition & Food Research Institute, Netherlands, will describe non-invasive methods to determine oxygen in a package. TNO Voeding has developed a new optical sensor to measure oxygen. The method is based on the quenching of a fluorescent substance. Paper 81-3

D. Putnam of Pacific Technologies, Inc. will describe an optical sensor and instrument for measuring oxygen inside packaged products. The technology employs an oxygen-sensitive indicator incorporated at very low concentrations into flexible packaging materials. Paper 81-4

E. Hurme of the Technical Research Centre of Finland will discuss developments in nondestructive detection of food package leaks. The most effective method of detecting leakage nondes-tructively throughout the whole distribution chain from the manufacturer to the consumer is to use a visual leak indicator permanently attached to the package. Visual leak indicators that are based on the detection of oxygen and carbon dioxide will be reviewed. Paper 81-5

C.R.F. Grosso of UNICAMP will discuss degradable films obtained from gelatin and phthalate acetate cellulose mixtures. Degradable and/or edible films were initially developed to function as barriers to water and oxygen permeation. New applications include active films and films which regulate the diffusion of components with specific biological or chemical activities. Paper 73D-35

K.M. Kim of the University of Nebraska will discuss the effects of heat curing on SPI film properties under various time, temperature, and pressure conditions. Paper 73D-32

A Sampling of Services, Packaging, and Processing Exhibits

Advanced Software Designs will exhibit its product development software, ProductVision®, Version 3.0, for the food and beverage industry. Integrated approval process tracking increases efficiency, cost effectiveness, and accountability. Comprehensive audit-tracking modules help automate regulatory tracking and reporting requirements. Ingredient declaration and nutrition labeling functions have been enhanced to reduce time devoted to label mockup and development. Physical properties and costs are tracked automatically, and “what-if” tools provide quick product prototyping capabilities. Booth 1463

Alcide Corp. will exhibit its Sanova antimicrobial for controlling foodborne pathogens on poultry, red meat, and intact fruits and vegetables. Additional approvals are expected soon for use on sausage and comminuted meats and on poultry post-chill. Booth 662

BioSterile Technology, Inc., will feature three electron-beam food irradiation systems. The Nutribeam 500/2 is a compact, in-line, dual-beam system for disinfection and pasteurization of foods, particularly grains, dry granular materials, and certain liquids. It uses two direct-current 500-keV electron beams accelerated to an output of 30 kW capable of processing 4–6 metric tons/hr. The Nutribeam 5000 is a compact, in-line, 5-MeV, 2-kW electron beam irradiation system capable of multiple-mode processing of varying density loads at the same time. It can bereadily incorporated into food processing lines. The Nutribeam 10M is a 10-MeV, 50-kW system capable of processing 10–20 tons/hr. It is designed for high throughput or for relatively dense food packages and can be installed in an existing facility or a new physical plant. Booth 1412

Boley & Associates Inc. will exhibit its ozonated water machine, the Ozonice®, which provides continuous or intermittent, on-demand or automatic supply of ozonated water for washing and sanitizing seafood, poultry, equipment, etc. The 26-in x 31-in x 14-in machine supplies highly ozonated water at up to 16 gal/min. Booth 2170

Compusense, Inc., will exhibit its data collection software, Compusense® Commuter, which gives users the ability to collect sensory and consumer testing data via a laptop or personal computer anywhere, anytime. It allows users to obtain immediate results in the field, whether home-use test, mall intercept, walk-by taste test, or point-of-sale program. All that is needed is the software file, a computer, a kiosk, and a power supply. Booth 1563

Eastman Chemical Co. will exhibit food container packaging, including VersaTray plastic—a dual-oven plastic for the home meal replacement market. Booth 2623

Food Safety Net Services, Ltd., will exhibit its comprehensive, integrated network of laboratory, consulting, auditing, and educational services. The company also provides crisis management programs and regulatory support. Booth 3560

GeneScan USA, Inc. will exhibit its analytical testing services, including quantitative PCR analysis, biochip production, PCR kits, and synthetic biomolecules. The company provides full-service analytical food and agricultural testing, as well as PCR and ELISA testing of bioengineered foods and seeds. Booth 622

Genetic-ID will exhibit its service for helping clients distinguish GMO from non-GMO ingredients through lot-testing or non-GMO certification of single or complex processes. The company provides summaries of new regulations and studies. It also provides “real-time” quantitation for GA21 corn. Booth 1576

IFANCA, the Islamic Food and Nutrition Council of America, will describe its Crescent M halal certification services, which are now being offered in North and South America, Europe, North Africa, and China. Booth 5606

Invictus Systems Corp. will exhibit its packaging software, Facts Panel Genie, which simplifies changing the nutrition facts panels and other panels on food packages. The software can edit each label section separately, quickly update and print labels, calculate nutrition figures, and generate customized labels. The company will also exhibit its Pro-Map™ software for processing and other applications. It uses an intuitive spreadsheet to gather process information such as product formulation, raw material management, product costing, specification document management, product labeling, government regulations reporting, product nutrition, and hazard analysis. Booth 455

Marketing Management, Inc. will exhibit software solutions for food and drink manufacturers and retailers. The software includes features such as recipe development, calculations of ingredient lines, nutritional and sensitive ingredients, and digital photo handling. Booth 816

Mintel International Group Ltd. will exhibit its Global New Products Database. The database monitors worldwide product innovation in the consumer packaged goods markets, offering coverage of new product activity for competitor monitoring and product idea generation. It covers food, beverage, and non-food sectors; 31 categories and 101 sub-categories; and all key global markets. It features pictures, ingredients, product details, and descriptions of all key new products; fully searchable fields; and the ability to save search criteria. Booth 5513

NASA Food Technology Commercial Space Center, located at Iowa State University, Ames, Iowa, is leading a national effort to develop foods and food processing technologies that enhance space missions and advance commercial food products through cooperative efforts with NASA scientists and technologists, commercial companies, and academic researchers. The center is interested in developing food products and processes for long-term space exploration and habitation and is seeking commercial and academic research partners for products and processes that will be used both in space and on earth. Booth 1014

National Food Laboratory will exhibit its product–package interaction analysis services. The NFL combines its expertise and in-depth experience to help companies overcome the twin hurdles of winning FDA approval and consumer acceptance on new or improved products. They routinely tailor product–package interaction studies to meet changing FDA protocols, as well as safeguard food and beverage products from packaging interaction surprises. Its guidance can make the difference between getting a successful product to market first, or losing market share while a product is hamstrung by regulatory or consumer perception problems. Sensory evaluation of food or beverage products is an NFL specialty. Booth 1756

Paper Systems, Inc. will exhibit the EZPak, a flexible intermediate bulk container for nonhazardous liquid products. It’s waterproof, reusable, and collapsible. It replaces wooden bins and other rigid totes with fewer parts, less assembly time, and no clean-out costs for reuse. Booth 1249

Star-K Kosher Certification will exhibit its worldwide kosher certification services. The organization, recognizing that new companies considering going kosher are faced with the daunting task of distinguishing between the relative merits of numerous agencies, has published an in-depth article (see www.star-k.org) on choosing a suitable certification organization. Star-K provides personal service, enabling clients to discuss the complexities of their operations and kosher applications with a rabbi sufficiently knowledgeable to converse comfortably with food technologists and quality assurance personnel. Booth 3131

WRH Industries, Ltd. be exhibit its SN-Series stack-and-nest trays and dollies designed for in-plant processing, meat chilling, commissary delivery, cook/chill applications, and blast freezing. The company also manufactures metal dollies, stainless-steel tunnel-style washing machines, and stacker/destacker systems to complement the trays. Booths 4824, 6112

by SARA LANGEN

Assistant Editor