PACKAGING

Products & Technologies

Thou Shalt Not Pass—Barrier Plastic Packaging

Barrier is defined in many ways by food packaging practitioners. Some deal with physical protection. Others are obsessed with liquid moving through passages; still others with water vapor. Since the emergence of plastic materials as practical package materials, oxygen has been the principal environmental culprit whose movement must be controlled. For about a quarter century, or since the development of polyester as a carbonated beverage bottle structure, another focus has been on carbon dioxide. Flavor barrier is increasingly crucial in food and beverage content protection by packaging, and how could we forget fat (grease) and hydrocarbon barriers?

How much barrier is required depends on:

• The product and its environment—chemistry, temperature, history, time, climate, expected shelf life in distribution, and deteriorative vectors and their kinetics.

• The leakages and physical disruptions inherent or otherwise present in the package structural elements, such as closures or pinholes and cracks from packaging machine damage.

• Reactions that adversely affect the food contents.

The concept of barrier packaging usually—but certainly not always—deals with reducing or blocking the permeation of oxygen gas through plastic package materials. It is interesting that this notion omits too many of the crucial variables influencing the contained product. Thus, we receive messages that polyvinylidene chloride (PVDC) and ethylene vinyl alcohol (EVOH) are excellent “barriers. ”And we read of wondrous polymers such as polyethylene naphthalate (PEN) and nylon MXD6, and of the potential of nanocomposites and analogous inclusions that establish tortuous paths to stymie passage of gases.

Multilayer has been a standard technology to enhance oxygen barrier for more than 30 years. Born with lamination of better barrier materials such as aluminum foil with plastics, barrier was achieved through the erection of solid structures. When all-plastic structures began their ascent to the pinnacles of packaging, aluminum foil could not be effectively applied, especially to non-flat structures. Thus began the search for “barrier” plastics and analogues: disruptions, coatings, metallization, and related thin coatings.

Multilayer remains an effective means to achieve barrier: EVOH coextruded with polypropylene was a mainstream bottle structure for ketchup and for retortable buckets and hot-fill cans starting in the 1970s. The quest for transparency for ketchup and other condiment bottles led to coinjection blow molding of polyester with EVOH during the 1990s. Today, the battle is joined between the forces of polyester and those of polypropylene to determine which of these two base polymers will, with other barriers, dominate the barrier plastic bottle market. Polypropylene remains the better water vapor barrier and is more economical, while polyester retains its outstanding transparency and physical strength.

Intruding into the fray are the demands of the carbonated beverage, beer, and fruit beverage markets for ever-more effective barriers, each with different needs. Carbonated beverage interests are less concerned with oxygen than with carbon dioxide. Thus, when the developers offer enhancements such as oxygen scavengers to be either blended into the base polymer or co-injected into the core of a multilayer structure, the issues of carbon dioxide—and even moisture and flavor retention—are questioned.

Obviously, beer packagers are concerned with both carbon dioxide and oxygen, as well as water vapor and flavor scalping and visibility and heat resistance, the latter because most beer in the United States is thermally pasteurized. Those who bottle fruit beverages worry about oxygen because of the sensitivity of their products to this gas, but are now also into flavor scalping. And the debate on hot vs cold fill for microbiological stabilization is tempered by the question as to whether the target consumers really make their purchase decisions based on the better flavor and color resulting from aseptic packaging.

Coating Technologies

Coating basic plastic structures is hardly new, but the materials and the methods of applying the veneers that impart the desired properties to the package are, however. To date, all coatings have been passive, i.e., they remain essentially the same regardless of the internal or external environmental influences unless they are physically damaged, such as by the pressure of carbonation or by minute contractions resulting from loss of pressure as a result of permeation. Some barrier is offered by the basic polymer from which the film, bottle, or other piece is originally fabricated. And combination with other barrier technologies is not precluded by coating. Here are some of the newer barrier technologies:

• PVDC. In the past, and to a minor extent, even today, PVDC coating of polyester bottles has been commercial, but too many issues of economics and environmental concerns, especially in Europe, have slowed this technology.

• Bairocade. During the past five years, the most widely commercialized barrier coating technology has been Bairocade, a spray-applied thermoset epoxy amine from PPG Industries. This coating became commercial for the exteriors of polyester beer bottles made in Australia by Amcor (Fig. 1). In the U.S., Constar’s Starshield and juice bottles made by Graham Packaging Co. now employ PPG’s Bairocade oxygen-barrier coatings. Graham’s version is enhanced by the incorporation of an oxygen scavenger in the polyester wall structure.

• Plasma-Enhanced Chemical Vapor Deposition (PECVD). Chemical vapor deposition is the technology currently most commonly employed to apply glass or, more correctly, silicon oxide barrier coatings. In the past, glass was electron beam coated from solid-phase glass sublimated under very high vacuums, which, of course are very expensive. Most of today’s developmental and slightly commercial glass-coating technologies are PECVD. It is not new, having been proposed for glass deposition on films, sheets, and bottles by organizations such as Polar Materials and Airco in conjunction with Eastman Chemicals during the early 1990s.

PECVD technology is a means to apply a microscopically thin, approximately 40- to 60-nm-thick layer of silicon oxide on plastic surfaces. Under a “mild” vacuum, a silicon-containing chemical such as silane, i.e., hexamethyldisiloxane (HMDSO), is exposed to microwave or radiofrequency energy to convert it to aplasma. Diffusing over the entire surface of the plastic, the compound breaks into a mixture of the oxides plus residual gases that are evacuated. The silicon oxides bond to the plastic, creating either a multiple discontinuous or a continuous coating that functions to block the entry of gases such as oxygen, carbon dioxide, water vapor, and flavor. Silica coatings, however, may not adhere well or uniformly to surfaces and may be brittle, leading to cracking under pressure or change in dimensions due to loss of pressure within carbonated beverage bottles.

Plasma coatings may essentially be classified as carbon interior, silica interior, and silica exterior:

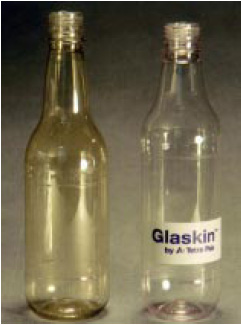

Carbon Interior. Two interior carbon coatings are offered. One, called Actis (left in Fig. 2), by Sidel, Norcross, Ga., is described as amorphous carbon deposited on the interior of a finished polyester bottle. The plasma, based on acetylene, is formed by a microwave energy source. The coating is about 200 nm thick and has high clarity but with a slight amber tint. Being on the interior, the coating resists gas desorption from the plastic and flavor scalping. The company recently received a letter of no objection from the Food and Drug Administration for direct beverage contact, and the polyester bottles with the Actis coating are now being used commercially for Pepsi-Cola’s Mountain Dew Code Red carbonated beverage (Fig.3) to prolong carbon dioxide retention.

The other, called Plasma Nano Shield or PNS (formerly called Diamond-Like-Coating, DLC), from Kirin/Mitsubishi in Japan, uses a radiofrequency source plus internal and external electrodes to ionize the gas that ultimately produces a coating 20–40 nm thick that is an excellent gas and water vapor barrier.

Silica Interior. Tetra Pak, Lund, Sweden, supplies a coating called Glaskin (right in Fig. 2). The silicon oxide coating is created on a bottle interior by reacting HMDSO with oxygen. Treated bottles are reported to have double the oxygen/carbon dioxide barrier of pristine polyester. (A common descriptor for barrier is the number of times better, or “X” multiples, the coated bottle’s oxygen barrier is than the base polyester’s oxygen barrier.) The coating on the interior offers the same benefits as Actis but suffers from the same questions of cracking and possible interaction with the contents with pressure changes as the bottle wall expands and contracts slightly. On the other hand, because of their location on the outside of the bottle structure, exterior coatings do not block the loss of dissolved oxygen from the contents or flavor scalping.

Silica Exterior. The BestPET system developed by Krones, Milwaukee, Wis., in cooperation with user Coca-Cola, uses an energy-intensive evaporative process to generate the ions that coat the bottle exterior. Because the coating is relatively sensitive to abuse, a secondary coat that functions in synergy with the silica is applied to the surface. Carbon dioxide retention is improved by up to five times, using the new “X” designation mentioned above.

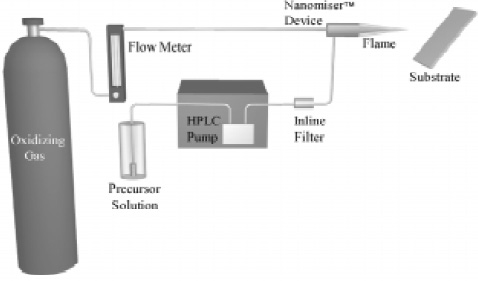

• Combustion Chemical Vapor Deposition (CCVD). Relatively new to the thin coating scene is the CCVD technology, developed by MicroCoating Technologies (MCT), Norcross, Ga. Developed for coating of submicron thin layers on electronic and analogous devices, it has been applied for plastic bottle and film coating. It differs from the other coating technologies by fact that it can be applied at atmospheric pressure, thus eliminating expensive vacuum chambers.

In this process (Fig. 4), the deposition solution containing the precursor to the coating material is atomized by means of the company’s proprietary atomizer, the Nanomiser™. An oxygen stream convects submicron droplets to a flame, where they are combusted to generate the coating material. Heat from the flame provides the energy to evaporate the droplets and for the precursors to react and to deposit the vapor on the package material substrate. The substrate is coated by drawing it into the path of the flame plasma.

Exposure time to the flame is so short that no significant substrate temperature increase is observed. No vacuum is required, and the process can be continuous, thus avoiding the costs and problems associated with conventional plasma discharge coating. Furthermore, when an organic coating is applied, it is inherently polymerized by the heat; therefore, thermoset plastics do not require a post-coating heat treatment, thus eliminating the expensive tunnel and its associated costs. Also, multilayer structures may be applied when needed.

The company reports that coatings applied using CCVD can be thinner yet achieve the same barrier as alternative technologies. Furthermore, plastic surfaces do not require pretreatment to achieve adhesion that is better than conventional plasma deposition. To date, developments have been with exterior coatings, all of which have demonstrated better physical abuse resistance than more conventional silica coatings. This successful application indicates that the company’s organic coating is sufficiently flexible to resist much physical abuse in packaging and distribution.

Like most of the other silica and carbon deposition technologies, CCVD is still in active developmental stages. Nevertheless, it is a family of technologies with great promise from a parent organization seeking food and beverage applications to elevate it into the commercial realm.

Other Issues

What about the environmental solid waste and pollution effects of thin-film coatings? Of course, at the current level of commercialization, no effect can possibly be measured. But what happens when the numbers increase to millions or even billions of bottles, all to better retain shelf life of contained carbonated beverages, beer, fruit juices and drinks, wines, and even water?

Under those circumstances, the quantities of coatings might have an effect on recycling efforts, but much less than might result from other technologies to increase barrier. As the methods for coating reduce the thickness, the mass of coating becomes less of a problem, but the question of the effect remains to be fully answered—and this can be done by actual scale-up and measurement, followed by further research and development.

If you are not yet bewildered by the array of barrier-enhancement technologies being offered, wait a few months, when more will certainly appear for evaluation. The key remains not the specific technology but rather the effect on the contained product. Whether passive or active, a new polymer or a multilayer, a coating or monolayer, or the coating is thin or ultrathin, the crucial variables remain: how much oxygen reacts with the contents, how much carbon dioxide is lost, how much flavor change takes place, and whether there are any interactions that all past empirical research has overlooked.

Food technologists and food packaging technologists should welcome the range of offerings but be conscious of their primary objectives—to protect the safety and quality of the contained food and beverage.

PRODUCTS & LITERATURE

Flexible Intermediate Bulk Container for transportation and storage of sensitive products that require special packaging features a variety of barrier liners, including metallized, foil, or clear ethylene vinyl alcohol copolymer materials. They provide extremely low oxygen, moisture, and vapor transmission rates against flavor and aroma loss, color degradation, and contamination, as well as protect against exposure to sunlight and ultraviolet radiation. The body fabric is polypropylene. For more information about the Guardmaster™ containers, contact Mulox, Inc., 7980 Industrial Hwy., Macon, GA 31297 (phone 877-285-5224, fax 478-784-1179).

Multi-Serve Hot-Fill Bottles made of polyethylene terephthalate (PET) are available in seven designs: Classic Round “Super Stock,” Classic Round “Weave,” Enhanced Round “Slim Stock,” “Enhanced Grip,” “Optima Grip,” “Rebound Grip,” “Square,” and “Stock Rectangle.” Custom designs under development include “Asymmetrical Round,” “Rectangle,” “Jug,” “Decorative Rectangle,” “Ergonomic Pinch,” “Squircular,” “Square,” and “4-Sided Grip.” The multi-serve, hot-fill, 64-oz bottles in the Ultimate line are suitable for beverages such as juices, nectars, sport drinks, isotonics, teas, etc. For more information or a brochure describing the line, contact Amcor PET Packaging, 10521 S. Hwy. M-52, Manchester, MI 48158 (phone 800-666-7741 or 734-428-4515, fax 734-428-4622).

Oxygen Absorbers in the Ageless® line are available in a variety of shapes, sizes, formulations, and formats to provide extended shelf life of foods. Absorber packets, available in formulations for dry, oily, or moist foods, low-temperature foods, and delicate foods, can be inserted into a barrier package either automatically or manually. Label-format absorbers can be placed inside a package, directly under an outer package label, or behind an opaque printed area. And card-format absorbers in the shape of trays combine packaging, presentation, and positioning by extending shelf life, nestling and protecting the product, and carrying a marketing or promotional message. For more information, contact Mitsubishi Gas Chemical America, Inc., 520 Madison Ave., 17th Floor, New York, NY 10022 (phone 212-752-4620).

Oxygen-Scavenging System, the Cryovac® IS System, consists of the company’s OS Films, the Model 4100 series ultraviolet-light-triggering unit, and a specially developed quality assurance program. The award-winning, polymer-based films quickly remove residual oxygen in modified-atmosphere packaging and vacuum packaging, achieving less than 0.1% (ppm) levels of oxygen in 3–8 days. Since the oxygen scavenger is part of the packaging material, it is invisible to the naked eye and is therefore said to be more attractive to consumers than iron-based sachets, extrusion additives, labels, and coatings. The system is said to be equally effective with wet or dry foods and can be used in numerous applications, including cooked meats, smoked and processed meats, nuts, snack foods, and fresh pasta. For more information, contact Cryovac, subsidiary of Sealed Air Corp., P.O. Box 464, Duncan, SC 29334-0464 (phone 800-845-3456 or 864-433-2000, fax 864-433-2134).

Vacuum Pouches for hand-filling of case-ready sliced deli meats are said to provide high clarity, excellent seal strength, and superior physical properties. The three sided pouches are 3 mil thick and come in a wide range of sizes. For more information, contact Inovapack, 40 Vreeland Ave., Suite 107, Totowa, NJ 07512 (phone 888-876-3456).

by AARON L. BRODY

Contributing Editor

President and CEO, Packaging/Brody, Inc.

Duluth, Ga.